Knowledge about Stained Glass Grinder

Stained glass is a beautiful art form that dates back centuries, and one of the tools used to create these pieces is the stained glass grinder. This device is used to shape and smooth the edges of stained glass pieces so that they fit perfectly together. For those looking to create their own stained glass pieces, having knowledge about stained glass grinders is essential.

Firstly, it’s important to understand the different types of stained glass grinders available. There are two main types – the manual grinder and the electric grinder. Manual grinders require more physical effort to use, but they’re easier to control and can produce more precise results. Electric grinders are more powerful and efficient, making them a popular choice for professional stained glass artists.

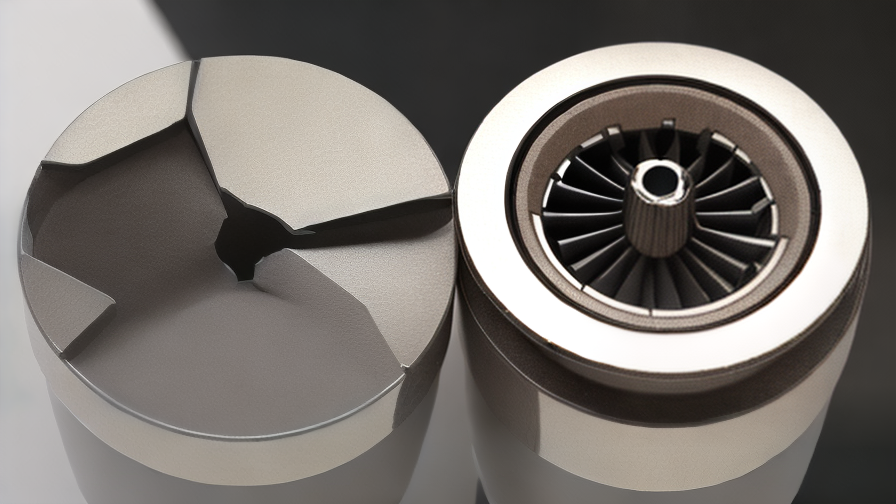

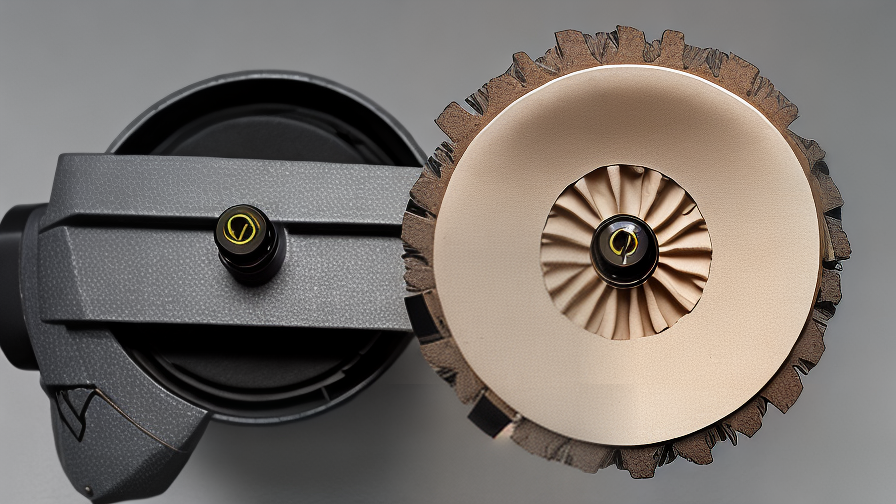

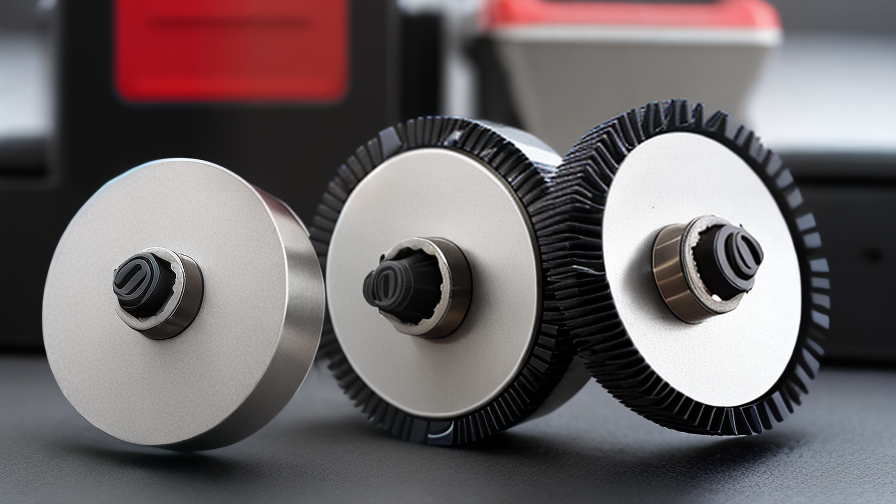

The shape and size of the grinder head is also an important consideration. Grinder heads come in a range of shapes and sizes, with different grits to achieve different finishes. Beginners may want to start with a medium-sized grinder head with a fine or extra-fine grit to create smooth edges on their pieces.

Safety is also a crucial aspect of using a stained glass grinder. Protective goggles should always be worn to protect the eyes from glass dust and debris, and it’s important to keep the work area clean to prevent slips and falls. Additionally, grinders should never be used wet or near water, as this can cause electric shock.

Finally, it’s important to understand the proper techniques for using a stained glass grinder. The glass should be held firmly against the grinding surface, and the grinder head should be moved in a circular motion around the edges of the piece. It’s important not to apply too much pressure, as this can cause the glass to break.

In conclusion, having knowledge about stained glass grinders is essential for anyone looking to create their own stained glass pieces. Understanding the different types of grinders available, the importance of safety, and the proper techniques for grinding will help ensure a successful and enjoyable stained glass experience.

Various Types of Stained Glass Grinder

