Types and Applications of sintered slabs

Sintering is a process of compacting and forming a solid mass of material through the application of heat and pressure without melting the material. This results in a sintered slab, which is a dense, durable, and highly uniform material with excellent mechanical and thermal properties.

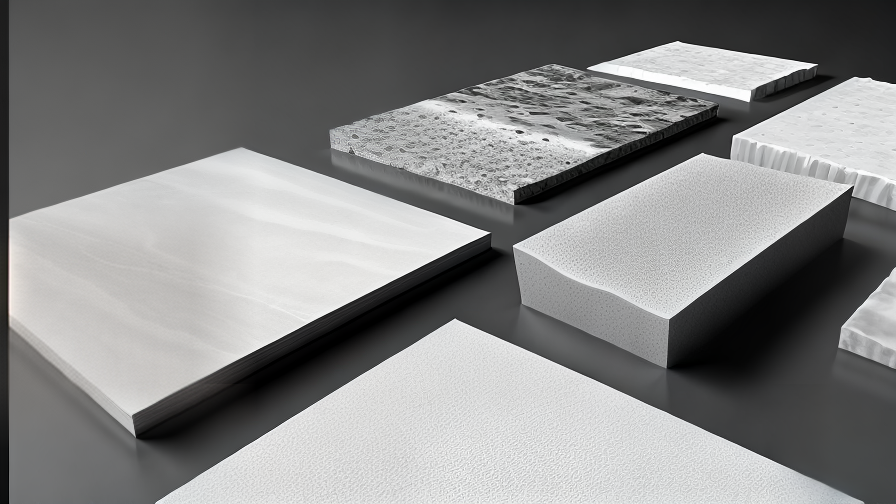

One of the most common applications of sintered slabs is in the construction industry, where they are used as a cost-effective and eco-friendly alternative to traditional building materials such as concrete, stone, and brick. Sintered slabs can be made from a wide range of materials, including ceramic, metal, and composites, and can be designed to mimic the color, texture, and appearance of natural stone.

Another application of sintered slabs is in the manufacturing of high-performance cutting tools for the automotive, aerospace, and medical industries. Sintered carbides, for example, are widely used in machining applications due to their excellent hardness, wear resistance, and toughness. Additionally, sintered ceramics are used in the production of high-precision bearings, valves, and seals due to their high temperature resistance, low-friction properties, and chemical stability.

Sintered slabs are also used in the production of advanced electronic components such as substrates, capacitors, and filters. Sintered ceramics, in particular, are highly insulating and can withstand high voltages, making them ideal for use in applications such as power distribution systems, electronic circuits, and sensors.

In conclusion, sintered slabs offer a wide range of applications across many industries due to their excellent mechanical and thermal properties. Whether it’s for construction, manufacturing, or electronics, sintered slabs are an attractive option for those looking for a high-performance, cost-effective, and eco-friendly material.

Benefits and Feature of Utilizing sintered slabs

Sintered slabs are high-quality, durable, and versatile materials that offer numerous benefits for different applications. Here are some of the features and benefits of utilizing sintered slabs.

1. High strength and durability – Sintered slabs are made by compressing and heating raw materials such as natural minerals, clay, and silica at high temperatures. The result is a material that is highly resistant to scratches, stains, UV rays, and extreme temperatures. They are also non-porous and low-maintenance, making them perfect for outdoor and indoor applications.

2. Design flexibility – Sintered slabs come in a wide range of colors, patterns, finishes, and textures. This versatility allows designers to create unique and custom designs that look natural, elegant and can fit different styles. They can easily blend with different materials like wood, metal, and concrete to create unique and visually striking spaces.

3. Environmental sustainability – Most sintered slabs are made from natural raw materials, and they have a lower environmental impact compared to other similar materials like quartz and granite. They are also recyclable, further reducing their carbon footprint.

