Knowledge about Stretch Wrap Machine

Stretch wrap machines are used in industries to wrap and secure products for transportation and storage. It is a common automated machine that ensures safe and secure packaging of products while minimizing damages during transit. These machines are easy to operate and offer consistent wrapping results.

There are two types of stretch wrap machines – turntable and rotary arm machines. Turntable stretch wrap machines are used for wrapping products that are tall, bulky, or unstable. The pallet is placed on the turntable and rotates as the machine wraps the stretch film around it. On the other hand, rotary arm stretch wrap machines are used for wrapping lighter goods such as boxes or trays. The rotating arm moves around the stationary product, creating a tighter wrap.

When buying a stretch wrap machine, it is important to consider the type of goods to be wrapped. Different machines are designed for different products, so it is crucial to select the right machine for the job. The size and weight of the products should also be taken into consideration. Heavy-duty machines are required for larger and heavier products.

Maintaining the stretch wrap machine is essential to ensure it functions properly. Regular cleaning and inspection of the machine components can prevent breakdowns and ensure optimal performance. It is also important to use the right stretch wrap film to prevent product damage during transit.

In conclusion, stretch wrap machines are crucial to ensure safe and secure product packaging for transportation and storage. Selecting the right machine based on the type and weight of the products is essential. Proper maintenance and use of the right stretch wrap film can prevent damages and ensure optimal performance.

Various Types of Stretch Wrap Machine

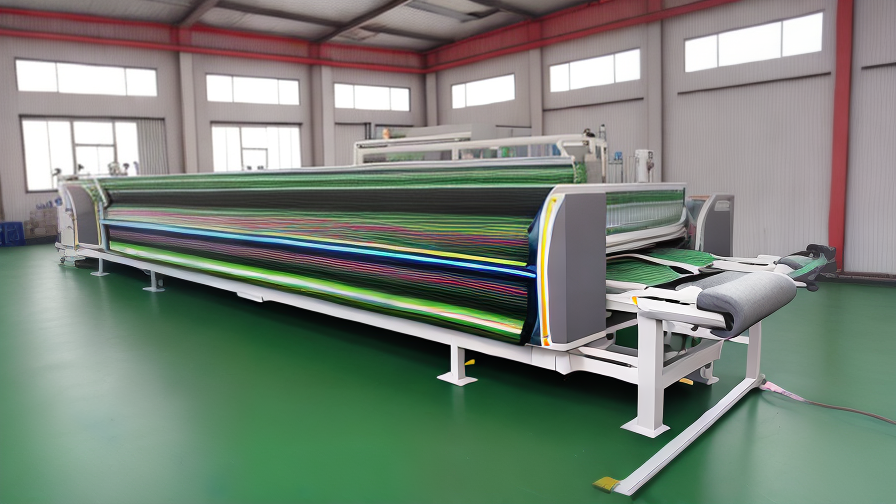

Stretch wrap machines are widely used in industries such as food processing, manufacturing, and logistics. These machines help to ensure the safe packaging of goods by wrapping them tightly in stretch film. There are various types of stretch wrap machines available on the market, each designed to suit different needs and requirements.

Semi-Automatic Stretch Wrap Machine: This type of machine is suitable for smaller operations or businesses that don’t require high-volume packaging. It requires an operator to load the pallet onto the turntable and secure the stretch film before starting the machine. The machine then rotates the pallet while the film is dispensed and wrapped around the goods.

Automatic Stretch Wrap Machine: This machine automatically wraps pallets of various sizes and shapes. It’s a faster and more efficient option compared to the semi-automatic machine. It can be customized to meet specific requirements and has an automated conveyor system which ensures faster wrapping and consistent quality.

Robotic Stretch Wrap Machine: This type of stretch wrap machine uses robots to wrap pallets. It has an automated system that does not require human intervention, meaning it can work continuously for long periods. It’s a perfect solution for large scale businesses and applications that require a high volume of stretch wrapping. The machine is fast, accurate and reduces labor costs.