Stained glass grinders are an essential tool for any artist or craftsman working with glass. They are used to smooth and shape the edges of glass, which can be difficult and dangerous work without the right equipment. There are various types of stained glass grinders available on the market, each with its own advantages and disadvantages.

The most common type of stained glass grinder is the flat lap grinder. This grinder has a flat disc that spins horizontally, with a water reservoir underneath to keep the glass cool and lubricated. It is ideal for smoothing and shaping the edges of flat pieces of glass, and can be used for larger pieces or for grinding small details.

Another type of stained glass grinder is the straight grinder. This grinder has a cylindrical shape and is designed to grind edges and curves on glass. It is smaller than a flat lap grinder, making it easier to use in tight spaces, but it is not as effective for shaping larger pieces of glass.

The belt sander is another type of stained glass grinder that can be used for shaping larger pieces of glass. It uses a belt that rotates vertically, and users can adjust the speed and pressure to achieve the desired result. While it is more powerful than other types of grinders, it is also more expensive and can be harder to use.

A more recent addition to the world of stained glass grinders is the diamond wire saw. This tool uses a wire with diamond particles to cut through glass, making it ideal for cutting intricate shapes and patterns. However, it is also more expensive and requires a steady hand and a lot of patience to use effectively.

In conclusion, there are many different types of stained glass grinders available, each with its own strengths and weaknesses. Depending on the specific needs of the project, artists and craftsmen can choose a grinder that will help them achieve the desired result with the least amount of effort and risk.

FAQ sourcing Stained Glass Grinder manufacturer from China

When it comes to sourcing a stained glass grinder manufacturer from China, there are many frequently asked questions (FAQs) that arise. Here are some of the top questions with multiple answers to help you find the right manufacturer for your needs.

Q: What should I look for in a stained glass grinder manufacturer from China?

A: Look for a manufacturer with a good reputation, experience in producing high-quality grinders, competitive pricing, and good customer service.

Q: How do I find stained glass grinder manufacturers in China?

