Knowledge about Steel Plate Bender

Steel plate benders are one of the most commonly used pieces of equipment in metal fabrication. These machines are used to bend and shape steel plates into various complex shapes and angles. However, in order to use these machines effectively, it is important to have a good understanding of how they work, what types of steel plates they can bend, and what safety precautions should be taken when operating them.

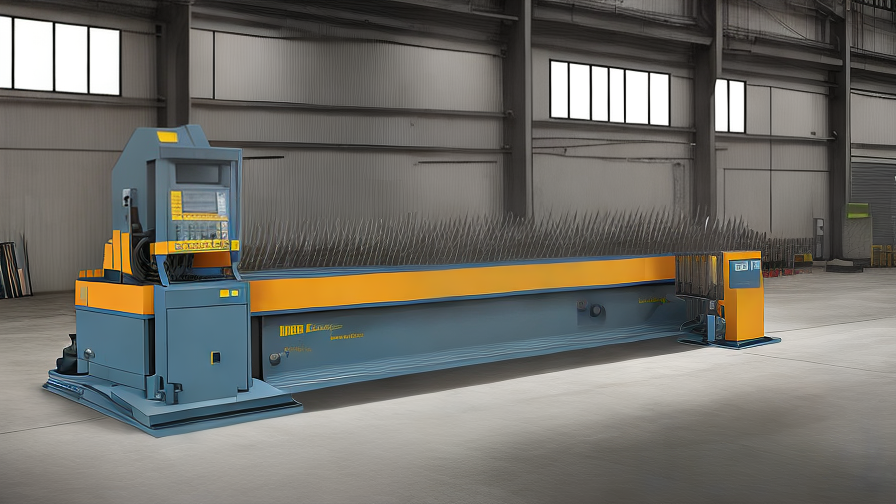

Firstly, it is important to note that there are two main types of steel plate benders: hydraulic and electromechanical. Hydraulic benders use a hydraulic pump to apply pressure to the steel plate, while electromechanical benders use electric motors and gears to bend the plate. Both types of benders can produce high-quality bends, but hydraulic benders are typically more powerful and can handle larger and thicker plates.

Secondly, it is essential to choose the right type of steel plate for the job. Steel plates come in a variety of thicknesses and strengths, and each plate bender has a maximum capacity that it can handle. It is important to follow the manufacturer’s recommendations when selecting the appropriate steel plate for a given job.

Finally, safety precautions are paramount when working with steel plate benders. Operators should always wear safety gloves and goggles to protect their hands and eyes from flying debris. Additionally, the workspace should be kept clean and uncluttered to avoid accidents, and the machine should be properly maintained and inspected regularly to ensure it functions properly.

In conclusion, understanding the basics of steel plate benders is crucial for anyone working in the metal fabrication industry. Knowing how these machines work, what types of steel plates they can bend, and how to operate them safely can help ensure successful and safe completion of any metal bending project.

Various Types of Steel Plate Bender

Steel plate bending machines come in many different forms and sizes, each designed for a specific type of operation. These machines use hydraulic power, mechanical power, or a combination of both to deform the steel plate to a desired shape. Here are some of the most common types of steel plate benders:

1. Press brake – This machine uses a hydraulic ram to apply force on a steel plate, bending it into a desired angle. The operator can adjust the positioning of the ram and the die to achieve different shapes.

2. Roll bender – This machine uses three rollers to bend the steel plate into a cylindrical shape. The operator can adjust the distance between the rollers to achieve different diameters.

