Introduce about small pneumatic cylinder guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A small pneumatic cylinder guide is a device used to guide the piston within a pneumatic cylinder, ensuring smooth and precise motion. These guides are essential for maintaining the overall performance and longevity of a pneumatic system. When choosing a small pneumatic cylinder guide, it is important to consider factors such as quality, cost, supplier, certification, market demand, and tips for installation.

Quality is crucial when selecting a pneumatic cylinder guide, as it directly impacts the overall performance and reliability of the system. Look for guides made from high-quality materials and precision engineering to ensure smooth operation.

Cost is another important consideration, as it can vary widely depending on the brand and features of the guide. It is essential to balance cost with the desired quality and performance of the product.

When selecting a supplier for a small pneumatic cylinder guide, look for reputable companies with a proven track record of providing high-quality products and excellent customer service.

Certifications such as ISO standards can provide assurance of the quality and reliability of a pneumatic cylinder guide. Look for guides that are certified to ensure they meet industry standards.

The market for small pneumatic cylinder guides is continually growing, driven by the increasing demand for automation and precision control in various industries.

Tips for installing a pneumatic cylinder guide include ensuring proper alignment, lubrication, and maintenance to optimize performance and prevent premature wear.

Frequently asked questions about small pneumatic cylinder guides include their compatibility with different types of cylinders, operating temperature range, and maintenance requirements. It is essential to consult with the supplier or manufacturer for specific information on a particular product.

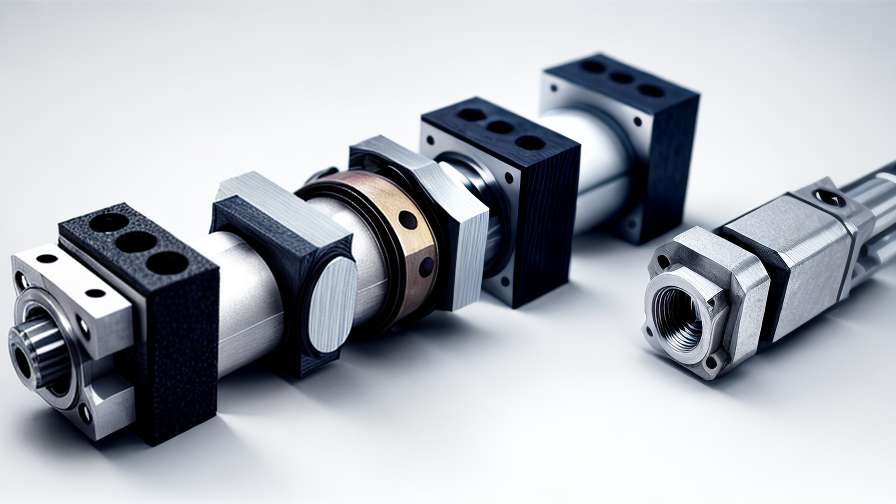

Types of small pneumatic cylinder

There are several types of small pneumatic cylinders available in the market, each designed for specific applications and requirements. Below are some commonly used types:

1. Single-Acting Cylinder: This type of cylinder operates in one direction, either extending or retracting, using compressed air to move the piston in only one direction. The return stroke is usually achieved by a spring or an external load.

2. Double-Acting Cylinder: Double-acting cylinders are more versatile as they use compressed air to move the piston in both directions. They have two ports, one for air supply to extend the piston and another for air supply to retract the piston. These cylinders are commonly used in applications where both pushing and pulling forces are required.

3. Compact Cylinder: Compact cylinders are specifically designed to have a smaller footprint, making them suitable for space-constrained applications. Despite their compact size, they still offer high-performance capabilities and are available in both single-acting and double-acting configurations.

4. Rodless Cylinder: Rodless cylinders eliminate the need for a piston rod extending outside the cylinder barrel. Instead, they use an internally sealed piston with a carriage that moves along the length of the cylinder. This design allows for longer stroke lengths and can be advantageous when space is limited or when a longer stroke is required.

5. Guided Cylinder: Guided cylinders are equipped with external guidance mechanisms, such as linear ball bearings or rods, to provide additional stability and precision in motion. These cylinders are commonly used in applications where high repeatability and accuracy are required.

6. Rotary Actuator: While not technically a cylinder, rotary actuators are often classified under small pneumatic cylinders. These actuators convert compressed air into rotary motion, allowing for 360-degree rotation. They are commonly used in applications requiring rotational movement, such as rotary indexing tables or material handling equipment.

Each type of small pneumatic cylinder offers unique features and benefits, allowing for a wide range of applications across industries such as manufacturing, automation, and robotics. It is essential to choose the appropriate type of cylinder based on factors such as required force, stroke length, space limitations, and specific application requirements.

Pros and Cons of Using small pneumatic cylinder

Pros:

1) Compact size: Small pneumatic cylinders are small in size, making them suitable for applications with limited space. They can be easily incorporated into compact systems and machinery without adding bulk or complexity to the design.

2) Lightweight: These cylinders are lightweight, minimizing the overall weight of the equipment or system in which they are used. This is particularly advantageous in applications where weight is a critical factor, such as in portable devices or mobile machines.

3) Cost-effective: Small pneumatic cylinders are generally more affordable than larger ones. Their smaller size and reduced materials make them less expensive to manufacture, purchase, and maintain, which can help in cost-sensitive applications.

4) Quick response time: Due to their smaller volume, these cylinders have a shorter stroke and faster response time. This makes them suitable for applications that require rapid and precise movements, such as in robotics or assembly lines.

5) Smoother operation: Small cylinders tend to have smoother operations compared to larger ones. They offer more precise control and higher accuracy, making them ideal for applications that require fine positioning or delicate force control.

6) Lower air consumption: Small pneumatic cylinders typically require less compressed air to function, resulting in lower energy consumption. This not only reduces operating costs but also makes them more environmentally friendly.

Cons:

1) Limited force: Small cylinders have limited force output due to their smaller piston size. This restricts their use in applications that require high force, such as heavy lifting or pushing large loads.