A: You can search for manufacturers online using search engines, directories, and marketplaces. You can also attend trade shows and exhibitions to meet manufacturers in person.

Q: What is the minimum order quantity (MOQ) for stained glass grinders in China?

A: MOQ can vary depending on the manufacturer. Some may have a MOQ of 100 units, while others may require a minimum order of 500 units or more. It’s important to clarify this with the manufacturer before placing an order.

Q: Can I get a sample of the stained glass grinder before placing a bulk order?

A: Yes, many manufacturers will provide samples for a fee. It’s important to test the sample to ensure the quality meets your expectations before placing a bulk order.

Q: What is the lead time for ordering stained glass grinders from China?

A: Lead time can vary depending on the manufacturer’s production schedule, the size of the order, and shipping distance. It’s important to clarify lead time with the manufacturer before placing an order.

Q: Can I customize the design of the stained glass grinder?

A: Many manufacturers offer customization options such as color, logo placement, and power source. It’s important to clarify customization options and any additional fees with the manufacturer before placing an order.

In conclusion, sourcing a stained glass grinder manufacturer from China can be a daunting task, but by asking the right questions and doing your research, you can find a reputable and reliable manufacturer to meet your

Applications of Stained Glass Grinder

Stained glass grinder is a versatile tool for working with stained glass, fusing glass, and smalti tiles. It grinds and shapes glass pieces to fit into any pattern or design like stained glass windows, mosaics, or home decor. The range of applications is broad, from hobbyist projects to professional jobs.

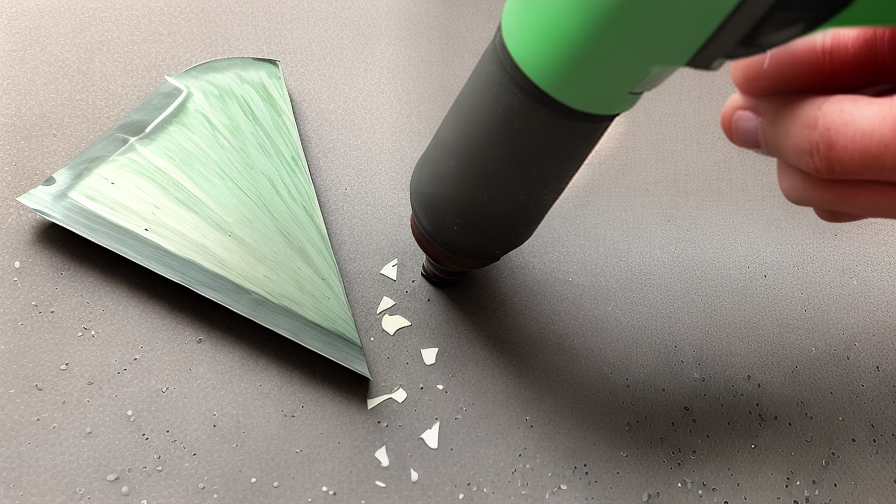

The primary use of a stained glass grinder is to grind and smooth the sharp edges of cut glass. After cutting glass with a glass cutter, the edges are rough and jagged. A stained glass grinder uses diamond bits to grind and smooth the glass edge. The grinder removes the uneven edges and shapes the glass to the desired size.

Another application of a stained glass grinder is for making intricate designs. The grinder can shape small pieces of glass to fit into tight spaces, allowing for unique designs and patterns. In stained glass windows, this technique allows for more detailed and intricate designs.

In fused glass, a stained glass grinder is used for coldworking. Coldworking is the process of grinding and polishing the edges of fused glass pieces. The grinder is used to shape, smooth, and polish the edges of the fused glass, creating a professional finish.

Smalti tiles, which are small glass tiles used in mosaics, require a special type of grinding. Smalti tiles are brittle and require careful grinding to maintain their shape and color. Using a stained glass grinder with a diamond smoothing bit results in precise smalti tiles and a perfect shape.

Stained glass grinders are also used for repairing damaged or broken stained glass windows. By removing the damaged pieces of glass and shaping new pieces to fit the space, a stained glass grinder allows for the restoration of the original design.

