Knowledge about Strip Packing Machine

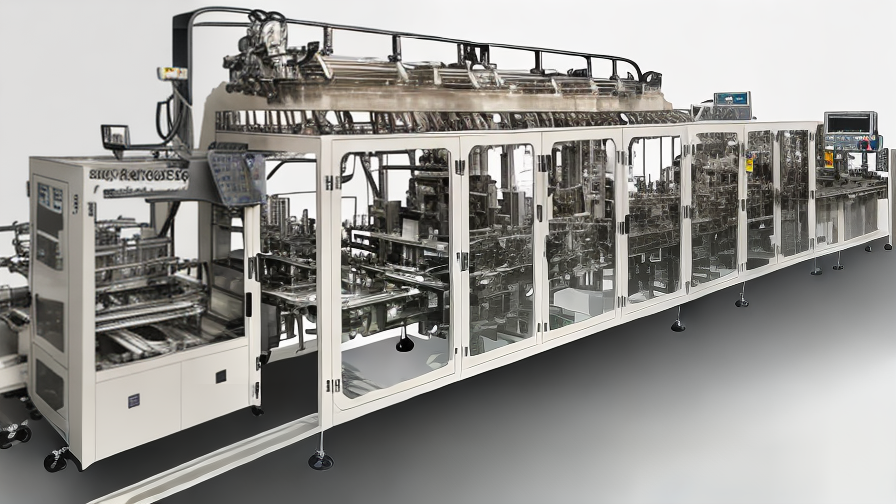

Strip packing machine is a packaging machine that is used to wrap a variety of products with a strip of plastic or paper. The machine is commonly used to package medicine tablets and capsules, but it can also be used for small consumer goods, such as candy, gum, and mints. With this machine, manufacturers can achieve a fast and accurate packaging process, which increases production efficiency and reduces the risk of product contamination.

The strip packing machine is made up of several parts, including a feeder system, a packaging material roll, a punching unit, an embossing unit, and a sealing station. The feeder system is responsible for moving the product into the machine, while the packaging material roll is used to feed the wrapping material into the machine. The punching unit is used to punch the wrapping material into the desired size and shape, while the embossing unit is responsible for printing information such as product name, expiry date, and manufacturer details. Finally, the sealing station is used to seal the package, ensuring that the product remains intact.

The strip packing machine offers several benefits to manufacturers. First, it allows manufacturers to package their products in small, easy-to-carry strips that are convenient for consumers. Second, the machine provides a reliable and consistent packaging process, which helps to reduce the possibility of product contamination. Third, the machine is easy to operate, which means that less time and money is spent on training operators. Finally, the machine is built to last, meaning that manufacturers can depend on it for years of consistent performance.

In conclusion, the strip packing machine is an essential tool for manufacturers who are looking to package their products quickly and accurately. With this machine, manufacturers can package their products in small, easy-to-carry strips that are convenient for consumers, while also enjoying a reliable and consistent packaging process. Whether you are in the pharmaceutical or consumer goods industry, you can rely on the strip packing machine to help you package your products effectively and efficiently.

Various Types of Strip Packing Machine

Strip packing machines are highly efficient and automated machines that are used to package products like pharmaceuticals, food, and confectionery. The demand for these machines has increased with the rise in production volumes and the need for cost-effective ways of packaging. The following are some of the various types of strip packing machines.

1. Rotary strip packing machine

This machine has a rotating platform with multiple stations that package products at a high speed. The machine uses horizontal and vertical rollers to pack products in strip form.

2. Intermittent strip packing machine

This type of machine is suitable for products with a long length, such as chewing gums, and it packs them into individual strips. It uses intermittent motion that allows the product to be fed into the machine at a specific time.

3. Horizontal strip packing machine

These machines are used to pack products that are wide in nature, like chocolate bars. They can form the package strip using heat sealing, ultrasonic sealing, or high-frequency welding.

4. Vertical strip packing machine

This type of packing machine is specially designed to pack products that can stand vertically, such as syringes, tablets and ampoules. The machine forms a tube or strip that accommodates the product.