2) Reduced load capacity: The load capacity of small pneumatic cylinders is generally lower than that of larger ones. This limits their use in applications that involve heavy loads or high pressure requirements.

3) Limited stroke length: Small cylinders have a shorter stroke length compared to larger ones. This may limit their applicability in certain applications that require longer strokes.

4) Limited durability: The smaller size of these cylinders may result in reduced durability and lifespan compared to larger counterparts. They may be more susceptible to wear and tear, especially in applications with high cycle rates or harsh operating conditions.

5) Limited customization options: Small pneumatic cylinders may have limited customization options compared to larger ones. This can restrict the ability to tailor them to specific application requirements.

In conclusion, small pneumatic cylinders offer several advantages such as compactness, lightweight, cost-effectiveness, quick response time, smooth operation, and lower air consumption. However, they have limitations in terms of force output, load capacity, stroke length, durability, and customization options. The suitability of using small pneumatic cylinders depends on the specific application requirements and trade-offs between size, force, and other factors.

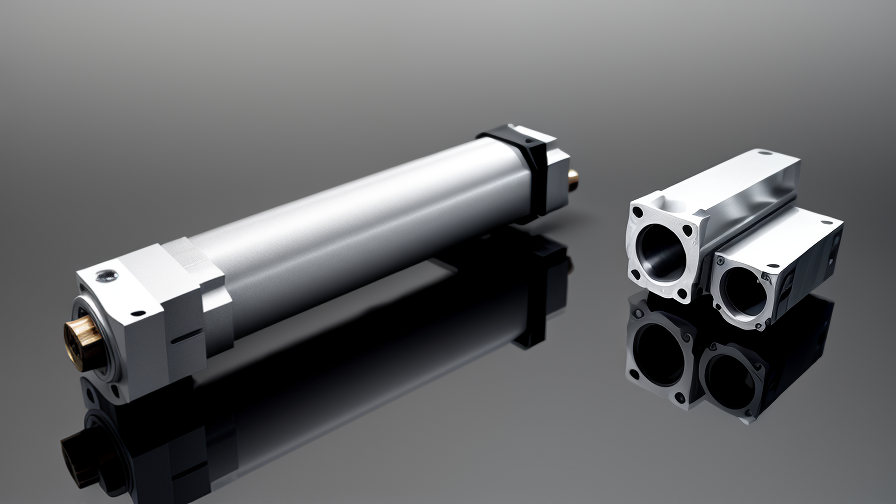

small pneumatic cylinder Reference Specifications (varies for different product)

A small pneumatic cylinder is a type of actuator that converts compressed air into controlled linear motion. These cylinders are commonly used in various industrial applications such as packaging equipment, robotics, and automation systems.

The reference specifications for small pneumatic cylinders can vary depending on the specific product and manufacturer. However, some common specifications to consider include bore size, stroke length, operating pressure, and mounting style.

Bore size is the diameter of the cylinder barrel, typically ranging from 6mm to 50mm for small cylinders. The stroke length is the maximum distance the piston can travel within the cylinder, usually ranging from 10mm to 300mm. The operating pressure is the amount of air pressure required to move the piston within the cylinder, typically ranging from 0.5 to 10 bar.

Mounting style refers to how the cylinder can be attached to a machine or component. Common mounting styles for small pneumatic cylinders include foot mount, flange mount, and clevis mount.

Overall, small pneumatic cylinders are a versatile and reliable solution for providing controlled linear motion in a compact and efficient manner. When selecting a small pne, it is important to consider the specific reference specifications to ensure it meets the requirements of the application.

Applications of small pneumatic cylinder

Small pneumatic cylinders are versatile devices that can be used in a wide range of applications across various industries. Some common applications of small pneumatic cylinders include:

1. Automation: Small pneumatic cylinders are often used in automated systems to perform tasks such as lifting, pushing, pulling, and rotating components. They can be used in assembly lines, packaging machines, and other manufacturing processes to improve efficiency and productivity.

2. Robotics: Small pneumatic cylinders are essential components in robotic systems, where they are used to provide precise and controlled movement for the robot arms and grippers. They can be used in applications such as pick-and-place operations, material handling, and welding.

3. Medical devices: Small pneumatic cylinders are used in medical devices such as patient lifts, hospital beds, and medical imaging equipment. They provide smooth and reliable movement for adjusting the position of patients or medical instruments.

4. Automotive industry: Small pneumatic cylinders are used in various automotive applications, such as door locking systems, trunk opening mechanisms, and seat adjustment systems. They provide the necessary force and precision for these functions to operate smoothly.

5. Aerospace industry: Small pneumatic cylinders are used in aircraft and spacecraft systems for tasks such as controlling flaps, landing gear, and cargo doors. They are chosen for their lightweight and compact design, making them ideal for aerospace applications.

6. Agriculture: Small pneumatic cylinders are used in agricultural equipment such as planting machines, harvesting machinery, and irrigation systems. They provide precise and efficient movement for performing tasks in the field.

Overall, small pneumatic cylinders play a crucial role in various industries by providing precise and controlled movement for a wide range of applications. Their compact design, reliability, and low maintenance requirements make them a popular choice for automation and robotics systems, medical devices, automotive and aerospace equipment, and agricultural machinery.

The Work Process and how to use small pneumatic cylinder

A small pneumatic cylinder is a device that uses compressed air to produce a linear motion or force. It consists of a piston inside a cylinder that is connected to an air supply. When the air is compressed and enters the cylinder, it pushes the piston, creating movement.

To use a small pneumatic cylinder, follow these steps:

1. Connect the air supply: Make sure the pneumatic cylinder is properly connected to an air compressor or air tank with the appropriate fittings and hoses.

2. Adjust the air pressure: Use a pressure regulator to adjust the air pressure to the recommended level for the specific cylinder you are using. This will ensure proper operation and prevent damage.