In conclusion, a stained glass grinder is an essential tool for working with stained glass, fusing glass, smalti tiles, and for repairing damaged stained glass windows. The applications of a stained glass grinder are broad, ranging from simple glass edge smoothing to intricate design work. A stained glass

Manufactured Products made of Stained Glass Grinder

Stained glass is a versatile material that has been used for centuries to create beautiful works of art. However, in order to bring stained glass to life, it must be cut, shaped, and ground. This can be a time-consuming and tedious process if done by hand. Fortunately, the stained glass grinder was invented to make this process faster and more efficient.

One of the most popular applications for the stained glass grinder is in the creation of manufactured products. The grinder provides the ability to cut and shape stained glass quickly and accurately, which makes it an ideal tool for creating various products.

One of the most common products made using a stained glass grinder is ornaments. Stained glass ornaments come in a variety of shapes and sizes, and add a touch of elegance to any room or Christmas tree. Other popular products include sun catchers, lamp shades, and decorative panels.

The grinder allows for intricate designs to be created by cutting and grinding small pieces of stained glass to fit together perfectly. This creates a mosaic-like effect that can be used to make a variety of products.

In addition to its use in creating manufactured products, the stained glass grinder is also used in the restoration of historical stained glass artwork. Many stained glass windows in churches and other historic buildings require restoration work to preserve their beauty. The grinder allows for damaged pieces of glass to be removed and replaced with new pieces that match the original design perfectly.

Overall, the stained glass grinder is an essential tool for anyone working with stained glass. It allows for intricate and accurate cuts to be made, which is essential for creating beautifully manufactured products. Its versatility also makes it an ideal tool for restoration work. With the help of a stained glass grinder, the possibilities for creating beautiful stained glass artwork are endless.

The Evolution history of Stained Glass Grinder

The evolution of stained glass grinders has been a fascinating process over the years. Initially, grinders were simple machines that were used to grind down unwanted edges on a piece of glass. However, as time went on, the technology behind stained glass grinders advanced, providing artists with the ability to create intricate designs and complex shapes.

One of the earliest forms of stained glass grinders was the foot-operated grinder. It was a simple device that used a foot pedal to control the grinding wheel. These grinders were used by craftsmen for shaping and smoothing the cut pieces of glass before creating a stained glass piece. The grinding wheel was typically made of stone, and it was manually moved back and forth over the glass surface to smooth rough edges.

In the early 1900s, electric motors were introduced to stained glass grinders. This invention allowed for more precise, controlled grinding of glass pieces, and the process became easier and more efficient. The electric motor also allowed for a faster grinding process, which was particularly useful for artists who needed to complete large glass works in a short amount of time.

Then, in the 1980s and 1990s, advancements in technology paved the way for modern stained glass grinders. These grinders are now lighter, more portable, and have a range of different options for grinding heads, which allow for a variety of tasks. Some grinders even use diamond bits for grinding, which provides superior precision and speed.

Overall, the evolution of stained glass grinders has mirrored the technological advancements of our time. From the simple foot-operated grinders of the past to the modern, efficient models used today, artists have been able to create more intricate and complex pieces than ever before. As new technologies continue to emerge, we can expect even more innovations in the future of stained glass grinding.

The Process of Stained Glass Grinder

Stained glass is a beautiful and intricate art form that is created by cutting and piecing together different colored glass pieces. The process of creating stained glass can be difficult and time-consuming, but with the help of a stained glass grinder, it can be made much easier.

