Knowledge about Rotary Tablet Machine

Rotary tablet machines are widely used in the pharmaceutical industry for the production of tablets. These machines are used to compress powders into tablets of the desired shape and size. They are used in the manufacturing of tablets for various purposes such as pain relief, antibiotics, vitamins, and more.

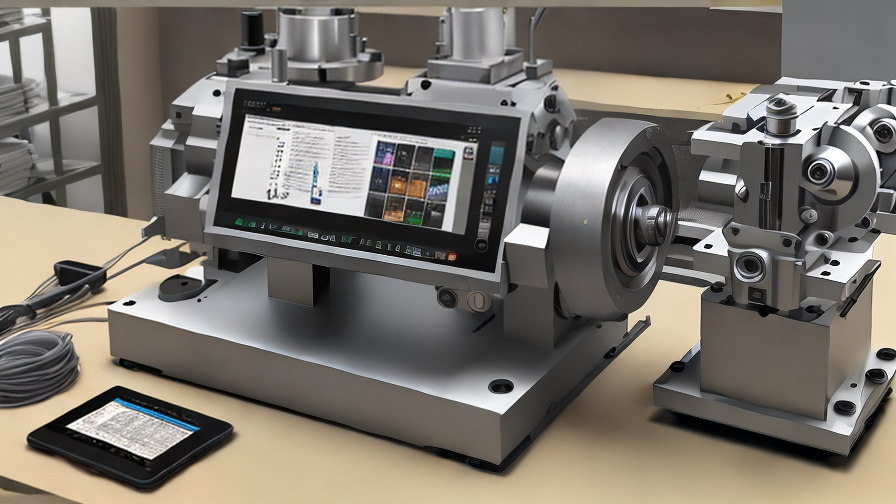

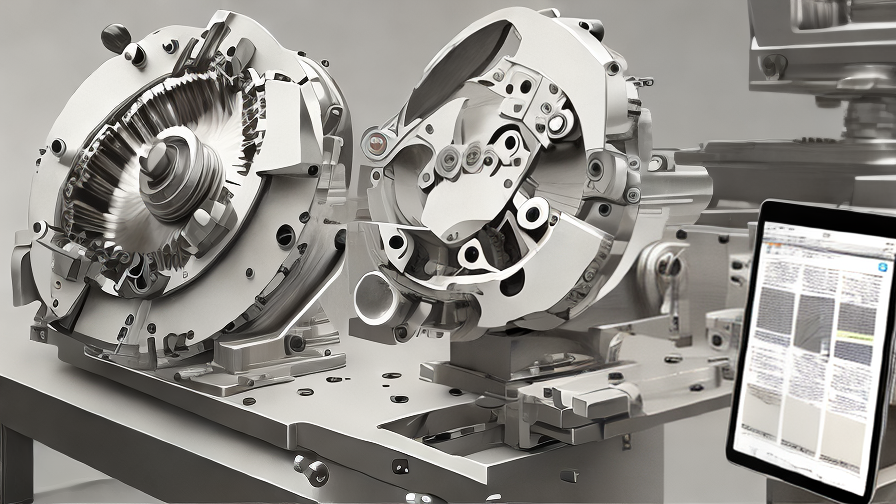

A rotary tablet machine consists of several components such as a feeder, hopper, dies, punches, and a compression system. The powders are fed into the hopper, which feeds them into the feeder. The feeder then delivers the powders to the dies, which are responsible for shaping the tablets. The punches are used to compress the powders and create the final tablet.

It is important to have a good understanding of the various components of the rotary tablet machine and their functions. Proper maintenance and calibration of the machine can ensure a high-quality tablet production. The machine must be cleaned and inspected regularly to ensure it is functioning properly.

The operator must also have a good knowledge of the properties of the powders being used. This includes factors such as particle size, density, and flow characteristics. Understanding these properties can help to prevent problems such as capping and sticking during the compression process.

