Introduce about submersible centrifugal pump guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

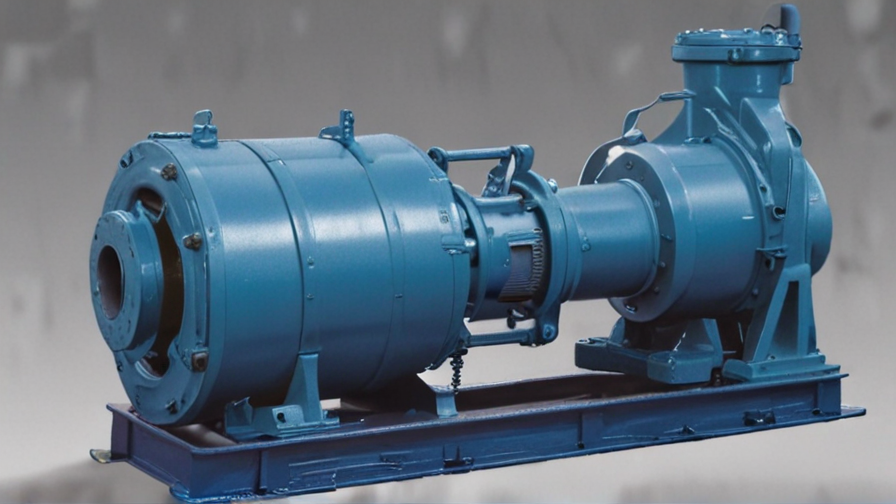

A submersible centrifugal pump is a type of pump that can be fully submerged in water or other liquids for pumping purposes. These pumps are widely used in various industries such as construction, agriculture, mining, and wastewater treatment. This guide aims to provide information about submersible centrifugal pumps, including their quality, cost, suppliers, certifications, market demand, useful tips, frequently asked questions, all within a limit of 300 words.

When it comes to the quality of submersible centrifugal pumps, it is crucial to choose a reliable and reputable brand or supplier. High-quality pumps are typically made from durable materials such as stainless steel or cast iron to ensure long-term operation and resistance to corrosion. Consideration should also be given to the motor power, pump flow rate, and maximum head or pressure the pump can generate.

In terms of cost, submersible centrifugal pumps vary depending on their specifications and the brand. Higher performance and more advanced features will generally result in a higher price. It is advisable to compare prices from different suppliers to find the most cost-effective option without compromising on quality.

Finding a certified supplier is important to ensure that the pumps meet industry standards and regulations. Look for suppliers that have obtained certifications such as ISO 9001:2015. This certification indicates that the supplier has implemented a quality management system to consistently provide high-quality products.

The market demand for submersible centrifugal pumps is continuously growing due to their efficiency and effectiveness in pumping applications. Industries such as agriculture, mining, and wastewater treatment heavily rely on these pumps, driving the market expansion.

Here are some tips to consider when purchasing submersible centrifugal pumps:

1. Determine the required flow rate and head for your specific application.

2. Check the pump’s maximum depth rating to ensure it matches the desired submergence level.

3. Consider the type of liquid being pumped and select a pump that is compatible with it.

4. Perform regular maintenance to prolong the pump’s lifespan and optimize its performance.

Frequently asked questions related to submersible centrifugal pumps may vary, but some common inquiries include installation procedures, troubleshooting tips, and recommended maintenance schedules.

In conclusion, submersible centrifugal pumps are versatile machines used in various industries. The quality, cost, supplier, certifications, market demand, tips, and FAQ shared in this guide serve as valuable information for individuals looking to select the right submersible centrifugal pump for their specific needs.

Types of submersible centrifugal pump

Submersible centrifugal pumps are specially designed pumps that can be fully submerged in water or other liquids, allowing them to function efficiently in various applications. They are widely used in industries such as wastewater treatment, mining, and irrigation. There are several types of submersible centrifugal pumps available, each designed for specific purposes.

1. Submersible Sewage Pumps: These pumps are used to handle sewage and wastewater containing solids. They are designed with a cutting mechanism that can chop up solids into smaller pieces, enabling smooth pumping and minimizing clogging issues.

2. Submersible Slurry Pumps: These pumps are specifically designed to handle abrasive and corrosive slurries with high solid concentrations. They are commonly used in mining operations, dredging, and other industrial applications where pumping highly viscous fluids is required.

3. Submersible Effluent Pumps: These pumps are used to transfer treated wastewater, commonly referred to as effluent, from septic tanks or sewage treatment plants. They are typically smaller in size compared to sewage pumps and are designed to handle clean or slightly dirty water.

4. Submersible Drainage Pumps: These pumps are used for general purpose dewatering applications like removing water from basements, construction sites, or underground tunnels. They are designed to handle clean or lightly contaminated water and are often portable for ease of use.