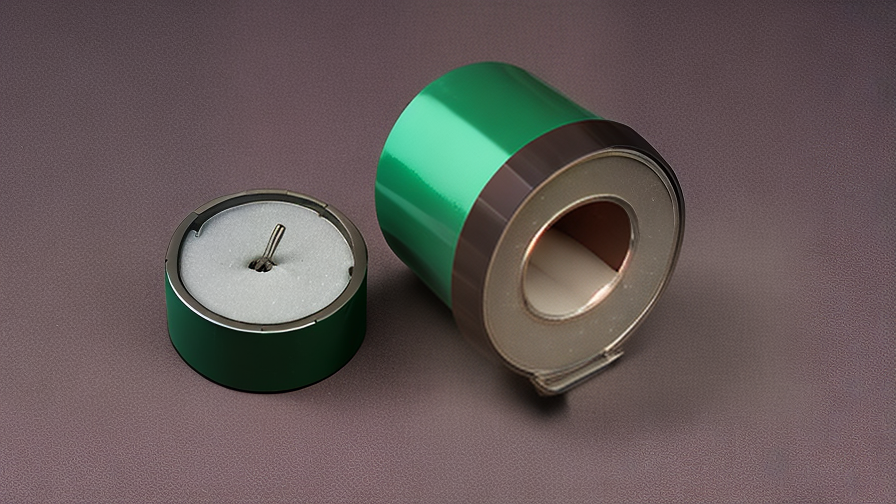

A stained glass grinder is a tool used to smooth and shape the edges of glass pieces used in stained glass art. This tool works by spinning a diamond-coated disk against the glass, which grinds away the rough edges and shapes the piece to the desired size and shape.

The process of using a stained glass grinder starts with selecting the glass pieces that will be used in the project. Once the pieces are chosen, they are cut to the desired size and shape using a glass cutter. After the pieces are cut, they will have rough and jagged edges that need to be smoothed out.

To use the stained glass grinder, the piece of glass is held firmly against the grinder’s spinning disk. The glass is moved back and forth across the disk, slowly grinding away the rough edges until they are smooth and even. This process is repeated for each glass piece until all of the edges are smooth and polished.

One important thing to keep in mind when using a stained glass grinder is safety. The diamond-coated disk spins at a high speed and can cause injury if not used properly. It is important to wear protective goggles and gloves when using the grinder and to keep the workspace clean and free of debris.

In conclusion, a stained glass grinder is an essential tool for anyone who enjoys creating stained glass art. It streamlines the process of shaping and smoothing glass pieces, making the creation of intricate designs much easier. With proper use and safety precautions, a stained glass grinder can help artists achieve stunning and professional-looking results.

Benefits Advantages of Utilizing Stained Glass Grinder

Stained glass art is fascinating and has been around for centuries. It has graced homes, religious institutions, public buildings, and museums, showcasing the beauty of its colored and textured glasses. While the art of staining glass has retained a traditional charm, modern technology has enabled artists and hobbyists to explore new possibilities and take it to a new level. A stained glass grinder is an essential tool for anyone passionate about this craft.

The primary benefit of using a stained glass grinder is that it helps you achieve precision and accuracy in your work. Glass grinders allow you to shape, angle, and trim the edges of the stained glass pieces to create the perfect fit. They help you grind access glass material, making each cut neat and tidy, preserving the quality of the glass edge.

Another advantage is that stained glass grinders allow you to create intricate and detailed work with minimum effort. Grinding the glass with a grinder enables you to create shapes and textures that are difficult to achieve using other tools. By using different grinding heads, you can create fascinating patterns, compound curves, and beveled edges that enhance your project’s beauty and elegance.

Using a stained glass grinder is also an eco-friendly option. Reusing materials is a core principle in crafting. Utilizing scraps of glass can help reduce waste and maximize resources. With glass grinders, you can store leftovers in small jars or containers and use them in another project, saving money and reducing waste.

Moreover, using a stained glass grinder is a smart investment in time efficiency. The grinder allows you to speed up your work without sacrificing quality. Doing cuts manually or using other tools can be a tedious and time-consuming process. A stained glass grinder can help you handle multiple pieces and cut them more precisely, getting more work completed in a shorter amount of time.

In conclusion, utilizing a stained glass grinder has many benefits and advantages. Precision, intricate detail work, eco-friendliness, and time efficiency are the main benefits of using a glass grinder in your work. With

Disadvantages Stained Glass Grinder

A stained glass grinder is a tool used by artists to shape and smooth the edges of glass pieces. While the grinder can be helpful in achieving a desired look for the glass piece, there are also some disadvantages to using it.