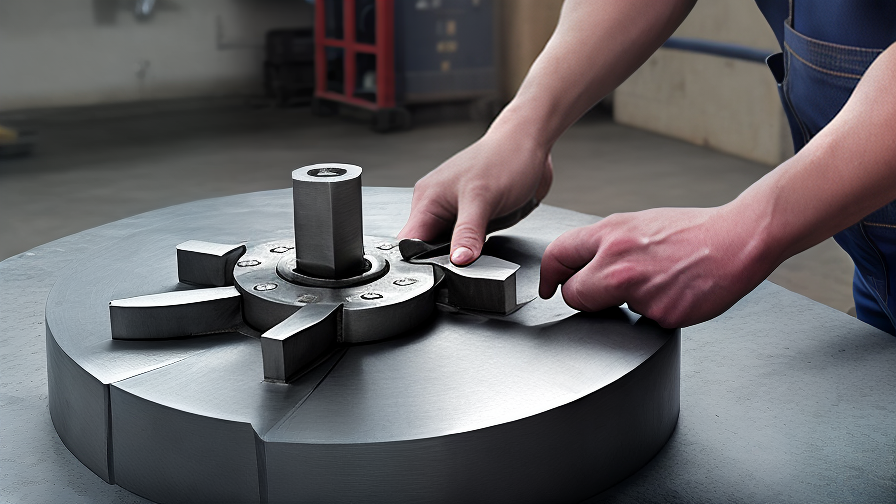

3. Pyramid roller – This machine uses four rollers to bend the steel plate into a cone or pyramid shape. One roller is fixed, while the other three rollers move up and down to apply pressure.

4. Plate roll – This machine uses two or three rollers to bend the steel plate into a cylindrical or conical shape. The operator can adjust the distance between the rollers to achieve different diameters.

5. Section bender – This machine uses multiple rollers to bend the steel plate into a curved shape. The operator can adjust the roller positions to achieve different radii.

6. Profile bender – This machine uses multiple rollers to bend the steel plate into a complex shape, such as an S-curve or a U-shape. The operator can adjust the roller positions to achieve different curves.

7. Pipe bender – This machine uses hydraulic power to bend steel pipes into a desired angle or shape. It can be used to create curves or angles in steel plates as well.

In conclusion, steel plate benders come in various types and sizes, each designed for a specific purpose. They are essential tools for fabricators, manufacturers, and construction companies who need to produce steel structures or components.

FAQ sourcing Steel Plate Bender manufacturer from China

If you are looking to source a steel plate bender manufacturer from China, you may have a few questions that need answering. Below are some frequently asked questions with multiple answers to help guide your search.

1. What features should I look for in a steel plate bender?

– The maximum bending capacity: Depending on the thickness of the steel you need to bend, you will want to make sure the machine has the appropriate capacity.

– Durability: A sturdy frame and high-quality components will ensure longevity and better performance.

– Automation: Advanced machines offer automated functions that improve speed and precision.

– Ease of use: Features such as digital displays and intuitive controls make the machine easier to operate.

2. What materials can a steel plate bender bend?

– Mild steel: This is the most common material used for bending.

– Stainless steel: A machine with higher power can bend stainless steel.

– Aluminum: Machines with multiple rollers can bend aluminum sheets with ease.

3. What price range should I expect for a steel plate bender?

– Entry-level machines can cost around $1,000 – $4,000.

– Mid-range machines range from $4,000 – $10,000.

– Industrial-grade machines can cost $10,000 and above.

4. What is the lead time for manufacturing and shipping?

– The manufacturing time can take anywhere from 10 – 30 days, depending on the complexity of the machine and the manufacturer’s workload.

– Shipping times depend on the shipping method and destination. Air freight can take 3 – 7 days, while sea freight can take 15 – 30 days.

5. What certifications should the manufacturer have?

– ISO 9001: This certification ensures that the manufacturer adheres to quality management standards.

– CE: This certification indicates that the machine complies with health, safety, and environmental regulations in the European Union.

In conclusion, when sourcing a steel plate bender manufacturer from China, considering the features, materials, price

Applications of Steel Plate Bender

A steel plate bender is an essential tool used in metal fabrication projects. It can be used to bend steel plates of various thicknesses, making it a versatile tool in the hands of skilled metalworkers. Here are some of the common applications of steel plate bender.

In the construction industry, steel plate benders are used to shape steel plates for use in building roofs, walls, and other structural components. The machine can easily shape steel into various angles and curves, which is necessary in creating architectural designs.

Another popular application of steel plate benders is in the manufacturing industry. The machine is used to make precision bends in metal sheets that are used in the production of automobile parts, aircraft parts, and other machinery.

Steel plate benders are also used in the shipbuilding industry. The machine can shape steel plates into curved and angled shapes that are used in the construction of ships, boats, yachts, and other watercraft.

In the HVAC (heating, ventilation, and air conditioning) industry, steel plate benders are used to make ductwork. The machine can bend and shape steel plates into the necessary shape and size for use in ductwork, which is an essential component of HVAC systems.

Finally, steel plate benders are also used in the art and design industry. Metal artists use the machine to create custom metal sculptures and other artistic designs. The machine allows for precise and intricate bends that are necessary in creating unique and beautiful pieces.