Horizontal Stretch Wrap Machine: This type of machine is suitable for wrapping long and heavy products such as lumber, pipes, and metal rods. The product is placed on the conveyor, and the machine wraps the stretch film around the product in a horizontal direction.

Vertical Stretch Wrap Machine: This machine is designed to wrap products that need to be wrapped from top to bottom. It’s suitable for products such as doors, windows, and furniture. It uses a vertical wrapping method and has a rotating arm that moves around the product while dispensing the film.

In conclusion, stretch wrap machines are essential for businesses looking to increase productivity and efficiency in their packaging process. There are different types of stretch wrap machines based on speed, size and type of goods, and each

FAQ sourcing Stretch Wrap Machine manufacturer from China

Sourcing a stretch wrap machine manufacturer from China can be a daunting process, but it doesn’t need to be. Here are some frequently asked questions (FAQ) and multiple answers to help you navigate through the process.

1. What is a stretch wrap machine?

A stretch wrap machine is a piece of equipment used to wrap products with a stretchable plastic film for the purpose of protection or preservation during transportation or storage.

2. Why should I source a stretch wrap machine manufacturer from China?

China is known for being a manufacturing powerhouse, especially in the packaging industry. The country has a vast network of factories that can produce high-quality products at a lower cost compared to manufacturers from other countries.

3. How can I find a reliable stretch wrap machine manufacturer in China?

You can start by searching for manufacturers online or through trade shows. It’s important to check their certifications, experience, and customer reviews. You can also ask for references and visit their factories to see their production processes firsthand.

4. What types of stretch wrap machines do Chinese manufacturers offer?

Chinese manufacturers offer a wide range of stretch wrap machines, including semi-automatic, automatic, and fully automatic models. They also offer customized machines to fit specific customer needs.

5. What are some key features to look for in a stretch wrap machine?

Some key features to look for include the speed of the machine, the film width, the maximum load weight, and the overall durability of the machine.

In conclusion, sourcing a stretch wrap machine manufacturer from China can be a great option for businesses looking to reduce costs while still ensuring high-quality products. By doing your research and asking the right questions, you can find a reliable manufacturer to meet your packaging needs.

Applications of Stretch Wrap Machine

Stretch wrap machines are commonly known in the packaging industry as they are used to wrap a variety of products. These machines are widely used in many different industries including pharmaceuticals, food processing, beverage, automotive, and electronics. Stretch wrap machines improve the efficiency of packaging processes, especially for high volume production lines. Here are some of the applications of stretch wrap machines:

1. Pallet Wrapping

Stretch wrap machines are used to wrap pallets with film to keep products secure during transportation. This process helps to prevent damage and loss of products during transit.

2. Food Packaging

Stretch wrap machines are used in the food industry to wrap and package different types of food products such as bread, meat, cheese, and even vegetables. This type of wrap ensures the product stays fresh and prevents spoilage.

3. Packaging of Beverages

Stretch wrap machines are widely used to wrap and package different kinds of beverages such as soda, beer, wine, and juice. The machine provides an efficient method of wrapping these products and also preventing breakages during transportation.

4. Pharmaceuticals

Stretch wrap machines are used in the pharmaceutical industry to wrap and package pharmaceutical products such as tablets, capsules, and vaccines. The machines help to protect these products from contamination and ensures their freshness.

5. Automotive Industry

Stretch wrap machines are used to wrap automotive parts such as tires, engines, and gears. This type of wrapping helps to prevent damage and scratches during transportation.

In conclusion, stretch wrap machines are versatile and have a wide range of applications. They provide an efficient method of wrapping products and ensure the safety and freshness of these products during transportation. These machines can also increase productivity and efficiency while reducing costs in the long run.