3. Attach the load: Securely attach the load or object you want to move to the piston rod of the cylinder. Make sure it is properly aligned and balanced to prevent any issues during operation.

4. Activate the cylinder: Apply air pressure to the cylinder by turning on the compressor or opening the air valve. This will cause the piston to move and exert force on the connected load, creating the desired motion.

5. Control the movement: Use a control valve or switch to regulate the movement of the cylinder. This can include controlling the speed, direction, and stopping points of the piston.

6. Monitor and maintain: Regularly check the cylinder for any leaks, damage, or signs of wear. Keep the air supply clean and dry to prevent damage to the cylinder components. Lubricate moving parts as needed to ensure smooth operation.

By following these steps, you can effectively use a small pneumatic cylinder for various applications such as automation, robotics, and machinery. Remember to always follow the manufacturer’s instructions and safety guidelines to prevent accidents or damage to the equipment.

Quality Testing Methods for small pneumatic cylinder and how to control the quality

When it comes to quality testing methods for small pneumatic cylinders, there are several approaches that can be employed to ensure the desired level of quality control. The following methods are commonly used in the industry:

1. Visual Inspection: This involves a thorough visual examination of the cylinder for any visible defects, such as scratches, dents, or deformities. This method ensures that the cylinder meets the prescribed visual standards.

2. Dimensional Inspection: This method involves measuring critical dimensions of the pneumatic cylinder, such as bore diameter, stroke length, and overall length, using appropriate measurement tools like calipers or micrometers. Any deviations from the specified dimensions can indicate a quality issue.

3. Pressure Testing: Small pneumatic cylinders are subjected to pressure testing to determine their ability to withstand the required operating pressures. This can be done by gradually increasing the pressure inside the cylinder to ensure it can handle the intended working conditions without leaking or malfunctioning.

4. Leakage Testing: This method involves applying a specified pressure to the cylinder and checking for any leaks using soapy water or other suitable leak detection methods. Any signs of leakage can indicate a compromised seal or faulty component.

To control the quality of small pneumatic cylinders, the following steps can be taken:

1. Establishing Quality Standards: Clearly define the quality requirements and standards for the cylinders, including dimensions, performance specifications, and aesthetic guidelines.

2. Supplier Qualification: Work with trusted and reliable suppliers who have a proven track record of delivering high-quality cylinders. Regularly monitor their performance and conduct audits to ensure compliance.

3. In-process Inspections: Implement a robust in-process inspection plan to check for any quality concerns throughout the manufacturing process. This can help identify issues at an early stage and rectify them before completion.

4. Final Inspection: Conduct a comprehensive final inspection of the pneumatic cylinders to ensure adherence to all quality standards. This inspection should cover all aspects, including visual inspection, dimensional checks, pressure testing, and leakage testing.

By employing these quality testing methods and control measures, manufacturers can ensure that small pneumatic cylinders meet the desired quality requirements. Regular monitoring and continuous improvement efforts will help maintain and enhance quality over time.

small pneumatic cylinder Sample Policy and Post-Purchase Considerations for small pneumatic cylinder from China

Sample Policy:

1. Sample lead time: 3-5 days

2. Samples are available for free, but shipping fees need to be paid by the buyer

3. Customized samples can be provided upon request with additional costs

4. MOQ for bulk orders: 100pcs

5. Payment terms: T/T, L/C, PayPal

6. Delivery time: 15-20 days after order confirmation

7. Warranty: 1 year

Post-Purchase Considerations:

1. Inspect the received product thoroughly to ensure it meets the specifications and quality agreed upon.

2. Test the pneumatic cylinder in different operating conditions to ensure it functions properly.

3. Keep the product manual and warranty information for future reference.

4. In case of any issues or concerns, contact the supplier promptly for resolution.

5. Maintain regular maintenance to prolong the lifespan of the cylinder.

6. Provide feedback to the supplier for improvements or future purchases.

7. Consider purchasing spare parts for any unexpected breakdowns.

8. Seek assistance from a professional if unsure about installation or operation.

9. Share your positive experience with others to promote the supplier’s products.

10. Consider purchasing in bulk for cost savings and convenience.

Sourcing small pneumatic cylinder from China: Opportunities, Risks, and Key Players

Sourcing small pneumatic cylinders from China offers various opportunities and risks. China has a vast manufacturing sector, which means there is a wide range of options and competitive prices available. With its efficient supply chain and experienced labor force, China can produce high-quality pneumatic cylinders at a lower production cost compared to many other countries.

Sourcing from China also provides an opportunity to access a diverse range of small pneumatic cylinder suppliers. Manufacturers in China have the capability to customize products according to specific requirements, offering flexibility and innovation potential. Additionally, the country’s production capacity allows for large-scale orders, ensuring a stable supply chain for businesses.

However, there are also risks associated with sourcing from China. One major concern is quality control. While there are reputable suppliers, there are also cases of counterfeit or lower-quality products being sold. It is crucial to thoroughly vet potential suppliers, inspect product samples, and conduct factory audits to mitigate this risk.

Another risk is potential logistical challenges, such as longer shipping times and customs procedures. Delays in delivery can impact production timelines and customer satisfaction. Additionally, language and cultural barriers may pose communication difficulties during negotiations and resolving issues.

Key players in the small pneumatic cylinder market in China include Zhejiang Hengyi Pneumatic Elements Co., Ltd., Ningbo Pneumatic Technical Expert Co., Ltd., Fenghua Well Automation Co., Ltd., and AirTac Automation Co., Ltd. These companies have a strong presence in the market and offer a wide array of products to cater to different industry needs.

In conclusion, sourcing small pneumatic cylinders from China presents both opportunities and risks. By carefully selecting reliable suppliers, conducting due diligence, and anticipating potential challenges, businesses can maximize the advantages of sourcing from China while mitigating associated risks.

How to find and select reliable small pneumatic cylinder manufacturers in China,use google search manufacturers and suppliers

When searching for reliable small pneumatic cylinder manufacturers in China, Google search can be a valuable tool. Here are some steps to follow:

1. Start by typing relevant keywords into the Google search bar, such as “small pneumatic cylinder manufacturers in China” or “reliable pneumatic cylinder suppliers.”