One disadvantage of using a stained glass grinder is that it can be time-consuming to use. It takes a certain amount of time to achieve the necessary level of smoothness on the edges of the glass piece. If an artist is trying to complete a project quickly, using a grinder may not be the best option.

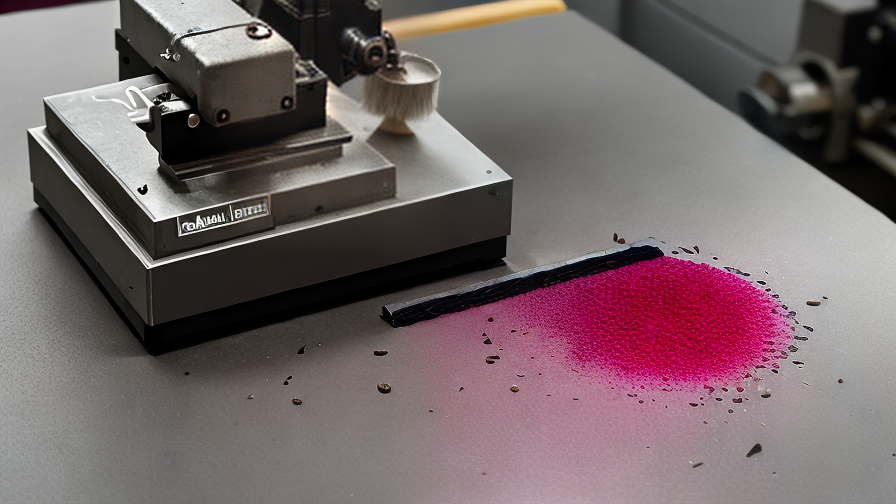

Another disadvantage of using a stained glass grinder is that it can be messy. The grinding process creates glass dust, which can be hazardous if inhaled. It is important to wear a mask and to clean up the dust regularly.

A stained glass grinder can also be expensive. Some models can cost hundreds of dollars, which may not be affordable for all artists. Additionally, the cost of replacement parts and maintenance can add up over time.

Finally, using a stained glass grinder requires some skill and practice. It can be difficult to achieve the desired level of smoothness without accidentally chipping or breaking the glass piece. Beginners may need to spend more time practicing and perfecting their skills before they can achieve the desired effect.

In summary, while a stained glass grinder can be a useful tool for artists, it also has some disadvantages. It can be time-consuming, messy, expensive, and requires skill and practice to use effectively. Artists should consider these factors before deciding whether or not to use a stained glass grinder in their work.

Selecting the Ideal Manufacturer Stained Glass Grinder

If you are a stained glass artist, having the right tools is essential to achieve the perfect finish. One critical tool in this kit is the stained glass grinder. There are many manufacturers of these grinders, all with their unique features, which can make selecting the perfect one for your needs daunting. However, selecting the ideal manufacturer stained glass grinder is possible if you follow these simple tips.

First, consider the power of the motor. A powerful motor will ensure that the grinder operates smoothly and doesn’t bog down when grinding tough glass textures. Therefore, you should look for a grinder with at least a 0.5 horsepower motor.

Second, consider the size and thickness of the glass you’ll be working on. A smaller glass grinder may work well for smaller projects, but for larger ones, opt for the bigger models. Additionally, the thickness of the grinding bit is essential, so choose one that is appropriate for the thickness of the glass.

Third, check the build quality of the grinder. A high-quality grinder should have a sturdy build, and the exterior should be made of durable materials. Additionally, the grinder’s surface should be non-slip to ensure your safety while using it.

Fourth, consider the usability of the grinder. Look for a grinder with easily accessible controls that are simple to use, and make sure it comes with a user manual to avoid confusion during operation. Additionally, it should be easy to disassemble and clean.

Lastly, consider if the manufacturer offers a warranty. A manufacturer that offers a warranty shows confidence in their product and provides added protection to the buyer in case of any defects or damages.