In conclusion, steel plate benders are essential tools in various industries. They can be used to bend and shape steel plates of different thicknesses, making it possible to create precision bends for use in structural and artistic applications.

Manufactured Products made of Steel Plate Bender

Steel plate bender is a specialized piece of equipment used to bend and shape steel plates into desired forms. A wide array of manufactured products can be created using steel plate benders including furniture, architectural features, and industrial equipment.

The steel plate bender can create precise bends and shapes with a variety of thicknesses and grades of steel. This helps manufacturers in creating an array of products that can be customized for any application.

Steel plate benders are commonly used in the manufacturing of industrial equipment, such as pressure vessels and heat exchangers. The equipment used in these applications often require specific shapes to be formed to ensure proper functionality and safety. The steel plate bender allows for these shapes to be created with precision and accuracy, making these products perform to their full potential.

Steel plate benders are also used in architectural applications, where they are used to create intricate designs for building facades, staircases, and other features. The use of steel plate benders in these applications ensures that the design is not compromised and that the final product is both aesthetically pleasing and functional.

In the realm of furniture design, steel plate benders are frequently used to create high-end, custom furniture pieces. This type of furniture often includes unique shapes and intricate detailing that can only be produced using a steel plate bender.

The versatility of steel plate benders allows for their use in a wide range of industries and applications. The creation of precise shapes and designs for industrial equipment, architectural features, and furniture makes the steel plate bender an essential tool for manufacturers.

The Evolution history of Steel Plate Bender

The steel plate bender, a tool used to bend and shape steel plates, has a long history of evolution. The earliest versions of the steel plate bender were simple hand tools used by blacksmiths to bend small sheets of metal. These tools consisted of a pair of metal jaws operated by a lever, which could be adjusted to bend the metal to the desired angle.

In the early 20th century, hydraulic steel plate benders were introduced, which made bending thicker materials much easier. These large machines used hydraulic pressure to bend the steel plate, allowing for greater control and accuracy during the bending process.

The development of computer-controlled steel plate benders has revolutionized the industry, enabling precise control over the bending angle and allowing for complex shapes to be easily created. These machines use robotic arms and computer programs to ensure that every bend is exact, reducing waste and increasing efficiency.

Today, steel plate benders are used in a wide range of industries, including construction, shipbuilding, and manufacturing. They are essential tools in the production of everything from sheet metal parts to large-scale steel structures.

The evolution of the steel plate bender has been a crucial factor in the growth and development of many industries. As the technology continues to improve, we can expect to see even more advanced and efficient steel plate benders in the future.

The Process of Steel Plate Bender

A steel plate bender is a machine that is used to bend steel plates. The process of bending steel plates requires a lot of skill and expertise. The process involves using a hydraulic press to bend the steel plates into the desired shape. Steel plate benders are commonly used in construction and manufacturing industries.

The process of steel plate bending starts with preparing the steel plate for bending. Before the bending process, the steel plate must be cleaned and stripped of any protective coatings, such as rust inhibitors or paint. This is done to prevent damage to the steel plate during the bending process.

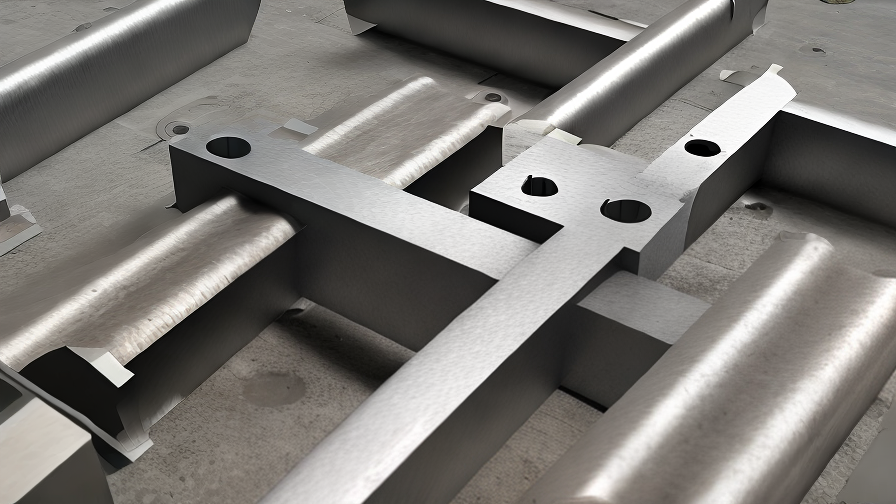

Once the steel plate is cleaned, it is positioned on the steel plate bender. The steel plate is positioned in between the two hydraulic press cylinders, which push against the plate to create the bend. The amount of pressure applied by the cylinders is determined by the thickness of the steel plate and the degree of bend required.