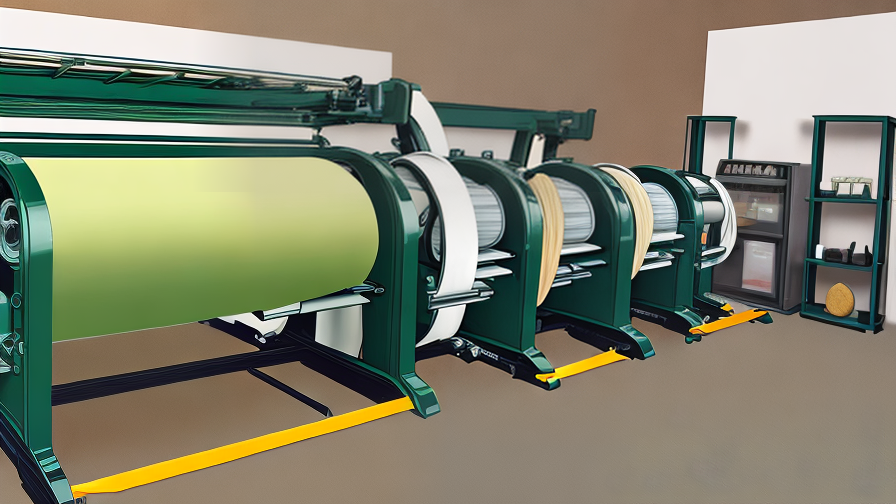

Manufactured Products made of Stretch Wrap Machine

Stretch wrap machines are widely used in the manufacturing industry to produce a range of products that require sturdy and durable packaging. Stretch wrap films have excellent elongation properties that makes them perfect for wrapping and protecting a wide range of items. Here are some of the manufactured products made of stretch wrap machine.

Pallet Wrapping: Pallets are a common sight in manufacturing facilities, and wrapping them in stretch film prevents items from falling over during transportation or storage. The wrapping process is fast and efficient, allowing the pallets to be quickly prepared for shipment or storage.

Food Wrapping: In the food industry, stretch films are used to wrap food items such as meat, fruits, and vegetables. Stretch films are perfect for preserving the freshness of food, reducing spoilage and waste. They are also safe for food contact and meet strict hygiene standards.

Industrial Packaging: Products that are bulky or heavy require special packaging solutions to ensure their safety during transportation. Stretch wrap machines can produce packaging materials that are strong enough to withstand harsh conditions while protecting their contents.

Medical Supplies: The medical industry requires strict packaging standards to ensure patient safety. Stretch wrap machines can produce sterile packaging materials that are highly resistant to moisture, bacteria, and other contaminants. The stretch films’ ability to conform to the shape of the product ensures a secure and robust packaging.

Clothing & Textiles: Stretch films are extensively used in the textile industry to wrap clothing and textile products. The stretch wrap machines can produce different types of films with varying thicknesses depending on the item’s size and shape.

In conclusion, stretch wrap machines produce films that are widely used in the manufacturing industry for various applications, including pallet wrapping, food wrapping, industrial packaging, medical supplies, and textiles. These high-quality films’ durability and reliable performance make them the ideal choice for manufacturers seeking sturdy packaging solutions.

The Evolution history of Stretch Wrap Machine

The stretch wrap machine has undergone a series of evolution over the years to meet the ever-changing demands of the packaging industry. In the early 1950s, manual stretch wrap machines were the norm. These machines required a lot of human labor as the operator had to manually wrap the products with the stretch wrap.

With time, the introduction of semi-automatic machines in the late 1960s saw an improvement in the packaging process. The first semi-automatic machine was tailored to suit the specific needs of the packaging industry; it could stretch, cut and wrap the product in no time.

Technology continued to evolve, and as a result, fully automatic stretch wrap machines became prevalent in the market. This level of automation is well suited for the mass production of products. It operates with minimal human intervention, giving room for higher production speed, consistency, and uniformity in product wrapping.

In the late 1990s, the industry innovated the rotating arm/turntable stretch wrap machine. This kind of machine made it easier for packaging large or tall products with precision, speed, and ease.

