Introduce about shrink packaging machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

Shrink packaging machines are efficient and reliable devices used to package various products using shrink films. They are widely used in industries such as food and beverages, pharmaceuticals, cosmetics, and more. This guide aims to provide a brief introduction to shrink packaging machines, including the aspects of quality, cost, suppliers, certifications, market, tips, and frequently asked questions (FAQs).

Quality: When choosing a shrink packaging machine, it is crucial to consider its quality. Look for machines made from durable materials that ensure longevity and reliability. Check for features such as adjustable sealing and cutting systems, temperature control, and accurate film positioning to ensure excellent packaging results.

Cost: The cost of shrink packaging machines can vary depending on their size, features, and capacity. It is essential to evaluate your specific packaging requirements and budget to find a machine that meets your needs without overspending. It is advisable to compare prices from different suppliers to get the best deal.

Supplier: Selecting a reliable supplier is vital to ensure you receive a high-quality shrink packaging machine. Look for reputable manufacturers or distributors known for their excellent customer service and after-sales support. Reading customer reviews or seeking recommendations can help in finding a trustworthy supplier.

Certification: When purchasing a shrink packaging machine, it is important to check for relevant certifications such as CE, ISO, or UL. These certifications ensure that the machine complies with industry standards and guarantees product safety and efficiency.

Market: The shrink packaging machine market is driven by the rising demand for efficient packaging solutions across various industries. Advancements in technology have resulted in the development of innovative shrink packaging machines, creating a competitive market with a wide range of options.

Tips: To ensure optimal performance and prolong the lifespan of your shrink packaging machine, regular maintenance, cleaning, and calibration are essential. Training your operators thoroughly on machine operation and safety measures can also help maximize efficiency and prevent accidents.

FAQs: Frequently asked questions regarding shrink packaging machines may include queries about suitable film types, machine capacity, power requirements, troubleshooting common issues, or the compatibility with specific products. (It is recommended to provide a concise but non-exhaustive list of FAQs).

In conclusion, shrink packaging machines are essential tools for efficient and attractive product packaging. Considering quality, cost, supplier reputation, certifications, market trends, and following maintenance tips are crucial when investing in these machines.

Types of shrink packaging machine

Shrink packaging machines are widely used in various industries for packaging products securely and preserving their quality. There are different types of shrink packaging machines available, each designed to cater to specific packaging requirements. Some of the most common types of shrink packaging machines include:

1. L-Sealer Shrink Wrapping Machine: L-sealer machines are used to wrap products in shrink film by forming an L-shaped seal around the product. These machines can handle a wide range of products of different sizes and shapes and are suitable for high-speed packaging operations.

2. Sleeve Wrapper Shrink Wrapping Machine: Sleeve wrapper machines are used to wrap products in shrink film by enclosing the product with a sleeve of film and sealing the edges using heat. These machines are ideal for packaging products of irregular shapes and sizes, such as bottles or cans.

3. Chamber Shrink Wrapping Machine: Chamber machines are used to wrap products in shrink film by placing the product in a sealed chamber, where the shrink film is applied and sealed around the product. These machines are suitable for packaging small to medium-sized products and provide a tight, secure seal.

4. Side Seal Shrink Wrapping Machine: Side seal machines wrap products in shrink film by sealing the film on the sides of the product rather than forming an L-shape seal. This type of machine is often used for packaging products with long or irregular shapes, such as furniture or windows.

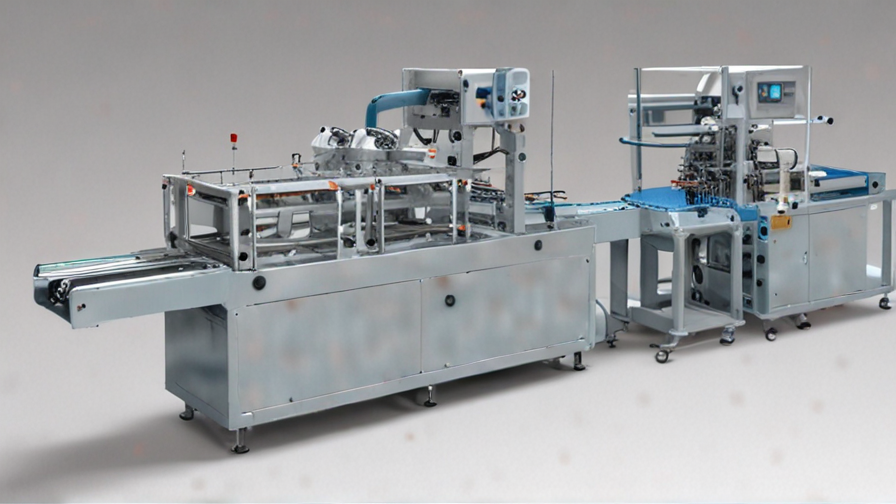

5. Automatic Shrink Packaging Machine: Automatic shrink packaging machines are fully automated systems that can handle the entire packaging process, including product feeding, film wrapping, sealing, and heat shrinking. These machines are suitable for high-volume packaging operations and offer increased efficiency and productivity.

6. Semi-Automatic Shrink Packaging Machine: Semi-automatic shrink packaging machines require some manual intervention in the packaging process, such as product placement or film feeding. These machines are suitable for small to medium-scale packaging operations and offer a cost-effective solution.

Each type of shrink packaging machine has its own advantages and is suitable for specific packaging requirements. Manufacturers and packaging professionals need to assess their product characteristics, production volume, and other factors to determine the most suitable type of shrink packaging machine for their needs.

Pros and Cons of Using shrink packaging machine

Shrink packaging machines have become increasingly popular in various industries due to their ability to provide a tight and secure packaging for products. However, like any other technology, using shrink packaging machines has its pros and cons.

Pros:

1. Product Protection: One of the main advantages of using shrink packaging machines is that they provide a high level of protection to the packaged product. The shrink film tightly encases the product, preventing any damage during transportation or storage. It acts as a barrier against moisture, dust, and UV rays, ensuring the product’s quality and freshness.

2. Visual Appeal: Shrink packaging enhances the product’s visual appeal, making it more attractive to consumers. The tight and smooth finish creates a professional and aesthetic look, increasing the product’s shelf presence and potential for sales.

3. Tamper-proof and Security: Shrink packaging provides tamper-evident protection, ensuring the product’s integrity. Once the film is sealed, it becomes difficult to open without leaving visible signs of tampering. This helps to prevent theft and contamination, especially in the food and pharmaceutical industries.

4. Versatility: Shrink packaging machines can handle a wide range of products irrespective of their shape, size, or material. From individual items to bundles, shrink packaging can accommodate diverse packaging needs, making it a versatile solution for various industries.

Cons:

1. Initial Investment: Shrink packaging machines require a significant initial investment, which may deter small businesses or startups from adopting this technology. The cost of the machine, installation, and maintenance needs to be carefully evaluated before making the investment.

