Types and Applications of saw tips

Saw tips are commonly used to cut through materials such as wood, metal, and concrete. There are different types of saw tips that are specifically designed for specific applications. Some of the most common types of saw tips and their applications are listed below.

1. Carbide Saw Tips: Carbide saw tips are made from a combination of tungsten carbide particles and a metallic binder. They are known for their hardness and strength, which makes them ideal for cutting hard materials such as concrete, tile, and metal.

2. Diamond Saw Tips: Diamond saw tips are made from industrial-grade diamonds and are commonly used to cut through abrasive materials such as glass, ceramics, and stones.

3. CBN Saw Tips: CBN (cubic boron nitride) saw tips are synthetic crystals that are similar to diamonds. They are commonly used to cut through hard materials such as metal and ceramics.

4. Steel Saw Tips: Steel saw tips are made from high-quality steel that is compatible with various types of saw blades. They are commonly used for cutting through wood and other soft materials.

The applications of saw tips are vast and varied. Saw tips are used in industries such as construction, manufacturing, and woodworking. They are also used by DIY enthusiasts for various projects around the house. Saw tips are commonly used in circular saws, band saws, and reciprocating saws to cut through materials.

In conclusion, saw tips are an essential part of any cutting tool. They provide a durable and long-lasting cutting edge that can withstand the rigors of cutting through a wide range of materials. The type of saw tip used will depend on the material being cut and the specific application.

Benefits and Feature of Utilizing saw tips

Utilizing saw tips has several benefits and features. Saw tips are used in saw blades that allow for cutting through tough materials. Here are some of the benefits and features of utilizing saw tips:

1. Extended durability: Saw tips are designed to last longer and withstand heavy use. This feature makes them valuable for businesses that require regular cutting of heavy materials such as wood, metals, and plastics.

2. Improved efficiency: The saw tips’ design ensures that they cut through materials easily and quickly. This feature can cut down on production time and improve the overall efficiency of the cutting process.

3. Enhanced precision: Saw tips ensure high precision in cutting. The precision feature minimizes the risk of error, which is crucial in industries such as construction and furniture making.

4. Cost-effective: Although saw tips may be more expensive than regular saw blades, their long-lasting feature ensures that they are cost-effective in the long run.

5. Flexible: Saw tips are designed for versatility, and they can be modified to fit a wide range of saws. This feature ensures they are adaptable for various cutting needs.

6. Reduced maintenance: Since saw tips are long-lasting and resistant to wear, they require minimal maintenance, translating to lower maintenance costs.

7. Improved safety: The sharpness of saw tips ensures that the cutting process is smooth, thus reducing the risk of accidents in the workplace.

In conclusion, the utilization of saw tips has several benefits and features that make them a worthwhile addition to any cutting process. From improved efficiency and precision to cost-effectiveness and flexibility, saw tips are undeniably a valuable investment for several industries.

The Process of saw tips

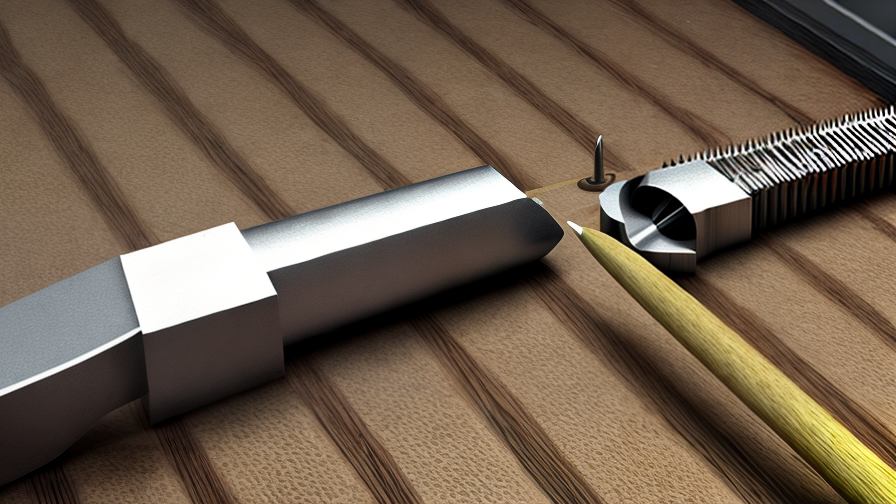

Saw tips are an important component in the manufacturing of saw blades. They are the tooth-like structures on the blade that come into contact with the material being cut. The process of creating saw tips involves several steps.

The first step is to select the material to be used for the saw tips. Carbide is a popular choice due to its hardness and durability. The selected material is then formed into the desired shape using various cutting tools and techniques. This process is typically done through grinding or milling.

Once the material is shaped, the saw tips are heated to a high temperature to harden them. The hardening process is also known as sintering. Sintering involves heating the tips to a temperature of around 1400°C in a vacuum or controlled atmosphere, which causes the material to bond and strengthen.

After the saw tips have been sintered, they are typically ground or polished to refine their shape and ensure that they are uniform in size and shape. This step involves the use of abrasive belts or diamond cutting tools to remove any imperfections in the surface of the tip and create a smooth surface.

Finally, the sharpening process can be done if required. This involves grinding the tips to create sharp edges that will cut through materials cleanly and efficiently.

In conclusion, the process of creating saw tips involves selecting an appropriate material, shaping it, sintering it, grinding or polishing it, and possibly sharpening it. The end result is a durable, efficient blade that is capable of cutting through a wide variety of materials.

How to use saw tips

Saw tips are a crucial component of any sawmill or woodworking operation. They are the small, hardened teeth that grip and cut through a variety of materials with precision and efficiency. To use saw tips effectively, it is necessary to follow a few key guidelines.

