Knowledge about Shrink Tunnel

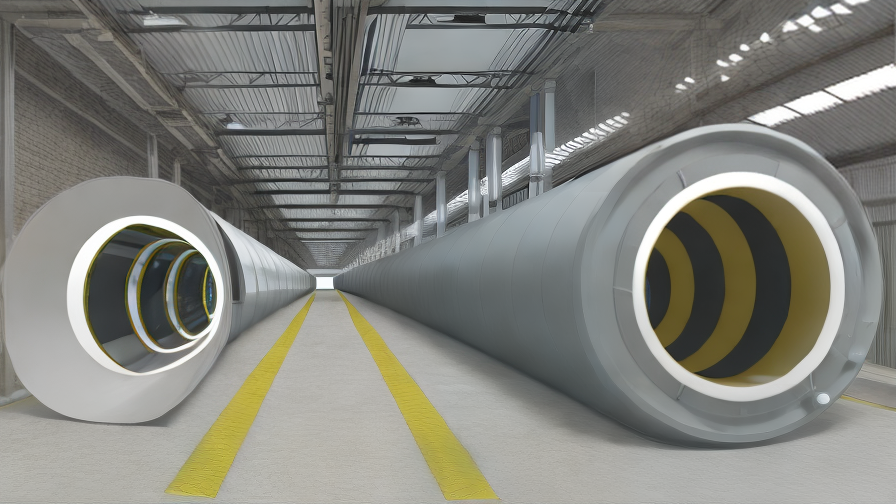

A shrink tunnel is a machine that uses heat to shrink wrap a product. It is a crucial piece of equipment in many industries, including food processing, pharmaceuticals, and consumer goods. A shrink tunnel typically consists of a conveyor belt that carries the product through a heated chamber or tunnel. The heat causes the plastic film wrapped around the product to shrink tightly, creating a tamper-evident seal that protects the product during shipping and storage.

There are several types of shrink tunnels, including infrared, radiant, and convection. Each type uses a different method to heat the product and shrink the film. Infrared shrink tunnels use infrared heaters to heat the film, while radiant shrink tunnels use metal plates to radiate heat onto the product. Convection shrink tunnels use fans to circulate hot air around the product. Each type has its own advantages and disadvantages, and the choice of the right type depends on the specific needs of the business.

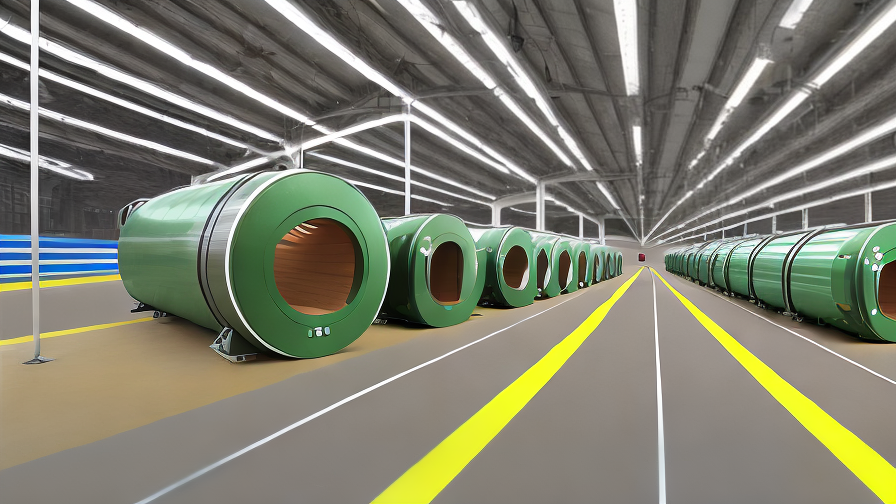

Shrink tunnels come in different sizes and capacities, ranging from small tabletop models to large industrial-sized machines. The size of the shrink tunnel depends on the size of the product being wrapped and the volume of production. Larger shrink tunnels are capable of handling high-volume production and can wrap large items, while smaller models are ideal for small businesses or for wrapping smaller items.

