Types and Applications of strecth film

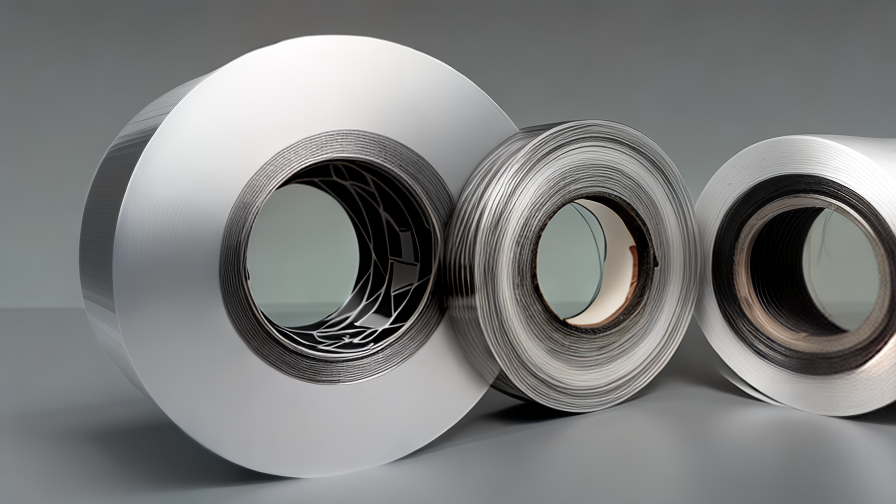

Stretch film, also known as stretch wrap, is a highly versatile film material that is often used for packaging, shipping, and storing various products. This type of film has the ability to stretch and conform to the shape of items, providing a secure and protective barrier around them.

There are several types of stretch film available on the market, each with unique properties and applications. These include hand stretch film, machine stretch film, and specialty stretch films.

Hand stretch film is typically used for smaller packaging applications that are done manually. This type of film is easy to handle and offers good stretchability. It is commonly used in warehouses, retail stores, and other industries for wrapping individual items such as boxes, pallets, and furniture.

Machine stretch film, on the other hand, is suitable for high-volume packaging applications that are done automatically. This type of film is designed to be used with stretch wrapping machines and offers greater strength and durability than hand stretch film. Machine stretch film is commonly used in industries such as food and beverage, pharmaceuticals, and manufacturing.

Specialty stretch films are designed for specific applications and may have unique properties such as higher puncture resistance, UV resistance, or anti-static properties. Examples of specialty stretch films include colored stretch films, VCI stretch films, and netting stretch films.

Stretch film is used in a variety of industries for a range of applications. It is ideal for protecting products during transit, preventing damage and ensuring that items arrive at their destination in perfect condition. Stretch film is also commonly used in warehouses and manufacturing plants for inventory management and securing goods on pallets. Other common applications include bundling and labeling products, wrapping construction materials, and protecting furniture during storage or relocation.

In conclusion, stretch film is a highly versatile packaging material that is essential for many industries. With various types of stretch films available, businesses can choose the best option for their specific needs and ensure that their products are properly protected during transport and storage.

Benefits and Feature of Utilizing strecth film

Stretch film, also known as stretch wrap, is a highly versatile and cost-effective packaging material that has gradually been replacing traditional packaging methods. It is a highly stretchable, elastic plastic film that can wrap and protect bulky items and offers numerous benefits over other packaging materials like shrink wrap, packing tape, etc.

Here are some of the major benefits and features of utilizing stretch film.

1. Protects against dust, dirt, and moisture: Stretch film provides excellent protection to goods against environmental factors like dust and dirt. It also helps to keep goods dry and protected from moisture and other harmful elements.

2. Enhances stability: The highly stretchable nature of the material provides a tight wrap around items, which enhances their stability and prevents them from shifting or toppling over.

3. Saves money: Stretch film is cost-effective and can significantly reduce packaging costs. It is available in various thicknesses and widths, which makes it an adaptable packaging solution for different applications.

4. Improved efficiency: The packaging efficiency of stretch film is much higher than other conventional packaging materials due to its stretchability and ability to conform to the contours and shapes of goods.