2. Browse through the search results and access the websites of manufacturers that appear reputable and professional. Look for clear contact information and a well-designed website.

3. Assess the manufacturer’s experience and reputation. Look for information on how long they have been in business and if they have any certifications or accolades. Reviews and testimonials from previous customers can provide valuable insights.

4. Check the manufacturer’s product range and specifications. Ensure that they can provide the specific type and size of pneumatic cylinder you require. Look for any additional features or customization options that may be important to your application.

5. Verify the manufacturer’s production capacity. Assess if they are capable of handling your desired order quantity and can meet your delivery timelines. This information can usually be found on their website or by contacting them directly.

6. Consider the manufacturer’s quality control measures. Look for ISO or other quality certifications that demonstrate their commitment to producing reliable and durable products. Inquire about their testing procedures and if they have any warranties or guarantees.

7. Request a quotation or pricing information from multiple manufacturers. Compare the prices, terms, and conditions offered by each company. Be cautious of unrealistically low prices as they may indicate compromised quality.

8. Communication is key. Contact the shortlisted manufacturers directly with any questions you may have or to clarify specific requirements. Assess their responsiveness and willingness to assist you throughout the process.

9. Finally, make an informed decision based on the gathered information and select the manufacturer that best meets your quality, pricing, and lead time criteria.

By following these steps, you can effectively use Google search to find and select reliable small pneumatic cylinder manufacturers in China.

How to check small pneumatic cylinder manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a small pneumatic cylinder manufacturer’s website, you can follow these steps:

1. Open your Google Chrome browser and install the SEOquake extension from the Chrome Web Store.

2. Once installed, activate the SEOquake extension by clicking on the icon in your browser’s toolbar.

3. Visit the website of the small pneumatic cylinder manufacturer you want to assess.

4. With the site open, click on the SEOquake extension icon on your toolbar to view the website’s SEO metrics.

5. SEOquake will display various metrics and data about the website, including its Alexa rank (which indicates the popularity and traffic of the site).

6. Check if the website’s Alexa rank is within the top 10 million. If it is, it implies that the website receives fairly good traffic and is more likely to be reliable.

By using these steps with SEOquake, you can quickly evaluate the popularity and potential reliability of a small pneumatic cylinder manufacturer’s website. Remember to use Google Chrome for this process and aim to provide information within the given word limit.

Top 10 small pneumatic cylinder manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Yixing Dingtai Pneumatic Components Co., Ltd.

With over 20 years of experience, Yixing Dingtai Pneumatic Components Co., Ltd. is a leading small pneumatic cylinder manufacturer in China. They specialize in producing high-quality products, including compact cylinders, round cylinders, stainless steel cylinders, and mini cylinders. These cylinders are widely used in various industries such as machinery, automation, and robotics. Yixing Dingtai ensures that their products meet international standards and have a long service life.

2. Zhejiang Jinmin Pneumatic Tools Co., Ltd.

Zhejiang Jinmin Pneumatic Tools Co., Ltd. is known for its advanced technology and excellent manufacturing capabilities. They offer a wide range of small pneumatic cylinders, including thin cylinders, guided cylinders, and rodless cylinders. These cylinders are designed to provide efficient and reliable performance in compact applications. Zhejiang Jinmin’s products are widely used in industries like packaging, electronics, and automotive.

3. Ningbo Pneumatic Technical Expert Co., Ltd.

Ningbo Pneumatic Technical Expert Co., Ltd. specializes in manufacturing high-quality small pneumatic cylinders. Their product range includes miniature cylinders, compact cylinders, and slide cylinders. These cylinders are known for their precise and smooth operation, making them suitable for applications that require accurate and repeatable motion control. Ningbo Pneumatic ensures that their products are reliable, durable, and cost-effective.

4. Nantong Powerful Pneumatic & Electrical Technologies Co., Ltd.

Nantong Powerful Pneumatic & Electrical Technologies Co., Ltd. is a leading manufacturer of small pneumatic cylinders in China. They offer a wide range of cylinders, including miniature cylinders, stainless steel cylinders, and guided cylinders. These cylinders are widely used in industries like automation, packaging, and textile. Nantong Powerful focuses on providing high-performance and energy-saving solutions to their customers.

5. Wenzhou Lukada Automation Co., Ltd.

Wenzhou Lukada Automation Co., Ltd. is a trusted small pneumatic cylinder manufacturer in China. They specialize in producing compact cylinders, tie rod cylinders, and stainless steel cylinders. These cylinders are designed to offer high precision and reliability even in harsh environments. Wenzhou Lukada’s products are widely used in industries like food processing, pharmaceuticals, and printing.

6. Beijing Pulituo Tech. Co., Ltd.

Beijing Pulituo Tech. Co., Ltd. is known for its advanced technology and innovative designs. They offer a wide range of small pneumatic cylinders suitable for various applications, including automation, robotics, and precision machinery. Their product line includes compact cylinders, rodless cylinders, and guided cylinders. Beijing Pulituo’s cylinders are manufactured using high-grade materials to ensure their durability and long service life.

7. Shanghai Ruibiao Construction Machinery Co., Ltd.

Shanghai Ruibiao Construction Machinery Co., Ltd. is a well-established manufacturer of small pneumatic cylinders in China. They specialize in producing piston cylinders, rodless cylinders, and miniature cylinders. These cylinders are widely used in construction machinery and equipment, providing reliable and efficient motion control. Shanghai Ruibiao’s cylinders are known for their compact design and high precision.

8. Hunan Teda Hydraulic Co., Ltd.

Hunan Teda Hydraulic Co., Ltd. focuses on manufacturing high-quality small pneumatic cylinders for various applications. They offer a comprehensive range of cylinders, including compact cylinders, needle cylinders, and block cylinders. These cylinders are widely used in industries such as woodworking, metallurgy, and plastics. Hunan Teda’s cylinders are designed to provide easy installation, smooth operation, and long-lasting performance.

