Knowledge about Spiral Wrapping Band Manufacturer

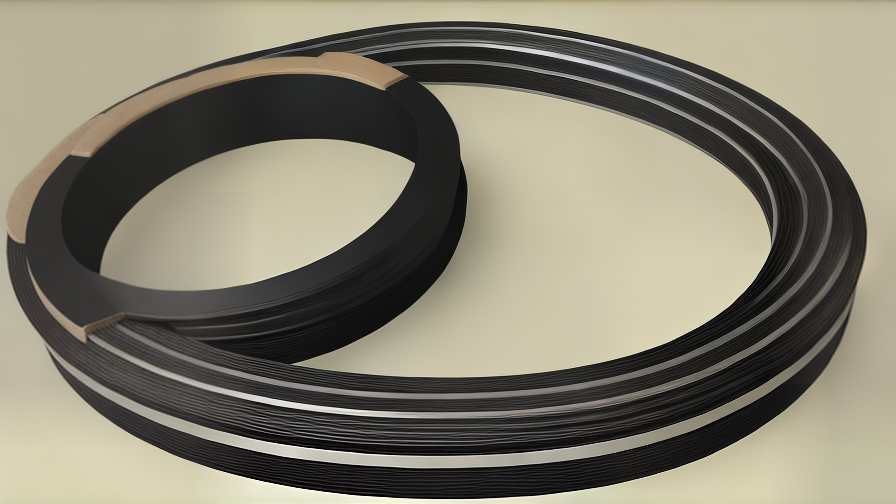

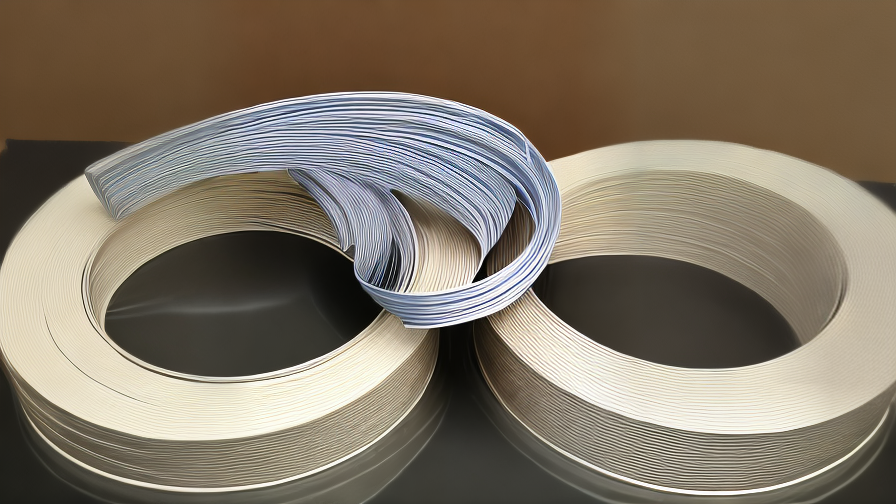

Spiral wrapping bands are an essential component in wire management systems. These bands help to organize and protect wires, tubing, and cables from abrasion, damage, and entanglement. Hence, choosing the right spiral wrapping band manufacturer is crucial to ensure maximum protection and organization of wires.