2. Production Speed: Shrink packaging machines may have limitations in terms of production speed. Depending on the machine type and product size, the packaging process may take longer compared to other packaging methods. This could potentially impact overall productivity.

3. Film Selection: The choice of shrink film is crucial to ensure optimal packaging. Selecting the wrong type of film may result in issues like wrinkles, poor sealing, or low film clarity. Additional testing and experimenting with different films may be necessary to find the most suitable option, which can add time and cost to the packaging process.

4. Environmental Impact: Shrink packaging typically involves the use of plastic films, which contribute to plastic waste. While some shrink films are recyclable, others may not be easily recycled, leading to environmental concerns. It is essential to consider sustainable alternatives or recyclable materials to minimize the environmental impact.

In conclusion, shrink packaging machines offer numerous advantages such as product protection, visual appeal, and tamper-proof packaging. However, the initial investment, production speed limitations, film selection challenges, and environmental impact should be carefully considered to make an informed decision about adopting this packaging method.

shrink packaging machine Reference Specifications (varies for different product)

The shrink packaging machine is a versatile and efficient equipment used in various industries for packaging different types of products. It is designed to provide a secure and tamper-proof wrapping around the product, enhancing its presentation and protecting it during transportation and storage.

The reference specifications of the shrink packaging machine may vary depending on the specific product being packaged. However, there are some common features and capabilities found in most machines. These specifications ensure that the machine can meet the requirements of different industries and products.

One of the key specifications is the speed of the machine, which determines the number of packs it can produce per minute. The speed can vary from 20 to 100 packs per minute, depending on the size and complexity of the product. This feature is crucial for high-volume production lines, where efficiency and productivity are essential.

Another important specification is the size range of products that the machine can handle. Shrink packaging machines come in different sizes to accommodate a variety of product dimensions. Machines can handle products ranging from small individual items to larger items like boxes or bundles.

The shrink film type and thickness are also vital specifications. The machine should be capable of working with different types of shrink films, such as PVC, polyolefin, or polyethylene. The thickness of the film may vary depending on the product’s fragility and sensitivity to heat.

Additionally, the machine’s control system plays a crucial role. It should have a user-friendly interface, allowing operators to adjust various settings easily. The control system enables precise control over the shrink film temperature, conveyor speed, and sealing pressure, ensuring consistent and reliable packaging results.

Other specifications may include the power supply requirements, such as voltage and frequency, as well as safety features like emergency stop buttons and automatic fault detection systems. The machine should also be designed for easy maintenance and cleaning, minimizing downtime and ensuring smooth operations.

In summary, the shrink packaging machine is a versatile and efficient piece of equipment used for packaging various products. Its specifications may vary depending on the product, but key features include speed, size range, film type, control system, power supply, and safety features. These specifications ensure optimal performance and reliable packaging results for different industries and products.

Applications of shrink packaging machine

Shrink packaging machines are widely used across various industries for packaging and sealing products using shrink films. These machines offer numerous advantages, making them an essential component of modern packaging processes. Here are some applications of shrink packaging machines:

1. Food and Beverage Industry: Shrink wrapping helps in preserving the freshness and extending the shelf life of food products. It is extensively used for packaging perishable items like fruits, vegetables, meat, seafood, bakery goods, and ready-to-eat meals. Shrink films provide excellent protection against moisture, contaminants, and tampering, ensuring that the products reach consumers in optimal condition.

2. Pharmaceuticals and Healthcare: Shrink packaging is crucial for the pharmaceutical industry to maintain the integrity and sterility of medical devices, surgical instruments, drug packages, and healthcare products. The machines offer precise and secure wrapping, safeguarding against contamination, while also enhancing product identification and traceability.

3. Cosmetics and Personal Care: Shrink packaging machines are used to package skincare products, cosmetics, perfumes, and personal care items. Shrink films provide a professional and attractive appearance, creating a visually appealing package that also safeguards the products from external elements like dust, sunlight, and moisture.

4. Electronics and Industrial Goods: Shrink wrapping is common in the electronics industry for packaging products like CDs, DVDs, computer peripherals, and electronic components. It protects fragile items from scratches and damage during transit, and also prevents static interference. For industrial goods, shrink packaging offers protection against corrosion, dust, and moisture.

5. Retail and E-commerce: Shrink-wrapped products are popular in the retail industry as they provide a tamper-evident seal, ensuring the safety and quality of products during transportation and storage. Shrink packaging machines are widely used in e-commerce fulfillment centers for wrapping and sealing individual items or bundling multiple products together.

6. Promotional and Gift Items: Shrink wrapping adds value to promotional items like pens, stationery, calendars, and personalized gifts. It creates an attractive, transparent packaging that enhances the visual appeal and protects the items from damage. Shrink packaging can also be used for gift baskets, bundling products together for a cohesive presentation.

In summary, shrink packaging machines find diverse applications across industries, including food, pharmaceuticals, cosmetics, electronics, retail, and more. Their ability to provide secure sealing, improve product visibility, and extend shelf life makes them indispensable for modern packaging processes.

The Work Process and how to use shrink packaging machine

The work process of a shrink packaging machine involves several steps to ensure effective packaging of items. Here is a brief overview of the process:

1. Preparation: First, the machine needs to be set up and prepared for operation. This includes ensuring that the necessary materials such as shrink film and packaging supplies are available and loaded into the machine.

2. Loading: The items to be packaged are placed into the appropriate packaging material. This could be individual products or a group of products depending on the packaging requirements.

3. Sealing: The machine uses heat to seal the edges of the packaging material to create a bag around the items. This ensures that the items are securely contained within the packaging.

4. Shrinkage: Once the sealing is complete, the packaged items are passed through a heat tunnel or oven. The heat causes the shrink film to shrink and tightly conform to the shape of the items, creating a snug and professional-looking packaging.

5. Cooling: After the shrinkage process, the packaged items are allowed to cool down. This step is important as it helps the packaging material to retain its shape and secure the items within.

6. Inspection and labeling: Once cooled, the packaged items are inspected to ensure the packaging is intact and the items are properly secured. Labels or any other necessary markings can also be added at this stage.

To use a shrink packaging machine effectively, it is important to carefully follow the manufacturer’s instructions and safety guidelines. Ensure that the machine is properly set up and calibrated before operation and that all necessary materials are loaded correctly. Regular maintenance and cleaning of the machine are also important to ensure optimal performance.

During operation, it is essential to monitor the machine and the packaging process to detect any issues or malfunctions. This could include monitoring the heat, speed, and tension settings to ensure consistent and high-quality packaging. Regularly inspect the packaged items to ensure proper sealing and shrinkage.

In conclusion, the work process of a shrink packaging machine involves preparation, loading, sealing, shrinkage, cooling, and inspection. Following the manufacturer’s instructions and proper machine maintenance are vital for effective use. Regular monitoring and inspection during operation are essential to ensure high-quality packaging results.

