Introduce about steel plate fabrication guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

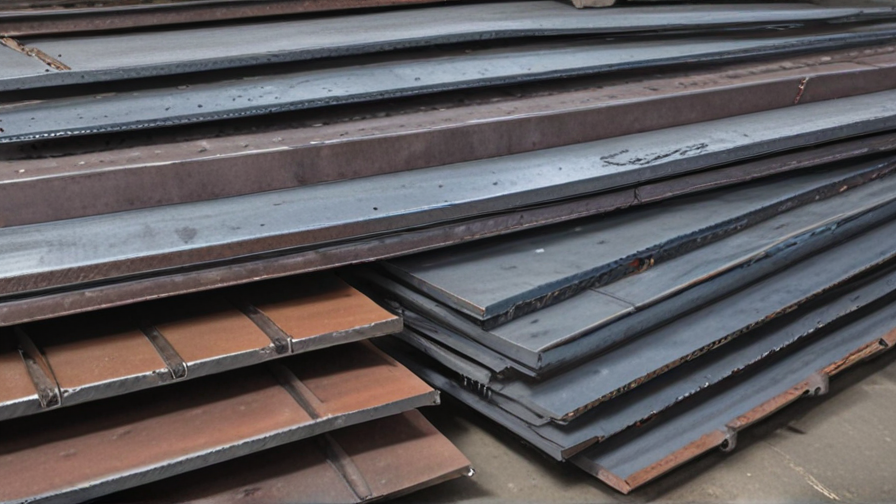

Steel plate fabrication is a manufacturing process that involves shaping and manipulating steel plates to create various structures and components. This guide aims to provide an overview of steel plate fabrication, covering aspects such as quality, cost, suppliers, certifications, market, tips, and frequently asked questions (FAQs).

Quality is of utmost importance in steel plate fabrication, as it determines the durability and reliability of the final product. To ensure high quality, fabricators use advanced techniques like laser cutting, welding, bending, and machining. It is crucial to select a reputable and experienced fabricator who can deliver precision and superior craftsmanship.

Cost is a significant factor to consider in steel plate fabrication. The cost depends on several factors, including the complexity of the design, type of steel used, quantity required, and any additional surface finishes or treatments. Obtaining multiple quotes from different fabricators and comparing their prices and services can help in finding a cost-effective solution.

When selecting a supplier for steel plate fabrication, it is essential to consider their capabilities, track record, and customer reviews. A reliable supplier should have expertise in handling a wide range of steel plate thicknesses and sizes, as well as different steel grades such as stainless steel, carbon steel, or alloy steel.

Certifications play a vital role in ensuring the quality and compliance of steel plate fabrication. Look for fabricators that hold relevant industry certifications, such as ISO 9001 for quality management systems or ASME certification for manufacturing pressure vessels. These certifications indicate that the fabricator follows strict quality control procedures and adheres to industry standards.

The market for steel plate fabrication is vast, with applications in industries like construction, oil and gas, mining, and transportation. The demand for fabricated steel plates is driven by infrastructure development and industrial growth. Global suppliers and manufacturers exist to meet this demand, offering a wide range of steel plate options.

Here are a few tips to consider when engaging in steel plate fabrication:

1. Provide detailed and accurate specifications to the fabricator to ensure the desired outcome.

2. Collaborate closely with the fabricator to discuss design considerations, material selection, and cost optimization.

3. Regularly inspect and maintain fabricated steel plates to prolong their lifespan.

4. Consider outsourcing certain fabrication processes, such as surface finishing or coating, to specialized providers to improve efficiency and cost-effectiveness.

Frequently Asked Questions (FAQs):

Q: What kind of steel grades are commonly used in plate fabrication?

A: Common steel grades used in fabrication include stainless steel, carbon steel, and alloy steel. The choice depends on the specific application and required mechanical properties.

Q: Can steel plates be customized to specific shapes and sizes?

A: Yes, steel plates can be customized through techniques like laser cutting, bending, and welding to achieve the desired shape and size.

Q: How can I ensure the quality of steel plate fabrication?

A: Quality can be ensured by selecting a reputable fabricator who holds relevant certifications and has a proven track record of delivering high-quality products.

In conclusion, steel plate fabrication is a versatile and crucial process in various industries. Understanding the factors related to quality, cost, suppliers, certifications, and market can help in making informed decisions and achieving successful fabrication projects.

Types of steel plate fabrication

Steel plate fabrication is the process of shaping steel plates into desired structures or products through cutting, bending, welding, and other techniques. There are several types of steel plate fabrication methods, each suited for different purposes and applications.

1. Cutting: Cutting is an essential step in steel plate fabrication. It involves separating the steel plate into desired sizes and shapes. There are various methods used for cutting steel plates, including:

– Flame cutting: Also known as oxy-fuel cutting, this method uses a flame torch to heat the plate and an oxygen stream to burn and remove the material.

– Plasma cutting: A high-velocity plasma jet is used to cut through the steel plate accurately and quickly.

– Laser cutting: Utilizing a high-powered laser beam, this method delivers precise and clean cuts, ideal for intricate designs.

2. Bending: Bending is the process of forming and shaping a steel plate into a specific angle or curve. It is typically achieved using hydraulic or mechanical press brakes. Bending is crucial for creating structural components, such as beams, channels, and fins.

3. Welding: Welding is commonly used in steel plate fabrication to join multiple steel plates together securely. Different welding methods may be employed, including:

– MIG (Metal Inert Gas) welding: This process uses a wire electrode to create an electric arc, producing the weld.

– TIG (Tungsten Inert Gas) welding: Utilizing a non-consumable tungsten electrode, TIG welding facilitates precise and high-quality welds.

– Arc welding: In this method, an electric current is passed through an electrode to create an electric arc, melting the steel plates and creating a weld joint.

4. Forming and Rolling: This fabrication technique involves using specialized machinery to shape steel plates into cylindrical or conical structures, such as pipes, tanks, and cones. The process is commonly called plate rolling or rolling.

5. Machining and Drilling: Steel plate fabrication often requires additional machining and drilling to achieve the desired dimensions, holes, or cut-outs. These processes may be done using computer numerical control (CNC) machines, which ensure precision and accuracy.

6. Surface Treatment: This final step involves applying protective coatings, such as paint, powder coating, or galvanization, to steel plates. These treatments enhance the durability, corrosion resistance, and aesthetic appearance of the fabricated products.

In conclusion, steel plate fabrication encompasses various methods and techniques to shape and manipulate steel plates into desired structures and products. The specific fabrication process used depends on the intended purpose, design, and specifications of the final product.

Pros and Cons of Using steel plate fabrication

Steel plate fabrication offers several advantages and disadvantages that need to be considered before using it.

Pros:

1. Strength and durability: Steel plates are known for their exceptional strength and durability. They can withstand heavy loads, resist deformation under high pressure, and are resistant to corrosion and impact, making them suitable for various applications.