In conclusion, having a good knowledge of rotary tablet machines is crucial in the manufacturing of tablets. This knowledge can help to ensure a high-quality tablet production, prevent machine problems, and ensure safety in the manufacturing process. Proper training of operators, regular maintenance of the machine, and understanding the properties of the powders are all important factors in the successful operation of a rotary tablet machine.

Various Types of Rotary Tablet Machine

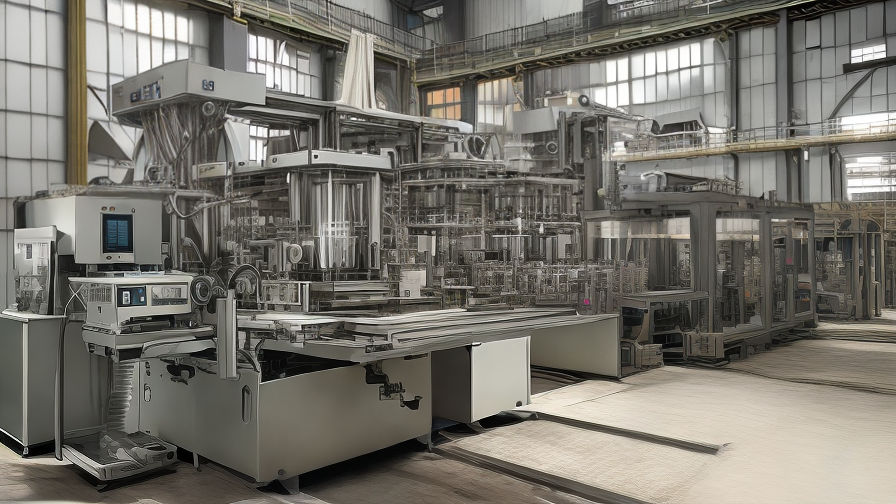

Rotary tablet machines are equipment widely used in pharmaceutical and chemical industries to produce tablets in large quantities. These machines are designed to efficiently compress powder or granules into the shape and size of tablets with minimum error. There are a variety of rotary tablet machines available in the market, each catering to specific needs of different industries. In this article, we will discuss various types of rotary tablet machines.

Single Punch Rotary Tablet Machine: The single punch rotary tablet machine is the most basic and oldest type of tablet machine. It operates by utilizing a single punch to compress the powder into tablets. Although it is simple in design, the single punch rotary tablet machine is reliable and suitable for small batch productions.

Multilayer Rotary Tablet Machine: As the name suggests, the multilayer rotary tablet machine is designed to produce multi-layer tablets with different colors and properties. It is useful in the pharmaceutical industry to combine two or more APIs into a single tablet to increase drug efficacy and reduce the pill burden on patients.

High-Speed Rotary Tablet Machine: This machine is popular in industries that need to produce tablets in large quantities. It has a high-speed compression rate that can produce up to 200,000 tablets per hour. The machine’s high-speed compression rate is attributed to its advanced technological features that ensure optimum tablet quality.

Double-Sided Rotary Tablet Machine: The double-sided rotary tablet machine has two punches operating simultaneously to produce two tablets with each compression cycle. This type of machine is commonly used in the pharmaceutical industry to boost production capacity.

Conclusion: In conclusion, rotary tablet machines are essential equipment in the pharmaceutical and chemical industries. These machines come in different types, each catering to specific needs of different industries. However, the choice of the machine to be used should depend on production volume, type of tablets to be produced, and the required tablet quality.

FAQ sourcing Rotary Tablet Machine manufacturer from China

If you are looking for a reliable and trustworthy rotary tablet machine manufacturer from China, there are several frequently asked questions you may have. We have compiled a list of the most common questions and provided multiple answers below to help you make an informed decision.

1. What types of rotary tablet machines do you manufacture?

We manufacture a wide range of rotary tablet machines, including single punch tablet machines, double punch tablet machines, high-speed rotary tablet machines, and automatic rotary tablet machines.