The operator then sets the angle of the bend and activates the hydraulic press. The press cylinders start to push against the steel plate, gradually bending it into the desired shape. The operator then checks to ensure that the bend is even and accurate before releasing the pressure.

The process of bending steel plates requires precision, control, and expertise. The operator must have a thorough understanding of the equipment and the properties of the steel plate being bent. The operator must also have the necessary safety training to operate the machine and protect themselves from injury.

In conclusion, the process of steel plate bending is an important part of the manufacturing and construction process. Steel plate benders require a high level of skill, experience, and attention to detail. With the high demand for steel plates in various industries, the process of steel plate bending will continue to be an essential part of manufacturing and construction processes for years to come.

Benefits Advantages of Utilizing Steel Plate Bender

Steel plate bending is a process that is important in the metalworking industry. Bending steel plates requires expertise and specialized equipment. In this process, a steel plate bender is used to curve metal sheets to the desired angle or shape.

Steel plate bender is an essential tool that has numerous benefits and advantages. Unlike other equipment, this bending machine is straightforward to use, and it comes with various features that make the handling of metal sheets less daunting.

One of the major advantages of steel plate bender is its versatility. This machine can bend steel plates of various thicknesses and sizes. It has the capability of producing different shapes, including U-shaped, V-shaped, and straight bends. With this bending machine, metal workers can create complex structures like cylinders, cones, and elliptical shapes with ease.

Another benefit of using a steel plate bender is its accuracy. This machine is designed with an intuitive control panel that allows the operator to make precise adjustments to achieve accurate bends. The machine also has measurement markings that ensure that the bends are perfectly aligned.

The steel plate bender also saves time and reduces labor costs. This machine can produce multiple bends in a single operation, which enhances productivity. It also eliminates the need for manual labor, which can be physically demanding and time-consuming.

The durability of the steel plate bender is also a significant advantage. This machine is made of high-quality materials that are designed to withstand the rigors of heavy-duty metalworking operations. It requires minimal maintenance, and with proper care, it can last for years.

Finally, the steel plate bender is a safer machine compared to other metalworking equipment. It is designed with safety features that protect the operator from accidents or injuries. The machine also has a sturdy base that ensures stability during the bending process, reducing the risk of workplace accidents.

In conclusion, the steel plate bender is a valuable tool in the metalworking industry that offers numerous benefits and advantages. It is versatile, accurate, time-saving, durable, and

Disadvantages Steel Plate Bender

A steel plate bender is a machine used in metal fabrication to bend steel plates. While steel plate benders are essential machines in metal fabrication, there are a few disadvantages that come with their use.

Firstly, steel plate benders are relatively large and heavy machines. This makes them difficult to move from place to place, and requires a dedicated space for their operation. Additionally, the setup of the machine can be time-consuming, which can result in increased production time.

Secondly, steel plate benders are noisy machines. The operation of the machine may create a loud noise level that can be harmful to workers, especially if they are subjected to prolonged exposure to the noise. To mitigate the noise level, workers should wear personal protective equipment such as ear muffs.

Thirdly, steel plate benders require skilled operators. The machine’s operation is complex, and only people with specialized training and expertise can operate them. Therefore, companies must invest in training their employees, which can increase the overall costs of production.

Lastly, steel plate benders require regular maintenance to ensure optimal operation. As with any machine, regular maintenance is vital to prolong the machine’s life and avoid costly repairs. Therefore, companies must invest time and resources to maintain their steel plate benders.

In conclusion, while steel plate benders are an essential machine in the manufacturing industry, they come with their disadvantages. A steel plate bender’s large size and weight, noisy operation, the need for skilled operators, and regular maintenance requirements can increase costs and production time. However, with proper use, training, and maintenance, these disadvantages can be mitigated, and the benefits of the machine can be realized.

Selecting the Ideal Manufacturer Steel Plate Bender

Selecting the ideal manufacturer steel plate bender requires thorough research and consideration. This critical task is because steel plate benders play a significant role in multiple industries, such as construction, transportation, and manufacturing. The following factors are essential when selecting the ideal manufacturer steel plate bender.