Selecting the ideal manufacturer stained glass grinder may seem overwhelming, but with these tips, you can make an informed choice. Remember to consider the motor power, size, build quality, usability, and warranty offered by the manufacturer. Happy grinding!

Things to Consider When Purchasing Stained Glass Grinder

Stained glass grinder is an essential tool to have when working with stained glass. It is used to shape, smooth and polish the edges of the glass. When purchasing a stained glass grinder, there are several things to consider.

Firstly, the size of the grinding surface is important. A larger grinding surface allows for more glass to be worked on at the same time, while a smaller surface is more precise for intricate designs. Consider the size of the glass pieces that you will be working with to determine the appropriate size of the grinding surface.

Secondly, the power of the motor is an important factor. A more powerful motor allows for faster grinding and can handle tougher jobs, such as thicker glass. However, a powerful motor can also be louder and heavier, so it is important to find the right balance for your needs.

Thirdly, the type of grinder head is important. There are several types of grinder heads available, including diamond bits, tungsten carbide bits, and electroplated bits. Diamond bits are the most durable and are best for heavy-duty use, while tungsten carbide bits are better for shaping and smoothing smaller pieces of glass.

Fourthly, it is important to consider the price of the grinder. A stained glass grinder can range from under $100 to over $500, depending on the features and quality. It is important to find a grinder that fits your budget while also meeting your needs.

Finally, consider the brand and reputation of the manufacturer. Some of the most popular brands include Glastar, Gryphon, and Diamond Tech. Read reviews and do your research to find a manufacturer that has a good reputation for quality and customer service.

In conclusion, purchasing a stained glass grinder requires careful consideration of factors such as size, power, grinder head, price, and brand reputation. By taking the time to research and evaluate your needs, you will be able to find a grinder that meets your requirements and helps you create beautiful stained glass pieces.

Properties of Stained Glass Grinder

Stained glass grinders are essential tools for any stained glass work. They help in smoothing and shaping the edges of the stained glass to fit perfectly into the design. The primary function of a stained glass grinder is to grind away rough edges or sharp angles on the glass pieces without breaking or cracking them.

One of the most important properties of a stained glass grinder is its motor power. The more powerful the motor, the faster and smoother the grinding process. A high-speed motor also helps in tackling tough and thick glass pieces.

Another important feature of a stained glass grinder is the grinding bit. Most of the grinders come with diamond bits which are suited to grinding glass. They come in different sizes and shapes differentiated based on the type of grinding they perform. Fine grit bits, for instance, are used for light grinding jobs, while coarse grit bits are used for heavy grinding work.

The size of the work surface is another vital property to consider when selecting a grinder. Larger surface areas are ideal when working on larger glass pieces. Grinders, such as the Glastar All-Star Grinder, come with a 9” x 10” work surface, which can handle most standard-sized glass pieces.

Water is also an essential element when using a grinder. It helps to lubricate the grinding process, keeping the glass cool and preventing it from cracking. Some grinders come with built-in water reservoirs, which help in reducing mess and keeping the glass pieces clean.

Opting for a grinder with adjustable settings is also important. Grinders such as the Inland Wizling CG Grinder come with adjustable settings that allow for precise grinding on delicate or intricate pieces.

In conclusion, a stained glass grinder is a necessary tool for any stained glass artist, and choosing the right grinder is crucial. Key properties to consider include motor power, grinding bit, work surface area, water usage, and adjustable settings. With the right grinder, any stained glass artist can achieve the desired smooth and polished finish.

How to use Stained Glass Grinder

Stained glass grinders are an essential tool for any stained glass artist. These grinders allow artists to shape and grind the edges of stained glass pieces to achieve the perfect shape and size. Learning how to use a stained glass grinder can be intimidating, but with a little practice, it can become a simple and enjoyable process. Follow these steps to learn how to use a stained glass grinder:

1. Safety first: As with any power tool, safety should be your priority. Wear eye and ear protection to prevent injuries from flying glass and make sure the grinder is set up on a stable surface.