2. What materials do you use in your rotary tablet machines?

We use high-quality stainless steel and other durable materials to ensure the longevity of our machines.

3. What is your production capacity?

Our production capacity varies depending on the type and size of the machine. However, we have the capability to produce large quantities of rotary tablet machines to meet our clients’ needs.

4. Do you offer customized designs?

Yes, we offer customized designs to meet our clients’ specific requirements. Our team of engineers will work with you to create a design that is tailored to your needs.

5. What is your lead time for production and delivery?

Our lead time varies depending on the size and complexity of the machine, as well as the quantity ordered. However, we strive to deliver our products in a timely manner to ensure our clients’ satisfaction.

6. What is your payment method?

We accept various payment methods, including wire transfer, credit card, and PayPal.

7. Do you provide after-sales support?

Yes, we provide comprehensive after-sales support to ensure our clients’ machines are operating at optimal performance. Our team of technicians is available to provide assistance and repairs when necessary.

Choosing a reliable and reputable rotary tablet machine manufacturer is crucial for ensuring the success of your business. By asking these questions and selecting an experienced and trustworthy manufacturer, you can rest assured that your investment will deliver the performance and quality you expect.

Applications of Rotary Tablet Machine

Rotary Tablet Machine is a device that is commonly used in the pharmaceutical and nutraceutical industries. Its main function is to compress powder into tablet form. The applications of this machine are vast and can be seen in many industries besides pharmaceuticals. Here are a few applications of Rotary Tablet Machine.

Firstly, it is mainly used for the production of medicinal tablets. The machine can be utilized to blend various active pharmaceutical ingredients together to produce single or multiple dose tablets. These tablets may contain various vitamins and minerals, which can be used as dietary supplements or in the treatment of various diseases.

Secondly, Rotary Tablet Machine has applications in the food industry too. It can be used to produce compressed tablets for enhancing the nutritional value of various products. For example, compressed vitamin tablets can be added to food products such as cereal bars or energy drinks.

Thirdly, the machine can be used in the production of pet food supplements. Tablets can be prepared with essential nutrients to provide pets with a balanced diet. Similarly, in the agricultural sector, the machine can produce fertilizer tablets with various plant nutrients.

Fourthly, Rotary Tablet Machine has wide applications in the cosmetics industry as tablets can be compressed with various ingredients such as vitamins, minerals, and plant extracts that can improve skin health or delay the onset of aging.

Finally, the machine can also produce cleaning tablets with active ingredients that help to remove stubborn stains or disinfect surfaces.

In conclusion, Rotary Tablet Machine is a versatile device that can be used in a wide range of industries. It is particularly essential in the pharmaceutical and nutraceutical fields, but it has other applications such as food, cosmetics, pet nutrition, agriculture, and cleaning products. Utilizing this technology can help industries achieve their product goals with speed and efficiency.

Manufactured Products made of Rotary Tablet Machine

Rotary Tablet Machine is a device used for producing tablets, which are solid dosage forms in a compact shape to be administered orally. Tablets are commonly used for medication, nutritional supplements, and other health- and wellness-related purposes. Rotary Tablet Machines are used in various industries, including pharmaceuticals, food, and nutritional supplements.

Numerous products are made using the Rotary Tablet Machine, including antibiotics, painkillers, antacids, vitamins, and minerals. These medicines are essential for maintaining and improving health conditions. It is essential to ensure the quality of products before releasing them in the market, which is why the Tablet Machine plays a crucial part in quality control.

The Rotary Tablet Machines’ technology makes it easier to alter the shape and size of the tablets produced. This feature is essential as it allows manufacturers to customize tablets to meet the demands of different patients. The rotary process ensures that the tablets are of high quality and consistent in size, shape, and weight. This way, the end-users can have easy to swallow tablets that contain accurate doses, which provides the correct therapeutic effect.

The use of Rotary Tablet Machine has revolutionized the production of nutritional supplements, making it easier for manufacturers to produce high-quality supplements that help boost individuals’ health. The tablets are also easier to store and transport, ensuring that the quality of products is maintained all through the value chain.