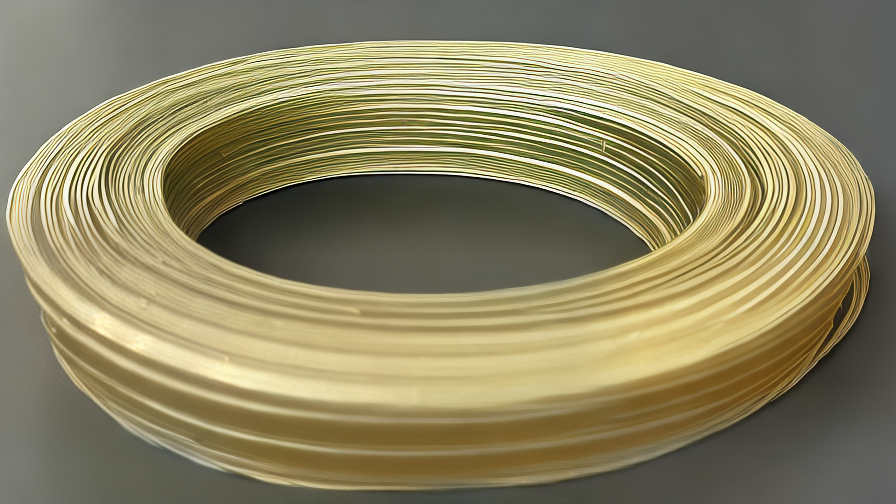

One essential factor to consider when choosing a spiral wrapping band manufacturer is the quality of their products. The manufacturer should use high-quality materials such as polyethylene, polypropylene, or nylon in making their bands. Quality materials ensure that the bands are durable, resistant to wear and tear, and have excellent electrical insulation properties.

Another factor to consider is the manufacturer’s experience in the industry. A manufacturer with vast experience in the production of spiral wrapping bands is more likely to have extensive knowledge and expertise in the manufacturing process, product development, and customer satisfaction. Additionally, a manufacturer with a broad customer base and positive reviews is an indication of their product quality and reliability.

A manufacturer’s production capabilities and capacity are also important considerations. The manufacturer should have state-of-the-art equipment and production methods that guarantee consistent quality and high output. They should also have a flexible production capacity that can cater to small and large clients’ requirements.

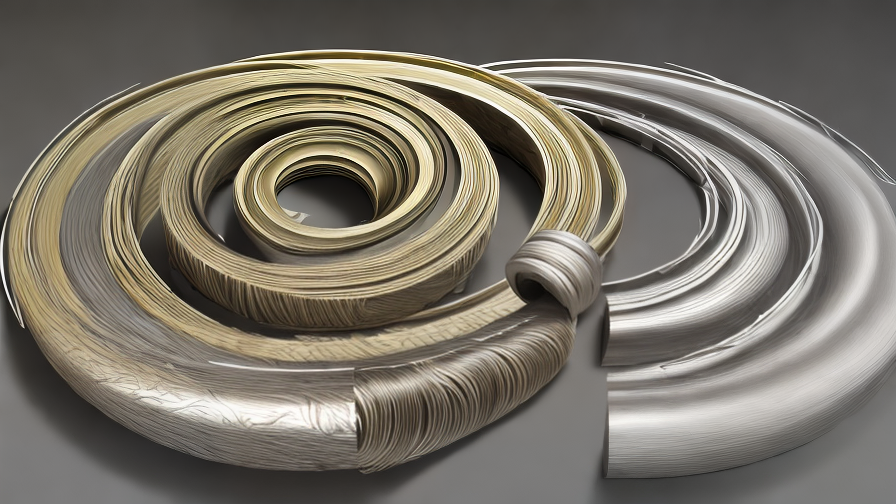

The availability of customization options is another important factor when choosing a spiral wrapping band manufacturer. The manufacturer should offer a range of colors, sizes, and materials to cater to different clients’ needs. They should also be able to produce customized bands to suit specific application requirements.

In conclusion, choosing the right spiral wrapping band manufacturer is essential to ensure that the wires are protected and well-organized. A manufacturer with a reputation for producing high-quality products, vast industry experience, excellent production capabilities, and customization options is the ideal choice.

Various Types of Spiral Wrapping Band Manufacturer

There are various types of spiral wrapping band manufacturers in the market. Spiral wrapping bands are an essential tool for cable and wire management, and they are widely used in many industries, including telecommunications, automotive, and aerospace.