4. Large format sizes – Sintered slabs are available in sizes up to 10ft x 5ft, and they can be installed without grout lines. This makes them ideal for creating seamless and uniform surfaces, which adds to the design’s aesthetic appeal.

5. Versatility – Sintered slabs can be used for a wide range of indoor and outdoor applications such as kitchen countertops, bathroom vanity tops, flooring, and exterior cladding. Because of their durable and non-porous nature, they can withstand the rigors of daily use and the harsh outdoor elements.

In summary, utilizing sintered slabs provides designers and homeowners with a high-quality and sustainable material that is not only visually appealing but durable, versatile, and easy to maintain.

The Process of sintered slabs

Sintered slabs are a type of ceramic material produced through a process called sintering. Sintering involves heating the raw materials, usually a type of clay or kaolin, to a high temperature until they fuse together, forming a dense, strong material.

The process of producing sintered slabs begins with the selection and mixing of raw materials. These raw materials are then ground and mixed with water to form a slurry. The slurry is then poured into a mold to form a block, which is then dried to remove any excess moisture.

The dried block is then placed in a furnace and heated to a temperature of around 1200-1400°C. This process causes the particles in the block to fuse together, forming a dense material. The furnace is then cooled slowly to prevent any cracking or warping of the sintered slab.

Once the sintering process is complete, the slab is inspected for any defects or imperfections. It is then cut into the desired size and shape using diamond blades. The edges are then smoothed and polished to create a uniform finish.

Sintered slabs are known for their excellent durability, strength, and resistance to heat, chemicals, and scratches. They are widely used in applications such as flooring, countertops, walls, and facades in both residential and commercial buildings.

Overall, the process of producing sintered slabs involves selecting, mixing, molding, drying, sintering, inspecting, cutting, and polishing to create a strong, durable, and versatile material.

How to use sintered slabs

Sintered slabs are a type of engineered stone surface made by compacting and fusing together various types of stone, such as quartz, feldspar, and porcelain, at extremely high temperatures. They are becoming increasingly popular in both residential and commercial applications due to their durability, versatility, and wide range of design options.

Here are some ways sintered slabs can be used:

1. Countertops: Sintered slabs are perfect for kitchen or bathroom countertops, as they are non-porous, heat-resistant, and scratch-resistant. They are also available in a variety of colors and patterns, so you can choose a design that complements your decor.

2. Wall cladding: Sintered slabs can be used as a durable and easy-to-maintain option for bathroom or kitchen wall cladding. The slabs can be cut to size and applied to any surface, including curved or uneven walls.

3. Flooring: Sintered slabs are an excellent option for both indoor and outdoor flooring. They are slip-resistant, scratch-resistant, and can be used for a wide range of applications, from pool surrounds to high-traffic commercial areas.

4. Furniture: Sintered slabs can be used to make furniture such as tables, benches, and shelving. The resulting products are both stylish and durable, and can withstand heavy use.

5. Facades: Sintered slabs can be fabricated into panels that can be used as building facades or cladding. They are resistant to weathering and UV exposure, making them an ideal option for buildings in harsh climates.

In conclusion, sintered slabs are an excellent option for a wide range of applications due to their durability, versatility, and aesthetic appeal. Their non-porous, heat-resistant, and scratch-resistant properties make them ideal for use in high-traffic areas and environments where hygiene is a top priority. They are also available in a variety of colors and patterns, making them suitable for any design aesthetic.

sintered slabs Manufacturer,Supplier and Wholesale

We are a reputable sintered slabs manufacturer, supplier, and wholesale company committed to delivering high-quality sintered slabs to our clients. Our company has years of experience in the manufacturing industry, and we take pride in our ability to manufacture top-grade sintered slabs that meet the needs of various industries.

Our sintered slabs are made of carefully selected raw materials- natural minerals, and compacted using hydraulic presses and fired at an extremely high temperature under controlled conditions to fuse the particles together. This process makes our sintered slabs dense, resistant to water, and boosts their mechanical strength.