The success of shrink wrapping depends on several factors, including the quality of the film, the temperature in the tunnel, and the speed of the conveyor belt. Improper settings can result in poorly wrapped products or even damage to the product. It is important to properly calibrate the shrink tunnel to ensure a perfect result every time.

In conclusion, knowledge of shrink tunnels is essential for businesses that require tamper-evident packaging. The choice of the right type and size of the shrink tunnel is critical to the success of the production process. Proper calibration of the machine is also crucial to ensure high-quality results. By understanding the benefits and limitations of shrink tunnels, businesses can make informed decisions about the best equipment for

Various Types of Shrink Tunnel

Shrink tunnels are machines that use heat to shrink wrap products for transportation or storage. They come in various types depending on the type of product being wrapped and their individual requirements. Below are a few types of shrink tunnels:

1. Steam Shrink Tunnel: This type of tunnel is used to shrink-wrap products that are sensitive to high temperatures. The tunnel works by using steam to heat-shrink the wrapping material. The steam is generated using a boiler and is channeled through the tunnel to shrink-wrap the product.

2. Infrared Shrink Tunnel: These types of tunnels use infrared radiation to shrink the wrapping material around the product. The radiation heats up the wrapping material, which then shrinks and tightly fits around the product. This type of tunnel is used for products that are sensitive to heat and require gentle handling.

3. Hot Air Shrink Tunnel: Hot air shrink tunnels work by blowing hot air over the wrapping material to shrink it around the product. This type of tunnel is used for products that require high-temperature and high-speed shrinking.

4. Electric Shrink Tunnel: Electric shrink tunnels use electrical heating elements to heat the wrapping material and shrink it around the product. This type of tunnel is commonly used for small to medium-sized products and is ideal for companies with limited space.

5. Hybrid Shrink Tunnel: Hybrid tunnels combine two or more of the above types, depending on the requirements of the product being wrapped. They are designed to provide flexibility and efficiency in the shrink-wrapping process.

In conclusion, shrink tunnels are essential machines used in the packaging industry to ensure products are properly wrapped and protected during transportation and storage. The selection of a shrink tunnel depends on the type of product being wrapped and its individual requirements, such as sensitivity to high temperatures. Therefore, companies need to choose the appropriate tunnel to ensure their products are efficiently and safely shrink-wrapped.

FAQ sourcing Shrink Tunnel manufacturer from China

Sourcing a shrink tunnel manufacturer from China can be overwhelming and time-consuming; thus, we have compiled some frequently asked questions and multiple answers to help you seamlessly find a reliable shrink tunnel supplier.

1. What is a shrink tunnel, and how do you identify the best manufacturer?

A shrink tunnel is a packaging machine that uses heat to shrink packaging materials such as PVC, PE, and POF. To identify the best shrink tunnel manufacturer, it would be best to check their experience, certifications, customer reviews, and quality of their products.

2. What are the benefits of sourcing shrink tunnels from China?

China is home to some of the best shrink tunnel manufacturers, offering high-quality products at an affordable price. Additionally, sourcing from China means access to a variety of options, fast production time, and excellent customer service.

3. How do you ensure quality from a shrink tunnel manufacturer in China?

To ensure quality from a shrink tunnel manufacturer in China, it is vital to conduct due diligence by checking certifications and product specifications. Additionally, verify the quality of materials used and the manufacturing process.

4. How long does it take to receive your shipment from China?

The lead time for shrink tunnel orders from China varies depending on the order quantity and complexity. However, most suppliers provide a lead time estimate between 15-30 days, while shipping time ranges between 20-40 days.

5. What is the average cost of sourcing a shrink tunnel from China?

The cost of sourcing a shrink tunnel from China varies depending on specifications, quantity, and the manufacturer. However, on average, a basic shrink tunnel may cost between $2,500 to $8,000, while high-end machines may cost upwards of $15,000.