5. Automatic strip packing machine

The automatic strip packing machine is more advanced and has a wider range of functionality. It can provide customizable packing options, including easy open strips, child-resistant strips, and tamper-evident seals.

6. Flexible strip packing machine

This machine type provides flexibility in product packing, making it possible to change the format quickly. The machine can pack products in different matrices, including square, round, or rectangular strips.

In conclusion, strip packing machines have become an essential tool for many industries, and manufacturers must choose the most appropriate type that fits their production requirements. The type of strip packing machine will depend on the product size or shape, packaging requirements, and production volume. Understanding each machine’s strengths and weaknesses can help manufacturers make the best

FAQ sourcing Strip Packing Machine manufacturer from China

Sourcing a strip packing machine manufacturer from China can seem like a daunting task, but with proper research and understanding, it can be a smooth process. Below are some frequently asked questions (FAQs) with multiple answers to help you navigate the process.

1. What should I consider when sourcing a strip packing machine manufacturer from China?

– Research the manufacturer’s reputation

– Check their certifications and compliance with industry standards

– Read reviews and testimonials from past clients

– Understand their pricing and payment terms

– Evaluate their customer service and after-sale support

2. How can I find a reliable strip packing machine manufacturer in China?

– Search online directories, such as Alibaba, Global Sources, or Made-in-China.com

– Attend trade shows and exhibitions, such as Canton Fair or Shanghai International Packing Machinery Exhibition

– Reach out to industry organizations, such as the Packaging Machinery Manufacturers Institute (PMMI) or the China Packaging Federation (CPF)

– Ask for referrals from other businesses in your industry

3. What types of strip packing machines are available from Chinese manufacturers?

– Automatic strip packing machines

– Semi-automatic strip packing machines

– High-speed strip packing machines

– Vacuum seal strip packing machines

– Pharmaceutical strip packing machines

4. Can Chinese manufacturers customize strip packing machines to fit my specific needs?

– Yes, many manufacturers offer customization services to meet your unique requirements.

5. What is the payment process for purchasing from a Chinese strip packing machine manufacturer?

– Most manufacturers require a 30% deposit upfront, with the remaining balance due upon completion of the order.

– Payment methods vary, but common options include wire transfer or letter of credit (L/C).

In conclusion, sourcing a strip packing machine manufacturer from China requires thorough research and evaluation of various factors. However, with the right approach, it can lead to successful partnerships and efficient machine production.

Applications of Strip Packing Machine

Strip packing machine is a packaging system that has diverse applications in various industries. It is used for packing a wide range of products, including pharmaceuticals, food and beverages, cosmetics, and household items. The machine performs the task of packaging a product in a strip form or sachet, which makes it convenient and easy to use.

Pharmaceutical industry:

One of the primary applications of strip packing machines is in the pharmaceutical industry. The machine is used for packing tablets, capsules, and other solid dosage forms. The packaging provides a barrier against air and moisture, which ensures that the medication maintains its efficacy and shelf life. Its use also reduces the likelihood of human error in the packaging of drugs.

Food and Beverage Industry:

In the food and beverage industry, the strip packing machines are used to package different products, such as packets of sugar, coffee, and tea. These sachets are convenient for catering services, hotels, and airlines. Also, it is useful for packing spices, seasonings, and other food ingredients.

Cosmetic Industry:

In the cosmetic industry, strip packing machines are used to package face masks, serums, and other skincare products. The sachets provide a hygienic solution for packaging these products, and customers appreciate the ease of use and portability provided by the strip packaging.

Household Items:

Strip packaging machines exhibit a vast range of applications in the packing of household items such as soaps, detergents, and cleaning agents. The sachets provide a convenient solution for consumers to transport small quantities of products without carrying the whole container.

In conclusion, the strip packaging machine helps to make the packaging process more efficient and cost-effective in various industries. It provides an innovative solution that caters to the needs of both the manufacturer and the consumer.

Manufactured Products made of Strip Packing Machine

The strip packing machine is a reliable and versatile piece of equipment that is utilized in many different manufacturing processes. Strip packing machines are used primarily to create high-quality packaging for a wide range of products. They are often used to produce products such as granules, powders, tablets, capsules, and other small items.