In conclusion, the use of Rotary Tablet Machine in the manufacturing industry has increased efficiency and quality assurance in the production of tablets, reducing the chances of defective products. These machines also play an increasingly important role in ensuring the supply of necessary medication across the globe. Being both effective and efficient, the Rotary Tablet Machine is now an essential tool used in many industries to provide individuals with quality and accessible products.

The Evolution history of Rotary Tablet Machine

Rotary tablet machines have been in use for more than a century, and their design has undergone significant changes over time. These machines were first introduced in the early 1900s as a way to mass-produce tablets for the pharmaceutical industry. The early machines were manually operated and could produce only a few hundred tablets per hour.

In the 1920s, the first automatic rotary tablet machines were developed. These machines could produce up to 20,000 tablets per hour and were powered by electricity. The rotary tablet machine design was further improved in the 1940s with the introduction of hydraulic presses. This allowed for more precise control over the compression of the tablet, resulting in higher quality tablets.

In the 1950s and 1960s, rotary tablet machines were outfitted with electronic controls and became even more efficient. The introduction of the computer in the 1970s revolutionized the manufacturing process for rotary tablet machines. Today, these machines can produce hundreds of thousands of tablets per hour with near-perfect accuracy.

Rotary tablet machines have also become more specialized over time. There are now machines designed specifically for the nutraceutical industry, which produce tablets that contain vitamins, minerals, and other supplements. These machines can also produce tablets that are coated to make them easier to swallow and more visually appealing.

The future of rotary tablet machines looks bright, with continued improvements in technology allowing for even greater precision and efficiency. The next generation of rotary tablet machines will likely be fully automated, with robotics and artificial intelligence playing a key role in the manufacturing process.

In conclusion, the evolution of the rotary tablet machine has been a remarkable journey. From simple manual machines to highly automated systems, rotary tablet machines have continued to transform the manufacturing process for tablets. The constant innovation and improvement in this technology have paved the way for the production of high-quality tablets that can improve the health and well-being of people around the world.

The Process of Rotary Tablet Machine

Rotary tablet machines are widely used in the pharmaceutical industry to manufacture tablets. The process of rotary tablet machine involves several stages. Firstly, the raw materials for the tablet formulation are mixed in a high shear mixer. The mixing process ensures that the active ingredient is evenly distributed in the mixture. Excipients, such as binders, lubricants, and fillers, are also added to the mixture to improve the tablet’s quality.

The mixed ingredients are then transferred to the hopper. The hopper feeds the rotary tablet machine, which is made up of a number of stations. At each station, the tablet is formed by pressing the mixture between two punches, which move up and down. The upper punch compresses the mixture into a tablet, while the lower punch holds the tablet in place. Different shapes and sizes of punches can be used to make tablets of varying shapes and sizes.

The tablet is then transferred to the ejection station, where it is pushed out of the machine and collected in a tray. The ejected tablets are inspected for any visible defects, such as cracks or chips. Any tablets that do not meet the required standards are discarded.

The last stage of the process involves coating the tablets. The coating adds a layer of protection to the tablet and improves its appearance. It can also mask the unpleasant taste or smell of the active ingredient. The coating can be applied using a coating pan or a spray coater. The tablets are rotated in the pan, while the coating liquid is sprayed onto them. The coating is dried under controlled conditions to ensure that the tablets maintain their shape and quality.

In conclusion, the process of rotary tablet machine plays a crucial role in the manufacture of tablets. It involves several stages, from mixing the raw materials to coating the finished tablets. The use of rotary tablet machines has greatly improved the efficiency of the tablet manufacturing process and has enabled pharmaceutical companies to produce high-quality tablets with consistent properties.

Benefits Advantages of Utilizing Rotary Tablet Machine

Rotary tablet machines are widely used in the pharmaceutical industry due to the outstanding benefits they provide. The benefits of a rotary tablet machine can be summed up in three main advantages: efficiency, productivity, and reliability.