In conclusion, sourcing a shrink tunnel manufacturer from China can be a great way to access high-quality products at an affordable price. However, conducting due diligence and verifying quality is essential to ensuring that your investment in the best value for your business.

Applications of Shrink Tunnel

Shrink tunnels are versatile machinery commonly used in the packaging industry. Its primary purpose is to apply heat to polyethylene plastic that surrounds products to shrink and form a tight seal. Shrink tunnels work by passing the plastic packaging through a heated tunnel that shrinks and conforms tightly to the shape of the product.

One of the most significant applications of shrink tunnels is in the production of retail products such as cosmetics, food, and technology. With the use of shrink tunnels, manufacturers can create a high-quality and consistent appearance of packaging, resulting in improved product appearance and brand recognition.

Another notable application of shrink tunnels is in the shipping industry. It is used to heat-shrink the packaging of products to provide added protection during transportation, eliminating the need for additional padding, thus reducing packaging costs.

Additionally, shrink tunnels are also used in the pharmaceutical industry where they can shrink the packaging and maintain a sterile packaging environment. Shrink tunnels can sterilize the packaging materials, ensuring that the product is safe and fresh for consumer use.

Furthermore, shrink tunnels can be used for custom packaging, where it can customize and mold the plastic close to the product, thus securing and protecting it to meet customer demand. Additionally, shrink tunnels are used in logistics centers where they repackage products into smaller sizes for convenient shipping and better storage organization.

In conclusion, shrink tunnels play a vital role in the packaging industry, and their application extends far beyond what has been briefly highlighted. With efficient and consistent packaging, shrink tunnels have been able to optimize the supply chain, reduce costs, and offer proficient tamper-evident packaging, ensuring that products remain safe and meet expectations.

Manufactured Products made of Shrink Tunnel

Shrink tunnels are used to create various manufactured products that require packaging and a professional finish. The tunnel uses heat to shrink the packaging material, which tightly wraps around the product, giving it a secure seal.

One popular product that can be made using a shrink tunnel is the shrink wrap. This particular type of wrap is used to tightly wrap products, creating a tamper-proof seal. Shrink wrap is commonly used when transporting products or for storage as it protects the product from external factors such as moisture and dust.

Shrink tunnels are also used to create shrink sleeves, which are commonly seen on bottles, cans and other packaging. Shrink sleeves are a popular alternative to traditional label methods as it offers a full, 360-degree coverage of the product. This type of packaging is commonly used in the food and beverage industry where strong branding plays a crucial role in sales.

Tamper-evident seals are another product that can be created using a shrink tunnel. These seals are commonly used to secure the contents of the package, for example, medicine bottles, ensuring that they are not tampered with before use.

Aside from packaging products, shrink tunnels can also be used to create unique manufactured products. Shrink tubing is a good example of this. It is widely used in the electronics industry where it can be used to insulate and protect cables and wires.

In conclusion, the use of a shrink tunnel offers a fast and efficient way to create professional-looking products. It is widely used across many industries, including food and beverage, electronics, and manufacturing. With its versatility and ability to handle a wide range of packaging materials, shrink tunnels have become an essential piece of equipment for many businesses.

The Evolution history of Shrink Tunnel

The shrink tunnel is a machine used in packaging that is used to shrink-wrap products using heat technology. The evolution history of shrink tunnels starts from the early 1950s, where the demand for packing and wrapping products significantly increased.

The first shrink tunnel machines were large chamber-style machines that required a lot of space and utilized a great deal of energy. The technology was improved in the 1960s and 1970s, with the introduction of smaller, more efficient designs.