2. Set up the grinder: Attach the grinder head to the machine and lubricate it with water to prevent overheating. Adjust the angle of the work surface to make it easier to access the glass from different angles.

3. Prepare the glass: Cut the glass to the desired shape and size using a glass cutter. Use a marker or pencil to mark where the grinder should start and stop.

4. Begin grinding: Turn on the grinder and hold the glass against the grinder head, moving it back and forth along the marked area. Keep the glass in constant motion to avoid creating grooves or flat spots.

5. Check your progress: Periodically stop grinding and examine your progress. Use a felt marker or light to make any visible scratches, which will help you see where more grinding is needed.

6. Smooth the edges: Switch to a finer grit grinding head to finish smoothing the edges.

7. Clean up: Once you’ve finished grinding, use a damp cloth to clean up the glass and the grinder.

Using a stained glass grinder can take some practice, but with patience and the right technique, you’ll be able to create smooth, professional-looking pieces in no time. Always prioritize safety and take your time to achieve the desired results. Happy grinding!

Glossary Terminology Terms for Stained Glass Grinder

Stained glass grinding is a vital process when it comes to producing high-quality stained glass artwork. The use of a grinder is necessary for smoothing rough edges and shaping pieces of glass. If you are new to this fascinating and creative field, you might not be familiar with the terminology that accompanies the use of a stained glass grinder. In this article, we will define some of the key terms that you may encounter when working with a stained glass grinder.

1. Grit: The abrasive material used on the grinder’s grinding surface to smooth and shape the glass. Different grits are used for different stages of the grinding process.

2. Grinding surface: The surface on the grinder where the abrasive grit is applied to the glass.

3. Coolant: A liquid used to cool the glass and grinder during the grinding process. Water is the most common coolant used in stained glass grinding.

4. Diamond bit: A diamond-coated grinding bit used on the grinder’s grinding surface to grind and shape the glass.

5. Resin bit: A grinding bit made with a resin bonding material, a cheaper alternative to the diamond bit.

6. Face shield: A protective shield that covers the face and eyes when grinding, protecting the wearer from flying glass shards.

7. Splash guard: A protective shield that covers the grinding surface, preventing water and glass debris from splashing outside of the machine.

8. Foot pedal: A mechanical device used to control the speed of the grinder.

9. Kiln wash: A coating applied to the surface of the glass before firing to prevent it from sticking to the kiln shelf.

10. Firing schedule: A programmed schedule used to control the temperature, duration, and cooling rate of the glass firing process.

As you can see, learning the terminology behind stained glass grinding is critical to producing successful finished pieces. So, as you begin your journey in this exciting field, familiarize yourself with these essential terms, and don’t forget to take safety precautions when working with a grinder

Stained Glass Grinder Price

Stained glass grinders are an essential tool for artists who work with stained glass. They allow the artist to shape and smooth the edges of the glass, which is necessary for creating beautiful and intricate designs. However, stained glass grinders can come with a hefty price tag, and it is important for artists to understand their options and budget accordingly.

The price of a stained glass grinder can vary depending on a variety of factors. The quality of the materials, the power and size of the motor, and the brand name can all contribute to the overall cost. Entry-level grinders can be found for as little as $50, while high-end models can cost upwards of $500.

When considering the price of a stained glass grinder, it is important to consider the features that are necessary for your specific projects. If you work with larger pieces of glass, you may need to invest in a grinder with a larger grinding surface. If you work on projects frequently or on a larger scale, a more powerful motor may be necessary to keep up with the demands of your work.

If you are just starting out with stained glass work or have a tighter budget, there are plenty of affordable options available. Many entry-level grinders offer enough power and room to get started with basic projects. Used grinders can also be a great option for those on a budget. Websites such as eBay or Craigslist can offer used grinders at a discounted price.

Ultimately, the price of a stained glass grinder should be considered an investment in your art. A high-quality grinder can last for years, and the quality of your work can improve as you hone your skills with the tool. When budgeting for a grinder, it is important to consider the long-term benefits to your art and the potential return on investment.