Quality Testing Methods for shrink packaging machine and how to control the quality

There are several quality testing methods that can be used for shrink packaging machines to ensure their efficiency and effectiveness. These methods include:

1. Visual Inspection: This involves checking for any visible defects in the machine components such as misalignment, loose or broken parts, damaged seals, or irregularities in the shrink film wrapping.

2. Performance Testing: This method involves running the machine with test products to evaluate its performance. It includes measuring the speed and accuracy of the machine, the quality of shrinkage, the tightness of the wrapping, and the overall packaging integrity.

3. Film Testing: This method focuses on evaluating the quality of the shrink film used in the packaging process. It includes assessing the thickness and clarity of the film, its heat-shrinking capability, and its ability to adhere properly to the product being packaged.

4. Environmental Testing: This method involves subjecting the shrink packaging machine to various environmental conditions to test its durability and reliability. It includes testing the machine’s performance under different temperatures, humidity levels, or vibrations to ensure its stability and consistency.

To effectively control the quality of shrink packaging machines, several measures can be taken:

1. Establishing Quality Standards: Clearly define quality standards and specifications for the machine components, performance, and packaging outputs. Ensure that all operators adhere to these standards during the manufacturing and testing processes.

2. Regular Maintenance: Implement a regular maintenance schedule to ensure that all machine components are functioning properly. This includes routine cleaning, lubrication, calibration, and timely replacement of worn-out parts.

3. Training and Monitoring: Train the operators on proper machine operation, maintenance, and quality control protocols. Regularly monitor their performance and provide feedback to ensure adherence to quality standards.

4. Documentation and Record-Keeping: Maintain comprehensive documentation of quality control activities, such as test results, inspection reports, maintenance records, and operator training records. This helps to identify any recurring issues and enables effective troubleshooting.

5. Supplier Audits: Regularly audit and evaluate the suppliers of machine components and shrink films to ensure their quality and adherence to specifications.

By implementing these quality testing methods and control measures, manufacturers can ensure that their shrink packaging machines consistently produce high-quality packaging outputs, leading to customer satisfaction and improved overall operational efficiency.

shrink packaging machine Sample Policy and Post-Purchase Considerations for shrink packaging machine from China

Sample Policy:

When purchasing a shrink packaging machine from China, it is important to consider the sample policy provided by the manufacturer. Ideally, the manufacturer should offer free samples or at least provide a sample machine at a discounted price for testing and evaluation purposes. This allows the buyer to assess the quality, functionality, and suitability of the machine for their specific packaging needs. Additionally, the sample policy should include provisions for returning or exchanging the machine if it does not meet the buyer’s requirements or if it is found to be defective or damaged upon arrival.

Post-Purchase Considerations:

After purchasing a shrink packaging machine from China, there are several post-purchase considerations that should be taken into account. Firstly, it is crucial to inspect the machine thoroughly upon delivery to ensure that it has been shipped without any damage. Any defects or damages should be reported to the manufacturer immediately to initiate the necessary corrective actions.

Secondly, the buyer should familiarize themselves with the machine’s operating instructions and safety precautions. It is important to understand how to properly load and adjust the machine, as well as follow any recommended maintenance routines. This will ensure optimal performance and prolong the lifespan of the machine.

Furthermore, it may be beneficial to establish a relationship with the manufacturer or supplier for ongoing technical support and after-sales service. This will be advantageous in case of any troubleshooting or repair needs in the future. It is also important to inquire about the availability of spare parts and whether the manufacturer can provide them in a timely manner.

Lastly, it is recommended to monitor the machine’s performance and efficiency over time to ensure that it continues to meet the packaging requirements. Regular maintenance and periodic inspection can help identify any potential issues early on and prevent production disruptions.

In conclusion, when purchasing a shrink packaging machine from China, it is crucial to consider the sample policy provided by the manufacturer, as well as various post-purchase considerations such as inspection upon delivery, machine operation and maintenance, technical support, spare part availability, and ongoing performance monitoring.

Sourcing shrink packaging machine from China: Opportunities, Risks, and Key Players

Sourcing shrink packaging machines from China can present various opportunities for businesses due to the country’s well-established manufacturing capabilities and competitive pricing. China is known for its vast range of manufacturing expertise and advanced technology, making it an attractive destination for businesses seeking cost-effective shrink packaging solutions.

One of the key opportunities when sourcing shrink packaging machines from China is the ability to access a wide range of options. China has a large number of manufacturers offering a variety of shrink packaging machine designs, functionalities, and capacities. This allows businesses to choose a machine that best suits their specific packaging needs and requirements.

Additionally, Chinese manufacturers often offer competitive pricing due to lower labor and production costs. This can result in cost savings for businesses, especially when compared to sourcing from manufacturers in other countries.

However, there are also risks associated with sourcing shrink packaging machines from China. One of the main risks is the possibility of encountering quality issues or unreliable suppliers. To mitigate this risk, it is crucial for businesses to thoroughly research and investigate potential suppliers, ensuring they have a proven track record of manufacturing high-quality shrink packaging machines.

Another risk to consider is potential language and communication barriers. Ensuring clear communication with Chinese suppliers is essential to avoid misunderstandings and ensure that the desired specifications and requirements are met.

Some key players in the shrink packaging machine market in China include Shenzhen Sam and Shenzhen Henno Packaging Technology Co., Ltd. These companies have a reputation for producing high-quality shrink packaging machines and have established themselves as reliable suppliers in the industry.

In conclusion, sourcing shrink packaging machines from China can offer opportunities for businesses to access a wide range of options and competitive pricing. However, it is important to carefully vet suppliers, address potential quality and communication issues, and work with trusted key players in the market to mitigate risks.

How to find and select reliable shrink packaging machine manufacturers in China,use google search manufacturers and suppliers

When looking for reliable shrink packaging machine manufacturers in China, utilizing Google search can be an effective method. Here are the steps to follow:

1. Begin by conducting a search using relevant keywords such as “shrink packaging machine manufacturers in China” or “reliable shrink machine suppliers.” This will provide a list of potential manufacturers and suppliers.

2. Visit the websites of the manufacturers or suppliers that appear in the search results. Look for well-designed and informative websites that provide detailed information about their products, services, and company background. A professional and user-friendly website is an indicator of a reliable manufacturer.

3. Explore the range of products offered by the manufacturers. Ensure that they specialize in shrink packaging machines and have a wide variety of machines suitable for different industry needs. Assess whether their machines fulfill your specific requirements regarding material type, size, production capacity, and automation level.

4. Check if the manufacturer has relevant certifications and quality management systems, such as ISO 9001. This ensures that they adhere to international quality standards and are committed to producing reliable machines.