First, it is important to choose the correct type of saw tip for the specific application. There are different types of saw tips designed for cutting different materials, such as wood, metal, plastic, or composite materials. It is necessary to match the saw tip with the material being cut to ensure optimal performance and longevity.

Next, it is important to maintain the saw tips properly. This involves keeping them clean and free of debris, as well as sharpening them regularly to maintain their sharp cutting edge. Proper maintenance also extends the lifespan of the saw tips, reducing the need for frequent replacements.

When using saw tips, it is important to use the proper cutting technique. This involves applying a consistent amount of pressure to the saw blade, making sure to keep the blade perpendicular to the material being cut. Overly aggressive or erratic cutting can lead to premature wear and damage to the saw tips.

In addition, it is important to monitor the saw tips for signs of wear or damage, such as chipping or cracks. If these issues arise, it is necessary to replace the affected saw tips to prevent further damage or safety hazards.

In sum, using saw tips effectively involves selecting the correct type of saw tip, maintaining them properly, using the proper cutting technique, and monitoring them for signs of wear or damage. By following these guidelines, saw tips can provide reliable and efficient cutting performance for a variety of materials.

saw tips Manufacturer,Supplier and Wholesale

If you are involved in any kind of woodworking or metalworking, then you would know the importance of using saws for a perfect cut. But having the right saw is not enough, you also need the right saw tips to enhance the functionality and durability of your saw blades. A good saw tip not only helps in achieving a cleaner and smoother cut but also ensures a longer lifespan of your saw blade.

As a manufacturer, supplier, and wholesale of saw tips, we understand the significance of providing high-quality products to our customers. Our saw tips are made from premium quality materials that are durable, sturdy, and efficient. We have a variety of saw tips for different types of saws including circular saws, band saws, and chain saws. Our products are designed to fit seamlessly into your blades, ensuring optimal performance and reliability.

Whether you are looking for saw tips for cutting wood, metal, or any other material, we have you covered with our extensive range of custom saw tips. Our products are made to suit different blade sizes and types, and we offer a range of tip shapes including flat, square, and pointed. We also provide customization services to meet specific customer demands, making sure that our products fit the desired specification of our customers.

We are committed to providing our customers with the best products and services, and that is why we have a quality control team that ensures that every single piece of our saw tips passes strict quality control standards. We also offer competitive pricing for our products, making sure that our customers get the best value for their money.

In conclusion, if you are looking for a reliable manufacturer, supplier, and wholesale of saw tips, you should consider us. We provide high-quality products, extensive customization options, strict quality control standards and offer competitive pricing. Our goal is to ensure that our customers get the best products and services possible, and we continually strive to achieve that goal.

saw tips Price

Saw tips are one of the most critical components of any saw blade. They are the tiny teeth that produce the cutting action and are responsible for the quality of the cut. The price of saw tips varies depending on their material, shape, and design. Generally, carbide saw tips are more expensive than steel saw tips due to the former’s superior wear resistance and longevity.

The cost of individual saw tips can range from a few cents to several dollars. The primary factors that influence saw tip prices include the manufacturer, quality, and type. Low-quality saw tips tend to be cheaper, but they are also more prone to chipping, dulling, and breaking during use, leading to a shorter blade life.

Before choosing saw tips, it’s important to consider the material being cut and the cutting conditions. If the material is harder or abrasive, it’s recommended to use carbide saw tips due to their superior wear resistance. Other factors that affect saw tip prices include the blade shape and design, the number of teeth, and the size of the blade.

It’s also worth noting that the cost of saw tips shouldn’t be the only factor considered when choosing a blade. While cheaper saw tips may seem like a good deal initially, they will ultimately cost more in the long run due to frequent replacements and lower quality cuts.

In conclusion, the price of saw tips can vary significantly from a few cents to several dollars, depending on the quality, manufacturer, and type. When choosing saw tips, it’s essential to consider the material being cut and the cutting conditions, as well as the blade’s shape, design, and size. While cheaper saw tips may seem like a good deal initially, they can ultimately cost more due to shorter blade life and lower quality cuts, making it important to invest in high-quality saw tips for optimal cutting performance and efficiency.

FAQ sourcing saw tips manufacturer from China with multiple answers

Q: How can I source a saw tips manufacturer from China?

A: There are several ways to source a saw tips manufacturer from China. You can attend trade fairs, search online directories, or work with a sourcing agent.

Q: What are some popular trade fairs in China for sourcing saw tips manufacturers?

A: The Canton Fair, Shanghai International Hardware Show, and China International Hardware Show are popular trade fairs in China for sourcing saw tips manufacturers.

Q: How can I verify the credibility of a saw tips manufacturer from China?

A: You can verify the credibility of a saw tips manufacturer from China by checking if they have relevant certifications, asking for references, or visiting their factory for an inspection.

Q: What are some important factors to consider when choosing a saw tips manufacturer from China?

A: Some important factors to consider when choosing a saw tips manufacturer from China include their experience, production capacity, quality control measures, and pricing.

Q: Can I request samples from a saw tips manufacturer in China?

A: Yes, most saw tips manufacturers in China offer samples upon request. However, there may be fees associated with producing and shipping the samples.

Q: What is the typical lead time for saw tips manufacturing in China?

A: The typical lead time for saw tips manufacturing in China varies depending on the quantity and complexity of the order. It can range from a few weeks to several months.

Q: What are some common payment terms when working with a saw tips manufacturer from China?

A: Common payment terms when working with a saw tips manufacturer from China include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal.

Q: How can I communicate effectively with a saw tips manufacturer from China?

A: You can communicate effectively with a saw tips manufacturer from China by using clear and concise language, providing detailed specifications and requirements, and using visuals and diagrams when necessary. It is also recommended to have a translator or interpreter if there are language barriers.