5. Submersible Well Pumps: These pumps are used to draw water from underground wells for residential, agricultural, or industrial applications. They are designed to work at higher pressures and depths, capable of delivering water from deep wells.

6. Submersible Fountain Pumps: These pumps are designed specifically for decorative fountains and water features. They come in various sizes and flow rates to create different water effects, such as spraying, bubbling, or cascading.

7. Submersible Fire Pumps: These pumps are used in firefighting applications where reliable water supply is essential. They are designed to handle high discharge pressures and are often equipped with features like self-priming and automatic start-up.

In conclusion, submersible centrifugal pumps are available in various types to cater to different needs and applications. Whether it is handling sewage, slurry, effluent, drainage, well water, or even creating beautiful water features, there is a submersible centrifugal pump to suit every requirement.

Pros and Cons of Using submersible centrifugal pump

Submersible centrifugal pumps are specialized pumps that can be submerged in liquid to effectively move fluids from one place to another. These pumps have several advantages and disadvantages, outlined below.

Pros:

1. Efficient operation: Submersible centrifugal pumps are highly efficient due to their direct immersion in the liquid being pumped. This eliminates the need for long suction lines and reduces energy losses, resulting in higher overall efficiency.

2. Space-saving: These pumps do not require a separate pump room or dedicated pump housing because they can be directly submerged in the liquid. This saves valuable floor space and allows for flexible installation options.

3. Lower noise levels: Submersible centrifugal pumps are known for their low noise and vibration levels. Since they are submerged, they are insulated by the liquid, minimizing noise transmission and providing a more pleasant working environment.

4. Reduced maintenance: Compared to surface-mounted pumps, submersible centrifugal pumps require less maintenance. They have fewer moving parts, thus reducing the risk of wear and tear. Additionally, they are less prone to cavitation, a phenomenon that can damage pumps over time.

5. Versatility: Submersible centrifugal pumps can handle a wide range of fluids, including clean water, wastewater, sludge, and abrasive liquids. This versatility makes them suitable for various industries such as mining, construction, agriculture, and municipal water systems.

Cons:

1. Higher initial cost: Submersible centrifugal pumps tend to have a higher upfront cost compared to surface-mounted pumps. This cost is due to their specialized design, materials, and installation requirements.

2. Limited access for maintenance: While submersible pumps require less maintenance, when they do require service or repair, it can be more complicated. Accessing the pump underwater may require specialized equipment and skilled personnel, which can increase maintenance costs and downtime.

3. Potential for overheating: Submersible pumps rely on the surrounding liquid to dissipate heat generated by the motor. If the liquid level drops or the pump is operated in dry conditions, the motor can overheat and potentially fail.

4. Limited maximum pressure: Submersible centrifugal pumps may have limitations in terms of the discharge pressure they can generate. If high-pressure applications are needed, alternative pump designs might be more suitable.

5. Risk of contamination: If the liquid being pumped is contaminated, there is a risk of damage to the pump or motor. Regular cleaning and maintenance are necessary to prevent buildup or blockages that could affect pump performance.

In conclusion, submersible centrifugal pumps offer numerous benefits such as efficiency, space-saving design, reduced maintenance, and versatility. However, they also have drawbacks including higher initial costs, limited access for maintenance, potential overheating, limited maximum pressure capabilities, and the risk of contamination. Ultimately, the suitability of submersible centrifugal pumps depends on the specific needs and requirements of the application.

submersible centrifugal pump Reference Specifications (varies for different product)

A submersible centrifugal pump is a device that is designed to operate underwater and generate high-pressure flow by converting the mechanical energy of a rotating impeller into fluid kinetic energy. These pumps are commonly used in various industries, including oil and gas, mining, wastewater treatment, and agriculture, to efficiently transport fluids.

The reference specifications of submersible centrifugal pumps can vary depending on the particular product and application. However, there are some common features and parameters that are typically provided in these specifications.

One of the key specifications is the pump’s capacity, which refers to the volume or flow rate of fluid that the pump can handle. This is typically expressed in gallons per minute (GPM) or liters per second (L/s).

The head or total dynamic head (TDH) is another important parameter. It is a measure of the pressure that the pump can generate and is usually expressed in feet or meters. The TDH takes into account factors such as the vertical distance the pump needs to lift the fluid, as well as friction losses in the pipes and fittings.

The power rating of the pump, measured in horsepower (HP) or kilowatts (kW), indicates the amount of power required to drive the pump. This parameter is dependent on the pump’s capacity and head.

The pump’s construction materials and design features are also specified. Submersible centrifugal pumps are typically made from corrosion-resistant materials such as stainless steel or cast iron with protective coatings. They may also have features like a built-in check valve, thermal overload protection, or a seal system to prevent water from entering the motor.

Other specifications may include the voltage and frequency of the power supply, the maximum operating temperature, and the maximum submergence depth that the pump can withstand.