One of the main advantages of using strip packing machines is the ability to produce products that are uniform in size and shape. This means that they can be packaged with ease, making them ideal for mass-production processes. The strip packing machine is also highly efficient and reliable, ensuring that each product is manufactured to a high standard.

Another benefit of using strip packing machines is their versatility. These machines can be used to produce a wide range of different products, including food items, cosmetics, and pharmaceuticals. They can be customized to cater to the specific needs of each manufacturing process, ensuring that the end-product is of the highest quality.

Strip packing machines are also highly automated, which means that they require very little operator intervention. This makes them ideal for use in large-scale manufacturing processes where speed and efficiency are essential. Most strip packing machines are also equipped with advanced software and sensors, which allow for precise control over every aspect of the manufacturing process.

In conclusion, manufactured products made using strip packing machines are of the highest quality and are ideal for use in a wide range of different industries. These machines offer numerous benefits including versatility, reliability, and automation. They are an essential tool for any manufacturing company looking to increase productivity and efficiency while reducing costs.

The Evolution history of Strip Packing Machine

Strip packing machines are an essential component of modern manufacturing facilities. These machines are used for packaging different products in a single strip, which is then cut into individual units. The evolution of strip packing machines has been remarkable, and the history of its development is one of progressive innovation, from manual machines to fully automated ones.

The initial strip packing machines were manual and required an operator to manually load the products into the machine and operate the machine. These machines were labor-intensive and time-consuming, and their efficiency was limited. The first automated strip packing machine was invented in the early 1940s, which revolutionized the packaging industry.

The first automated strip packing machine used mechanical means to feed the products into the machine and pack them into strips. These machines were powered by motors, and the packager had more control over the packaging process. The first semi-automatic strip packing machines that could pack more products at a time were introduced in the 1950s. Although the operator still had to input the products into the machine and operate it, the machine’s efficiency was improved, and it could pack more products in less time.

The introduction of computer controls in the 1970s ushered in a new era of automation. The machines could now be programmed to handle various product sizes and shapes, and their speed increased. Computer-controlled machines also improved accuracy and reliability, reducing the rate of errors in packaging.

The early 2000s saw the introduction of fully automatic strip packaging machines that could handle multiple types of products and packaging sizes. These machines featured robotic arms that could pick and place products in the packaging, reducing labor costs and increasing efficiency.

The latest innovation in strip packing machines is the incorporation of artificial intelligence, which makes them even more versatile and adaptive. They can now adjust to different products’ sizes, shapes and weight, and optimize the packaging process for maximum efficiency.

In conclusion, the evolution of strip packing machines has been remarkable, from manual machines to fully automated ones, and from mechanical to computer-controlled

The Process of Strip Packing Machine

Strip packing machines are widely used in the pharmaceutical and food industries as they ensure efficient and effective packaging of products. The process of strip packing involves the use of a machine that passes a strip material through a series of rollers, which form pockets or cavities. The product is then inserted into the pockets, and the machine seals the strip material on both sides of each pocket to create individual packs.

The strip material used in strip packing is usually made of a thin, flexible material, such as aluminum or plastic, that can be easily molded and sealed. Once the strip material is fed into the strip packing machine, it moves through rollers that form the pockets. The pockets can be of varying sizes and shapes, and they can be customized to fit various products.

The product is then dispensed into each pocket through a feeding system. The feeding system ensures that the product is accurately placed in each pocket without spillage or waste. Once the product is in place, the machine proceeds to seal the strip material on both sides of each pocket. Some machines use heat sealing, while others use cold sealing methods.

After sealing, the strip is cut into individual packs. This process ensures that each pack is well-sealed and contains the right amount of product. Depending on the machine, the packs are then stacked, counted, and packaged for shipping or storage.

The strip packing process is highly automated, ensuring high levels of efficiency and accuracy. Additionally, it reduces the need for manual packing, which can be time-consuming and less accurate. The machines are also designed to handle a range of products, from tablets and capsules to confectionery and snacks.