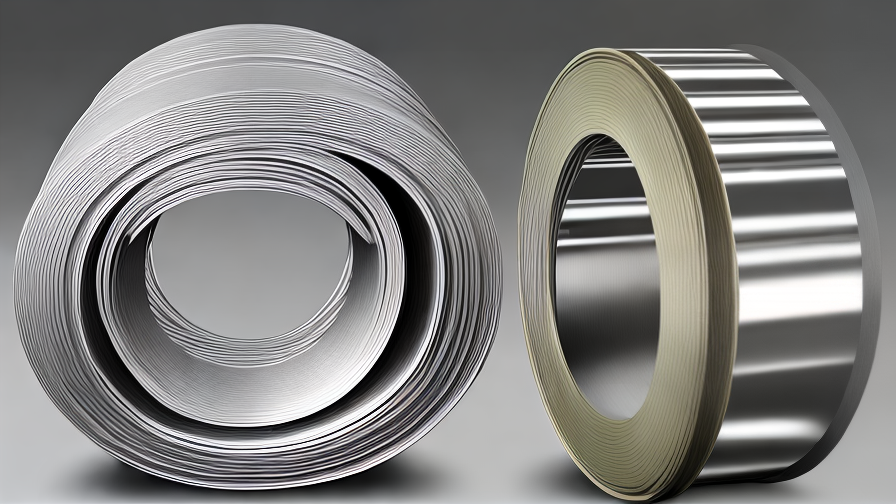

The first type of spiral wrapping band manufacturer is the general manufacturer. This manufacturer produces a wide range of spiral wrapping bands, including different sizes, colors, and materials. General manufacturers cater to a broad range of industries and provide their customers with a diverse selection of products.

Another type of spiral wrapping band manufacturer is the specialized manufacturer. These manufacturers produce spiral wrapping bands in specific shapes and sizes to meet the needs of specific industries. For example, a specialized manufacturer may produce spiral wrapping bands exclusively for the aerospace industry.

Some manufacturers also produce spiral wrapping bands made from different materials. For example, some manufacturers produce spiral wrapping bands made from polyethylene, while others make their products from PVC or nylon. This variety in materials allows different manufacturers to cater to different industries, based on their specific needs.

Finally, some manufacturers produce spiral wrapping bands with different features, such as self-locking or heat-resistant properties. These features cater to industries with specific requirements, such as the automotive industry, which requires heat-resistant spiral wrapping bands to handle high temperatures.

In conclusion, there are various types of spiral wrapping band manufacturers, providing a broad range of products to meet different industries’ needs. The general and specialized manufacturers, manufacturers of different materials, and manufacturers of spiral wrapping bands with unique features all play a vital role in the cable and wire management industry.

FAQ sourcing Spiral Wrapping Band Manufacturer manufacturer from China

If you are looking for a reliable source of spiral wrapping bands, China is a great place to start. You may have some questions in mind about the process of sourcing and working with a spiral wrapping band manufacturer from China. In this article, we have compiled a short FAQ to help answer some of your queries.

1. Why choose a spiral wrapping band manufacturer from China?

China is known for its manufacturing capabilities and is home to many high-quality manufacturers, including those that produce spiral wrapping bands. By sourcing a manufacturer from China, you can access lower production costs while still getting dependable products.

2. How do I find a reliable manufacturer?

To find a reliable manufacturer, do some research and scrutinize their certifications, experience, and customer feedback. You can also ask for samples and request references from previous customers.

3. What materials are used for spiral wrapping bands?

Spiral wrapping bands in China are made from a range of materials, including PE, PVC, and PP. Depending on the intended use, the manufacturer can recommend the most suitable material for your product.

4. Can I customize my spiral wrapping bands?

Yes, you can customize your spiral wrapping bands to suit your specifications. Typically, you can customize the color, size, shape, and material of your band.

5. What is the minimum order quantity?

The minimum order quantity (MOQ) usually depends on the manufacturer. Some manufacturers might have higher MOQs, while others are more flexible. It is advisable to inquire about the MOQ before making any orders.

6. How long does it take to receive my order?

The time it takes to receive your order depends on the manufacturer and your location. Typically, it can take anywhere from a few days to several weeks. Make sure to discuss the delivery time frame with your manufacturer beforehand.