2. Versatility: Steel plate fabrication allows for the production of a wide range of shapes and sizes. It can be customized to meet specific project requirements, making it suitable for a variety of applications in industries such as construction, manufacturing, automotive, and aerospace.

3. Cost-effective: While the initial cost of steel plate fabrication might be higher compared to other materials, its longevity and low maintenance requirements make it cost-effective in the long run. Steel’s high strength-to-weight ratio also allows for the design of lighter structures, reducing material and transportation costs.

4. High thermal conductivity: Steel plates have good thermal conductivity, allowing them to dissipate heat quickly. This property makes them suitable for applications that involve high temperatures and rapid heat transfer, like in boilers, heat exchangers, and nuclear power plants.

Cons:

1. Weight: Steel plates can be heavy, especially in larger sizes and thicker gauges. This can pose logistical challenges during transportation and installation, requiring specialized equipment and additional costs.

2. Corrosion susceptibility: Although steel is known for its corrosion resistance, it can still be susceptible to rust and corrosion over time, especially when exposed to harsh environments. Proper coatings and maintenance are required to prevent deterioration.

3. Welding challenges: Joining steel plates through welding can be complex and time-consuming, requiring skilled welders and specialized equipment. This can increase the overall fabrication cost and time.

4. Environmental impact: Steel production has a considerable environmental impact, including high energy consumption and carbon emissions. However, modern manufacturing processes are increasingly focusing on reducing these environmental effects.

In conclusion, steel plate fabrication offers many advantages, including strength, durability, versatility, and cost-effectiveness. However, its weight, corrosion susceptibility, welding challenges, and environmental impact should be carefully considered before choosing it as the construction material.

steel plate fabrication Reference Specifications (varies for different product)

Steel plate fabrication is a process by which steel plates are shaped, cut, and welded to create various metal structures and components. It is crucial to follow reference specifications for each product to ensure that the fabrication process meets the required quality, strength, and dimensional standards.

The reference specifications for steel plate fabrication may vary depending on the specific product being fabricated. These specifications are often provided by engineering drawings, project specifications, industry standards, and codes. They define the requirements for the material composition, mechanical properties, dimensions, tolerances, welding procedures, and surface finish, among other factors.

One of the key considerations in steel plate fabrication is the material selection and composition. The reference specifications will outline the required grade of steel, such as mild steel, high-strength low-alloy (HSLA) steel, or stainless steel, along with any additional elements or treatments needed for specific applications. The mechanical properties, including yield strength, tensile strength, and impact resistance, must also meet the specified requirements.

Dimensional accuracy is another important aspect of steel plate fabrication. The reference specifications define the allowable tolerances for various dimensions, such as length, width, thickness, and hole diameters. These tolerances ensure that the fabricated components fit together accurately during assembly and function as intended.

Welding procedures are a critical part of steel plate fabrication. The reference specifications provide guidelines for preparing the edges of the plates, welding techniques, and filler material selection. These procedures ensure strong and reliable weld joints that meet the specified strength and integrity requirements.

The surface finish of fabricated steel plates may also be specified in the reference specifications. This includes requirements for cleaning, deburring, and any necessary protective coatings to prevent corrosion or improve aesthetics.

Following the reference specifications is essential to maintain the quality, performance, and safety of the fabricated steel plates. Adhering to these specifications ensures that the finished products meet the necessary standards and can withstand the intended environmental and operational conditions.

In summary, steel plate fabrication requires following reference specifications that detail material composition, mechanical properties, dimensional tolerances, welding procedures, and surface finish requirements. By adhering to these specifications, fabricators can produce high-quality steel plates that meet the required standards for the intended applications.

Applications of steel plate fabrication

Steel plate fabrication is a versatile process that involves cutting, shaping, and bending steel plates to create various products. These fabricated steel plates find applications in a wide range of industries, including construction, manufacturing, automotive, energy, and transportation. Here are some key applications of steel plate fabrication:

1. Construction: Steel plate fabrication plays a vital role in the construction industry. It is used to create structural components like beams, columns, and trusses, which provide strength and support for buildings, bridges, and infrastructure projects. Fabricated steel plates are also used in the construction of staircases, platforms, and walkways.

2. Manufacturing: Steel plate fabrication is extensively used in the manufacturing sector to create equipment, machinery, and storage tanks. These fabricated steel plates are used in industries such as aerospace, mining, agriculture, and food processing. They form the foundation for manufacturing equipment and provide durability and structural integrity to withstand heavy loads and harsh operating conditions.

3. Automotive: Steel plate fabrication is an essential process in the automotive industry. It is used to manufacture various components, including chassis, frames, body panels, and suspension systems. Fabricated steel plates offer high strength and impact resistance, ensuring the safety and structural integrity of vehicles.

4. Energy sector: Steel plate fabrication is widely employed in the energy sector. It is used to manufacture equipment for power plants, including boilers, heat exchangers, and storage tanks. The fabricated steel plates can withstand high temperatures and pressures, making them suitable for the production and transportation of oil, gas, and other energy resources.

5. Transportation: Steel plate fabrication is crucial for the transportation industry. It is used in the construction of ships, barges, and offshore platforms, providing the strength and durability required for marine environments. Additionally, it is used in the manufacturing of railway cars, trucks, trailers, and containers, ensuring the safe transportation of goods.

In summary, steel plate fabrication is a versatile process with applications in construction, manufacturing, automotive, energy, and transportation industries. The fabricated steel plates provide strength, durability, and versatility, making them suitable for a wide range of products and applications.

The Work Process and how to use steel plate fabrication

Steel plate fabrication is the process of transforming sheets of steel into a desired product or component through various manufacturing techniques. This process involves cutting, bending, shaping, and assembling steel plates to form a final product with specific dimensions and properties.

The work process of steel plate fabrication typically starts with material selection. The type of steel plate chosen depends on the intended application and required strength, durability, and corrosion resistance. Once the steel plates are selected, they are cut into the desired shape using tools such as plasma cutters, laser cutters, or water jet machines. Cutting steel plates requires precision to achieve accurate dimensions.

After cutting, the next step is bending or shaping the steel plates. This is done using press brakes or rolling machines. Press brakes apply force to bend the steel plates into the desired angle or curve, while rolling machines shape the plates into cylindrical or conical forms. The bending process ensures that the steel plate matches the required design specifications.

Once the steel plates are cut and bent, they are assembled or welded together. This can involve joining multiple plates to form a larger structure or attaching additional components such as brackets or reinforcements. Welding is the most common method used for joining steel plates, and it requires skilled operators who can use techniques like arc welding or gas welding to ensure strong and reliable connections.

Finally, the fabricated steel plates are subjected to finishing processes. This may involve grinding, sanding, or polishing the surfaces to enhance their appearance and remove any sharp edges or imperfections. Additionally, surface treatments like painting or galvanizing may be applied to provide corrosion resistance and improve longevity.