In conclusion, the strip packing process involves the use of a machine that forms pockets on a strip material, dispenses products into each pocket, seals the pockets, and cuts the strip into individual packs. The process is highly automated and efficient, making it a popular choice for many industries.

Benefits Advantages of Utilizing Strip Packing Machine

Strip packing machines are one of the most efficient and innovative products available on the market today. These machines are designed for small to large scale industries to help streamline their packaging processes.

One of the most prominent advantages of utilizing a strip packing machine is its ability to save time and money. They significantly reduce the manual labor required for packaging and increase the speed of the packaging process. This means that the operation can produce more goods in less time, which ultimately leads to cost savings on labor expenses.

Strip packing machines are also designed to be highly accurate when it comes to portioning product quantities. This eliminates any inconsistencies in the packaging of goods, which can lead to customer complaints or even possible recalls. The accuracy also assures that the intended quantity of product is distributed in the correct manner, leading to greater customer satisfaction.

These machines are incredibly versatile and can be used with a wide variety of products, including powder, granules, liquids, and pills. They can be used to package a range of products from food and beverages to pharmaceuticals and healthcare products. This versatility makes them a useful tool for any industry that requires packaging solutions.

Along with all these benefits, strip packing machines are also environmentally friendly. With the use of eco-friendly packaging materials, these machines limit the amount of waste created during the packaging process. This is not only good for the environment but also adds value to any company’s green credentials.

In conclusion, utilizing a strip packing machine has numerous advantages compared to traditional packaging methods. It is one of the most efficient and innovative solutions for small to large scale industries. With its time and cost savings, accuracy, versatility, and environmental benefits, these machines are a must-have for any company looking to streamline their packaging processes.

Disadvantages Strip Packing Machine

The strip packing machine has been a popular packaging solution for various industries, especially the food and pharmaceutical sectors. However, as with any technology, there are some disadvantages to this packaging option that must be considered before making a purchase.

One of the main disadvantages of strip packing machines is their limited capacity. They are typically designed to handle a specific range of product sizes, and if the products fall outside of this range, it can be difficult to achieve consistent sealing and packaging quality.

Another drawback of strip packing machines is that they require a significant amount of time and effort to change between different product sizes. This can be a major inconvenience for manufacturers who need to switch between different packaging lines frequently.

In addition, strip packing machines can be relatively expensive to purchase and maintain. They often require regular servicing and replacement of parts, which can add up over time. Furthermore, the cost of operating and maintaining a strip packing machine may not be feasible for small producers.

Finally, the environmental impact of strip packing must also be considered. Many of these machines use plastic film to seal the product, which can contribute to environmental pollution. Additionally, the disposal of used film and other packaging materials can be challenging and costly.

In conclusion, while strip packing machines offer many advantages, they are not without their drawbacks. Manufacturers should carefully consider the limitations and costs associated with these machines before making a purchase. It is important to weigh the benefits and disadvantages of strip packing machines against other packaging options to determine the best packaging solution for a particular product and business.

Selecting the Ideal Manufacturer Strip Packing Machine

When it comes to selecting the ideal manufacturer strip packing machine, there are a few key considerations that you need to keep in mind. Here are some of the most important factors to consider:

1. The type of packaging you need: Strip packing machines come in a range of sizes and styles, each designed for specific types of packaging. You’ll need to think about the size and shape of your products, as well as any special features they have (e.g. odd shapes or fragile materials), in order to select a machine that can handle them securely and efficiently.

2. The level of automation you need: Some strip packing machines are fully automated, while others require more manual input. Depending on your needs (and your budget), you’ll need to consider which level of automation is most appropriate for your business.

3. The speed and output capacity of the machine: Strip packing machines can vary widely in terms of their speed and output capacity. If you have a high-volume production line, you may need to invest in a machine that can keep up with your demand.

4. The quality of the machine: Of course, you’ll want to choose a manufacturer that produces high-quality machines that are built to last. Look for manufacturers with a reputation for producing durable, reliable machines that require minimal maintenance.