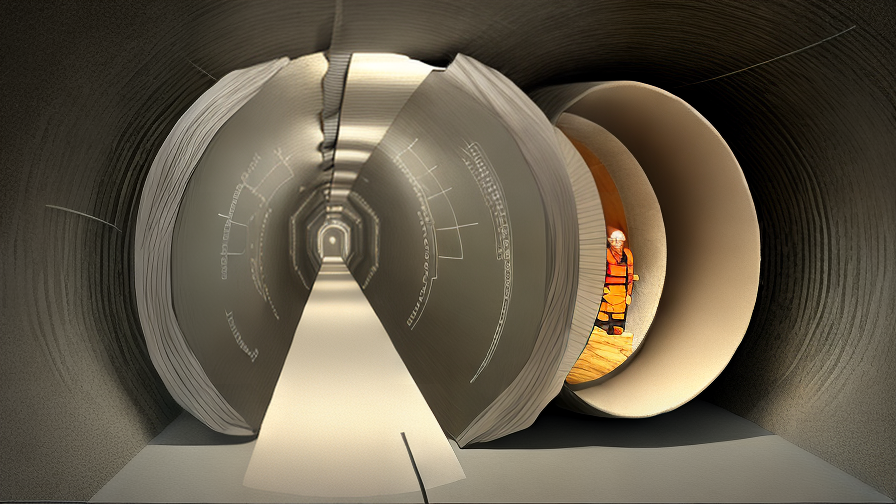

By the 1980s, the push for more advanced packaging solutions led to the introduction of the tunnel-style design. This design allowed for greater precision and control over the packaging process, as well as more flexibility in terms of the types of products that could be wrapped.

In the 1990s, shrink tunnels saw the implementation of digital controls, which allowed for even greater precision and flexibility in the packaging process. This technology is used to ensure that the products are heated to the correct temperature for the correct amount of time, which results in a more consistent and professional-looking end product.

In recent years, shrink tunnels have become even more advanced, with the introduction of automated systems that can handle the entire packaging process from start to finish. These advanced systems use robotic arms and computer-controlled machines to handle everything from product placement to heat sealing and conveyor movement.

In conclusion, the evolution history of shrink tunnels is a testament to the continued innovation and improvement in the packaging industry. As new technologies are developed and implemented, the packaging process becomes more efficient, more precise, and more flexible, resulting in a better end product for manufacturers and consumers alike.

The Process of Shrink Tunnel

A shrink tunnel is a machine used to shrink-wrap products to protect them during storage and shipping. The process of shrink tunnel involves wrapping products in plastic, heating them to a specific temperature, and then shrinking the plastic wrap around the product to create a tight, protective seal.

The first step of the shrink tunnel process is to place the product on a conveyor belt that carries it into the tunnel. Once inside the tunnel, the product is exposed to a heat source that heats the plastic wrap to a specific temperature. The heat source can come from electric heaters, hot air, infrared radiation or steam.

The heated plastic wrap then shrinks around the product due to the thermal energy it absorbs. The shrinking process creates a snug and secure seal that protects the product during shipment from moisture, dust, and other potential hazards.

There are different types of shrink tunnels available in the market, such as tabletop tunnels, medium size automatic tunnels and large enrobing tunnels. Each type of shrink tunnel can be customized to suit specific needs and requirements.

The benefits of using a shrink tunnel are numerous. Apart from providing protection and preventing damage to the shipped products, shrink tunnels are highly efficient and cost-effective. They require minimal labor and packaging material, thus reducing the overall packaging cost.

In conclusion, a shrink tunnel is an important machine used in the packaging industry. The process of shrink tunnel is straightforward and results in a secure and professional-looking package. With different types of shrink tunnels available, manufacturers can choose the best option that meets their specific product packaging needs.

Benefits Advantages of Utilizing Shrink Tunnel

Shrink tunnels are an integral part of modern packaging processes, primarily used to wrap products in plastic films or packaging material. These tunnels provide a consistent and efficient method of shrink wrapping, with many benefits over other packaging options. Utilizing a shrink tunnel for packaging has a variety of advantages that can benefit businesses of all sizes.

One of the primary benefits of using a shrink tunnel is that it can improve the overall aesthetics of a product. Shrink-wrapped products are tightly sealed and protected from dirt, dust, and moisture. This makes the product appear more professional, clean, and attractive to potential customers. Additionally, shrink-wrapping allows manufacturers to print graphics, branding, and other product information onto the film, which further enhances its appearance and visibility.