The orbital stretch wrap machine, which came into existence in the early 2000s, added value to the packaging process by offering supreme protection to products. The machine offers high-quality packaging by wrapping products continuously, ensuring total product protection.

In conclusion, the evolution of stretch wrap machines has improved the packaging industry’s efficiency, productivity, and competitiveness. The industry continues to be revolutionized by more innovative designs and advanced technology. It is exciting to see what the future holds in the evolution of the stretch wrap machine.

The Process of Stretch Wrap Machine

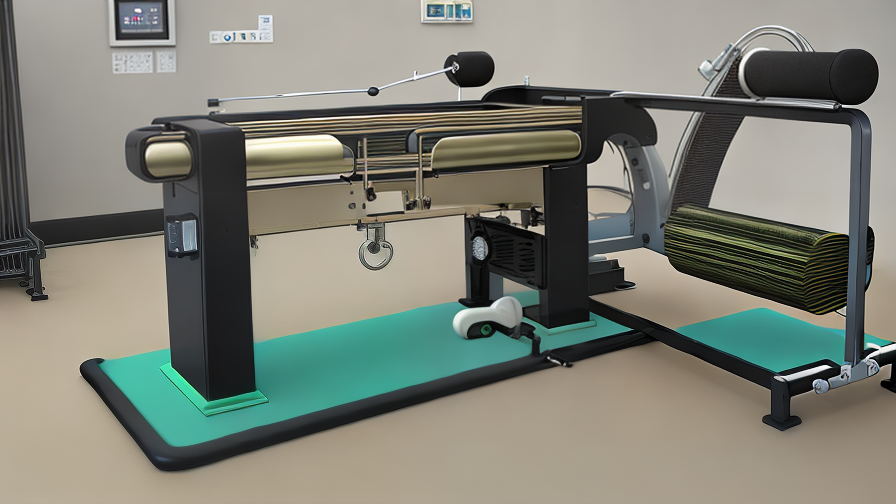

Stretch wrap machines are commonly used in industrial and commercial settings to securely and efficiently bundle and protect products for distribution or storage. The process of stretch wrapping involves the application of stretch film to a product or group of products using a machine.

The first step in the process is to prepare the product to be wrapped. This may involve arranging the products on a pallet or conveyor belt to ensure they are stable and evenly positioned. Once the products are in place, the machine operator initiates the wrapping process.

The stretch wrap machine uses a roll of stretch film that is mounted on a dispenser. The film is unwound and fed through the machine, where it is applied to the product using various mechanisms such as a rotating turntable, a stationary mast or a mobile carriage.

As the stretch film is fed through the machine, it is stretched and pulled tightly around the product, forming a strong and secure bond. The amount of stretch applied to the film can be adjusted to suit different product types and wrapping requirements.

Once the product is fully wrapped, the machine will automatically cut the stretch film and secure it in place using heat or pressure. The wrapped product can then be removed from the machine and is ready for distribution or storage.

Overall, the stretch wrap machine is a highly efficient and effective way to securely wrap a wide range of products. It offers superior protection during transport and storage, while also reducing the time and labour required for manual wrapping. With the ability to customize the wrapping process to suit different products, it is an essential tool for many industries.

Benefits Advantages of Utilizing Stretch Wrap Machine

Stretch wrap machines are used in various industries to secure and protect products during transportation and storage. They offer numerous benefits and advantages over traditional wrapping methods, such as hand wrapping, and can significantly improve efficiency and productivity. Here are some of the benefits and advantages of utilizing a stretch wrap machine:

1. Consistency: A stretch wrap machine applies the same level of tension and wrapping consistency every time, ensuring that your products are packaged securely and consistently. This consistency helps prevent accidents or damages to the product during transportation, such as items falling off a pallet.

2. Time-saving: Wrapping products by hand can be a tedious and time-consuming experience. As compared to manual wrapping, a stretch wrap machine can wrap pallets and packages at a much faster rate than human labor. It can also be programmed to wrap specific loads automatically, allowing you to spend your time on other tasks.