In conclusion, working with a spiral wrapping band manufacturer from China can be a great move for your business. Conduct proper research, communicate with the manufacturer, and make sure to clarify any doubts before

Applications of Spiral Wrapping Band Manufacturer

Spiral wrapping band is a flexible and durable solution that is used in various industrial applications. It is made of high-quality plastic material that offers protection and organization to cables, wires, hoses, and other components. Spiral wrapping band manufacturer offers a range of products that are ideal for bundling, labeling, and securing cables and wires in different environments.

One of the significant applications of spiral wrapping band is in the automotive industry. It is used to organize and protect various cables and wires in cars and other vehicles. This helps to prevent tangling and damage to the wires or cables, which can cause malfunctions in the electrical system. Spiral wrapping band is also used in the construction industry, where it is ideal for securing and protecting cables, wires, and hoses during construction work. This helps to ensure the safety of workers and prevents damage to the components.

Another popular application of spiral wrapping band is in the telecommunications industry. With the increasing number of cables and wires used in telecommunications systems, it has become essential to organize and protect them. Spiral wrapping band manufacturer provides products that are resistant to abrasion, UV radiation, and high temperatures, making them ideal for use in the telecommunications industry.

Spiral wrapping band is also used in the medical industry to protect and organize various cables and wires used in medical devices. The band is used to prevent tangling and ensure the safety of patients and healthcare providers. In addition to these industries, spiral wrapping band finds applications in the aerospace, marine, and electronics industries, among others.

In conclusion, the applications of spiral wrapping band are diverse and widespread. The product offers excellent protection and organization to cables and wires in various industries, making it an essential component for maintaining safety and efficiency in industrial processes. Spiral wrapping band manufacturer provides high-quality products that are designed for different environments and purposes.

Manufactured Products made of Spiral Wrapping Band Manufacturer

Manufactured products made of spiral wrapping band are an excellent solution for cable and wire management. Spiral wrapping band manufacturers produce a range of spiral bands that can be used in many different industries, including electrical, automotive, and construction.

Spiral wrapping bands are highly flexible and provide a secure, protective covering for cables and wires. They are made from high-quality materials such as polyethylene or polypropylene, which makes them highly durable and resistant to damage from UV rays, chemicals, and extreme temperatures.

The most significant advantage of the spiral wrapping band is its versatility. Their flexibility allows them to be easily fitted to cables of varying diameters and lengths. The band’s spiral design ensures that cables and wires are tightly bundled together, resulting in a neat and organized appearance.

Spiral wrapping bands are also highly cost-effective. They are durable and have a long lifespan, making them perfect for use in applications that require long-term protection. They are also easy to install, saving considerable time and effort during installation.

In conclusion, manufactured products made of spiral wrapping band are an excellent solution for cable and wire management. The bands are highly versatile, durable, and cost-effective, making them perfect for use in a range of different industries. For organizations looking to improve cable and wire management, spiral wrapping band manufacturer should be the top choice.

The Evolution history of Spiral Wrapping Band Manufacturer

Spiral wrapping bands have become widely used for organizing and protecting cables in various industries. The history of spiral wrapping band manufacturing can be traced back to the 1960s when plastic extrusion technology was introduced. Initially, spiral wrapping bands were made of PVC or polyethylene materials and primarily used in the automotive industry. For several decades, Spiral wrapping band manufacturers improved the technology and quality of the product.

In the 1990s, spiral wrapping bands became more common in other industries, including telecommunications, computer, and home appliances. The demand for higher quality and different characteristics of materials grew, such as fire-resistant, UV resistant, or halogen-free. To meet these requirements, Spiral Wrapping band manufacturers began using TPE, TPU, Nylon, and other materials.