To utilize steel plate fabrication effectively, it is crucial to have a clear understanding of the desired product design and specifications. Accurate measurements and proper planning are essential to ensure that the fabrication process meets the intended requirements. Working with experienced fabricators who have expertise in steel plate fabrication is also beneficial, as they can provide technical guidance and advice throughout the process.

In summary, steel plate fabrication involves cutting, bending, shaping, and assembling steel plates to create a final product or component. By selecting the appropriate materials and employing various manufacturing techniques, steel plates can be transformed into structures that meet specific design and performance criteria. Proper planning, measurement, and collaboration with skilled fabricators are key to achieving successful steel plate fabrication projects.

Quality Testing Methods for steel plate fabrication and how to control the quality

Quality testing methods for steel plate fabrication involve various techniques to ensure that the fabricated steel plates meet the required quality standards. Some of the commonly used methods include:

1. Visual Inspection: A visual examination is performed to check for any surface defects, such as cracks, scratches, or stains on the steel plates.

2. Dimensional Inspection: This method includes verifying the dimensions and tolerances of the steel plates against the specified requirements using measuring tools like calipers, micrometers, or laser scanners.

3. Non-Destructive Testing (NDT): NDT techniques are employed to evaluate the structural integrity of the steel plates without causing any damage. Popular NDT methods include ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing.

4. Mechanical Testing: Mechanical properties, such as tensile strength, yield strength, elongation, and hardness, are tested to ensure that the steel plates have the desired strength and ductility. This can be done using universal testing machines or hardness testers.

5. Chemical Analysis: Steel plates are analyzed for their chemical composition to verify if it meets the specified limits. This is essential to ensure that the steel possesses the required corrosion resistance, weldability, and other mechanical properties.

To control the quality of steel plate fabrication, various measures can be taken:

1. Define clear quality standards and specifications, including dimension, tolerance, surface finish, mechanical properties, and chemical composition.

2. Implement regular inspection and testing procedures at different stages of fabrication, including receiving the raw materials, during processing, and before the final delivery.

3. Conduct periodic training programs for the workforce to enhance their understanding of quality requirements and the importance of maintaining quality standards.

4. Establish proper documentation and record-keeping systems to capture the inspection and testing results, non-conformities, and corrective actions taken.

5. Continuously monitor and review the quality performance through internal audits, customer feedback, and benchmarking against industry standards.

6. Implement a robust quality control system, such as ISO 9001 or other relevant standards, to ensure consistent quality and continual improvement of the fabrication process.

By employing these testing methods and control measures, steel plate fabrication companies can ensure that the produced plates meet the required quality standards, providing safe and reliable products to their customers.

steel plate fabrication Sample Policy and Post-Purchase Considerations for steel plate fabrication from China

At [Company Name], our steel plate fabrication processes are carried out with utmost precision, ensuring the highest quality standards. We source our materials from trusted suppliers in China, known for their expertise in steel manufacturing. To ensure a smooth purchasing experience, we have outlined our sample policy and post-purchase considerations below:

Sample Policy:

1. We offer free samples of our steel plates to potential buyers, allowing them to assess the quality and suitability for their specific requirements.

2. Shipping charges for samples are borne by the buyer.

3. Samples are dispatched within 3-5 working days upon request.

4. Samples are sent via reliable courier services, and the buyer will be provided with the tracking details.

Post-Purchase Considerations:

1. Upon placing an order, we provide detailed specifications and drawings for approval to ensure accuracy and conformance to the buyer’s requirements.

2. Our team of experts closely monitors the manufacturing process, maintaining regular communication with our Chinese partners, to ensure efficiency and adhere to the agreed-upon timelines.

3. Quality control checks are conducted at every stage of fabrication to ensure that the end product meets the required standards.

4. We facilitate third-party inspections upon request to provide additional assurance to our customers.

5. Packaging is done in a secure manner to prevent any damage during transportation. We take responsibility for any damage that may occur during shipping, and replacements will be provided as needed.

6. Our customer support team is readily available to address any concerns or queries after the purchase. We aim to provide prompt and satisfactory solutions to ensure customer satisfaction.

[Company Name] strives to build long-term relationships with our clients, and we are committed to providing top-notch products and services. With our extensive experience in steel plate fabrication and our reliable partners in China, we assure you of a seamless and reliable purchasing process.Sourcing steel plate fabrication from China: Opportunities, Risks, and Key Players

Sourcing steel plate fabrication from China offers several opportunities for businesses worldwide. China is known for its large-scale steel production capabilities, which often results in cost-effective pricing for steel plate fabrication. The country’s advanced manufacturing infrastructure and technology also ensure high-quality products. Additionally, China has a vast network of steel plate fabrication suppliers, allowing businesses to find a wide range of options for their specific needs.

However, sourcing from China also comes with certain risks. One of the main concerns is quality control. While China has made significant progress in improving product quality, there are still instances of substandard products. It is crucial to conduct thorough due diligence and quality checks to ensure the supplier meets international standards. Communication and cultural differences can also pose challenges during the negotiation and production process, which should be managed effectively. Intellectual property protection is another risk, as China has a history of intellectual property infringement. Businesses should take appropriate measures to protect their designs and technological know-how.

Several key players dominate the steel plate fabrication market in China. Some of the prominent companies include Nippon Steel Corporation, Baosteel Group Corporation, and Posco. These companies offer a wide range of steel plate fabrication services, including cutting, bending, welding, and surface treatment. They have extensive experience and expertise in serving diverse industries such as construction, automotive, energy, and shipbuilding. However, there are also numerous smaller and specialized manufacturers that cater to specific requirements, offering customization options.

In conclusion, sourcing steel plate fabrication from China provides opportunities for cost-effectiveness, high-quality products, and a wide range of options. However, businesses should carefully consider and manage the risks associated with quality control, communication, cultural differences, and intellectual property protection. Conducting thorough due diligence and working with reputable suppliers are essential for a successful sourcing experience.

How to find and select reliable steel plate fabrication manufacturers in China,use google search manufacturers and suppliers

Finding and selecting reliable steel plate fabrication manufacturers in China can be a daunting task, but using Google search along with some key strategies can help simplify the process. Here are some steps to follow:

1. Begin with a Google search: Use relevant keywords like “steel plate fabrication manufacturers in China” to initiate your search. This will provide you with a list of potential manufacturers and suppliers.

2. Narrow down the options: Go through the search results and visit the websites of different manufacturers. Look for experience, certifications, and company profile to assess their credibility. Evaluate their range of services and capabilities.

3. Check customer reviews and ratings: Look for customer feedback or reviews on the manufacturer’s website or other trusted platforms like Google Reviews. This will give you insights into their reputation and the experiences of previous customers.

4. Assess quality control measures: Reliable manufacturers should have stringent quality control measures in place to ensure the production of high-quality steel plates. Look for information about their quality control processes, certifications (such as ISO 9001), and any quality assurance guarantees.