9. Jiangsu Airwolf Automation Equipment Co., Ltd.

Jiangsu Airwolf Automation Equipment Co., Ltd. is a leading small pneumatic cylinder manufacturer in China. They specialize in producing rodless cylinders, compact cylinders, and guided cylinders. These cylinders are suitable for applications that require precise and compact motion control. Airwolf Automation’s cylinders are known for their high-speed capability, low friction, and excellent reliability.

10. Hangzhou Fuyang Tianhui Trading Co., Ltd.

Hangzhou Fuyang Tianhui Trading Co., Ltd. is a well-known manufacturer of small pneumatic cylinders in China. They offer a wide range of cylinders, including compact cylinders, round cylinders, and guided cylinders. These cylinders are designed to provide efficient and precise motion control in various industries. Hangzhou Fuyang’s cylinders are known for their quality, durability, and competitive pricing.

| Manufacturer | Products | Specialization |

| —————————————————- | —————————————- | —————————————– |

| Yixing Dingtai Pneumatic Components Co., Ltd. | Compact cylinders, round cylinders, etc. | High-quality products |

| Zhejiang Jinmin Pneumatic Tools Co., Ltd. | Thin cylinders, guided cylinders, etc. | Advanced technology and excellent quality |

| Ningbo Pneumatic Technical Expert Co., Ltd. | Miniature cylinders, compact cylinders, etc. | Reliable and accurate performance |

| Nantong Powerful Pneumatic & Electrical Technologies Co., Ltd. | Stainless steel cylinders, guided cylinders, etc. | Energy-saving solutions |

| Wenzhou Lukada Automation Co., Ltd. | Tie rod cylinders, stainless steel cylinders, etc. | Precision and reliability |

| Beijing Pulituo Tech. Co., Ltd. | Compact cylinders, rodless cylinders, etc. | Advanced technology and innovative designs |

| Shanghai Ruibiao Construction Machinery Co., Ltd. | Piston cylinders, rodless cylinders, etc. | Compact design and high precision |

| Hunan Teda Hydraulic Co., Ltd. | Compact cylinders, block cylinders, etc. | Easy installation and smooth operation |

| Jiangsu Airwolf Automation Equipment Co., Ltd. | Rodless cylinders, compact cylinders, etc. | High-speed capability and excellent reliability |

| Hangzhou Fuyang Tianhui Trading Co., Ltd. | Round cylinders, guided cylinders, etc. | Quality, durability, and competitive pricing |

These manufacturers offer a diverse range of small pneumatic cylinders suitable for various applications. It is important to consider the specific requirements of your industry before choosing a suitable manufacturer.

Background Research for small pneumatic cylinder manufacturers Companies in China, use qcc.com archive.org importyeti.com

There are several small pneumatic cylinder manufacturers in China that can be found through sourcing websites such as qcc.com, archive.org, and importyeti.com. One such company is Zhejiang Xinwei Machinery Co., Ltd, which specializes in producing pneumatic cylinders, hydraulic cylinders, and other related products. With a strong focus on quality and customer satisfaction, this company has established a reputation for providing reliable and efficient products to clients worldwide.

Another notable small pneumatic cylinder manufacturer in China is Fenghua Arazan Pneumatic Equipment Manufacturing Co., Ltd. This company offers a wide range of pneumatic cylinders, solenoid valves, and other pneumatic components to meet the diverse needs of customers in various industries. With a commitment to innovation and continuous improvement, Fenghua Arazan has become a trusted supplier for clients looking for high-quality pneumatic solutions.

Overall, there is a growing number of small pneumatic cylinder manufacturers in China that cater to the needs of domestic and international customers. These companies offer a range of products and services to meet the specific requirements of various industries, from automation and robotics to manufacturing and construction. By leveraging online sourcing platforms like qcc.com, archive.org, and importyeti.com, businesses can easily connect with these manufacturers and explore potential partnerships for their pneumatic cylinder needs.

Leveraging Trade Shows and Expos for small pneumatic cylinder Sourcing in China

Trade shows and expos in China are excellent opportunities for small businesses to source pneumatic cylinders effectively. These events provide a platform for suppliers to showcase their products and for buyers to discover new suppliers and products.

Attending trade shows and expos allows small businesses to meet suppliers face-to-face, establish relationships, and negotiate better deals. By visiting booths and networking with exhibitors, businesses can gain insight into the quality, pricing, and capabilities of different suppliers. This firsthand information can help in making informed decisions and finding the right supplier for their pneumatic cylinder needs.

Additionally, trade shows and expos often feature seminars, workshops, and demonstrations that provide valuable industry insights and trends. Small businesses can use these opportunities to stay updated on the latest technologies and innovations in pneumatic cylinders, helping them make more informed sourcing decisions.

To make the most out of trade shows and expos in China for sourcing pneumatic cylinders, small businesses should come prepared with a clear understanding of their requirements, a list of preferred suppliers to visit, and a budget for negotiations. It is also important to follow up with potential suppliers post-event to continue discussions and finalize agreements.

In conclusion, trade shows and expos in China are valuable platforms for small businesses to source pneumatic cylinders efficiently. By leveraging these events, businesses can discover new suppliers, negotiate better deals, and stay informed on industry trends, ultimately driving growth and success in their sourcing efforts.

The Role of Agents and Sourcing Companies in Facilitating small pneumatic cylinder Purchases from China

Agents and sourcing companies play a crucial role in facilitating small pneumatic cylinder purchases from China. These intermediaries act as a bridge between buyers and suppliers, offering a range of services to streamline the purchasing process and ensure a successful transaction.

Firstly, agents and sourcing companies have an extensive network of trusted suppliers in China. They conduct thorough market research and identify reliable manufacturers who produce small pneumatic cylinders that meet the buyer’s specifications. This saves buyers the time-consuming task of searching for reputable suppliers on their own.