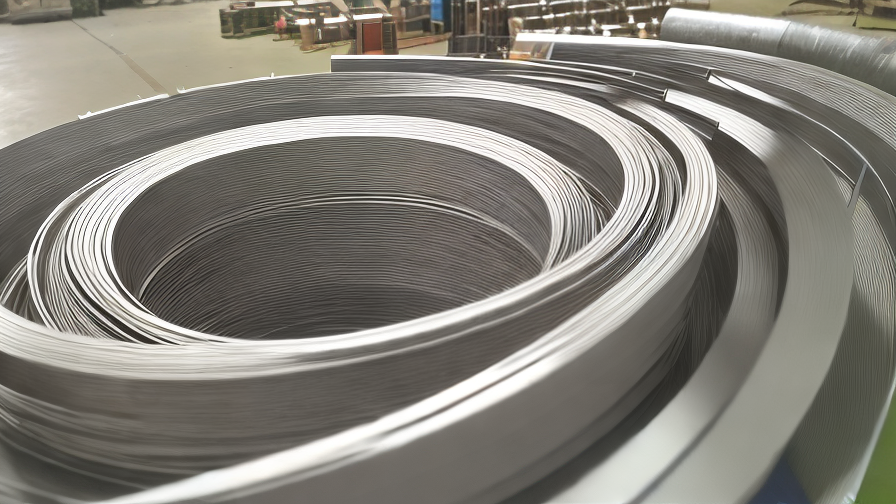

The evolution of spiral wrapping band manufacturing has seen changes in production techniques, including the use of more advanced machines and automated production lines. This has allowed for higher production efficiency, lower costs, and shorter lead times. Furthermore, cooperation with material suppliers and underwriters to ensure compliance with temperature, fire, and other safety standards has been established.

Recently, spiral wrapping bands have advanced further in design and function. The latest pre-slit and self-wrapping bands have made installation and maintenance more convenient. Various colors have been introduced for color-coding applications as well. Apart from being used in different industries, spiral wrapping bands have also found applications in military and space industries.

Overall, the evolution of spiral wrapping band manufacturing has shown progression in quality, efficiency, and innovation. With continuous development in design and materials, spiral wrapping bands will continue to be an essential component in organizing and protecting cables.

The Process of Spiral Wrapping Band Manufacturer

Spiral wrapping band is a widely-used cable management product that is commonly used to prevent tangled wires and cables. This product is made with flexible, durable materials that allow for a tight but comfortable fit around cables of different sizes. Spiral wrapping band manufacturer often employs several steps to produce high-quality products that meet the needs of their customers.

The manufacturing process starts with the selection of materials. Spiral wrapping band manufacturers typically use polyethylene or polypropylene to produce their products due to their flexibility and durability. The selected material is then extruded into long, thin tubes that are pulled through a series of rollers to create a smooth surface and uniform thickness.

The next step in the process involves cutting the extruded material into narrow strips of varying widths. The strips are then fed into a coiling machine where they are wound into tight spirals. The diameter of the coiling machine is adjusted based on the required size of the spiral wrapping band.

Once the spirals are formed, they are heated in an oven to ensure that they maintain their shape. The temperature and duration of heating depend on the type and thickness of the material.

After heat treatment, the spirals are allowed to cool for a specified period. They are then measured to ensure that they meet the specifications of the customer. If the spirals are too big, too small, or not consistent in their diameter, they are sent back for further processing or rejected.

In conclusion, the process of spiral wrapping band manufacturing involves several steps, including material selection, extrusion, cutting, coiling, heating, cooling, and quality control. These steps ensure that manufacturers produce high-quality products that meet the requirements of their customers. Spiral wrapping band is a versatile product that is used in various industries, including automotive, electrical, and telecommunications.

Benefits Advantages of Utilizing Spiral Wrapping Band Manufacturer

Spiral wrapping bands are an ideal solution for all cable organization needs. Used in various industries and household tasks, these bands hold cords and cables together, maintain stability and keep them from tangling. A spiral wrapping band manufacturer is the ultimate source of custom-sized bands that offer benefits beyond just cable management.

Utilizing a spiral wrapping band manufacturer has numerous benefits that can enhance cable management efforts, increase safety, and improve overall product functionality.

Firstly, a manufacturer can provide customized bands, which can fit any application sizes, shapes or materials. This makes them suitable for all types of applications and environments, from heavy industrial machinery to household electronics. Manufacturers can also supply multiple color options to serve numerous identification and organization needs.