5. Consider experience and expertise: Look for manufacturers with a proven track record and extensive experience in steel plate fabrication. Assess their expertise in handling various types of steel and their ability to meet specific requirements.

6. Request samples and certifications: Once you shortlist a few potential manufacturers, request samples to assess the quality of their products. Additionally, ask for relevant certifications such as material test certificates (MTCs) to ensure compliance with industry standards.

7. Communication and responsiveness: Contact the shortlisted manufacturers and observe their communication style and responsiveness. A reliable manufacturer should be prompt, responsive, and open to answering any queries or concerns.

8. Consider trade shows and exhibitions: Participating in industry-related trade shows or exhibitions in China can provide an opportunity to meet and personally evaluate potential manufacturers. This allows you to observe their products, facilities, and engage in face-to-face discussions.

Remember, due diligence is vital when selecting a reliable steel plate fabrication manufacturer in China. Thoroughly research each potential manufacturer, verify their credibility, and assess their capabilities before making a final decision.

How to check steel plate fabrication manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of a steel plate fabrication manufacturer’s website, you can follow these steps using Google Chrome and the SEOquake extension within a limited 300 word count:

1. Install SEOquake: Download and install the SEOquake extension for Google Chrome from the Chrome Web Store.

2. Search for the manufacturer: Open Google Chrome and enter the name of the steel plate fabrication manufacturer in the search bar.

3. Analyze search results: SEOquake provides an SEO analysis of each search result. Look for the website of the manufacturer in the top 10 million (10M) results, indicated by the “Rank” column in the SEOquake pop-up. Sites ranked within the top 10M are generally more reliable as they have higher visibility.

4. Visit the manufacturer’s website: Click on the website link and open it in a new tab.

5. Evaluate the website: Once you land on the manufacturer’s website, assess its reliability using the following criteria within 300 words:

– Design and user experience: A well-designed website with an intuitive user interface can indicate a reputable manufacturer. Check if the website is easy to navigate and visually appealing.

– Content quality: Verify if the website provides detailed and accurate information about their steel plate fabrication services, including specifications, certifications, and any relevant industry affiliations or partnerships.

– Contact information: Legitimate manufacturers typically provide multiple ways to contact them, such as phone numbers, email addresses, and physical addresses. Ensure this information is visible and easily accessible.

– Portfolio and testimonials: Look for a portfolio of past projects and customer testimonials on the website. This can provide insights into the manufacturer’s experience, capabilities, and client satisfaction.

– Certifications and compliance: Consider if the manufacturer displays certifications or compliance with industry standards on their website. This demonstrates their commitment to quality and adherence to regulations.

By using SEOquake to check the manufacturer’s website ranking in the top 10M search results and evaluating the website design, content quality, contact information, portfolio, testimonials, and certifications, you can assess the reliability of the steel plate fabrication manufacturer’s website.

Top 10 steel plate fabrication manufacturers in China with each 160 words introduce products,then use markdown create table compare

Top 10 Steel Plate Fabrication Manufacturers in China

1. Baosteel Group Corporation:

Baosteel Group is one of the largest steel plate fabrication manufacturers in China. They offer a wide range of steel plates, including hot-rolled, cold-rolled, galvanized, and wear-resistant plates. These plates are used in various industries such as construction, automotive, and machinery manufacturing.

2. Hesteel Group:

Hesteel Group is known for its high-quality steel plates, which are available in different grades and thicknesses. Their products find applications in shipbuilding, bridge construction, and oil and gas pipelines. Hesteel Group focuses on delivering superior performance and durability.

3. Shougang Group:

Shougang Group specializes in the production of medium and heavy plates. Their steel plates are widely used in manufacturing heavy machinery, mining equipment, and construction materials. Shougang Group boasts advanced manufacturing facilities and emphasizes product quality control.

4. Wuhan Iron and Steel Group Corporation (WISCO):

WISCO is a leading steel plate manufacturer in China, offering a comprehensive range of plates for various applications. Their products are widely used in the automotive industry, engineering machinery, and energy equipment manufacturing. WISCO is renowned for its technologically advanced steel products.

5. Ansteel Group Corporation:

Ansteel Group is a prominent manufacturer of steel plates, focusing on high-strength structural steel products. They provide customers with a wide range of options, including carbon structural steel plates, low-alloy structural steel plates, and pressure vessel steel plates.

6. Magang Group Holding Co., Ltd. (MaSteel):

MaSteel is a leading steel plate fabrication manufacturer in China. They specialize in producing high-quality steel plates, including weather-resistant plates, heat-resistant plates, and wear-resistant plates. MaSteel’s products are widely used in construction, machinery manufacturing, and transportation industries.

7. Jinxi Iron and Steel Group:

Jinxi Iron and Steel Group is known for its specialized steel plate manufacturing capabilities. They offer a diverse range of steel plates, including carbon structural steel plates, alloy structural steel plates, and bridge construction plates. Jinxi Iron and Steel Group prioritizes customer satisfaction and product quality.

8. China Baowu Steel Group Corporation Limited:

Baowu Steel Group is one of the largest steel manufacturers in China, providing a wide range of steel plates for multiple industries. Their products are known for their superior quality, high strength, and excellent corrosion resistance.

9. Shandong Iron and Steel Group Co., Ltd. (Shandong Steel):

Shandong Steel specializes in manufacturing high-quality steel plates, including carbon structural steel plates, shipbuilding steel plates, and pressure vessel steel plates. They focus on delivering reliable and durable products that meet customer requirements.

10. Jiangsu Shagang Group Company Ltd:

Jiangsu Shagang Group is a leading steel plate manufacturer, offering a wide range of high-quality steel plates. Their products are extensively used in construction, automotive manufacturing, and machinery industries. Jiangsu Shagang Group is committed to providing innovative solutions and excellent customer service.

| Manufacturer | Notable Products | Applications |

|—————-|——————|————–|

| Baosteel Group Corporation | Hot-rolled, cold-rolled, galvanized, and wear-resistant plates | Construction, automotive, and machinery manufacturing |

| Hesteel Group | High-quality steel plates in different grades and thicknesses | Shipbuilding, bridge construction, and oil and gas pipelines |

| Shougang Group | Medium and heavy plates | Heavy machinery, mining equipment, and construction materials |

| Wuhan Iron and Steel Group Corporation (WISCO) | Comprehensive range of plates for various applications | Automotive industry, engineering machinery, and energy equipment manufacturing |

| Ansteel Group Corporation | High-strength structural steel plates | Carbon structural steel plates, low-alloy structural steel plates, and pressure vessel steel plates |

| Magang Group Holding Co., Ltd. (MaSteel) | Weather-resistant plates, heat-resistant plates, and wear-resistant plates | Construction, machinery manufacturing, and transportation industries |

| Jinxi Iron and Steel Group | Carbon structural steel plates, alloy structural steel plates, and bridge construction plates | Various construction and manufacturing applications |

| China Baowu Steel Group Corporation Limited | Various steel plates with superior quality and high strength | Multiple industries and applications |

| Shandong Iron and Steel Group Co., Ltd. (Shandong Steel) | Carbon structural steel plates, shipbuilding steel plates, and pressure vessel steel plates | Wide range of industries and applications |

| Jiangsu Shagang Group Company Ltd | High-quality steel plates | Construction, automotive manufacturing, and machinery industries |

These top 10 steel plate fabrication manufacturers in China offer a diverse range of products suitable for various industries. Their commitment to superior quality, advanced technology, and customer satisfaction has made them leaders in the steel manufacturing industry.