5. Look for customer reviews and testimonials on the manufacturer’s website or other reliable platforms. Positive feedback from satisfied customers indicates the manufacturer’s reliability and the quality of their machines.

6. Contact the manufacturer directly using the provided contact information. Inquire about their product details, manufacturing capabilities, pricing, delivery time, and after-sales service. A reliable manufacturer should be responsive, transparent, and able to address your queries promptly.

7. Consider visiting trade shows or exhibitions related to packaging machinery in China. This provides an opportunity to meet manufacturers in person, examine their machines, and discuss your requirements face-to-face.

8. When evaluating different manufacturers, compare their prices, warranty periods, and support services. It is advisable to obtain quotations from multiple manufacturers for the same specification of machines to make an informed decision.

9. Remember to verify the manufacturer’s legitimacy and reliability by conducting a background check. This includes verifying their business license, checking their registration with relevant authorities, and confirming their reputation in the industry.

By following these steps, one can efficiently find and select reliable shrink packaging machine manufacturers in China using Google search. Remember to exercise due diligence throughout the process to ensure the best quality and reliability for your packaging machine investment.

How to check shrink packaging machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a shrink packaging machine manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the website on Google Chrome, a widely used and trusted web browser.

2. Install SEOquake: Install the SEOquake extension on your Google Chrome browser. SEOquake is a reliable SEO tool that provides information about a website’s ranking and other important metrics.

3. Check the Alexa Ranking: After installing SEOquake, you can see the Alexa Ranking of the website on the top right corner of your browser. Alexa Ranking is a useful metric to determine a website’s popularity and traffic volume. If the website’s Alexa Ranking is within the top 10 million, it usually indicates a decent level of reliability.

4. Assess other SEO parameters: SEOquake provides several other SEO metrics that can help you evaluate the credibility of the website. These include the number of indexed pages, backlink information, and social media engagement. Review these parameters to get a better understanding of the website’s reliability.

5. Cross-reference information: Additionally, it can be helpful to cross-reference the information you find on the website with other reputable sources. Check if the website provides comprehensive details about the manufacturer, their experience, certifications, customer reviews, and contact information.

6. Keep an eye on the website’s design and functionality: A reliable manufacturer’s website should have a professional design, easy navigation, and functionality. Look for clear product descriptions, specifications, and images. Make sure the website appears legitimate and trustworthy.

Remember to trust your instincts and exercise caution when assessing the reliability of a website. If something seems suspicious or too good to be true, it’s always best to do further research or consider contacting the manufacturer directly for more information.

Top 10 shrink packaging machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Qingdao Ausense Packaging Equipment Co., Ltd.:

– Ausense specializes in manufacturing high-speed shrink packaging machines suitable for various industries. Their products include automatic side sealers, L-sealers, and shrink tunnels. These machines are known for their efficiency, durability, and user-friendly operation, enabling businesses to achieve precise and seamless shrink packaging.

2. Shanghai Kuko Packing Machinery Co., Ltd.:

– Kuko offers a wide range of shrink packaging machines, including sleeve wrappers, heat shrink tunnels, and automatic shrink labeling machines. With a focus on innovative technology, their products provide advanced features like intelligent control systems, superior energy savings, and effective protection for products during transportation and storage.

3. Wenzhou T&D Packaging Machinery Factory:

– T&D specializes in the manufacture of shrink wrapping machines, including fully automatic and semi-automatic models. Their machines feature quick packaging with precise film cutting and sealing, making them ideal for packaging food, beverages, cosmetics, and electronic products.

4. Shenzhen Jiazhao High Tech Co., Ltd.:

– Jiazhao produces a range of shrink packaging machines, such as L-sealers, automatic shrink wrapping machines, and chamber shrink wrap machines. These machines are designed for various industries and offer quick and efficient packaging solutions, ensuring product safety and enhancing aesthetics.

5. Guangzhou XTIME Packaging Equipment Co., Ltd.:

– XTIME specializes in the production of automated shrink packaging machines, including side sealers, sleeve wrappers, and shrink tunnels. Their machines feature PLC control systems, adjustable speed, and temperature settings, ensuring stable packaging performance for industries like food, pharmaceuticals, and cosmetics.

6. Ruian Huada Machinery Co., Ltd.:

– Huada manufactures high-speed shrink packaging machines suitable for various products. Their range includes L-sealers, sleeve wrappers, and heat tunnels. The machines are designed for easy operation, precise sealing, and energy efficiency, thereby providing optimal packaging results.

7. Dongguan Rener Automation Technologies Co., Ltd.:

– Rener offers a comprehensive line of shrink packaging machines, including sealing machines, L-sealers, and shrink tunnels. Their machines are designed to be versatile, robust, and easy to maintain, providing effective packaging solutions for industries like stationery, electronics, and daily necessities.

8. Suzhou Labelong Packaging Machinery Co., Ltd.:

– Labelong specializes in manufacturing a wide range of shrink packaging machines, including automatic shrink wrapping machines, heat tunnels, and sleeve wrappers. Their machines offer efficient packaging with precise film cutting, sealing, and heat shrinking capabilities, delivering reliable packaging solutions for various products.

9. Shantou Xingwei Packing Equipment Co., Ltd.:

– Xingwei produces shrink packaging machines like automatic side sealers, sleeve wrappers, and shrink tunnels. Their machines are compact, low in noise, and feature easy control systems, ensuring efficient packaging for food, beverage, and pharmaceutical industries.

10. Guangzhou Mingke Packaging Machine Co., Ltd.:

– Mingke specializes in the production of shrink wrapping machines, including automatic side sealers, L-sealers, and shrink tunnels. Their machines are known for their high packaging efficiency, precise sealing, and user-friendly operation, making them suitable for industries like printing, cosmetics, and stationery.

| Rank | Manufacturer | Products Offered |

|——|—————————————|————————————————————|

| 1 | Qingdao Ausense Packaging Equipment | Automatic side sealers, L-sealers, shrink tunnels |

| 2 | Shanghai Kuko Packing Machinery | Sleeve wrappers, heat shrink tunnels, automatic labeling |

| 3 | Wenzhou T&D Packaging Machinery | Fully automatic and semi-automatic shrink wrapping machines |

| 4 | Shenzhen Jiazhao High Tech | L-sealers, automatic shrink wrapping machines, chamber wrap |

| 5 | Guangzhou XTIME Packaging Equipment | Side sealers, sleeve wrappers, shrink tunnels |

| 6 | Ruian Huada Machinery | L-sealers, sleeve wrappers, heat tunnels |

| 7 | Dongguan Rener Automation Technologies | Sealing machines, L-sealers, shrink tunnels |

| 8 | Suzhou Labelong Packaging Machinery | Automatic shrink wrapping machines, heat tunnels |

| 9 | Shantou Xingwei Packing Equipment | Automatic side sealers, sleeve wrappers, shrink tunnels |

| 10 | Guangzhou Mingke Packaging Machine | Automatic side sealers, L-sealers, shrink tunnels |

Background Research for shrink packaging machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

Shrink packaging machines are widely used in various industries for packaging and protecting products. China has emerged as a major player in the manufacturing and exporting of shrink packaging machines. Here is a brief background research on some well-known shrink packaging machine manufacturers in China.