Secondly, spiral wrapping bands safeguard conductors and cables from over-bending, chaffing, cracking or any other potential fault during installation, operation or maintenance. By using a band, the cables stay in place and the band protects the cables from any movement, thus reducing wear and tear of the cables.

Thirdly, using bands from a reliable manufacturer reduces the cost of damaged or broken cables, as well as the accident risks associated with loose or tangled cables.

The manufacturing process of these bands also ensures that they can operate in harsh or remote environments, as they offer protection from water, dirt, dust or harsh chemicals. With exceptional resistance to heat and UV radiation, spiral wrapping bands guarantee longevity and durability.

In conclusion, utilizing a spiral wrapping band manufacturer has numerous benefits that can enhance cable management, increase safety, and improve overall product functionality. Customization, protection from damages and safety-efficiency are just some of the reasons why these bands are a must-have for every industrial application.

Disadvantages Spiral Wrapping Band Manufacturer

Spiral wrapping bands have become increasingly popular in recent years due to their versatility and ease of use. They are commonly used in several industries such as automotive, electrical, and construction, just to mention a few. However, like any other product, spiral wrapping bands have some disadvantages when it comes to their manufacturing process.

Firstly, spiral wrapping bands are made using plastic, which is a non-biodegradable material. This means that after their useful life, they end up in landfills where they take hundreds of years to decompose. Manufacturers need to find ways to recycle and dispose of plastic, which can be costly and time-consuming.

Secondly, the manufacturing process of spiral wrapping bands is complex, which requires specialized equipment and skilled labor. This means that the cost of production is high, which reflects in the final price of the product. This may make spiral wrapping bands less attractive to consumers on tight budgets or those who prefer cheaper alternatives.

Additionally, spiral wrapping bands may not be suitable for heavy-duty use. Although they are durable, they may not be able to withstand extreme temperatures, harsh chemicals, or heavy weights. This may limit their use in some applications, such as the construction industry, where heavy-duty packaging is required.

Lastly, during the manufacturing process, spiral wrapping bands may develop defects such as irregularities in shape and size. These manufacturing defects may compromise the quality of the product, leading to possible safety risks. Manufacturers need to ensure quality control measures are put in place to minimize the occurrence of such defects.

In conclusion, while spiral wrapping bands have several advantages, such as versatility and ease of use, their manufacturing process also has some notable drawbacks. These include their non-biodegradable nature, high production costs, limited heavy-duty use, and the risk of manufacturing defects. It’s important for manufacturers to address these issues to provide high-quality products and improve their environmental impact.

Selecting the Ideal Manufacturer Spiral Wrapping Band Manufacturer

When it comes to selecting the ideal manufacturer for spiral wrapping bands, there are a few key factors that a company should consider. Spiral wrapping bands are used to organize and protect cables and wires, and they come in different diameters and lengths to accommodate different needs. Here are some things to look for in a spiral wrapping band provider:

1. Quality: The quality of the spiral wrapping bands is of utmost importance. The bands should be made from durable materials that can withstand abrasion and stretching. The manufacturing process should ensure that the bands are consistent in size, shape, and strength.

2. Variety: A good manufacturer should offer a variety of spiral wrapping bands to choose from. This allows you to find the right size and length for your specific application. Some manufacturers also offer customization options, such as different colors and labeling, to help you organize your cables even better.

3. Service: Look for a manufacturer that provides excellent customer service. They should be able to help you choose the right products for your needs, answer any questions or concerns you may have, and provide timely delivery.

4. Pricing: While price is important, it should not be the only factor in selecting a manufacturer. Be wary of manufacturers that offer significantly lower prices than their competitors, as this may be a sign of poor quality or inconsistent supply.

5. Reputation: Do your research and read reviews from other companies that have used the manufacturer before. A good reputation speaks volumes about the quality of the products and the level of service provided.

By taking these factors into consideration, a company can select the ideal manufacturer for their spiral wrapping band needs. Investing in quality spiral wrapping bands can help reduce the need for costly repairs and replacements, making it a worthwhile investment for any business.