Background Research for steel plate fabrication manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to steel plate fabrication, China is known as one of the largest manufacturers in the world. To conduct background research on companies in this industry, three prominent platforms can be utilized: qcc.com, archive.org, and importyeti.com.

1. QCC.com (企查查): This is a comprehensive business information platform in China that provides data on companies, including their registered information, financial status, industry classification, shareholder information, and more. By searching for steel plate fabrication manufacturers on qcc.com, one can access essential background details about the companies, such as their legal status, capital structure, and business scope.

2. Archive.org: Using the Internet Archive’s Wayback Machine feature, found at archive.org, one can access historical snapshots of company websites. This allows researchers to track the evolution of a company’s online presence, including changes in services offered, certifications obtained, collaboration history, and other relevant information. By analyzing archived versions of steel plate fabrication manufacturers’ websites, researchers can gain insights into the company’s development over time.

3. Importyeti.com: This is an online directory and search engine that focuses on connecting buyers with suppliers in China. By searching for steel plate fabrication manufacturers on Importyeti.com, researchers can access data such as company profiles, product descriptions, export history, and trading activities. This information can provide a comprehensive overview of a company’s production capacity, product range, and international presence.

By utilizing these platforms, researchers can extensively study steel plate fabrication manufacturers in China. They can gain insights into a company’s background, financial standing, historical development, and international trading activities. These resources can aid in making informed decisions when selecting potential partners or suppliers in the steel plate fabrication industry.

Leveraging Trade Shows and Expos for steel plate fabrication Sourcing in China

Trade shows and expos are valuable platforms for sourcing steel plate fabrication in China. These events bring together manufacturers, suppliers, and buyers, enabling them to establish connections and explore potential business opportunities. By leveraging such trade shows and expos, businesses looking to source steel plate fabrication in China can access a wide range of suppliers and assess their capabilities, quality, and pricing.

Participating in trade shows and expos allows businesses to interact directly with suppliers, facilitating face-to-face communication, and building relationships. This personal interaction provides an opportunity to ask detailed questions, negotiate terms, and gain a better understanding of the supplier’s capabilities and processes. Additionally, it enables buyers to evaluate the quality of the steel plates, ensuring they meet the required specifications and standards.

Trade shows and expos also provide a platform for businesses to compare different suppliers and their offerings. With numerous companies exhibiting their products and services under one roof, buyers can assess and compare various options, their pricing, and additional value-added services. This helps in making informed decisions and finding the most suitable supplier for their steel plate fabrication needs.

Furthermore, trade shows and expos often feature seminars, workshops, and demonstrations from industry experts. These educational sessions allow businesses to gain knowledge about the latest trends, technologies, and innovations in steel plate fabrication. By staying updated with the industry, buyers can make informed decisions, assess the potential of new techniques, and choose suppliers that incorporate advanced manufacturing processes.

In conclusion, trade shows and expos provide businesses with a unique opportunity to source steel plate fabrication in China. By participating in these events, buyers can establish connections, evaluate suppliers, compare options, and stay updated with the latest industry trends. This proactive approach can help businesses find reliable suppliers that meet their specific requirements and ensure the quality of their steel plate fabrication.

The Role of Agents and Sourcing Companies in Facilitating steel plate fabrication Purchases from China

Agents and sourcing companies play a vital role in facilitating steel plate fabrication purchases from China. With their expertise and local knowledge, they bridge the gap between international buyers and Chinese suppliers, enabling a smooth and efficient procurement process.

One of the key responsibilities of agents and sourcing companies is to identify reputable and reliable steel plate fabricators in China. They have an extensive network and conduct thorough research to find manufacturers with the required certifications, production capabilities, and quality standards. By vetting potential suppliers, they ensure that buyers receive products that meet their specifications and industry requirements.

Moreover, agents and sourcing companies facilitate communication between buyers and Chinese suppliers. Language and cultural barriers can often hinder effective communication, leading to misunderstandings and delays. These intermediaries act as translators and negotiators, ensuring clear and accurate communication between both parties. They help buyers convey their requirements and preferences to the suppliers and provide feedback on samples or prototypes, minimizing the risk of miscommunication and defective products.

Agents and sourcing companies also assist in the sourcing and negotiation of pricing and terms. They have extensive market knowledge and experience in negotiating with Chinese suppliers, which helps to obtain the best possible pricing and terms for the buyers. They can leverage their networks to compare quotes from multiple suppliers, ensuring competitive pricing and favorable conditions.

Furthermore, agents and sourcing companies provide quality control and inspection services during the manufacturing process. They conduct regular factory visits to monitor production progress, inspect the quality of materials and workmanship, and ensure adherence to agreed-upon specifications. This reduces the risk of substandard products or counterfeit materials, ensuring that buyers receive high-quality steel plates.

In summary, the role of agents and sourcing companies in facilitating steel plate fabrication purchases from China is crucial. They assist buyers in finding reliable suppliers, enabling effective communication, negotiating favorable terms, and ensuring quality control throughout the manufacturing process. Their expertise and local knowledge contribute to a seamless procurement experience, fostering successful business partnerships between international buyers and Chinese suppliers.

Price Cost Research for steel plate fabrication manufacturers Companies in China, use temu.com and 1688.com

When it comes to steel plate fabrication manufacturers in China, two popular platforms for price cost research are temu.com and 1688.com. These platforms offer a wide range of options for buyers to connect with reputable manufacturers and source products at competitive prices.

Temu.com, also known as “Made-in-China.com,” is a global business-to-business (B2B) platform that connects buyers and suppliers from various industries. It provides a comprehensive database of steel plate fabrication manufacturers in China. By utilizing the search filters on the website, buyers can narrow down their options based on location, product specifications, and certifications. The platform also allows buyers to directly contact manufacturers, request for quotations, and negotiate prices. Temu.com is widely recognized for its user-friendly interface and extensive supplier verification process.

On the other hand, 1688.com, owned by Alibaba Group, is the largest wholesale marketplace in China. Although the website is primarily in Mandarin, it offers an extensive range of steel plate fabrication manufacturers at competitive prices. Buyers can utilize its advanced search options to find manufacturers based on their specific requirements. 1688.com provides detailed product information, including specifications, prices, and minimum order quantities. However, it is important to note that buyers may need the assistance of a Chinese translator or sourcing agent for effective communication on this platform.