5. The level of support and service offered by the manufacturer: Finally, make sure you select a manufacturer that provides excellent support and service, both during and after the sale. This can include things like technical support, training, and maintenance services, all of which can help you get the most out of your investment.

By keeping these factors in mind, you can select the ideal manufacturer strip packing machine for your business needs, helping you improve your packaging efficiency and streamline your production line.

Things to Consider When Purchasing Strip Packing Machine

When it comes to the pharmaceutical industry, strip packing machines have become an essential tool in production. They are machines that are used to pack pharmaceutical products into strip packs. However, choosing the right strip packing machine can be quite challenging. That is why in this article, we will discuss the things to consider when purchasing a strip packing machine.

First, you need to consider the production capacity of the machine. The production capacity of the machine determines the number of strip packs that can be produced within a specific period. You need to ensure that the production capacity of the machine aligns with your production needs.

Secondly, consider the size and dimension of the machine. You need to ensure that the machine will fit in your production facility. You also need to consider the space for the operator to work around the machine.

Thirdly, choose a machine that is easy to operate. You need to ensure that the machine comes with a clear and easy-to-understand manual. The machine should also have an intuitive control panel that can be operated by any worker with minimum training.

Fourthly, you should consider the machine’s reliability and durability. A machine that is reliable and durable will require less maintenance and help you save costs in the long run. Choosing a machine that is built with high-quality materials ensures that the machine lasts longer.

Lastly, it is important to consider the safety features of the machine. A machine with safety features such as safety interlocks, guards, and sensors can reduce the risk of accidents and injuries while operating the machine.

In conclusion, choosing the right strip packing machine requires careful consideration. When purchasing a strip packing machine, consider the production capacity, size and dimension, ease of operation, reliability and durability, and safety features. By considering these factors, you can ensure that you purchase a machine that meets your specific production needs and help you achieve your business goals.

Properties of Strip Packing Machine

Strip packing machine is an essential industrial equipment that facilitates the packaging of various products. The device’s functionality is designed to sort, cut, seal, and label products accurately, rhythmically, and hygienically. Most strip packaging machines are manufactured from high-quality materials that are durable and resistant to rust, corrosion, and other elements that may affect the products’ quality.

Properties of Strip Packing Machine

The prominent features of strip packing machine include:

1. High-speed production – Strip packing machines are renowned for their ability to handle a large volume of products in a minimal time frame. The machine’s capacity varies depending on the model, but they can process hundreds of products in a minute.

2. Accurate packaging – Strip packing machines are equipped with advanced technology, which ensures the precision of every packaged product. The machine’s mechanism is designed to measure, cut, and seal each product accurately, producing consistent results throughout the entire production process.

3. User-friendly interface – Strip packing machines feature an intuitive user interface that makes it easy for operators to control the equipment. The machine’s interface allows operators to adjust the speed, temperature, and other parameters that impact the packaging process.

4. Versatility – Strip packing machines are highly adaptive and can handle different types of products, ranging from pharmaceuticals, food, and cosmetic products, among others.

5. Hygienic packaging – Strip packing machines are engineered to uphold hygiene, a critical aspect of product packaging. The machine’s packaging is airtight, and its design prevents any form of contamination.

6. Easy maintenance – Strip packing machines require minimal maintenance, which reduces the overall operational cost of the equipment. The machine’s components are easily accessible, and the machine has a straightforward assembly.

Conclusion

In summary, strip packing machines are essential industrial equipment for manufacturers that require efficient, high-speed packaging of their products. The machine’s properties, including versatility, accuracy, and user-friendliness, make it an ideal machine for various products, such as pharmaceuticals,

How to use Strip Packing Machine

A strip packing machine is a great tool for businesses that need to package items for sale or shipping. These machines are used to package items in a wide variety of industries, including food, pharmaceuticals, and electronics. If you are thinking of using a strip packing machine for your business, here are some tips to help you get the most out of it.

1. Choose the right machine. There are many different types of strip packing machines available, so it is important to choose the right one for your business. Consider the size of the items you need to package, the volume of packaging you need to do, and your budget.