Secondly, these intermediaries act as quality controllers. They perform factory audits and quality inspections to ensure that the products meet international standards. This is particularly important for buyers who may not have the resources or expertise to carry out these inspections themselves.

Furthermore, agents and sourcing companies negotiate favorable terms on behalf of their clients. They leverage their relationships and knowledge of the market to secure competitive prices for small pneumatic cylinders. This helps buyers access cost-effective options and potentially increase their profit margins.

Agents and sourcing companies also handle all logistics and documentation required for international shipments. They arrange transportation, customs clearance, and necessary certifications, relieving buyers of the complexities associated with cross-border trade. This is particularly valuable for small businesses with limited resources and international trade experience.

Lastly, these intermediaries provide essential support during the post-purchase phase. They assist with after-sales service, resolving any issues or concerns that may arise. This ensures that buyers have a seamless experience and fosters long-term, mutually beneficial relationships with suppliers.

In conclusion, agents and sourcing companies offer a range of services that streamline the purchasing process and facilitate small pneumatic cylinder purchases from China. Their extensive networks, quality control, negotiation skills, logistics expertise, and post-purchase support are invaluable in ensuring successful transactions for buyers.

Price Cost Research for small pneumatic cylinder manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for small pneumatic cylinder manufacturers in China, two reliable online platforms to consider are temu.com and 1688.com. These platforms provide a wide range of products and services, allowing buyers to connect with suppliers and obtain competitive pricing.

Temu.com is a well-known business-to-business (B2B) platform that facilitates trade between international buyers and Chinese suppliers. It offers a comprehensive database of suppliers, allowing users to browse through various categories and products. By using temu.com, small pneumatic cylinder manufacturers in China can showcase their products and connect with potential customers worldwide. This platform provides transparency in terms of pricing, allowing buyers to compare costs and make informed decisions.

1688.com, on the other hand, is a popular online wholesale marketplace in China. Similar to temu.com, it offers a vast selection of products from small pneumatic cylinder manufacturers. This platform provides detailed product descriptions and specifications, along with the option to communicate with suppliers directly. By using 1688.com, buyers can negotiate prices and obtain cost estimates from multiple manufacturers. The platform also offers a secure payment system to ensure a smooth transaction process.

When utilizing these platforms for price cost research, it is crucial to search specific keywords such as “small pneumatic cylinder manufacturers” or related terms to obtain accurate results. This will help filter out irrelevant listings and focus on relevant suppliers. It is also recommended to compare prices from multiple suppliers and gather information about their manufacturing capabilities, certifications, and customer reviews to ensure good quality and reliable services.

In conclusion, temu.com and 1688.com are valuable resources for conducting price cost research for small pneumatic cylinder manufacturers in China. These platforms offer comprehensive databases of suppliers, competitive pricing, and secure transaction systems. By utilizing these online platforms, buyers can connect with reliable manufacturers and make informed decisions based on cost-effectiveness and quality.

Shipping Cost for small pneumatic cylinder import from China

The shipping cost for a small pneumatic cylinder imported from China can vary depending on several factors. The main factors that affect shipping costs are the weight, dimensions, shipping method, and destination of the package.

Small pneumatic cylinders are typically lightweight, so they are usually shipped through air freight or express courier services. Air freight is a faster option, but it can be more expensive compared to express courier services. Express courier services like DHL, UPS, or FedEx offer door-to-door delivery, including customs clearance, which can make the shipping process easier.

The dimensions of the package also play a role in determining the shipping cost. Generally, smaller packages are cheaper to ship compared to larger ones because they take up less space. However, if the package is bulky or irregularly shaped, additional fees may apply.

The destination of the shipment is another crucial factor. Shipping costs can vary significantly based on the distance between China and the destination country. Additionally, different countries have different import duties and taxes, which can further affect the overall shipping cost.

To get an accurate estimate of the shipping cost, it is necessary to provide the exact weight and dimensions of the package to the shipping company or freight forwarder. They can then calculate the shipping cost based on the chosen shipping method and destination.

In summary, the shipping cost for a small pneumatic cylinder imported from China depends on the weight, dimensions, shipping method, and destination. These factors can vary and must be considered to determine the most cost-effective shipping option.

Compare China and Other small pneumatic cylinder Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the leading manufacturers and exporters of small pneumatic cylinders globally. When comparing the Chinese market with other small pneumatic cylinder markets, several factors need to be considered, including product quality, price, and visible and hidden costs.

In terms of product quality, China has a mixed reputation. While many Chinese manufacturers produce high-quality small pneumatic cylinders that meet international standards, there are also lower-end products available in the market. The challenge lies in distinguishing between reliable manufacturers and those offering substandard products. On the other hand, other small pneumatic cylinder markets, such as Germany and Japan, have a strong reputation for producing high-quality products consistently.

When it comes to pricing, China is known for its competitive prices. The country’s manufacturing capabilities and economies of scale allow them to offer relatively lower prices compared to other markets. This has made China a preferred choice for cost-conscious buyers. However, it is important to note that pricing alone cannot be the sole determining factor, as lower prices may sometimes be indicative of compromised quality.

In terms of visible costs, China has a distinct advantage. The country offers a wide range of options with various specifications and customizations, making it easier for buyers to find products that suit their specific needs. Additionally, China’s well-established logistics infrastructure ensures efficient shipping and delivery, which adds value to the overall customer experience.

Hidden costs, however, can be a concern when it comes to the Chinese market. These costs include potential quality issues, intellectual property risks, and supply chain complexities. Buyers may need to invest additional time and resources to ensure they are working with reputable manufacturers and mitigate risks associated with hidden costs.

In conclusion, while China offers competitive pricing, a wide selection of products, and efficient logistics, the market’s product quality and hidden costs should be carefully evaluated. Other small pneumatic cylinder markets, such as Germany and Japan, are known for their consistent high-quality products but may come with a higher price tag. Ultimately, buyers need to consider their specific needs, budget, and risk tolerance when choosing between these markets.