5. Supports sustainability: Many stretch films are recyclable, which helps to reduce waste and support eco-friendly practices.

6. Easy to use: Stretch films are user-friendly and can be applied with minimal effort and specialized equipment. Additionally, the ability to customize the film’s width and thickness allows for greater flexibility when packaging goods.

In conclusion, stretch film offers significant benefits over other packaging materials and can be an excellent way to enhance the security, stability, and overall presentation of goods. Its cost-effectiveness, versatility, and eco-friendly nature make it an ideal choice for businesses and organizations looking to improve their packaging processes.

The Process of strecth film

Stretch film is a commonly used packaging material that is made up of thin plastic film. Its primary function is to wrap around and secure objects in order to provide protection during transportation or storage. The manufacturing process can differ depending on the intended use and the type of material used, but the following is a general guide to the process of producing stretch film.

1. Resin Preparation: The plastic material used to make stretch film is typically made from a mixture of polymers, such as polyethylene, and other additives like pigments, UV-resistant agents, and processing aids. The mixture is melted, and the resulting molten resin is cooled to form a solid.

2. Extrusion: The cooled resin is then fed into an extruder machine, which melts it again and shapes it into a thin, flat sheet. This sheet is then cooled once more as it is wound onto a spool.

3. Casting: Alternatively, the molten resin can be cast onto a web, which is then cooled and rolled up onto a spool.

4. Slitting: The resulting film can be then passed through a slitting machine, which cuts the film into narrower widths.

5. Stretching: The film is then stretched either mechanically or manually, which helps to orient the polymer molecules and increase their strength and elasticity.

6. Roll Formation: The film is then wound onto a large roll to make it easier to transport and use.

The resulting stretch film is strong, flexible, and resilient, making it an ideal material for protecting products during transit or storage. It is available in a variety of thicknesses and widths to suit different applications, and can even be customized with printing or color treatments to suit specific branding or packaging requirements.

How to use strecth film

Stretch film, also known as cling film or plastic wrap, is a thin, stretchable and transparent plastic material commonly used for wrapping and sealing items. Here are some steps on how to use stretch film effectively:

1. Prepare the objects you want to wrap – ensure that they are clean, dry and tidy.

2. Hold the roll of stretch film with one hand and pull the film out with the other hand.

3. Wrap the stretch film around the item and ensure that it overlaps itself by a couple of centimeters.

4. Stretch the film to increase its tension as you wrap it around the item – this helps to create a tighter and more secure layer.

5. Make sure you have wrapped the entire item completely and tightly.

6. Cut the stretch film with a sharp knife or scissor and ensure that you leave enough extra cling film to cover the entire item and give it a few extra layers of wrap.

7. Secure the end of the stretch film to the item with a small piece of sticky tape.

Stretch film is a versatile material that can be used to wrap almost anything – from boxes, parcel and furniture to food items to prevent air and moisture. Stretch films come in different sizes, thicknesses and strengths, depending on the application.

To use stretch film effectively:

– Avoid overstretching the cling film as it might tear and may not adhere properly.

– Ensure that the stretch film is not too thin that it can easily puncture through.

– Store your stretch film away from heat, sunlight and moisture as these can cause the film to become brittle and lose its adhesive properties.

In summary, stretch film is a useful material that can help protect your items. By following the above steps, you can use stretch film effectively with minimal wastage and cost.

strecth film Manufacturer,Supplier and Wholesale

Stretch film is a highly versatile and durable material that is widely used in various industries for packing, storing and shipping items. Such film is beneficial for its exceptional elasticity, durability, and strength. A reliable strecth film manufacturer, supplier, and wholesaler is crucial to ensure that businesses receive excellent quality products that meet their specific packaging requirements.

A strecth film manufacturer produces stretch film using high-quality raw materials and advanced manufacturing processes. The raw materials used include linear low-density polyethylene (LLDPE) and low-density polyethylene (LDPE). LLDPE offers higher tensile strength, puncture resistance, and elongation than LDPE. The manufacturing process involves the extrusion of the polyethylene resin into a thin film of varying thicknesses, widths and lengths.