3. Labor Saving: Manual wrapping can take a considerable amount of time and effort, and businesses could potentially save thousands of dollars in labor costs when using stretch wrap machines.

4. Reduced Film Costs: Stretch wrap machines are designed to use only the necessary amount of film required to secure a product. There is often a high risk of over-carriage with manual wrapping leading to wastage. This can help reduce film consumption and increase cost-effectiveness.

5. Improved Load Stability: When used correctly, stretch wrap machines improve load stability and prevent damage during transportation. This is due to consistent tension and wrapping method, ensuring that the load remains in place and protected from shifting or falling.

In conclusion, utilizing a stretch wrap machine is a smart investment for any business that wants to improve its packaging process. The benefits of using a stretch wrap machine include time-saving, reduced film costs, improved product stability, consistent wrapping, and labor-saving. Moreover, it is more environmentally friendly to opt for machine wrapping than manual wrapping. The investment will ultimately save you time and money, improve your bottom line, and help protect your products during transportation and storage.

Disadvantages Stretch Wrap Machine

Stretch wrap machines can be a valuable asset to any warehouse or distribution center. They are designed to streamline the packaging process, enhancing productivity and unloading speeds. However, like any piece of equipment, stretch wrap machines do come with some disadvantages that need to be considered before investing in one.

Firstly, stretch wrap machines are known for their high initial cost. Compared to manual wrapping methods, these machines can be quite expensive, and it is not always feasible for small businesses with a limited budget. Additionally, stretch wrap machines require electricity to operate, which further increases the cost of ownership.

Another disadvantage of stretch wrap machines is their limited flexibility in adjusting to different sizes of loads. Stretch wrap machines are designed to wrap uniform pallets, and if you have items of varying sizes or shapes, the machine may not be able to accommodate them. This limitation can lead to additional labor costs if the items need to be wrapped manually.

Maintenance is also an issue with stretch wrap machines. These machines require regular maintenance to ensure optimal performance, meaning additional labor expenses for businesses. Moreover, as these machines are mechanical, regular wear and tear can damage the equipment, leading to costly repairs.

Lastly, stretch wrap machines require a significant amount of space to operate effectively. For small warehouses, this can be an issue, leading to packing constraints.

In conclusion, while stretch wrap machines are great for improving the efficiency and speed of the packaging process, they come with some disadvantages that can make them less feasible for some businesses. These include the high initial cost, inflexibility regarding the size of loads, maintenance expenses, and space constraints. Therefore, businesses need to consider these factors before investing in one.

Selecting the Ideal Manufacturer Stretch Wrap Machine

When it comes to packaging your products safely and securely, a stretch wrap machine is a valuable investment. However, with so many options available in the market, selecting the ideal manufacturer stretch wrap machine can be overwhelming. Here are some factors to consider in selecting an ideal manufacturer stretch wrap machine:

Capacity: The first factor to consider when selecting an ideal manufacturer stretch wrap machine is the capacity. Before selecting a manufacturer, you need to know the size and weight of the products you would like to wrap. This will help you choose a machine that can handle your desired capacity.

Automation: It is essential to consider the level of automation required in your packaging process. Some manufacturers offer fully automated machines, while others offer semi-automated machines. Selecting the ideal manufacturer stretch wrap machine will depend on the level of automation required in your packaging process.

Film width: The width of the film used on the stretch wrap machine is another factor to consider. The width of the film will depend on the width of your product. Therefore, select a manufacturer that offers a variety of film width options.

Budget: The cost of the machine will also determine the ideal manufacturer stretch wrap machine to select. You need to set a budget and compare prices from different manufacturers to get the best deal. However, beware of low prices as they sometimes indicate low-quality machines.

Ease of use: Lastly, an ideal manufacturer stretch wrap machine should be easy to use. Since the machine will be used by different operators, it should have an easy-to-understand user interface and require minimal training.