For price cost research on temu.com and 1688.com, it is crucial to analyze multiple manufacturers and compare their pricing, quality, and lead times. Buyers should consider factors such as production capacity, manufacturing capabilities, and customer reviews. Additionally, it is advisable to engage in communication with the shortlisted manufacturers to gather more information and negotiate prices based on volume and product customization.

In conclusion, temu.com and 1688.com are valuable platforms for conducting price cost research on steel plate fabrication manufacturers in China. Through these platforms, buyers can connect with reputable suppliers, review product details, and negotiate competitive prices. By carefully evaluating manufacturers and their offers, buyers can source high-quality steel plate fabrication products at favorable prices.

Shipping Cost for steel plate fabrication import from China

The shipping cost for steel plate fabrication imports from China can vary depending on various factors such as the weight and dimensions of the shipment, the shipping method chosen, and the destination. Generally, there are two main shipping methods – sea freight and air freight.

Sea freight is typically the more cost-effective option for heavy and bulky shipments like steel plates. The cost is usually calculated based on the volume or weight of the shipment and the distance to the destination port. Additional charges may include customs clearance fees, port handling fees, and insurance costs. It is important to consider that sea freight has a longer transit time compared to air freight.

On the other hand, air freight provides faster transit times but is more expensive. The cost is usually calculated based on the weight of the shipment and the destination airport. Additional charges may include handling fees and customs clearance fees.

To estimate the shipping cost, it is recommended to contact shipping companies or freight forwarders, providing them with the necessary details such as the weight and dimensions of the steel plates, the pickup location in China, and the destination port or airport. They will be able to provide a more accurate quote based on these details and the current freight rates.

It is important to mention that shipping costs may be subject to fluctuations due to factors like fuel prices, exchange rates, and any additional services required. Therefore, it is advisable to request quotes from multiple shipping providers and compare their prices and services to ensure the best shipping cost for your steel plate fabrication imports from China.

Compare China and Other steel plate fabrication Markets: Products Quality and Price,Visible and Hidden Costs

China is known as one of the largest steel plate fabrication markets globally, offering a wide range of products in terms of quality and price. However, it is essential to compare China’s market with other steel plate fabrication markets to understand the differences in product quality, pricing, and visible and hidden costs.

In terms of product quality, China has been criticized for producing low-cost, mass-produced items that may not meet international quality standards. While it is true that China offers a vast array of products, the quality can vary significantly. Some manufacturers prioritize quantity over quality, resulting in products that may be prone to defects or have shorter lifespans. On the other hand, other steel plate fabrication markets, such as Germany or Japan, are renowned for their exceptional product quality, precision, and durability. These markets often have stricter quality control measures, ensuring that the products meet the highest standards.

When it comes to pricing, China often offers competitive prices due to its low labor and production costs. This advantage makes Chinese steel plate fabrication products more affordable compared to those from other markets. However, it is essential to consider visible and hidden costs. Visible costs include product price, packaging, and shipping expenses, which may still make Chinese products more economically viable. However, hidden costs can arise from quality issues, such as product failures or recalls, which can lead to additional expenses for repairs, replacements, or potential legal implications. Other steel plate fabrication markets may have higher initial product prices, but their superior quality often translates into reduced hidden costs in the long run.

In summary, China’s steel plate fabrication market offers a wide range of products with varying quality levels and competitive pricing. However, it is crucial to consider potential hidden costs associated with lower-quality products. Other markets, such as Germany or Japan, may provide higher-quality products with higher initial prices but lower hidden costs. Ultimately, the choice between China and other markets depends on the specific requirements, budget, and long-term considerations of the buyer.

Understanding Pricing and Payment Terms for steel plate fabrication: A Comparative Guide to Get the Best Deal

Pricing and payment terms for steel plate fabrication can vary greatly depending on the company, project specifications, market conditions, and other factors. To ensure you get the best deal, it is crucial to have a comparative approach and consider multiple factors before finalizing your decision.

When it comes to pricing, it is recommended to obtain quotes from multiple fabricators. This allows you to compare prices and negotiate if needed. However, it is important to remember that the lowest price does not always guarantee the best value. Factors such as quality, delivery time, and customer service should also be taken into account.

Fabricators commonly base pricing on factors such as the type and grade of steel required, the thickness and dimensions of the plates, and the complexity of the fabrication process. Additional factors like finishing, surface treatment, and any required testing or certification can also influence pricing. It is essential to clearly communicate your project requirements to the fabricators to ensure accurate quotes.

Payment terms can also vary among fabricators. Common options include upfront payment, progress payments, or payment upon completion. It is advisable to discuss payment terms and negotiate a mutually agreed-upon schedule before starting the project. Consider the financial stability and reputation of the fabricator when determining your comfort level with their proposed payment terms.

Other important considerations include lead times, shipping costs, and any associated taxes or duties. Some fabricators offer volume-based discounts, so it is worth discussing this possibility if your project requires a significant quantity of steel plates.

Finally, it is crucial to have a written agreement or contract that outlines all the agreed-upon terms, including pricing, payment terms, project specifications, and delivery schedule. This helps avoid misunderstandings and ensures everyone is on the same page.

To summarize, understanding pricing and payment terms for steel plate fabrication involves obtaining multiple quotes, comparing factors beyond price alone, negotiating payment terms, considering additional project requirements, and having a clearly defined agreement. By following this comparative guide, you can increase your chances of getting the best deal for your steel plate fabrication needs.

Chinese Regulations and Industry Standards Certifications for steel plate fabrication,Import Regulations and Customs for steel plate fabrication from China

Chinese Regulations and Industry Standards Certifications for steel plate fabrication play a crucial role in ensuring the quality and safety of steel products. Various certifications and regulations are in place to protect both the domestic and international markets.

One of the essential certifications is the China Compulsory Certification (CCC), which is required for certain products, including steel plates, before they can be sold in the Chinese market. This certification ensures that the product meets the necessary safety and quality standards set by the Chinese government.

In addition to CCC, there are several industry standards certifications that steel plate fabrication companies can obtain to demonstrate their compliance with specific quality requirements. These include the ISO 9001 certification for quality management systems, the ISO 14001 certification for environmental management systems, and the OHSAS 18001 certification for occupational health and safety management systems.

Importing steel plate fabrication products from China involves compliance with import regulations and customs procedures. Importers need to be aware of the regulations enforced by their respective countries to avoid any legal issues or delays in the import process. These regulations may include requirements for product quality, safety, and labeling.

Importers should also be familiar with customs procedures, including documentation requirements, duty rates, and import restrictions. It is crucial to work with a reputable customs broker or freight forwarder experienced in handling steel plate fabrication imports from China to ensure a smooth customs clearance process.

In conclusion, Chinese Regulations and Industry Standards Certifications for steel plate fabrication are essential for ensuring the quality and safety of steel products. Importers should understand and comply with import regulations and customs procedures to successfully import steel plate fabrication products from China.