Shrink tunnels are also highly efficient and time-saving. With a shrink tunnel, a product can be wrapped in a matter of seconds, compared to hours when using traditional packaging methods. Additionally, shrink-wrapping machines are automated, meaning that they require minimal physical effort and can be operated by one or two persons. This ensures that the packaging process is streamlined, and businesses can attend to other essential tasks.

Another essential advantage of using a shrink tunnel is that it reduces the overall packaging and shipping costs. Shrink-wrapped products are more compact, making them easier to store and transport. They take up less space, which translates to lower shipping costs. Additionally, shrink-wrapping material is lightweight, reducing the overall weight of the product and limiting the need for bulky packaging.

Shrink tunnels provide high-quality, tamper-evident packaging. This is paramount for products that are prone to damage or contamination, such as food or medical supplies. Shrink-wrapped products seal in freshness and prevent contamination by displaying if the product has been tampered with.

In conclusion, the utilization of a shrink tunnel is a wise investment for any business that requires high-quality packaging, time-saving, efficiency, and cost reduction. Shrink-wrapping ensures that the

Disadvantages Shrink Tunnel

Shrink tunnels are widely used in the packaging industry for wrapping and sealing products. However, despite their benefits, they also have several disadvantages.

Firstly, shrink tunnels can be quite expensive, which can be a significant disadvantage for small businesses or start-ups. The machinery alone can cost thousands of dollars, and additional costs may include installation, maintenance, and repairs.

Secondly, shrink tunnels can be time-consuming. Depending on the size of the product, it can take up to several minutes for the shrink wrap to fully seal, which can decrease productivity levels significantly.

Moreover, shrink tunnels can be challenging to operate without proper training or experience. A slight variation in temperature or the speed of the conveyor belt can result in inconsistent shrink wrapping, which can lead to product damage, loss, or an unsatisfactory final appearance.

Another disadvantage of shrink tunnels is their energy consumption. The machines require high temperatures and substantial electricity use, which can lead to expensive utility bills.

Additionally, shrink tunnels produce a lot of heat, which can be unsafe for operators and can make the workplace uncomfortable. This heat can also affect the quality of certain products, such as food items, by changing their taste or texture.

Lastly, shrink tunnels contribute to plastic waste. Shrink wrap is not biodegradable and can take hundreds of years to decompose, leading to environmental concerns.

In conclusion, while shrink tunnels offer many benefits, including airtight and tamper-proof packaging, they also have several drawbacks. These limitations include high costs, time-consuming operations, the need for training, energy consumption, workplace safety considerations, and environmental impacts. Consequently, businesses must carefully consider these factors before investing in a shrink tunnel for their packaging needs.

Selecting the Ideal Manufacturer Shrink Tunnel

Selecting the ideal manufacturer shrink tunnel can be a daunting task, especially if you don’t know what to look for. Several factors go into making the right choice when it comes to a shrink tunnel. These include the speed, the size, the type of packaging material, and the overall cost.

To start, speed is a crucial factor when selecting a shrink tunnel. You need to consider the number of packages you intend to shrink per minute, and the time it takes for the tunnel to cool down after running. If you’re running many packages in a single day, then look for a tunnel that can handle a high output. On the other hand, if you’re running a smaller number of packages, then a tunnel with lower output capacity will be ideal.

The size of the tunnel is another significant consideration. You need to think carefully about the size and shape of the product you intend to pack. A tunnel with a larger working space will cater to larger products. Similarly, smaller tunnels will handle smaller packages.

Another factor to consider is the type of packaging material to use. Some manufacturers shrink tunnels are specific to certain packaging materials such as PVC, Polyolefin or Polyethylene. Thus, it is essential to check if the tunnel is compatible with the desired material so that the product is of good quality.

Lastly, is the cost of acquiring the tunnel machine. You need to compare the cost of different manufacturers available in the market. To select the best option for you, you need to check the quality of the machine, consumer reviews and the warranty.