First, efficiency is one of the primary benefits of using a rotary tablet machine. In comparison to other methods of tablet production, a rotary tablet machine is much more efficient. It can produce hundreds of tablets in a matter of minutes that are very consistent in size, shape, and weight. This enables manufacturers to produce a large volume of tablets with minimal variation in quality while minimizing waste and increasing productivity.

Second, the productivity of a rotary tablet machine is unbeatable. With the use of a rotary tablet machine, companies enjoy faster completion of production cycles, which translates to more money earned. Rotary tablet machines are highly automated systems that require very little operator intervention, and this reduces the risk of human errors. The whole process of tablet production is fully shutdown-proof as there is minimal contact with human operators.

Lastly, reliability is another considerable advantage of using a rotary machine. Unlike other production tools, rotary tablet machines have the ability to withstand harsh production environments without breaking down. They have sturdy construction and can handle a range of tablet shapes and sizes. This reliability allows manufacturers to confidently invest in the equipment and use it for many years without worrying about repairs or replacement.

In conclusion, rotary tablet machines are highly beneficial to the pharmaceutical industry. They offer increased efficiency, productivity, and reliability, which reduce the cost of production, boost profits, and deliver high-quality products. Maximizing these advantages translates to a significant competitive advantage for pharmaceutical companies.

Disadvantages Rotary Tablet Machine

Rotary tablet machines, also known as rotary pill presses, are widely used in the pharmaceutical industry to manufacture tablets of consistent size, shape, and weight. However, these machines have some disadvantages that should be considered before purchasing them.

One of the significant disadvantages of rotary tablet machines is their high cost. These machines are expensive to purchase, install, and maintain. They require skilled operators who have the knowledge to operate, troubleshoot, and repair them. This can be a significant financial burden, especially for small pharmaceutical companies.

Another disadvantage of rotary tablet machines is their limited flexibility. These machines are designed to manufacture a specific type of tablet, and changing the shape or size of the tablet requires significant adjustments to the machine’s tooling. Therefore, they are not suitable for a wide variety of tablet manufacturing needs.

Rotary tablet machines can also be slow and time-consuming. The production speed of a rotary tablet machine is slower than other tablet manufacturing processes. This can be a bottleneck in the production process, leading to delays in product delivery.

The translation of rotary tablet machines is another disadvantage. These machines produce tablets by compressing powder into a tablet. This can lead to a reduction in the density of the tablet, affecting the dissolution rate and bioavailability of the active ingredient. Therefore, the tablet produced by rotary tablet machines may not be as effective as tablets produced by other processes.

In conclusion, while rotary tablet machines offer benefits such as consistency in size, shape, and weight of tablets, they also have significant disadvantages, including their high cost, limited flexibility, slow production speed, and reduced density of the tablet. Therefore, before deciding to invest in a rotary tablet machine, it is essential to weigh the advantages and disadvantages to determine if it is the right investment for your pharmaceutical company.

Selecting the Ideal Manufacturer Rotary Tablet Machine

When it comes to selecting a rotary tablet machine manufacturer, there are several factors to consider. The ideal manufacturer should offer advanced technology, high-quality machines, and exceptional after-sales support.

The first factor to consider is the technology used in the manufacturing process. The ideal rotary tablet machine manufacturer should utilize state-of-the-art technology to ensure the highest level of precision and efficiency. This will ensure that the machine produces high-quality tablets consistently.

Secondly, a good manufacturer should offer a range of rotary tablet machines suited for different production capacities. This will enable you to select a machine that matches your production needs, thereby increasing efficiency and reducing operational costs.

Thirdly, the ideal tablet machine manufacturer should provide exceptional after-sales support. This includes technical assistance, maintenance, and spare parts availability. You want to work with a manufacturer that provides quick and reliable support, ensuring minimum downtime in case of any machine breakdown.