In conclusion, selecting the ideal manufacturer stretch wrap machine will depend on your packaging needs, level of automation required, film width, budget, and ease of use. It is essential to consider these factors to avoid making a costly mistake that could affect your production and packaging process.

Things to Consider When Purchasing Stretch Wrap Machine

If you are in the packaging industry, a stretch wrap machine can be a game-changer for your business. It can help you to speed up your packaging process, save money, and improve the quality of your packaging. However, purchasing the right stretch wrap machine is key to getting these benefits. Here are some things to consider when purchasing a stretch wrap machine.

1. Machine type and size

There are various types of stretch wrap machines, including turntable, rotary arm, and orbital. Choose a machine that best suits your packaging needs. Consider the size of the machine and its capacity to handle your products.

2. Durability and reliability

A stretch wrap machine is a significant investment, and you want to ensure that you purchase a durable and reliable machine. Look for a machine made of high-quality materials and has a reputation for being reliable.

3. Cost

Stretch wrap machines can vary in price, depending on the features and capabilities they offer. Be sure to consider your budget and compare the cost of the machine with the benefits it offers.

4. Ease of use and maintenance

Choose a machine that is easy to use, and your employees can quickly learn how to operate it. Look for a machine that requires minimal maintenance, saving you time and money in the long run.

5. Safety features

Stretch wrap machines can be dangerous if not used correctly. Choose a machine that has adequate safety features, such as emergency stop buttons and barriers.

6. Customer support and warranty

Lastly, consider the customer support and warranty offered by the manufacturer. A good warranty protects your investment and gives you peace of mind. Look for a manufacturer that provides excellent customer support and is readily available to assist you in case of any issues.

In conclusion, purchasing a stretch wrap machine requires careful consideration. When selecting a machine, consider its type and size, durability, cost, ease of use and maintenance, safety features, and customer support and warranty. With these factors in mind, you will be able to select the best

Properties of Stretch Wrap Machine

Stretch wrap machines are essential in the packaging industry. These machines are specifically designed to wrap products, boxes, and pallets. There are two types of stretch wrap machines, which includes semi-automatic and automatic machines. These machines have different properties that make them ideal for different types of packaging tasks.

One of the main properties of stretch wrap machines is their speed. Automatic machines are incredibly fast and can package large volumes of items within a short time. Semi-automatic machines, on the other hand, require some manual input, making them slower than their automatic counterparts. However, they are useful for smaller packaging tasks.

Another property of stretch wrap machines is their flexibility. Companies can use these machines to package items of different sizes and shapes using different types of stretch wrap materials. The materials used to wrap items include PVC, polyethylene, and Polyolefin. These materials are available in clear, tinted, or colored options.

The machines are quite durable, making them suitable for use in different settings. They are made of high-quality materials that can withstand harsh working conditions. Most machines are fitted with safety measures to prevent accidents in the workplace. Additionally, most stretch wrap machines are easy to maintain, making them ideal for companies that want to minimize their maintenance costs.

Finally, stretch wrap machines are eco-friendly. They are manufactured using eco-friendly materials and have a low carbon footprint. This makes them an excellent choice for companies that are environmentally conscious. The machines are designed to use minimal energy and resources, making them ideal for companies that want to reduce their carbon footprint.

In conclusion, stretch wrap machines are an essential component of the packaging industry. The machines come with different properties that make them ideal for different packaging tasks. They are fast, flexible, durable, easy to maintain, and eco-friendly. Companies can choose from semi-automatic and automatic machines depending on their packaging needs.

How to use Stretch Wrap Machine

Stretch wrap machine is a highly efficient device that is used to wrap large quantities of goods on pallets or other similar objects. It comes in handy for businesses that have a large amount of inventory and require a secure way to transport it.

To use the stretch wrap machine, start by setting up the machine according to the manufacturer’s instructions. Usually, it involves plugging the machine into an electrical outlet and adjusting the tension of the wrap film based on the size of the object to be wrapped.