1. Qingdao Australia Packaging Equipment Co., Ltd.

Qingdao Australia Packaging Equipment Co., Ltd., established in 1995, is a prominent manufacturer of shrink wrapping machines in China. They specialize in the production of fully automatic shrink packaging machines and have a strong focus on research and development. This company has a reputation for providing high-quality machines that are reliable and efficient.

2. Zhongshan Kaikai Packaging Machinery Co., Ltd.

Zhongshan Kaikai Packaging Machinery Co., Ltd. is a leading manufacturer of shrink packaging machines in China. With over 20 years of experience, they offer a wide range of machines including automatic sleeve sealing machines, shrink tunnels, and L-sealing machines. Their machines are known for their precision, durability, and user-friendly operation.

3. Ruian Huadong Packing Machinery Co., Ltd.

Ruian Huadong Packing Machinery Co., Ltd. is a well-established manufacturer of shrink packaging machines in China. They specialize in the production of automatic sleeve sealing machines, shrink wrapping machines, and shrink tunnels. Their machines are widely used in food, beverage, and cosmetic industries. The company focuses on technological innovation to meet the evolving needs of the market.

4. Wenzhou Brother Machinery Co., Ltd.

Wenzhou Brother Machinery Co., Ltd. is a leading shrink packaging machine manufacturer based in China. They have a diverse product range that includes automatic L-sealing shrink wrapping machines, sleeve sealing machines, and shrink tunnels. The company takes pride in providing cost-effective solutions and excellent after-sales service to their customers.

To gather more detailed information about these manufacturers, one can refer to QCC.com, where company profiles, product range, and customer reviews can be found. Archived versions of their websites on Archive.org could provide historical insights. ImportYeti.com can be explored to gain insights into their import and export activities, giving information on the countries they export to and the volume of their shipments.

Overall, China boasts several reputable manufacturers of shrink packaging machines that offer a wide range of options to cater to different industry needs. It is always recommended to thoroughly research and compare different manufacturers based on factors like product quality, customer reviews, after-sales service, and pricing before making a purchase decision.

Leveraging Trade Shows and Expos for shrink packaging machine Sourcing in China

Trade shows and expos can be valuable platforms for sourcing shrink packaging machines in China. These events provide opportunities to connect with numerous suppliers, gain insights into the latest technologies and trends, and compare different offerings all in one place.

China is known for its vast manufacturing capabilities, and trade shows and expos showcase an array of shrink packaging machine manufacturers and suppliers from various regions. Visiting these shows allows buyers to explore a wide range of options and find the best fit for their specific requirements.

These events also offer a chance to evaluate the quality of the machines firsthand. Buyers can observe the build quality, durability, and functionality of the machines on display, enabling them to make more informed purchasing decisions. Additionally, they can interact with experienced sales representatives and technical experts who can provide detailed product information and address any queries or concerns.

Trade shows and expos in China also provide an excellent opportunity for networking. Engaging with industry professionals, potential business partners, and other buyers can lead to valuable connections and collaborations. These networking opportunities can open doors to new suppliers or partnerships, ensuring a reliable and efficient supply chain for shrink packaging machines.

To make the most out of trade shows and expos, buyers should plan their visit in advance and set clear objectives. Researching the exhibitors list and booth locations, as well as the schedule of seminars or conferences related to shrink packaging technology, can help optimize time and resources. It’s also important to prepare a list of questions or specific requirements to discuss with potential suppliers.

Overall, attending trade shows and expos in China can be an effective strategy for sourcing shrink packaging machines. These events provide a comprehensive platform for discovering suppliers, evaluating quality, networking, and staying updated on the latest industry developments. By leveraging these opportunities, buyers can find the most suitable and cost-effective solutions for their shrink packaging needs.

The Role of Agents and Sourcing Companies in Facilitating shrink packaging machine Purchases from China

Agents and sourcing companies play a vital role in facilitating shrink packaging machine purchases from China. These entities act as intermediaries between buyers and manufacturers, simplifying the procurement process and ensuring a smooth transaction.

One of the key roles of agents and sourcing companies is to help buyers identify reliable and reputable Chinese manufacturers of shrink packaging machines. They have extensive networks and knowledge of the market, allowing them to connect buyers with high-quality suppliers. This saves buyers valuable time and effort in searching for suitable manufacturers and eliminates the risk of dealing with untrustworthy or substandard suppliers.

Agents and sourcing companies also assist in negotiating favorable terms and conditions of the purchase. They have experience in dealing with Chinese manufacturers and possess strong negotiation skills. This allows them to secure competitive pricing and favorable payment terms on behalf of the buyers. Additionally, they can help navigate any cultural or language barriers that may arise during negotiations, ensuring effective communication between both parties.

Furthermore, agents and sourcing companies handle the logistics and shipping aspects of the purchasing process. They arrange all necessary paperwork, customs clearance, and transportation of the shrink packaging machines from China to the buyer’s destination. This relieves buyers of the burden of managing the complex logistics involved in international trade and ensures a hassle-free delivery of the purchased goods.

Overall, agents and sourcing companies act as trusted partners for buyers looking to purchase shrink packaging machines from China. They provide valuable market knowledge, connect buyers with reliable manufacturers, negotiate favorable terms, and handle logistics. By utilizing their services, buyers can enjoy a seamless purchasing experience and have peace of mind knowing that their procurement needs are being efficiently handled.

Price Cost Research for shrink packaging machine manufacturers Companies in China, use temu.com and 1688.com

Shrink packaging machines are widely used in the packaging industry for various products, and China is known for its vast manufacturing capabilities in this sector. To conduct price cost research for shrink packaging machine manufacturers in China, two popular online platforms can be utilized: temu.com and 1688.com.

Temu.com is a B2B online marketplace that connects buyers and suppliers globally. It offers a wide range of products, including packaging machinery. By using the search function on the website and specifying the product as “shrink packaging machine,” one can find numerous manufacturers in China. The platform provides product details, specifications, pricing information, and contact details for each manufacturer. It also offers a messaging system to directly communicate with the suppliers for further inquiries or negotiations.

1688.com, operated by Alibaba Group, is another popular online platform mainly serving the Chinese market. It is a B2B e-commerce website that provides access to a vast number of suppliers and manufacturers in China. Similar to temu.com, one can search for shrink packaging machine manufacturers by using relevant keywords. The platform offers detailed product listings with pricing information, product specifications, and seller ratings. It also provides a communication tool for direct contact with manufacturers.