Things to Consider When Purchasing Spiral Wrapping Band Manufacturer

When it comes to packaging, the importance of using sturdy and reliable materials cannot be overstated. One of the materials that have gained popularity in recent years is spiral wrapping bands. These bands come in handy to wrap cables and wires together, making them safe and easy to handle. The demand for spiral wrapping bands has led to the emergence of numerous manufacturers in the market. If you are considering purchasing spiral wrapping bands, here are critical things to consider when choosing a manufacturer.

Quality of the Spiral Wrapping Band

The quality of the materials used to make the spiral wrapping band should be your top consideration. Look for a manufacturer who uses high-quality materials that can withstand wear and tear. The bands should have a strong grip that ensures that they hold onto the cables tightly. A sturdy and durable spiral wrapping band will save you time and money in the long run.

Price

Pricing is another critical consideration when purchasing spiral wrapping bands. You want to make sure that you get the best pricing without compromising on quality. Research different manufacturers and compare their prices. Choose the one that offers quality spiral wrapping around bands at an affordable price.

Customer reviews

Before purchasing spiral wrapping band manufacturer, take some time to research customer reviews. This not only helps you determine the quality of the bands but also gives you an idea of the manufacturer’s customer service. Choose a manufacturer with positive customer reviews as this indicates that they offer quality bands and excellent customer service.

Customizations

If you require customized spiral wrapping bands, look for a manufacturer who can customize the bands according to your specifications. This is crucial if you have specific requirements that standard spiral wrapping bands cannot meet.

Conclusion

Purchasing spiral wrapping bands requires careful consideration. Look for a manufacturer who offers quality bands, affordable pricing, excellent customer service, and customizations if needed. This guarantees that you get the best value for your money and high-quality spiral wrapping bands that serve their purpose.

Properties of Spiral Wrapping Band Manufacturer

Spiral wrapping bands are an essential tool to manage cable and wire lines. They are made of a high-quality material that is durable, flexible, and resistant to abrasion. Spiral wrapping bands can be used in various applications, including automotive, data communication, and office equipment. To ensure that you get the best spiral wrapping band, you need to choose the right manufacturer. Here are some of the properties of a reliable spiral wrapping band manufacturer:

1. High-quality products

The best spiral wrapping band manufacturer should provide high-quality products. The products should be made of durable material that can withstand tough conditions. The manufacturer should have a quality control system to ensure that every product meets the required standards.

2. Wide range of products

A good spiral wrapping band manufacturer should offer a wide range of products to meet different customer needs. They should have different sizes, colors, and materials to cater to every customer’s specific requirements.

3. Competitive pricing

Pricing is an essential factor when choosing a spiral wrapping band manufacturer. A good manufacturer should offer competitive pricing without compromising on the quality of their products. They should have a pricing system that is transparent and easy to understand.

4. Excellent customer service

A reliable spiral wrapping band manufacturer should have excellent customer service. They should have a responsive team that can answer customer queries and provide helpful information. They should also have a customer support system that allows customers to contact them easily.

5. Quick delivery

The manufacturer should provide quick delivery services to their customers. They should have a well-structured logistics system that ensures timely delivery of products. They should also have a system for tracking orders to keep customers updated on the status of their orders.

In conclusion, choosing the right spiral wrapping band manufacturer is essential to get high-quality products that meet your specific needs. A reliable manufacturer should offer high-quality products, a wide range of products, competitive pricing, excellent customer service, and quick delivery services. With these properties in mind, you can choose a spiral wrapping band manufacturer that

How to use Spiral Wrapping Band Manufacturer

Spiral wrapping band is a product used for bundling and protecting wires, cables, hoses, and other types of cords. If you want to use spiral wraps for your organization or personal use, it is important to know the manufacturer’s guide. Here are a few steps to follow when using a spiral wrapping band manufacturer.

1. Choose the Right Size and Material – Spiral wrapping band comes in different sizes and materials based on the item you want to bundle. Choose a material that matches your environment and type of wire or cable. For example, if your wire is exposed to high temperatures, choose a high-temperature-resistant spiral wrap.