Next, place the object that is to be wrapped on the pallet, ensuring that it is positioned at the center. Start the machine, and place the stretch wrap film on the object. Hold the film in place and start wrapping the object by moving the machine around it. Ensure that the film is wrapped tightly around the object and there are no creases or folds.

Once the entire object is wrapped, cut off the film from the machine, and tuck the remaining edge of the film under the bottom layers of the wrap to secure it. You can then use the heat gun to heat the film, which will shrink it and make it more secure.

Using stretch wrap machine can save a considerable amount of time and money while ensuring that goods are protected during transportation. Proper use of the machine ensures that goods remain secure and free from damage.

Glossary Terminology Terms for Stretch Wrap Machine

Stretch wrap machines are an essential resource for facilitating the packaging process in industries around the world. These machines can wrap pallets, packs, and other items with precision and efficiency. They use a stretchable plastic film to secure and protect products during transportation or storage. If you are new to the field or have been operating stretch wrap machines for a while, these glossary terminology terms for stretch wrap machines will help you understand the technical terms that come with this equipment.

1. Load weight capacity: This term refers to the maximum weight that a stretch wrap machine can handle. Before selecting a stretch wrap machine, you will need to determine the weight of the products you will be wrapping.

2. Film Stretch Ratio: It describes the amount of stretch applied to the film by the machine. It is essential to consider the film stretch ratio before selecting the machine as it affects the packaging quality, cost, and strength.

3. Turntable: A flat platform that rotates to wrap the load. Stretch wrap machines can either have a manual turntable or a powered one.

4. Film carriage: It is the part of the stretch wrap machine that holds the film and controls its movement. It ensures that the film is applied evenly to the load.

5. Control panel: Where the operator can set up and adjust the machine’s speed, film tension, and other parameters.

6. Film tension: It is the amount of tensile pressure applied to the film by the stretch wrap machine. It is essential to set the correct film tension to avoid damaging the products.

7. Cycle: A complete process that includes loading a product onto a turntable, wrapping it with the film, and discharging the wrapped product.

8. Safety features: Stretch wrap machines have safety features such as emergency stop buttons and safety sensors, which ensure the safety of the operator and the product.

Conclusion

The success of your packaging process depends on your understanding of stretch wrap machine terminology. We hope this glossary of terms will help you operate your stretch

Stretch Wrap Machine Price

Stretch Wrap Machine Price

Stretch wrap machines are commonly used in industrial applications to ensure that products are securely packed and protected during shipping or storage. These machines use stretch wrap film to tightly wrap around pallets, boxes, or other items. In recent years, the demand for stretch wrap machines has increased due to their efficiency and convenience. However, the cost of these machines can be a major concern for businesses, especially for those who are just starting up. In this article, we will discuss the factors that affect the stretch wrap machine price and provide insights on how to find the best deal.

Factors Affecting Stretch Wrap Machine Price

The cost of a stretch wrap machine depends on various factors such as:

Machine Type – There are different types of stretch wrap machines available in the market. The most common types are semi-automatic, automatic, and robotic. Semi-automatic machines require manual intervention to load and unload products, while automatic machines require minimal human intervention. On the other hand, robotic machines are fully automated and can handle complex wrapping patterns. The price of a stretch wrap machine increases with its degree of automation.

Production Capacity – The production capacity of a stretch wrap machine is another factor that affects its price. Machines that can handle a high volume of products require more advanced features and components, which result in higher costs.

Brand – The brand of the machine is also a significant factor in determining its price. Established and reputable brands often offer higher quality machines with better features, which come at a premium price.

How to Find the Best Deal

When purchasing a stretch wrap machine, it is essential to look for the best deal that fits your budget and requirements. Here are some tips on how to find the best deal:

Research – Conduct research on different brands and types of stretch wrap machines. This will help you compare prices and features and make an informed decision.

Used Machines – Consider purchasing a used stretch wrap machine. Used machines are often cheaper than new ones, and many sellers offer a warranty or service to ensure the machine