Additionally, you should choose a manufacturer that offers comprehensive training for the operation and maintenance of their tablet machines. This will ensure that you are equipped with the knowledge and skills needed to operate the machine safely and effectively.

Finally, you should choose a manufacturer with a good reputation in the industry. This can be achieved by checking online reviews, testimonials, and referrals from other customers.

In conclusion, selecting the ideal manufacturer rotary tablet machine requires careful consideration of several factors. You need to choose a manufacturer that uses advanced technology, offers a range of machines suited to your production capacity, provides exceptional after-sales support, and has a good reputation in the industry. By selecting the ideal manufacturer, you will have the best chance of achieving increased efficiency, reduced costs, and optimal results.

Things to Consider When Purchasing Rotary Tablet Machine

If you’re in the market for a rotary tablet machine, there are a few factors to consider before making your purchase. Here are some things to keep in mind to ensure you choose the right machine for your specific needs:

1. Production Capacity: One of the most important factors to consider is the production capacity of the tablet press. You need to ensure that it can produce the required number of tablets within a specific time frame.

2. Speed: Speed is another important consideration when purchasing a rotary tablet machine. The speed of the machine will determine the number of tablets produced per minute, and therefore, you need to ensure that the machine you choose has the right speed for your needs.

3. Tablet size and shape: The size and shape of tablets is another critical factor to consider. You should identify the size and shape of the tablets you need in your production process and choose a rotary tablet press that can produce them.

4. Material: The material used for manufacturing the rotary tablet press is a factor that can impact the durability and performance of the machine. It is important to choose a machine made with high-quality materials that will last a long time and provide superior performance.

5. Safety: Safety is paramount in any pharmaceutical or food manufacturing environment. Ensure that the machine you purchase meets all necessary safety requirements and regulations.

6. Ease of maintenance: Finally, it is essential to consider the maintenance requirements of the machine before making a purchase. You should choose a rotary tablet press that is easy to maintain, with readily available spare parts and technical support.

In conclusion, purchasing a rotary tablet machine is a significant investment, and it is essential to consider all factors before making a decision. Make sure to identify your specific needs and perform thorough research and analysis before making a final choice. By taking the time to consider these factors, you can ensure that you purchase a rotary tablet press that meets your specific needs and provides long-lasting, high-quality results.

Properties of Rotary Tablet Machine

A rotary tablet machine is a device used in the manufacturing of tablets that are used in the pharmaceutical industry. Tablets are widely-used in the pharmaceutical sector due to their easy administration and easy handling compared to other forms of medication. These machines are designed to compress a mixture of active and inactive ingredients into a tablet form.

There are several properties of the rotary tablet machine that make it ideal for producing pharmaceutical tablets. Firstly, the machine is equipped with a rotating turret that holds the die punch set. This ensures that the punches align with the matrix to ensure uniform tablet thickness, making it easier for the user to handle and consume. Secondly, the machine is designed to produce consistent densities and weights of the tablets, thereby maintaining the potency of the drug. Additionally, the machine utilizes an adjustable compression force to ensure that the tablets are compressed to a specific degree, promoting high-quality product output.

Another essential feature of the rotary tablet machine is that it allows for easy sampling, inspection, and adjustment of the tablets during the manufacturing process. The machine can be easily accessed, and the operator can make changes to the settings if required, ensuring the tablets produced meet the required quality standards. Moreover, the machine’s modular design makes it easy to clean and maintain, ensuring that hygienic standards are met.

In conclusion, a rotary tablet machine has numerous advantages that make it the top choice for tablet manufacturing in the pharmaceutical industry. Its ability to produce uniform tablets with consistent densities, weights, and compression forces allows for the production of high-quality tablets. Additionally, the machine’s easy sampling, inspection, and adjustment, and its modular design make it easy to operate, clean, and maintain. These properties have led to the machine becoming an essential tool in the pharmaceutical industry, streamlining tablet production and improving the quality of medication produced.