When conducting price cost research, it is essential to consider various factors such as machine specifications, production capacity, quality, and after-sales services. Comparing prices among different manufacturers is crucial to determine the most competitive offers. Additionally, it is advisable to review customer reviews, ratings, and certifications to ensure the reliability and credibility of the manufacturers.

By utilizing temu.com and 1688.com, researchers can collect information on pricing, product specifications, and contact details of shrink packaging machine manufacturers in China. This comprehensive research will enable buyers to make informed decisions based on their specific requirements and budget.

Shipping Cost for shrink packaging machine import from China

The shipping cost for importing a shrink packaging machine from China will depend on various factors, including the dimensions and weight of the machine, the shipping method chosen, and the destination country. Here, we will discuss a general estimate of the shipping cost.

For smaller shrink packaging machines, air freight may be a suitable shipping method. The cost will typically range from $5 to $20 per kilogram, depending on various factors such as volume, urgency, and shipping service provider. For example, if the machine weighs 100 kilograms and the air freight rate is $10 per kilogram, the shipping cost would be approximately $1,000.

For larger shrink packaging machines, sea freight is commonly used. The cost is determined by the volume (cubic meter) or weight (ton) of the shipment. As an approximate estimate, the sea freight cost per cubic meter can range from $100 to $400, depending on factors such as the shipping route, carrier, and destination port charges. If the machine’s volume is 2 cubic meters and the sea freight rate is $200 per cubic meter, the shipping cost would be approximately $400.

In addition to the shipping cost, it is important to consider other expenses such as customs duties, import taxes, local handling charges, and any additional services required (such as insurance or customs brokerage).

It is advisable to consult with a freight forwarder or shipping agent who can provide accurate and detailed information based on your specific requirements. They can also help with customs clearance procedures, documentation, and other logistics aspects, ensuring a smooth and cost-effective import process.

Compare China and Other shrink packaging machine Markets: Products Quality and Price,Visible and Hidden Costs

China is known for its competitive market when it comes to shrink packaging machines. In terms of product quality, Chinese machines have made significant improvements over the years. Many Chinese manufacturers have invested in advanced technology and improved their production processes to increase the overall quality of their machines. However, it is still important to note that not all Chinese machines are of high quality. Some manufacturers may prioritize cost-cutting measures, which can compromise product quality.

When comparing prices, Chinese shrink packaging machines can often be found at lower prices compared to machines from other markets. This is primarily due to China’s lower manufacturing and labor costs. However, it is important to consider both visible and hidden costs when making a purchase decision. Visible costs include the actual machine price, while hidden costs encompass expenses such as maintenance, after-sales service, spare parts availability, and the lifespan of the equipment. In this regard, other markets may have an advantage in terms of a more established aftermarket support system, ensuring better customer service and availability of spare parts.

It is worth noting that some consumers may have concerns about intellectual property theft when purchasing Chinese machines. China has been known for its copycat manufacturing practices in the past, but the Chinese government has taken steps to improve intellectual property protection in recent years. However, buyers should still exercise caution and research the reputation and reliability of the manufacturer before making a purchase.

In conclusion, Chinese shrink packaging machines have significantly improved in terms of product quality, but it is important to exercise caution and choose reputable manufacturers. While Chinese machines are often priced competitively, hidden costs such as maintenance and after-sales service should be considered. Other markets may offer a more established aftermarket support system, but prices may be higher compared to Chinese machines. Ultimately, buyers should carefully evaluate their specific needs and consider factors such as quality, price, and support before making a purchasing decision in the shrink packaging machine market.

Understanding Pricing and Payment Terms for shrink packaging machine: A Comparative Guide to Get the Best Deal

When it comes to purchasing a shrink packaging machine, understanding pricing and payment terms is crucial in order to get the best deal possible. This comparative guide aims to provide essential information within a concise word limit of 300 words.

Firstly, it is important to research and compare prices from different manufacturers or suppliers. Prices can vary significantly based on factors such as machine size, capacity, features, and brand reputation. Obtaining quotes from multiple sources will enable a comprehensive comparison to identify the fairest price.

In addition to the upfront cost, it is essential to consider the long-term costs associated with the machine. This includes maintenance, spare parts, and energy consumption. Analyzing these expenses will give a better understanding of the overall investment required.

When discussing payment terms, it’s worth negotiating favorable conditions with the supplier. While some may demand full payment upfront, others may offer installment plans or financing options. Consider the company’s reputation, reliability, and customer reviews before committing to any payment terms.

It is also vital to inquire about warranty and after-sales support. A reliable manufacturer or supplier will provide a warranty period for their machine, ensuring any unforeseen glitches or faults can be resolved at minimal cost to the buyer. Understanding the extent of warranty coverage is crucial to avoid any potential future expenses.

Furthermore, don’t overlook the importance of certification and compliance. Ensure that the selected shrink packaging machine complies with relevant industry standards and safety regulations. This ensures the longevity and safe operation of the machine, preventing any potential legal issues or accidents.

Lastly, it is beneficial to consider the overall reputation and customer feedback of the manufacturer or supplier. Look for reliable testimonials or contact previous buyers to gain insights into their experience and satisfaction with the product and service provided.

In conclusion, when purchasing a shrink packaging machine, it is imperative to understand and compare pricing, long-term costs, payment terms, warranty, compliance, and the manufacturer’s reputation. This comparative guide provides a brief but comprehensive overview of the key factors to consider in order to secure the best deal possible.

Chinese Regulations and Industry Standards Certifications for shrink packaging machine,Import Regulations and Customs for shrink packaging machine from China

Chinese Regulations and Industry Standards Certifications:

In China, the manufacturing and sale of shrink packaging machines are regulated by various agencies and must comply with specific industry standards. One prominent agency responsible for regulating this industry is the China Packaging Machinery Industry Association (CPMIA). The CPMIA sets guidelines and industry standards to ensure the quality, safety, and performance of shrink packaging machines.

To ensure compliance with these standards, manufacturers must obtain certifications such as the China Compulsory Certification (CCC). The CCC is a mandatory certification required for certain products sold on the Chinese market, including packaging machinery, to ensure their safety and quality. Additionally, specific certifications like the ISO 9001 (quality management system) and the CE Mark (European conformity) may also be required for international market access.

Import Regulations and Customs:

When importing shrink packaging machines from China, it is important to comply with the relevant import regulations and customs procedures.

Firstly, importers must determine the tariff classification code for shrink packaging machines. This code is used for customs declaration and helps in determining the applicable customs duties.

Importers should ensure that the chosen supplier has the necessary export licenses and permits required by Chinese authorities. They should also verify the supplier’s reputation and product quality before engaging in any transactions.

Importers need to provide necessary shipping documents such as commercial invoice, packing list, bill of lading or airway bill, and any other relevant certificates and licenses as required by the importing country’s customs regulations.