A strecth film supplier offers a range of stretch films that cater to different packaging needs. These can include hand-wrapped and machine-wrapped stretch films. Hand-wrapped stretch films are ideal for small scale operations, whereas machine-wrapped stretch films are recommended for larger applications. Strecth film suppliers also offer custom solutions that cater to unique requirements such as pre-stretch, colored film, and UV resistance.

Strecth film wholesalers supply stretch films in large quantities at competitive prices. The benefits of buying from wholesalers include cost savings, convenience, and a variety of options. They offer flexible payment options, discounts on bulk purchases, and a reliable supply chain to ensure timely delivery.

In conclusion, the role of strecth film manufacturers, suppliers, and wholesalers is critical in providing businesses with reliable and exceptional quality stretch films. Businesses can benefit from the numerous packaging advantages offered by stretch films, including durability, flexibility, and protection. A reputable strecth film manufacturer, supplier, and wholesaler can be found by searching online or through referrals from other businesses.

strecth film Price

Stretch film, also known as cling film or plastic wrap, is a highly stretchable and flexible thin plastic material used for wrapping and securing items. It is commonly used in various industries such as food, medical, and logistics for packaging and protecting products.

The price of stretch film depends on several factors such as thickness, dimensions, and quantity. The thicker the film, the higher the price. The dimensions also affect the price, as larger rolls or sheets cost more than smaller sizes. Quantity is also a significant factor, as manufacturers offer discounts for bulk purchases.

The average price of stretch film is around $20 to $30 for a 1000-feet roll of standard 18-inch width and 80-gauge thickness. However, prices may vary depending on the brand and supplier.

High-quality stretch films that offer superior stretchability, tear resistance, and puncture resistance are typically more expensive than standard films. These films are preferred by industries that require heavy-duty packaging and protection such as construction, furniture, and automotive.

Eco-friendly stretch films made from biodegradable materials like corn starch, PLA or PBAT are also available with a slightly higher price than traditional stretch films. These films are becoming increasingly popular as more businesses are prioritizing eco-friendliness in their operations.

In conclusion, the price of stretch film varies based on certain factors such as thickness, dimensions, quantity, brand, and material. Stretch film is an essential material in various industries, and it’s important to choose the right one that meets your specific needs at a reasonable price.

FAQ sourcing strecth film manufacturer from China with multiple answers

Q: What is stretch film?

A: Stretch film, also known as stretch wrap or pallet wrap, is a type of plastic film commonly used to wrap and secure products or goods during transportation or storage. It is known for its stretchability, strength, and transparency.

Q: Who are the leading stretch film manufacturers in China?

A: There are several stretch film manufacturers in China, but some of the leading ones include Lldpe Stretch Film Co., Ltd., Qingdao Fangzheng Packing Co., Ltd., Shenzhen Yost Industrial Co., Ltd., and Wuxi Xinrun Protective Film Co., Ltd.

Q: What are the advantages of sourcing stretch film from China?

A: Sourcing stretch film from China can be advantageous in several ways. China has a vast manufacturing industry that is well-developed and has lower labor costs, which translates to lower production costs. Additionally, many Chinese manufacturers have extensive experience in manufacturing stretch film and use advanced technology to ensure high-quality products.

Q: What are the types of stretch film available from Chinese manufacturers?

A: Chinese stretch film manufacturers offer various types based on thickness, size, color, and application. The most commonly available types include cast stretch film, blown stretch film, hand stretch film, machine stretch film, UVI stretch film, VCI stretch film, and pre-stretch film.

Q: How do I select a reliable stretch film manufacturer from China?

A: When selecting a reliable stretch film manufacturer from China, you should consider factors such as the manufacturer’s experience, production capacity, product quality, pricing, certifications, and customer reviews. It is also advisable to ask for product samples and request a factory audit or visit to ensure that the manufacturer meets your requirements.

In conclusion, China is a reliable source of stretch film, and Chinese manufacturers offer various types and grades of stretch film. Sourcing stretch film from China can be advantageous in terms of cost and quality but requires careful selection of a reliable manufacturer.