In conclusion, selecting the ideal manufacturer shrink tunnel requires careful consideration of various factors. You need to consider the speed, size, type of packaging material, and the cost. Don’t rush the process but take some time, research, talk to other business owners, and choose the right shrink tunnel for your unique needs.

Things to Consider When Purchasing Shrink Tunnel

A Shrink tunnel is a vital piece of equipment, typically used in packaging industries to wrap and seal products using shrink film. The primary function of the machine is to apply heat to the shrink film, which shrinks and wraps snugly around the product, resulting in a tight and secure wrap.

When purchasing a shrink tunnel, there are a few key things to consider to ensure that you select the right machine for your specific needs. Firstly, it is essential to consider the size of the products you will be wrapping; this will determine the size of the tunnel opening needed. A tunnel that is too small or too big for your products will not provide optimal results, and it can also waste valuable energy.

Secondly, you need to consider the type of materials and the thickness of the shrink film you will be using. It is vital to select a machine that can handle your chosen film, without damaging your product or causing shoddy wrapping. Additionally, the tunnel’s conveyor speed should be adjustable to cater to varying film and product types.

Another crucial aspect is the level of automation needed for your packaging line. If your production requires a high volume of products, an automated conveyor system is essential. Likewise, if you plan to wrap products of varying sizes and shapes, an adjustable tunnel height and width are crucial.

Moreover, you need to consider the heating system for your shrink tunnel. Choose between hot air, infrared, or steam heating depending on the specific products you will be wrapping. Hot air systems are the most powerful and preferred by most companies. Additionally, if you are focusing on sustainability, you can choose tunnel systems that use a low level of energy.

Lastly, you need to consider the manufacturer’s reputation when purchasing a shrink tunnel. Ensure that the machine is of high quality, reliable and easy to maintain. A trusted manufacturer will provide superior equipment, advice, and support, and they will be responsive to your needs.

In conclusion, when purchasing a quality shrink tunnel machine, it is crucial to consider various

Properties of Shrink Tunnel

Shrink tunnel is a packaging machine that is commonly used in several industries such as food processing, pharmaceuticals, and cosmetics. Its main purpose is to wrap products in a tamper-proof and secure package.

One of the properties of shrink tunnels is that they are designed to provide consistent heat to the products passing through the tunnel. The heat generated by the machine causes the plastic film to shrink and conform tightly to the product, creating a tight and secure package.

Another important property of shrink tunnels is their ability to adjust to the various sizes of products passing through the machine. Shrink tunnels can be adjusted to accommodate different sizes of products, ensuring that each product is wrapped perfectly.

Shrink tunnels also have an adjustable conveyor speed, which allows them to handle different volumes of products. The conveyor speed can be controlled to match the production rate of the packaging line.

A good shrink tunnel should also have a precise temperature control system. This ensures that the right amount of heat is applied to the product, avoiding overheating or underheating, which can affect the quality of the packaged product.

Another important property of shrink tunnels is their durability. A well-designed shrink tunnel is constructed with high-quality materials that can withstand the harsh conditions of the packaging environment. These durable machines are designed to provide many years of reliable service.

In summary, shrink tunnels are an essential component of packaging lines in various industries. They provide consistent heat, can adjust to different sizes and volumes of products, have an adjustable conveyor speed and precise temperature control, and are built with durable materials. These properties ensure that products are wrapped securely and tamper-proof, guaranteeing the product’s quality and freshness.

How to use Shrink Tunnel

Shrink tunnels are a common sight in packaging facilities. These machines are used to shrink-wrap products with a material that tightens around the product, providing a neat and secure packaging. A shrink tunnel works by passing heated air over materials that have been wrapped around a product, shrinking the material and creating a tight and secure seal.

Here are some steps on how to use shrink tunnels:

1. Prepare your product for wrapping. Put your product into the wrapping material and tape it securely.

2. Load your shrink tunnel. Once your product is securely wrapped, load it onto the conveyor of the shrink tunnel. Make sure that it is positioned correctly in the center of the tunnel.