It is also crucial to comply with the customs regulations of the importing country. This may include payment of import duties, taxes, and any other fees imposed by the customs authorities. Importers may need to hire a customs broker or engage in the required customs procedures by themselves.

Furthermore, it is advisable to consult with a customs or trade professional to navigate through the complexities of import regulations and customs procedures to ensure a smooth import process while complying with all relevant requirements.

Sustainability and Environmental Considerations in shrink packaging machine Manufacturing

In recent years, there has been a growing emphasis on sustainability and environmental considerations in the manufacturing industry, including the production of shrink packaging machines. Shrink packaging machines are used to wrap products in a plastic film that shrinks tightly around them when heated. While this method of packaging offers many benefits, such as enhanced product protection and improved shelf life, it also presents certain environmental challenges.

One key environmental concern associated with shrink packaging machines is the use of plastic film. The widespread use of plastic in packaging has led to significant waste generation and environmental pollution. To address this issue, manufacturers are increasingly focusing on developing more sustainable alternatives to traditional plastic films. Biodegradable films made from renewable resources, such as plant-based materials, are being developed as a more eco-friendly option. Additionally, efforts are being made to improve the recycling and reusability of plastic films, reducing their overall environmental impact.

Another area of concern in the manufacturing of shrink packaging machines is energy consumption. These machines require significant amounts of energy to operate, particularly during the heating process that shrinks the plastic film. To minimize energy usage, manufacturers are investing in more energy-efficient technologies, including the use of advanced heating mechanisms and insulation materials. Additionally, incorporating smart sensors and control systems can help optimize energy consumption by adjusting the machine’s settings based on the specific requirements of each product being packaged.

Furthermore, the manufacturing process itself can have a significant impact on sustainability. Implementing sustainable manufacturing practices, such as reducing waste generation and optimizing resource utilization, is crucial. This can involve adopting lean manufacturing principles, using eco-friendly materials and components, and establishing recycling programs for waste generated during the production process.

In conclusion, the manufacturing of shrink packaging machines is increasingly embracing sustainability and environmental considerations. By focusing on the development of alternative and biodegradable films, minimizing energy consumption, and implementing sustainable manufacturing practices, manufacturers are making significant strides towards reducing the environmental impact of these machines. As the industry continues to prioritize sustainability, further innovations are expected to emerge, contributing to a more eco-friendly future for shrink packaging machine manufacturing.

List The Evolution history of “shrink packaging machine”

Shrink packaging machines have come a long way since their inception, evolving from manual processes to highly automated systems that can handle a wide range of products. Let’s explore the evolution history of the shrink packaging machine in under 300 words:

1. Early Manual Methods (19th century): The earliest form of shrink packaging involved manually applying heat to shrink films by using handheld heating devices. This labor-intensive process was slow and had limited applications.

2. Heat Shrink Tunnels (1950s): The introduction of the heat shrink tunnel revolutionized shrink packaging. These tunnels used heated air to shrink films around products as they passed through on a conveyor. The process was faster and more efficient than manual methods, leading to increased popularity.

3. Chamber Shrink Machines (1960s): Chamber shrink machines were developed to provide a controlled environment for shrink packaging. Products were placed inside a chamber, and the heat source was applied to shrink the film. This technology enabled better control over the shrinkage process.

4. L-Bar Sealers (1970s): L-bar sealers were introduced, allowing for the packaging of products with irregular shapes. This innovative machine used a heated sealing bar to cut and seal the shrink film around a product. It was a significant advancement in terms of versatility and efficiency.

5. High-Speed Automatic Systems (1980s-1990s): With the rise of automation, shrink packaging machines became more sophisticated and capable of higher speeds. Automated machines were equipped with sensors, conveyor belts, and precise heat control systems to ensure consistent and efficient packaging.

6. Continuous Motion Machines (2000s): Continuous motion shrink packaging machines were developed to further enhance speed and efficiency. These machines worked by continuously moving the product through the packaging process, minimizing downtime and increasing throughput.

7. Modern Robotics and Advanced Controls (present): Today’s shrink packaging machines combine robotics, advanced controls, and sophisticated software. This integration allows for precise and customizable shrink packaging solutions. Robotic arms can handle various product shapes, and sensors ensure optimal shrink film usage and quality.

In conclusion, the evolution of shrink packaging machines has transformed them from manual devices to highly automated systems with advanced features. From simple tunnels and chamber machines to complex continuous motion systems and robotics, shrink packaging machines continue to improve packaging efficiency, versatility, and reliability.

The Evolution and Market Trends in shrink packaging machine Industry

The shrink packaging machine industry has witnessed significant evolution and market trends over the years. Advancements in technology, changing consumer demands, and increasing automation have influenced the development of these machines.

One major evolution in the industry is the shift towards more advanced and efficient machinery. Manufacturers are incorporating state-of-the-art technology to enhance the performance and productivity of shrink packaging machines. These advancements enable higher processing speeds, greater accuracy, and improved packaging quality. Additionally, the integration of smart control systems and artificial intelligence has resulted in automated and self-adjusting machines, reducing the need for manual intervention and minimizing errors.

Another trend in the shrink packaging machine industry is the focus on sustainability and eco-friendly solutions. With growing environmental concerns, there has been a rising demand for machines that minimize packaging waste. This has led to the development of shrink packaging machines capable of using recyclable and biodegradable materials. Manufacturers are also incorporating energy-efficient features to reduce power consumption and carbon emissions during the packaging process.

Furthermore, customization and flexibility have become crucial factors in the market. Consumers are increasingly seeking personalized packaging solutions, and manufacturers are responding by offering machines that can accommodate different product sizes, shapes, and materials. Shrink packaging machines with adjustable settings and quick changeover capabilities are in high demand as they allow for efficient and cost-effective production.

The market for shrink packaging machines has also witnessed a shift towards the integration of smart technology and connectivity. IoT-enabled machines provide real-time data monitoring, remote control, and predictive maintenance capabilities. This connectivity enables manufacturers to optimize production, minimize downtime, and enhance overall efficiency.

In conclusion, the shrink packaging machine industry has evolved significantly due to technological advancements, changing consumer demands, and a focus on sustainability. Manufacturers are constantly innovating to meet the needs of the market, resulting in more efficient, flexible, and eco-friendly machines. The integration of smart technology and connectivity has further enhanced the capabilities of these machines, allowing for real-time monitoring and predictive maintenance. As the industry continues to grow, it is expected that these trends will shape the future of shrink packaging machines.

Custom Private Labeling and Branding Opportunities with Chinese shrink packaging machine Manufacturers

Chinese shrink packaging machine manufacturers offer custom private labeling and branding opportunities for businesses looking to establish a distinct identity in the market. These manufacturers understand the importance of branding and provide options to customize their machines with private labeling and branding elements.