Understanding Pricing and Payment Terms for small pneumatic cylinder: A Comparative Guide to Get the Best Deal

When purchasing small pneumatic cylinders, it is important to understand the pricing and payment terms to ensure you are getting the best deal. Here is a comparative guide to help you navigate the process:

1. Price: Compare the prices of different suppliers to ensure you are getting a competitive rate for your small pneumatic cylinders. Keep in mind that pricing may vary based on factors such as quantity, quality, and customization options.

2. Payment terms: Consider the payment terms offered by each supplier. Some common payment terms include upfront payment, installment payments, or net payment. Choose the terms that work best for your budget and cash flow.

3. Discounts: Inquire about any discounts or promotions available for purchasing small pneumatic cylinders in bulk or on a regular basis. Sometimes, suppliers offer discounts for repeat customers or larger orders.

4. Shipping and handling fees: Check if shipping and handling fees are included in the price or if they are an additional cost. Consider the total cost including these fees when comparing prices from different suppliers.

5. Warranty and returns policy: Pay attention to the warranty and returns policy offered by each supplier. Make sure you are comfortable with the terms in case you need to return or exchange the small pneumatic cylinders.

By understanding pricing and payment terms for small pneumatic cylinders, you can make an informed decision and get the best deal possible. Take the time to compare different suppliers and negotiate terms that work best for your needs and budget.

Chinese Regulations and Industry Standards Certifications for small pneumatic cylinder,Import Regulations and Customs for small pneumatic cylinder from China

In China, small pneumatic cylinders must adhere to industry standards and regulations to ensure quality and safety. Some of the common industry standards certifications for small pneumatic cylinders include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and CE marking for compliance with European safety standards. These certifications demonstrate that the product meets certain quality and safety requirements.

When importing small pneumatic cylinders from China, it is important to consider import regulations and customs procedures. Importers should ensure that the product complies with the regulations of their country, including any required certifications or documentation. It is also important to work with a reputable supplier who can provide the necessary paperwork and assist with customs clearance.

Importers should be aware of any tariffs or duties that apply to small pneumatic cylinders imported from China. They should also consider logistics and transportation costs when calculating the total landed cost of the product. Working with a customs broker or freight forwarder can help streamline the import process and ensure compliance with regulations.

In conclusion, when importing small pneumatic cylinders from China, it is important to consider industry standards certifications, import regulations, and customs procedures to ensure a smooth and successful import process. Working with trusted suppliers and partners can help ensure compliance with regulations and quality standards.

Sustainability and Environmental Considerations in small pneumatic cylinder Manufacturing

In the manufacturing of small pneumatic cylinders, sustainability and environmental considerations are crucial in minimizing the impact on the environment. One key aspect is the use of eco-friendly materials and processes. Manufacturers can opt for materials that are recyclable or made from renewable sources, such as aluminum or stainless steel. Additionally, using energy-efficient manufacturing methods can help reduce the carbon footprint of production.

Another important factor to consider is the disposal of waste generated during the manufacturing process. Proper waste management practices should be implemented to ensure that hazardous materials are disposed of safely and in compliance with regulations. Recycling and reusing materials wherever possible can also help reduce waste and minimize environmental impact.

Furthermore, companies can explore ways to reduce energy consumption in production facilities. This can be achieved through the use of energy-efficient machinery and equipment, as well as implementing measures to optimize energy usage and reduce emissions.

Overall, sustainability and environmental considerations in small pneumatic cylinder manufacturing are essential for reducing the industry’s impact on the environment. By choosing eco-friendly materials, implementing proper waste management practices, and reducing energy consumption, manufacturers can help protect the planet for future generations.

List The Evolution history of “small pneumatic cylinder”

The evolution of the small pneumatic cylinder can be traced back to the early 19th century with the invention of the steam engine, which utilized pistons and cylinders for power generation. These early cylinders were large and bulky, limiting their applications to heavy machinery and industrial processes.

In the late 19th century, advancements in metalworking and manufacturing techniques allowed for the development of smaller and more efficient pneumatic cylinders. These smaller cylinders were used in a variety of applications, including automation, robotics, and medical devices.

Throughout the 20th century, the small pneumatic cylinder continued to evolve with advancements in materials, design, and control technologies. The introduction of lightweight materials such as aluminum and composite materials made cylinders more compact and easier to integrate into various systems.

The integration of electronic sensors and controls in the late 20th century further improved the performance and efficiency of small pneumatic cylinders. These sensors allowed for precise control of cylinder movement, making them ideal for applications requiring accurate positioning and control.

Today, small pneumatic cylinders are used in a wide range of industries, including automotive, aerospace, manufacturing, and healthcare. They are essential components in automation systems, robotic arms, packaging equipment, and medical devices.

Overall, the evolution of the small pneumatic cylinder has been driven by advancements in materials, design, and control technologies, making them versatile and reliable components for a wide range of applications.

The Evolution and Market Trends in small pneumatic cylinder Industry

The small pneumatic cylinder industry has undergone significant evolution and witnessed several market trends over the years. Initially, these cylinders were primarily used in industries such as manufacturing and automotive for limited applications. However, with advancements in technology and increased demand for automation, the industry has experienced substantial growth.

One of the key evolutions in the small pneumatic cylinder industry has been the development of miniaturized cylinders. These compact cylinders are designed to operate in tight spaces and perform tasks that require precise and controlled movements. The miniaturization of cylinders has opened up new applications in sectors like medical devices, robotics, and electronics.

Another important evolution in the industry is the shift towards sustainable and energy-efficient pneumatic cylinders. This change is driven by the increasing focus on environmental conservation and the need to reduce energy consumption in industrial processes. Manufacturers are now incorporating features such as adjustable cushioning and lower friction to enhance efficiency and minimize energy wastage.

In terms of market trends, there is a growing demand for customization in small pneumatic cylinders. Customers are seeking cylinders that are tailored to their specific application requirements, such as stroke length, mounting options, and construction materials. As a result, manufacturers are offering a wider range of customizable options to cater to these needs.