3. Adjust the settings. Set the temperature and speed settings to match the characteristics of the wrapping material and the product. Check the manufacturer’s manual for recommended settings.

4. Turn on the machine. Once you have set the temperature and speed, turn on the shrink tunnel. The machine will begin to heat and move the product along the conveyor.

5. Monitor the process. Keep an eye on the shrink tunnel to make sure that everything is running smoothly. Watch for any issues with the wrapping material or the product.

6. Remove the product. Once the product has passed through the shrink tunnel, remove it carefully from the conveyor. Check the wrapping to make sure that it has been properly sealed.

7. Clean the shrink tunnel. To ensure the longevity of your shrink tunnel, it’s important to clean it regularly. Follow the manufacturer’s instructions for cleaning and maintenance.

Shrink tunnels are an essential tool in the packaging industry. By following these steps, you can safely and effectively use a shrink tunnel to package your products.

Glossary Terminology Terms for Shrink Tunnel

A shrink tunnel is a useful piece of equipment in packaging processes. This machine uses heat to shrink and seal plastic packaging around products to reduce the risk of damage during transportation. When using a shrink tunnel, it is important to understand the terminology associated with this kind of equipment. Here are a few essential glossary terminology terms for shrink tunnel:

1. Temperature Controls: Temperature controls refer to the heating elements in a shrink tunnel, and it allows the user to regulate the temperature required for the shrink process. This feature is essential as different films require different temperatures.

2. Conveyor Belt: Conveyor belt is the platform that moves the products through the shrink tunnel. It is essential to ensure that the conveyor belt travels at the appropriate speed and is appropriately adjusted for optimal shrink quality.

3. Heat Zones: Heat zones refer to the insulated walls within the tunnel that helps to maintain the temperature. With multi-zone heat, you can control the temperature consistency throughout the tunnel, which is critical when dealing with sensitive products.

4. Cooling Section: The cooling section is the region in which sealed film is cool air blasted to stabilize the packaging material and fixing the bag’s shape.

5. Shrink Film: Shrink film is used in shrink tunnels to wrap products as it holds tightly to the product and seals around it, holding it securely in place.

6. Air Flow System: An air flow system is a unique feature to shrink tunnels, and it helps to direct the hot air to the area that needs it. This ensures that the heat is used in the most efficient way possible and saves on energy.

Understanding the above terms is critical for the successful use of shrink tunnels. It helps in maximizing its potential and helps the user to get the best use out of it.

Shrink Tunnel Price

Shrink tunnels are an essential packaging solution for companies that require wrapping products such as food, cosmetics, or any consumer good. The shrink tunnel price varies by the machine’s features, size, and additional components. A basic, small-sized model could cost around $3,000, whereas a larger one with additional cooling fans and rollers could cost upwards of $8,000.

Several factors impact the starting price of a shrink tunnel. First, the size of the tunnel can affect the price. The bigger the tunnel, the higher the price tag, as larger models require more extensive manufacturing and longer lead times. Moreover, the additional features and components that come with the shrink tunnel increase the price of the machine. Features such as a n adjustable conveyor speed, additional temperature controllers or fans, and automatic unloading systems, can impact the price from $5,000 – $8,000.

Shrink tunnels are significant investments for businesses, and some may be hesitant to spend more on a machine. However, it’s also important to consider a shrink tunnel’s longevity and performance. A higher-priced machine may offer better heating and cooling control, higher durability, and fewer maintenance requirements. A cheap shrink tunnel may have a shorter lifespan and may require more frequent repairs or replacement, ultimately increasing costs over time.

It is best to consult with manufacturing experts for choosing the right shrink tunnel for your business. With so many options available, choosing the right equipment can be challenging. A reliable manufacturer that specializes in shrink tunnels and other packing equipment can provide guidance and help you make informed decisions.

In conclusion, the shrink tunnel price can vary considerably based on the machine’s size, features, and additional components. It is important to consider both upfront and long-term costs when selecting a shrink tunnel and ensure that it aligns with your business objectives. Working with a trusted manufacturer can help ensure you pick the right machine for your business.