Sustainability and Environmental Considerations in steel plate fabrication Manufacturing

Sustainability and environmental considerations have become increasingly important in all industries, including steel plate fabrication manufacturing. As the demand for steel products continues to rise, it is crucial for manufacturers to minimize their environmental impact and adopt sustainable practices throughout the production process.

One key aspect of sustainability in steel plate fabrication is the responsible sourcing of raw materials. Steel is primarily made from iron ore, which is a non-renewable resource. To promote sustainability, manufacturers should prioritize the use of recycled steel and scrap metal. This reduces the need for mining, conserves natural resources, and decreases energy consumption.

Another crucial consideration is energy efficiency. Steel production is energy-intensive, and reducing energy consumption helps lower greenhouse gas emissions and minimize the carbon footprint. Manufacturers should implement energy-efficient technologies and practices, such as optimizing manufacturing processes, using energy-efficient equipment, and utilizing renewable energy sources wherever possible.

Waste management is also a critical aspect of sustainability in steel plate fabrication. To minimize waste, manufacturers can implement recycling programs for scrap metal and properly dispose of hazardous materials. Additionally, they should explore ways to reduce material waste during the fabrication process, such as optimizing cutting and nesting methods.

Water conservation is another important consideration in steel plate fabrication. Manufacturers should strive to minimize water usage through recycling and implementing water management systems. By reducing water consumption, they can help conserve this valuable resource and minimize their environmental impact.

Furthermore, manufacturers can implement sustainable transportation practices to reduce emissions associated with the movement of raw materials and finished products. Utilizing efficient transportation methods, optimizing shipment routes, and using low-emission vehicles can all contribute to a more sustainable supply chain.

Lastly, manufacturers should prioritize the health and safety of their employees by implementing proper safety protocols and providing a safe working environment. This includes providing personal protective equipment, regular training, and monitoring air quality within the manufacturing facilities.

In conclusion, sustainability and environmental considerations in steel plate fabrication manufacturing are crucial for reducing the industry’s environmental impact. Responsible sourcing, energy efficiency, waste management, water conservation, sustainable transportation, and employee safety are all key factors to consider when striving towards a more sustainable and environmentally friendly manufacturing process.

List The Evolution history of “steel plate fabrication”

Steel plate fabrication has evolved significantly throughout history, revolutionizing various industries and advancing engineering techniques. From its early beginnings to modern times, here is a brief overview of the evolution of steel plate fabrication:

1. Ancient Times: The earliest forms of steel plate fabrication date back to ancient civilizations, particularly the Iron Age. Smiths in areas such as Mesopotamia, Egypt, and the Mediterranean began forging basic steel plates for weapons, tools, and armor.

2. Industrial Revolution: The Industrial Revolution in the 18th and 19th centuries marked a turning point in steel plate fabrication. The development of steam-powered machinery and the Bessemer process, a technique for mass-producing steel, led to increased production efficiency and availability.

3. Shipbuilding & Infrastructure: Steel plate fabrication gained prominence during the late 19th and early 20th centuries in shipbuilding and infrastructure projects. Steel plates became the primary material for constructing steamships, bridges, railways, and buildings due to their strength, durability, and flexibility.

4. World Wars: The demand for steel plate fabrication skyrocketed during World War I and World War II as it became a vital resource for armament manufacturing. The construction of battleships, tanks, and aircraft carriers relied heavily on steel plates fabricated to precise specifications.

5. Modern Techniques: The advent of advanced technologies in the 20th century revolutionized steel plate fabrication. Computer-aided design (CAD) software enabled precise modeling and engineering calculations, streamlining the fabrication process. CNC (Computer Numerical Control) machinery further improved accuracy and efficiency in cutting, bending, and welding steel plates.

6. Specialized Applications: Steel plate fabrication now caters to diverse industries, including aerospace, automotive, energy, and construction. The development of specialized alloys and coatings enhances specific characteristics, such as corrosion resistance, heat resistance, or high strength, to meet unique project requirements.

7. Automation and Robotics: In recent decades, automation and robotics have become integral to steel plate fabrication processes. Robotic arms, laser-cutting systems, and programmable machines have significantly improved precision, speed, and repeatability in fabrication, reducing manual labor and increasing productivity.

8. Sustainable Practices: The evolution of steel plate fabrication is closely tied to sustainability efforts. Recycling and reusing steel scrap have become common practices, reducing the environmental impact of production. Additionally, advancements in energy-efficient machinery and eco-friendly coatings contribute to a greener fabrication process.

The evolution of steel plate fabrication reflects the continuous advancement of industrial, engineering, and technological practices. From ancient blacksmithing to today’s automated robotic systems, this fabrication method remains essential for the production of critical structures and components.

The Evolution and Market Trends in steel plate fabrication Industry

The steel plate fabrication industry has undergone significant evolution and has been influenced by various market trends over the years. These trends have resulted in changes in the way steel plates are fabricated, as well as the demands of the market.

One of the key trends in the evolution of the steel plate fabrication industry is the advancement of technology. Technological advancements, such as computer-aided design and manufacturing (CAD/CAM), have revolutionized the fabrication process. These technologies have made it easier to design complex structures and streamline the production process, leading to increased efficiency and improved product quality.

Another trend that has shaped the steel plate fabrication industry is the focus on sustainability and environmental considerations. With increasing concerns over global warming and carbon emissions, there has been a growing demand for eco-friendly practices in the steel industry. As a result, fabricators have been adopting greener methods, such as using recycled steel and implementing energy-efficient processes, to reduce their environmental impact.

Additionally, the market trends in various sectors have influenced the steel plate fabrication industry. For example, the construction industry plays a significant role in driving the demand for steel plates. As the construction sector continues to expand globally, there is a growing need for steel plate fabricators to meet the requirements of infrastructure projects. This has led to increased competition among fabricators to provide high-quality products and services at competitive prices.

Furthermore, the offshore oil and gas industry has also had a significant impact on the evolution of the steel plate fabrication industry. The demand for specialized steel plates, such as those used in offshore platforms and pipelines, has increased as exploration and production activities move into deeper waters. Fabricators have had to adapt to the specific requirements of this sector, including stringent quality standards and certifications.

In conclusion, the steel plate fabrication industry has witnessed significant evolution and has been shaped by various market trends. The advancement of technology, increasing focus on sustainability, and the demands of sectors such as construction and offshore oil and gas have all played a role in shaping the industry. Fabricators who can adapt to these trends and provide innovative solutions will be well-positioned to succeed in a competitive marketplace.

Custom Private Labeling and Branding Opportunities with Chinese steel plate fabrication Manufacturers

– Custom private labeling and branding opportunities with Chinese steel plate fabrication manufacturers provide businesses with the chance to establish their unique identity and stand out in the market.