How to use Rotary Tablet Machine

Rotary tablet machine is a mechanical device that is used for the production of tablets. It is an important machine for the pharmaceutical and related industries, and its use requires precision and skills. Here are some guidelines for using Rotary tablet machine:

1. Preparation: Before using the rotary tablet machine, it is important to prepare the materials that will be used for the production of the tablets. These materials include the powdered or granulated active ingredient, the excipients, and the lubricants. The materials should be properly mixed and sieved to achieve a uniform particle size.

2. Loading the machine: The machine is operated by loading the hopper with the mixed powders or granulated materials. The feeder unit should also be loaded with the lubricant, which is usually in liquid form.

3. Adjusting the machine: The rotary tablet machine has several settings that need to be adjusted before use. These settings include the fill depth, the compression force, and the tablet diameter. These settings should be adjusted according to the specifications of the tablets being produced.

4. Compression: The rotary tablet machine compresses the materials in the hopper into tablets. The compression force should be adjusted to ensure that the tablets are of the desired weight and hardness.

5. Ejection: Once the tablets have been compressed, they are ejected from the rotary tablet machine. The ejection system should be properly adjusted to ensure that the tablets are ejected smoothly and with minimal breakage.

6. Cleaning: After use, the rotary tablet machine should be properly cleaned to prevent contamination and ensure that it is ready for the next use.

In conclusion, the rotary tablet machine is an essential machine for the pharmaceutical industry. Its proper use requires precision and adherence to the guidelines provided. By following these guidelines, one can produce high-quality tablets efficiently and effectively.

Glossary Terminology Terms for Rotary Tablet Machine

Glossary Terminology Terms for Rotary Tablet Machine

The rotary tablet machine is an essential equipment used for tablet production. Here are some glossary terminology terms used in rotary tablet machine operation:

1. Compression force – the force applied by the upper and lower punches during compression to produce a tablet.

2. Die plate – the component that houses the punch and die in the machine.

3. Die cavity – it is a shaped hole in the die plate that gives the tablet its desired shape.

4. Filling depth – the depth at which the powder or granules fill the die cavity before compression.

5. Powder flow – it is the rate at which powder flows through an opening in the container.

6. Turret – the rotating part of the tablet machine that holds the die plates and punches.

7. Cam track – the groove in the turret that controls the movement of the punches.

8. Turret diameter – the diameter of the turret that determines the number of die cavities.

9. Feed frame – it is the component that distributes and controls the amount of powder or granules fed into the die cavity.

10. Tablet thickness – the thickness of the tablet after compression.

Understanding these terms will help to operate rotary tablet machines efficiently, and it promotes high-quality tablet production.

Rotary Tablet Machine Price

When it comes to making tablets, a rotary tablet machine is the most reliable and efficient equipment in the pharmaceutical industry. This machine is designed to produce tablets in large quantities, thereby reducing the time and manpower required for the process. The price of this machine, however, can vary depending on various factors.

The rotary tablet machine price is influenced by the number of stations it has. The more the stations, the higher the cost of the machine. For instance, a 16-station rotary tablet machine will cost more than an 8-station machine. Also, the complexity of the machine design can significantly affect the price of the machine.

Another factor that can affect the rotary tablet machine price is the materials used in its construction. A machine made of high-quality materials such as stainless steel will naturally be more expensive than one made of less durable materials. Quality materials will ensure that the machine can withstand wear and tear, and can thus operate reliably for an extended period.

The brand of the rotary tablet machine can also affect its price. Some brands are known for producing high-quality machines and, therefore, charge a premium for their products. However, it’s worth noting that a higher price does not always indicate better quality. It’s essential to consider other factors such as customer reviews, maintenance costs, and machine lifespan.

In summary, when purchasing a rotary tablet machine, it is essential to consider various factors that can influence the machine’s price. The number of stations, the complexity of the machine design, the quality of construction materials, and the brand are critical factors in determining its cost. Therefore, before making a purchase decision, conduct thorough research to ensure that you buy a machine that suits your business needs and budget.