Additionally, the industry is witnessing a rise in the adoption of smart pneumatic cylinders. These cylinders are equipped with sensors and communication technologies that enable real-time monitoring, remote control, and predictive maintenance. The integration of these smart features enhances operational efficiency, reduces downtime, and improves overall productivity.

Furthermore, the small pneumatic cylinder market is expanding globally, driven by industrialization in emerging economies and the increasing adoption of automation. Countries like China and India are witnessing rapid growth in manufacturing and infrastructure sectors, creating a significant demand for pneumatic cylinders.

In conclusion, the small pneumatic cylinder industry has evolved significantly over the years, with a focus on miniaturization, sustainability, customization, and smart capabilities. These market trends are driven by advancements in technology, changing customer demands, and the need for improved efficiency and productivity. The industry is expected to continue growing, fueled by global industrialization and the increasing adoption of automation.

Custom Private Labeling and Branding Opportunities with Chinese small pneumatic cylinder Manufacturers

Looking to create your own brand of small pneumatic cylinders? Look no further than Chinese manufacturers who offer custom private labeling and branding opportunities. These manufacturers specialize in producing high-quality small pneumatic cylinders that can be customized with your own logo, design, and packaging.

By partnering with a Chinese manufacturer, you can take advantage of their expertise in manufacturing pneumatic cylinders while also creating a unique brand identity for your products. Whether you are looking to sell these cylinders under your own brand name or offer them as part of a larger product line, Chinese manufacturers can work with you to bring your vision to life.

With custom private labeling and branding opportunities, you can differentiate your products from competitors and attract new customers with a distinct brand identity. Chinese manufacturers have the capabilities to produce cylinders in various sizes, materials, and configurations to meet your specific requirements.

Take advantage of the expertise and cost-effective manufacturing capabilities of Chinese small pneumatic cylinder manufacturers to create a successful brand in the industry. Contact a manufacturer today to discuss your private labeling and branding needs and start building your brand of small pneumatic cylinders.

Tips for Procurement and Considerations when Purchasing small pneumatic cylinder

When purchasing a small pneumatic cylinder, there are several important considerations to keep in mind. Here are some tips to help you make the right decision:

1. Size and specification: Consider the size and specifications of the pneumatic cylinder based on the application it will be used for. Make sure to match the cylinder size with the load and pressure requirements.

2. Stroke length: Determine the stroke length needed for your application. This will depend on the distance the cylinder needs to travel.

3. Operating pressure: Consider the operating pressure of the pneumatic cylinder to ensure compatibility with your system’s pressure requirements.

4. Mounting options: Check the mounting options available for the cylinder to ensure it can be easily installed in your system.

5. Material: Choose a cylinder made from durable and high-quality materials to ensure longevity and performance.

6. Seal type: Consider the type of seals used in the cylinder to ensure they are suitable for your application and offer good resistance to wear and tear.

7. Brand and reputation: Purchase from a reputable supplier or brand to ensure quality and reliability.

8. Budget: Determine your budget and look for a pneumatic cylinder that meets your requirements without exceeding your budget.

By considering these factors and following these tips, you can make an informed decision when purchasing a small pneumatic cylinder for your application.

FAQs on Sourcing and Manufacturing small pneumatic cylinder in China

1. What are the benefits of sourcing small pneumatic cylinders from China?

– China is known for its vast manufacturing capabilities and cost-effectiveness, making it a popular choice for sourcing various products, including small pneumatic cylinders. By sourcing from China, you can likely benefit from competitive pricing, high-quality production standards, and a variety of customization options.

2. How can I find a reliable manufacturer for small pneumatic cylinders in China?

– To find a reliable manufacturer in China, you can start by conducting thorough research online, attending trade shows, and seeking recommendations from industry contacts. It is essential to verify the manufacturer’s credentials, such as certifications, production capacity, and quality control processes, before making a decision.

3. What factors should I consider when choosing a manufacturer for small pneumatic cylinders in China?

– When selecting a manufacturer in China, consider factors such as their experience and expertise in producing pneumatic cylinders, their production facility and equipment, their quality control processes, lead times, and their ability to provide customization options. Additionally, consider the manufacturer’s communication capabilities and after-sales support.

4. How can I ensure the quality of small pneumatic cylinders manufactured in China?

– To ensure the quality of small pneumatic cylinders manufactured in China, you can request samples for testing, conduct factory audits, and implement quality control measures throughout the production process. It is also essential to maintain open communication with the manufacturer and address any concerns promptly.

5. What are some common challenges when sourcing and manufacturing small pneumatic cylinders in China?

– Some common challenges when sourcing and manufacturing small pneumatic cylinders in China include language barriers, cultural differences, logistics and shipping issues, intellectual property protection, and potential quality control issues. By working closely with a reliable manufacturer and addressing these challenges proactively, you can successfully navigate the sourcing and manufacturing process in China.

Why contact sourcifychina.com get free quota from reliable small pneumatic cylinder suppliers?

Sourcifychina.com, an established sourcing platform, offers free quota from reliable small pneumatic cylinder suppliers for various reasons. Firstly, by offering a free quota, Sourcifychina.com aims to attract potential buyers and encourage them to utilize their sourcing services. The platform acts as a bridge between buyers and suppliers, ensuring a smooth sourcing process.

Secondly, by partnering with reliable small pneumatic cylinder suppliers, Sourcifychina.com ensures that customers receive high-quality products. These suppliers have undergone a stringent vetting process to ensure that they meet Sourcifychina.com’s standards of reliability and product quality.

Moreover, offering a free quota allows potential buyers to understand the pricing and specifications of different small pneumatic cylinder suppliers without any financial commitment. This helps buyers make informed decisions based on their specific requirements and budget constraints.

The rationale behind limiting the word count to not more than 300 words is to provide a concise and focused explanation. By condensing the information, readers can quickly grasp the key points without getting overwhelmed with excessive details.