2. Cut to the Right Length – Depending on the length of the cord or wire you want to bundle, determine the appropriate length of the spiral wrapping band. You can measure it against the cord, then cut it to size using scissors or a knife.

3. Wrap the Spiral around the Cord – Hold the end of the spiral wrap and start wrapping it around the cord, keeping it as tight as possible. The spiral wraps are designed to overlap slightly when you wrap them, so you can adjust the tension slightly.

4. Secure the Ends – Once you have wrapped the cord up with spiral wrap, it is essential to secure both ends to make sure the band does not come undone. You can use electrical tape or zip-ties to secure both ends.

5. Repeat the Steps – If you want to wrap multiple cords, repeat the process of selecting the right material, size, and length. Then wrap them in the same way as above.

Overall, using a spiral wrapping band manufacturer is an easy and simple process if you know what you are doing. Always make sure you choose the right size, material, and wrap the cords tightly before securing the ends. If you follow these steps, you can easily bundle and protect your cords from damage.

Glossary Terminology Terms for Spiral Wrapping Band Manufacturer

Spiral wrapping bands are used for bundling and protecting wires, cables, hoses, and tubes. Understanding the terminology used in the production of these bands can help manufacturers provide their customers with the best quality products. Below, we have compiled a glossary of essential terms used in spiral wrapping band manufacturing:

1. Resin: The raw material used to manufacture the spiral wrapping band. It can be made of various materials such as PVC, PE, or PP.

2. Extrusion: The process of melting the resin and forcing it through a die to form the shape of the spiral wrapping band.

3. Shore hardness: A measure of the hardness of the material. It is measured by the Shore hardness scale and indicated by a number. For example, a Shore hardness of 70 indicates that the material is very hard.

4. Tensile strength: A measure of the maximum load a material can withstand before breaking. It is usually measured in pounds per square inch (PSI).

5. Elongation: A measure of the amount of stretching a material can withstand before breaking. It is expressed as a percentage of the original length.

6. Cohesion: The ability of the material to bond to itself. It is essential in ensuring the durability of the spiral wrapping band.

7. Adhesion: The ability of the material to bond to other materials. It allows the spiral wrapping band to adhere to the wires or cables, protecting them from damage.

8. Temperature resistance: The ability of the material to function under different temperature conditions. The higher the temperature resistance, the better the material can withstand heat.

9. Flame retardant: The ability of the material to resist combustion or slow down its spread. It is essential for safety purposes.

10. UV resistance: The ability of the material to withstand exposure to ultraviolet (UV) radiation. It prevents the material from degrading or becoming brittle when exposed to the sun.

In conclusion, understanding these terminologies can help spiral wrapping band manufacturers

Spiral Wrapping Band Manufacturer Price

Spiral wrapping bands are the perfect solution to keep cables, wires, and hoses organized and safe from damages. These bands are flexible and easy to install, making them popular in various industries such as automotive, construction, and manufacturing.

The price of spiral wrapping bands may vary depending on several factors, including the quantity, material, and manufacturer. It’s essential to choose a manufacturer that offers high-quality bands at an affordable price.

When it comes to the price, manufacturers offer bulk discounts for customers who purchase a large quantity of spiral wrapping bands. The more bands you buy, the lower the price per unit may be.

Another factor that affects the price is the material. Spiral wrapping bands are available in different materials such as polyethylene, polypropylene, and nylon. The price of the bands may depend on the type of material used as some materials are more expensive than others.

Lastly, choosing a reputable spiral wrapping band manufacturer is essential to ensure that you’re getting your money’s worth. Experienced and established manufacturers often offer competitive prices and high-quality bands that meet industry standards.

In conclusion, the price of spiral wrapping bands may vary depending on the quantity, material, and manufacturer. It’s important to choose a manufacturer that offers affordable prices without sacrificing the quality of the bands. Bulk purchasing, selecting the right material, and partnering with a reputable manufacturer can lead to a cost-effective and reliable solution for cable management.