First, consider the manufacturer’s experience and reputation in the industry. A manufacturer with a proven track record of producing high-quality and durable steel plate benders is the ideal choice. Check customer reviews and ratings, online forums, and industry publications to determine the manufacturer’s reputation.

Secondly, select a steel plate bender that meets your specific needs. Different industries require different types of steel plate benders, depending on the thickness and size of the steel plate. Ensure that the manufacturer can customize the bender to your specific requirements.

Thirdly, the efficiency and speed of the steel plate bender are crucial in any industrial setting. Quality steel plate benders should have accurate and fast bending capabilities to increase productivity and reduce downtime.

Fourthly, safety is a crucial consideration when selecting a steel plate bender. Ensure that the manufacturer complies with safety regulations and standards, such as OSHA and CE. Additionally, the manufacturer should provide comprehensive safety manuals and training for your employees.

Finally, consider the cost and warranty of the steel plate bender. The ideal manufacturer should offer cost-effective options without compromising on quality. Additionally, they should provide a warranty on their products to protect you against any defects or malfunction.

In conclusion, selecting the ideal manufacturer steel plate bender requires careful consideration of the manufacturer’s reputation, customizability, efficiency, safety, cost, and warranty. Take your time to research and choose a manufacturer that meets your specific requirements and offers a high-quality and durable steel plate bender.

Things to Consider When Purchasing Steel Plate Bender

Steel plate benders are crucial tools for industrial and construction projects. They help in bending and shaping steel plates according to specific requirements. However, when purchasing a steel plate bender, there are several important factors to consider.

Firstly, consider the size of the steel plate bender. The size is determined by the width and thickness of the steel plates that need to be bent. A larger steel plate bender can handle thicker steel plates with ease, but it may not be a suitable option for projects that require smaller-sized bent steel plates.

Secondly, consider the type of material that the bender is made of. Steel plate benders are usually made of cast iron, steel, or aluminum. Cast iron and steel benders are more durable and can handle heavier loads, but they are also heavier and require more maintenance. Aluminum benders are lighter and more affordable, but they may not be as durable.

Thirdly, consider the bending angle that the bender can achieve. Different projects require different bending angles, and it is important to choose a bender that can handle the desired angles with ease.

Fourthly, consider the safety features of the bender. Steel plate benders can be dangerous if not used properly, and it is important to choose a bender with safety features such as emergency stop buttons, safety guards, and proper labeling.

Finally, consider the manufacturer of the bender. Choose a manufacturer with a good reputation and a history of producing quality steel plate benders. Make sure to read reviews and feedback from other customers to ensure that the bender you choose is reliable and efficient.

In conclusion, purchasing a steel plate bender requires careful consideration of factors such as size, material, bending angle, safety features, and manufacturer. By taking these factors into account, you can ensure that you choose a bender that is suitable for your specific project needs and that will provide reliable service for years to come.

Properties of Steel Plate Bender

Steel plate benders are an essential tool for metal fabrication. They are used to shape, bend, and design heavy-duty steel plates into various forms. With the right set of properties, steel plate benders can deliver accurate and efficient results.

The first important property commonly found in steel plate benders is the strength to resist deformation. Heavy metal plates require a lot of pressure to bend, so the tool must be very strong. Benders made of high-grade materials with excellent tensile and yield strength like aluminum bronze and ductile iron are highly recommended.

Another requisite property is hardness. Steel plate bender must have the ability to withstand wear and tear from constant use. Benders with a high level of hardness will last longer and require less maintenance.

Durability is another important property. Steel plate benders that are used for industrial purposes must be built to handle harsh working conditions. Good benders should be designed to endure both indoor and outdoor working environments.

Flexibility is an essential characteristic of a reliable steel plate bender. The tool should be versatile enough to accommodate various sizes and types of metal plates. The bender should also have an adjustable range of bending angles to allow for precision in design and to avoid any wastage of the metal plates.

Finally, safety is an important property that should not be overlooked. Steel plate benders must be designed with safety measures to protect the operator from potential accidents. Automatic shut-off systems, overload protection, and safety guards are some common safety features.

In conclusion, properties of steel plate benders like strength, hardness, durability, flexibility, and safety are important in ensuring an efficient and effective metal fabrication experience. It is therefore essential to consider these properties when selecting a steel plate bender for your industrial needs.