– By partnering with reputable manufacturers in China, businesses can take advantage of their expertise and cost-effective production capabilities to create quality steel plate products that bear their brand name and logo.

– Private labeling offers the advantage of exclusivity, allowing businesses to differentiate their products from competitors and enhance brand recognition.

– Chinese manufacturers are highly experienced in providing custom manufacturing solutions, meaning they can produce steel plates to specific size, shape, and design requirements. This enables businesses to create products tailored to their customers’ needs.

– The manufacturing process typically includes customization options such as surface treatments, finishes, and packaging design. This allows businesses to create a unique product line that resonates with their target market.

– Partnering with Chinese manufacturers also offers businesses the benefit of cost-effectiveness. China has a highly developed steel fabrication industry and is known for its competitive pricing. This allows businesses to achieve higher profit margins while offering quality products at competitive prices.

– Furthermore, Chinese manufacturers often have extensive supply chains and can source raw materials efficiently. This ensures a consistent supply of steel plates, minimizing disruptions to business operations.

– It is important for businesses to conduct thorough due diligence when selecting a Chinese manufacturer for private labeling and branding opportunities. Ensuring that the manufacturer follows quality standards, possesses the necessary certifications, and has a track record of reliability is crucial for a successful partnership.

– With the right Chinese steel plate fabrication manufacturer, businesses can establish their brand identity, offer customized products, benefit from cost-effectiveness, and gain a competitive edge in the market.

Tips for Procurement and Considerations when Purchasing steel plate fabrication

When it comes to purchasing steel plate fabrication, there are several considerations and tips that can help ensure a successful procurement process. Here are some key factors to keep in mind:

1. Specifications and requirements: Clearly define the specifications and requirements of the steel plate fabrication you need. This includes factors like size, thickness, material grade, and any specific tolerances or certifications required.

2. Quality assurance: Ensure that the supplier has a robust quality assurance system in place. This can be done by requesting documentation of their quality control processes, certifications, and past performance records.

3. Supplier evaluation: Conduct a thorough evaluation of potential suppliers. Consider their experience, reputation, financial stability, and capacity to meet your requirements in terms of quantity and delivery schedule.

4. Pricing and cost analysis: Obtain quotes from multiple suppliers and perform a cost analysis. Consider not only the initial purchase price but also any additional costs such as transportation, taxes, or import duties.

5. Material traceability: Verify that the supplier can provide material traceability documentation. This is important to ensure that the steel used in the fabrication meets required standards and specifications.

6. Communication and project management: Maintain open and regular communication with the supplier throughout the procurement process. Clearly communicate your expectations and delivery requirements to avoid any potential misunderstandings.

7. Contract terms and conditions: Carefully review and negotiate contract terms and conditions. Pay attention to clauses related to payment terms, delivery schedule, warranties, and dispute resolution mechanisms.

8. Supplier relationship management: Establish a good working relationship with the chosen supplier. Regularly assess their performance, provide feedback, and address any issues promptly.

9. Environmental considerations: Consider the environmental impact of the steel fabrication process. Choose suppliers that have environmentally friendly practices and certifications, such as ISO 14001.

10. Ongoing support: Assess whether the supplier offers ongoing support, such as technical assistance or post-sales services.

By considering these factors and following these tips, you can ensure a smooth procurement process for steel plate fabrication and increase the chances of obtaining a high-quality product that meets your requirements.

FAQs on Sourcing and Manufacturing steel plate fabrication in China

Q: Can I source steel plate fabrication from China?

A: Yes, China is a major producer and exporter of steel plate fabrication. They have a well-established manufacturing industry and offer competitive pricing compared to other countries.

Q: How can I find reliable suppliers in China?

A: There are several ways to find reliable suppliers in China. One option is to attend trade shows and exhibitions related to steel plate fabrication, where you can meet potential suppliers and assess their capabilities. Another option is to use online platforms and marketplaces that connect buyers with suppliers in China. It is important to conduct thorough research, check their certifications, and verify their production capabilities before engaging in business.

Q: What is the quality of steel plate fabrication from China?

A: The quality of steel plate fabrication from China can vary depending on the supplier. It is essential to conduct proper due diligence and select a supplier with established quality control processes. Many Chinese manufacturers have achieved international quality certifications such as ISO 9001, ensuring consistent quality standards.

Q: What is the typical pricing for steel plate fabrication in China?

A: Pricing for steel plate fabrication in China is generally more competitive compared to other countries. It is important to obtain quotes from multiple suppliers and negotiate pricing based on volume, complexity of the project, and customization requirements.

Q: How long does it take to manufacture steel plate fabrication in China?

A: The manufacturing lead time for steel plate fabrication in China can vary depending on the complexity of the project and the workload of the supplier. Typically, it can take a few weeks to a couple of months to complete the manufacturing process, including processing, fabrication, and finishing.

Q: Are there any import regulations or customs duties when sourcing steel plate fabrication from China?

A: Yes, there are import regulations and customs duties when sourcing steel plate fabrication from China. It is crucial to comply with the regulations of your country and ensure proper documentation for customs clearance. Consulting with a reputable freight forwarder or customs agent can help navigate through these requirements.

In conclusion, sourcing steel plate fabrication from China offers a cost-effective option, but due diligence in selecting reliable suppliers and ensuring quality is crucial. Understanding the import regulations and communicating clearly with the suppliers will help in a smooth sourcing process.

Why contact sourcifychina.com get free quota from reliable steel plate fabrication suppliers?

Sourcifychina.com offers a unique service where they provide free quotas from reliable steel plate fabrication suppliers. This service is beneficial for several reasons.

Firstly, Sourcifychina.com has established long-term relationships with various reputable steel plate fabrication suppliers in China. These relationships have been built on trust and mutual understanding, ensuring that the suppliers are reliable and provide quality products and services. By leveraging these relationships, Sourcifychina.com is able to negotiate on behalf of their clients and secure free quotas.

Secondly, by obtaining free quotas from reliable suppliers, Sourcifychina.com saves their clients both time and money. The process of sourcing suppliers, requesting quotations, and negotiating pricing can be time-consuming and costly. Sourcifychina.com simplifies this process by eliminating the need for their clients to search for and communicate with numerous suppliers individually. Instead, the clients can rely on Sourcifychina.com to handle all communication with the suppliers and obtain the best possible deals.

Furthermore, by offering free quotas, Sourcifychina.com allows their clients to assess the cost and feasibility of their steel plate fabrication projects without incurring any financial commitments. This allows the clients to make informed decisions and evaluate various pricing options before proceeding with any orders. It also eliminates any upfront financial risks associated with sourcing suppliers, as clients are not required to pay for the quotation process.

In summary, Sourcifychina.com obtains free quotas from reliable steel plate fabrication suppliers by leveraging their established relationships, providing cost and time savings for their clients, and allowing clients to assess their options without incurring any financial commitments. This service ultimately helps clients find the best steel plate fabrication supplier for their specific needs.