2. Prepare the items for packaging. Before you start using the machine, make sure that the items you need to package are properly prepared. This might involve sorting items by size, removing any excess packaging, or cleaning them before packaging.

3. Set up the machine. Once you have chosen the right machine, you will need to set it up. Follow the manufacturer’s instructions carefully to ensure that the machine is set up correctly.

4. Load the items onto the machine. Once the machine is set up, you can start loading the items onto it. Make sure that the items are properly positioned on the machine and that there are no obstructions that could cause problems during the packaging process.

5. Start the machine. Once everything is set up and the items are loaded onto the machine, you can start it up. Follow the manufacturer’s instructions carefully and make sure that you monitor the machine during the packaging process.

6. Clean the machine. After you have finished packaging your items, it is important to clean the machine thoroughly. This will help to ensure that it continues to function properly and that your items remain safe and hygienic.

Overall, a strip packing machine is a great investment for businesses that need to package items for sale or shipping. By following these tips, you can ensure that you are using your machine safely and efficiently, and that your items are properly

Glossary Terminology Terms for Strip Packing Machine

A strip packing machine is an essential device used in the pharmaceutical, food, and cosmetic industries for packing strips of tablets, capsules, and other products. To improve the understanding of this machine, we have compiled a glossary of common terminology terms associated with strip packing machines.

1. Strip feed: The section of the machine that feeds the materials, tablets, capsules, or products into the belt or foil wrapper, ensuring that they are evenly placed in each pocket of the foil strip.

2. Foil packaging: A packaging method that uses a continuous roll of metal foil material to form individual pockets for the products.

3. Heat sealing: A technique used to seal the formed pockets of the foil packages by applying heat and pressure, resulting in an air-tight seal.

4. Cut-off device: The component of a machine that separates a finished product from the continuous strip of packaging material.

5. Batch counter: A device that counts the number of strips produced by the machine, ensuring that the production process meets the required quantity.

6. Product hopper: The section of the machine that stores and dispenses the tablets, capsules, or other products into the foil packaging.

7. PLC Control: Programmable Logic Controllers are used to monitor and automate various tasks within the strip packing machine, optimizing the production process and ensuring consistent product quality.

8. Online printer: An optional feature that prints information such as expiry date, batch number, and other details on the finished package.

9. Filling accuracy: The ability of the machine to accurately dispense the required amount of product into each pocket of the foil packaging.

10. Vacuum suction: A mechanism that helps to remove any dust, debris or moisture, and ensures that the product remains clean before packaging.

In conclusion, having a good understanding of the terminologies used in strip packing machines is crucial in selecting the right equipment for your production needs, as well as operating and maintaining it effectively.

Strip Packing Machine Price

The strip packing machine is an essential tool used in the pharmaceutical, food, and cosmetic industry. Its function is to pack drugs, tablets, and capsules in uniform strips to ensure easy handling and to reduce the risks of contamination. The demand for these machines has led to the manufacture of different types of strip packing machines, with varying prices depending on their design, capacity, and features.

The price of a strip packing machine depends on several factors, such as the manufacturer, model, technical specifications, and the production scale. For instance, a small-scale machine designed to package 10,000 to 50,000 strips per day is relatively cheaper than a high capacity machine producing 500,000 to 1,000,000 strips per day. Depending on the machine’s design, prices differ due to the type of materials used, the accuracy of the packaging process, and the level of automation. Advanced models of strip packing machines can feature high-speed packaging with a touch screen operation for easy and efficient control, making them more expensive than low-end models.

Several manufacturers offer strip packing machines for sale, including big brands such as Bosch, IMA, and Marchesini Group. The market price also varies depending on the region and the local market competition. Typically, the cost of a brand new strip packing machine ranges from $50,000 to $250,000, depending on the model and manufacturer. However, the pricing varies, and customers are encouraged to compare prices across different suppliers.

In conclusion, a strip packing machine is a crucial investment for any business that requires pharmaceutical, cosmetic, or food packaging. The price of these machines is influenced by factors such as technical specifications, production capacity, and manufacturers. It is essential to compare pricing across different suppliers to get the best bang for the buck.