How to use Steel Plate Bender

A steel plate bender is a tool used for bending large pieces of metal into the desired shape. It is commonly used in industries that require high precision and accuracy when it comes to the shape and size of the metal. Here are some tips on how to use a steel plate bender.

Firstly, ensure that you have the right tools and equipment for the job, including gloves, safety glasses, and a protective coat or apron. Safety should always come first when working with metal as it can be sharp and dangerous.

Next, make sure that the steel plate is of appropriate thickness and width for the bender you are using. The machine manual will have guidelines on how to choose the right size of steel plate.

Before placing the metal on the machine, clean it thoroughly to remove any debris, rust, or oil on the surface. This will ensure that the bender produces a clean and smooth bend.

When using the bender, it is important to apply even force on both sides of the metal. This will ensure that the metal bends evenly without any kinks or cracks.

The bending process should be done slowly and cautiously, ensuring that the metal doesn’t get overstressed. Avoid forcing the metal beyond its limits as this can cause cracks or even break it.

Lastly, always remember to take good care of the steel plate bender after use. Clean it thoroughly, grease the moving parts, and store it in a dry and safe place.

In conclusion, using a steel plate bender requires patience, precision, and attention to detail. By following the steps outlined above, you can ensure that the metal bends evenly and accurately, giving you the desired shape and size for your project.

Glossary Terminology Terms for Steel Plate Bender

A steel plate bender is a handy tool that is used to bend and shape steel plates, tubes, and other similar materials. It is used in a variety of industries, from construction, manufacturing, automotive to agriculture.

To have a better understanding of the process and the tool, it is important to familiarize oneself with the terminology and terms used in the industry. Below are some of the most commonly used terminologies and their definitions.

1. Bend Angle – The angle at which the material is bent.

2. Capacity – The maximum amount of material that the bender can handle.

3. Die – A component in the bender that determines the bending angle.

4. Flattening – The process of flattening a bent material to reduce its curvature.

5. Gauge – The thickness of the material.

6. Mandrel – A component that reduces deformation during the bending process.

7. Radius – The distance from the center of the bend to the edge of the material.

8. Springback – The bending material’s tendency to return to its original position after bending.

9. Tonnage – The pressure applied to the material by the bender.

10. V-die – A component in the bender that supplies the force required to bend the material.

11. Wipe Bending – The process of using a component to press down on the material to create the bend.

12. Yield Strength – The stress at which the material begins to deform.

With a better understanding of the terminologies, one can easily communicate and operate a steel plate bender efficiently. It is essential to select the relevant components, such as the capacity, tonnage, and die, based on the material being bent, the radius required, and the thickness of the material.

In conclusion, the steel plate bender is an essential tool for a variety of industries, and it is prudent to have a clear understanding of the terminology used in the industry to use the tool without any complications or issues.

Steel Plate Bender Price

Steel plate benders are one of the essential tools for any metal fabrication project. They allow metalworkers to bend and shape steel plates precisely and efficiently. When it comes to purchasing a steel plate bender, the price is a significant consideration. The price of steel plate benders varies depending on various factors such as size, durability, features, and brand.

The size of the steel plate bender is a significant factor in determining the price. Smaller steel plate benders have a lower price tag and are suitable for light projects, while larger ones meant for heavy-duty projects are more expensive. Typically, prices range from a few hundred to thousands of dollars.

Another essential consideration is durability. Durable steel plate benders that can withstand pressure and last a long time tend to be priced higher than less durable models. As such, it is crucial to consider the purpose of the bender and how often it will be used to select a product that can meet your needs.

Features are another factor that determines the price of steel plate benders. For instance, some benders may come with additional features like digital control systems or automatic bending options. Such features tend to make the bender more expensive, but they can also increase the efficiency and accuracy of the work.

The brand of the steel plate bender also plays a significant role in determining the price. Well-known brands tend to charge more for their products as they have a reputation for high quality, durability, and reliability. Such brands also offer warranties and after-sales service, which may add to the overall cost.

In conclusion, the price of a steel plate bender depends on various factors. A buyer should consider several factors, including the size, durability, features, and brand before making a purchase decision. However, it is essential to note that higher prices do not always guarantee quality, and buyers should carefully evaluate their needs to find the right steel plate bender that fits their budget.