Our production line is equipped with state-of-the-art technology and machines that we regularly service and maintain for optimal performance and production of high-quality slabs. We also have a team of expert engineers and quality control specialists who continually supervise each stage of production to ensure that our sintered slabs meet the rigorous standards in the industry.

We offer a wide range of sintered slabs, including countertops, flooring, stairs, wall cladding, and exterior cladding, among others, available in various colors, sizes, and finishes.

Our services extend to wholesale and supply of sintered slabs, and we pride ourselves on the timely delivery of our products to our clients. We have a robust supply chain system that ensures that our sintered slabs reach our clients’ locations timely and with the utmost care.

In conclusion, we are a reliable sintered slab manufacturer, supplier, and wholesale company committed to providing the best quality products and services to our clients. Contact us today to learn more about our products and services.

sintered slabs Price

Sintered slabs are a popular material used in various architectural and design applications due to their durability, strength, and unique aesthetic appeal. These slabs are made from natural materials such as clays, feldspar and quartz, which are compressed and sintered at high temperatures, resulting in a highly compressed and dense material that is resistant to wear and tear, stains, and scratches.

The price of sintered slabs can vary widely depending on the quality, size, and thickness of the slabs, as well as the supplier and location. Generally, larger slabs tend to be more expensive as they require more labor and machinery during extraction, cutting, and transportation. Moreover, the quality of the sintered slab depends on the manufacturing process, and it is essential to ensure that one purchases from a reliable and reputable supplier to avoid sub-standard materials.

On average, the price of sintered slabs ranges from $50 to $200 per square foot. However, some high-end suppliers can charge as much as $400 per square foot for more luxurious and custom-made designs. It is advisable to compare prices from different suppliers and factor in any additional costs such as installation, transportation, and maintenance.

Finally, sintered slabs are a worthy investment due to their long-lasting and sustainable properties. They provide a unique aesthetic appeal to any space and can be used for various applications, including countertops, flooring, walls, and outdoor surfaces. Despite their higher price point, sintered slabs provide value for money due to their durability and low maintenance costs, making them a popular choice for those seeking quality and style in their design elements.

FAQ sourcing sintered slabs manufacturer from China with multiple answers

1. What is a sintered slab?

A sintered slab is a type of ceramic material that is manufactured by compacting and heating various raw materials at extremely high temperatures until they fuse together, forming a solid, dense material.

2. What are the advantages of using sintered slabs?

Sintered slabs are highly resistant to wear, abrasion, and impact, making them ideal for use in high-traffic areas. They are also highly durable and can withstand extreme temperatures and harsh weather conditions. Additionally, sintered slabs require minimal maintenance and are easily cleaned, making them a cost-effective and practical choice.

3. What materials are used to manufacture sintered slabs?

Sintered slabs are made from a variety of natural materials, including clay, feldspar, kaolin, and quartz. These raw materials are carefully selected and processed to ensure the highest quality finished product.

4. Why should I source sintered slabs from a manufacturer in China?

China is home to some of the world’s leading manufacturers of sintered slabs, with a wealth of experience and expertise in producing high-quality, durable products for a global market. Chinese manufacturers can offer competitive prices without compromising on quality, making them a popular choice among buyers worldwide.

5. How can I find a reliable sintered slab manufacturer in China?

There are a number of ways to source a reliable sintered slab manufacturer in China, including online research, trade shows, and referrals from industry contacts. It is important to do your due diligence and thoroughly research any potential suppliers before making a purchase, to ensure that they meet your quality and pricing requirements.

6. What certifications should I look for when sourcing sintered slabs from a Chinese manufacturer?

When sourcing sintered slabs from a Chinese manufacturer, it is important to look for certifications such as ISO 9001, which demonstrates that the manufacturer has implemented a quality management system. Other certifications to look for may include ISO 14001 (environmental management), OHSAS 18001 (occupational health and safety management), and CE marking (indicating compliance with European Union health, safety, and environmental standards).