Through private labeling, businesses can have their logos, company names, and other branding elements prominently displayed on the shrink packaging machines. This allows them to establish their brand presence and create a consistent identity across their packaging operations. By customizing the machines with their branding, businesses can also build brand recognition and loyalty among their customers.

Chinese shrink packaging machine manufacturers also offer branding opportunities by allowing businesses to choose the colors, patterns, and designs for their machines. This enables businesses to align the aesthetics of the machines with their brand image and create a visually appealing packaging solution that stands out in the market.

In addition to private labeling and branding customization options, Chinese shrink packaging machine manufacturers provide assistance and support to businesses throughout the branding process. They work closely with businesses to understand their branding requirements and provide guidance on the most effective customization options.

By collaborating with Chinese manufacturers, businesses can take advantage of their expertise in shrink packaging technology while creating a unique and distinguishable brand identity. This partnership allows businesses to leverage the manufacturing capabilities and cost-effective solutions offered by Chinese manufacturers, who are known for their quality products and competitive pricing.

In conclusion, Chinese shrink packaging machine manufacturers offer custom private labeling and branding opportunities to businesses. By customizing their machines with private labeling and branding elements, businesses can establish their brand presence, create a consistent identity, and differentiate themselves in the market. The support and guidance provided by Chinese manufacturers make this branding process seamless and successful.

Tips for Procurement and Considerations when Purchasing shrink packaging machine

When purchasing a shrink packaging machine, there are several considerations and tips for procurement that can help ensure you make the right choice:

1. Understand your packaging needs: Before purchasing a shrink packaging machine, determine your specific packaging requirements. Consider factors such as the size and shape of your products, the volume of production, and the type of material you will be using for shrink wrapping.

2. Research available options: There are various types of shrink packaging machines available in the market, including semi-automatic and fully automatic machines. Research different brands, models, and features to find the one that best suits your needs and budget.

3. Quality and durability: Look for a machine that is built to last and made with high-quality components. Ensure that the machine is manufactured by a reputable company that offers good warranty and after-sales support.

4. Size and space requirements: Consider the size and space availability in your production area. Measure the dimensions of the machine to ensure it fits comfortably in your workspace without causing any obstructions or safety hazards.

5. Capacity and speed: Evaluate the machine’s capacity and speed to ensure it can handle your production requirements. Consider the number of products you need to package per hour and choose a machine that can meet your desired output.

6. Ease of use and maintenance: Look for a shrink packaging machine that is user-friendly, with clear instructions and an intuitive interface. Additionally, consider the ease of maintenance and availability of spare parts to ensure smooth operation and minimal downtime.

7. Price and budget: Compare prices from different suppliers to get a sense of the market value for the machine. Set a realistic budget and consider the long-term return on investment while making your purchase decision.

8. Safety features: Check for safety features such as emergency stop buttons, safety interlock systems, and proper guarding to protect operators from accidents during operation.

9. Training and support: Ensure that the supplier provides comprehensive training on operating and maintaining the machine. Also, inquire about their after-sales support and availability of technical assistance if needed.

10. Read customer reviews and testimonials: Look for feedback from other customers who have purchased the same machine. This will give you valuable insights into the machine’s performance, reliability, and customer satisfaction.

By considering these tips and factors, you can make an informed procurement decision when purchasing a shrink packaging machine that aligns with your requirements and provides optimal efficiency and productivity for your packaging operations.

FAQs on Sourcing and Manufacturing shrink packaging machine in China

Q: Why should I source and manufacture shrink packaging machines in China?

A: Sourcing and manufacturing shrink packaging machines in China offers several advantages such as lower production costs, a wide variety of suppliers, and access to advanced manufacturing technology. China has a large number of experienced manufacturers who can offer competitive pricing due to lower labor and operational costs compared to other countries.

Q: How can I find reliable suppliers in China for shrink packaging machines?

A: Finding reliable suppliers can be done through various channels like attending trade shows, searching online directories, or working with sourcing agents based in China. It is important to conduct thorough research, perform background checks, and request samples or product specifications to ensure the quality and reliability of the suppliers.

Q: Are there any risks involved with sourcing and manufacturing shrink packaging machines in China?

A: Like any sourcing endeavor, there are some risks involved. Quality control can be a concern, so it is necessary to regularly inspect the manufacturing process and conduct quality checks. Communication and language barriers can also pose challenges, but working with experienced sourcing agents or hiring local translators can mitigate these obstacles.

Q: What certifications should I look for when sourcing shrink packaging machines from China?

A: When sourcing shrink packaging machines from China, it is essential to look for certifications such as ISO 9001, CE, and UL to ensure compliance with international quality and safety standards. These certifications demonstrate that the manufacturer follows proper manufacturing processes and adheres to regulatory requirements.

Q: How can I ensure the shrink packaging machines comply with my specific requirements?

A: It is crucial to clearly communicate your specific requirements and expectations to the supplier or manufacturer. Providing detailed product specifications, discussing customization options, and requesting samples or prototypes can help in achieving the desired outcome. Regular communication with the manufacturer during the production process is also beneficial to address any issues or changes.

In conclusion, sourcing and manufacturing shrink packaging machines in China can offer cost advantages and access to a wide range of suppliers. However, it is important to perform due diligence, seek reliable suppliers, ensure quality control, and communicate effectively to meet specific requirements and mitigate risks.

Why contact sourcifychina.com get free quota from reliable shrink packaging machine suppliers?

Sourcifychina.com offers a free quota from reliable shrink packaging machine suppliers for several reasons. Firstly, sourcing products from reliable suppliers is crucial for businesses to ensure the quality and effectiveness of the purchased machines. By partnering with reputable suppliers, sourcifychina.com strives to provide customers with shrink packaging machines that meet their requirements and expectations.

Secondly, by obtaining a free quota, customers can evaluate the various options available from different suppliers without incurring any financial commitment. This allows them to compare prices, features, and other factors to make an informed decision regarding the suitable shrink packaging machine for their specific needs. Such a service can save businesses time and effort in searching for reliable suppliers independently, as sourcifychina.com has already screened and verified the suppliers they work with.

Additionally, obtaining a free quota from reliable shrink packaging machine suppliers can provide customers with peace of mind, knowing that they are dealing with trustworthy manufacturers or distributors. This helps to reduce the risk of receiving substandard or counterfeit machines, which could potentially lead to production issues or costly repairs.

Furthermore, sourcifychina.com aims to facilitate smooth communication and negotiations between customers and suppliers. By acting as an intermediary, they help both parties overcome language and cultural barriers, ensuring effective communication and a better understanding of each other’s requirements. This service can be particularly valuable for businesses that do not have the resources or expertise to navigate the complexities of international trade.

In summary, sourcifychina.com offers a free quota from reliable shrink packaging machine suppliers to provide customers with access to quality products, allow for comparison and evaluation, reduce risks, and facilitate efficient communication. This service is designed to support businesses in making informed decisions and streamlining their sourcing process for shrink packaging machines.