It is important to consult the manufacturer’s reference specifications for a particular submersible centrifugal pump model as these can vary significantly. Properly understanding and selecting the appropriate pump according to the application’s requirements ensures optimal performance and longevity of the pump system.

Applications of submersible centrifugal pump

Submersible centrifugal pumps are versatile devices used in a wide range of applications. Their unique design allows them to operate while fully submerged in fluid, making them ideal for various industries such as agriculture, mining, wastewater treatment, and oil and gas.

In the agriculture sector, submersible centrifugal pumps are commonly used for irrigation purposes. These pumps can efficiently transport large volumes of water from a water source to agricultural fields, ensuring that crops receive an adequate supply of water for growth. Their ability to operate submerged helps prevent cavitation and extends their lifespan.

In the mining industry, submersible centrifugal pumps are utilized for dewatering underground mines. These pumps can handle both clean and dirty water, making them suitable for removing water from mine shafts, tunnels, and pits. Submersible pumps are preferred over other types of pumps in mining due to their reliability, durability, and ability to handle abrasive fluids.

Wastewater treatment plants heavily rely on submersible centrifugal pumps for various processes. These pumps are used for lifting and transferring sewage, sludge, and wastewater throughout the treatment system. Their ability to handle solids and corrosive fluids makes them vital in ensuring efficient and reliable wastewater management.

Submersible centrifugal pumps also find application in the oil and gas industry. They are used in offshore platforms for transferring crude oil, seawater, and other fluids. The submersible design of these pumps allows for easy installation and maintenance in challenging environments such as deep-sea installations.

Other applications include drainage in construction sites, flood control, and aquaculture. Submersible centrifugal pumps are often used for removing water from construction sites and preventing flooding in low-lying areas. In aquaculture, these pumps are utilized for maintaining water circulation in fishponds and ensuring optimum oxygen supply.

In conclusion, submersible centrifugal pumps offer numerous applications across various industries, including agriculture, mining, wastewater treatment, and oil and gas. Their ability to operate while submerged in fluid, combined with their reliability and durability, makes them indispensable in these sectors.

The Work Process and how to use submersible centrifugal pump

The work process of a submersible centrifugal pump involves several steps. Firstly, the pump is submerged in the fluid or liquid that needs to be pumped. This could be water, oil, sewage, or any other type of fluid. The pump is designed to be fully waterproof and sealed to prevent any leakage.

Next, the pump is powered on by connecting it to a power source, such as electricity or a generator. The motor in the pump starts rotating, which in turn rotates the impeller. The impeller is a key component of the pump and is responsible for creating the centrifugal force that moves the fluid.

As the impeller rotates, it creates a low-pressure zone at the center. This causes the fluid to be drawn into the pump through the suction inlet. The fluid then enters the pump housing, where it is accelerated by the rotating impeller. Due to the centrifugal force, the fluid is pushed towards the outer edges of the impeller and forms a high-pressure zone.

The high-pressure fluid is then discharged through the pump outlet or discharge port. From there, it can be transported through a pipe or hose to the desired location. The pressure and flow rate of the fluid depend on the design and specifications of the centrifugal pump.

To use a submersible centrifugal pump, it is important to ensure that it is properly installed and positioned in the fluid. The pump should be fully submerged to prevent any air from entering, which can cause cavitation and decrease the pump’s efficiency.

Regular maintenance and inspection of the pump are necessary to ensure its proper functioning. This includes checking for any clogs or debris that may obstruct the flow, monitoring the motor for any unusual noises or vibrations, and inspecting the seals and gaskets for any signs of wear or leakage.

In conclusion, a submersible centrifugal pump is a versatile and efficient tool for pumping fluids. By understanding its work process and following proper usage guidelines, one can effectively utilize this pump for various applications.

Quality Testing Methods for submersible centrifugal pump and how to control the quality

Quality testing methods for submersible centrifugal pumps ensure that the pumps meet the required standards and specifications for performance, reliability, and safety. These methods include:

1. Performance testing: This involves checking the pump’s performance under different operating conditions, such as flow rate, head, efficiency, and power consumption. The pump is connected to a test rig that simulates actual working conditions, and data is collected to verify its performance.

2. Leakage testing: To ensure that the pump is watertight and does not leak, a pressure test is conducted. The pump is pressurized with water and checked for any leakage points. This test is vital for submersible pumps to ensure their ability to operate underwater.

3. Material testing: The materials used in the construction of the pump, such as impeller, casing, and motor housing, need to be verified for their quality and durability. Material testing involves checking the composition, hardness, strength, and corrosion resistance of these components.

4. Electrical testing: Since submersible pumps operate under water, their electrical components need to be tested for insulation resistance, grounding, and motor performance. Electrical tests ensure the safe and reliable functioning of the pump, preventing any accidents or failures.

To control the quality of submersible centrifugal pumps, manufacturers can implement the following measures:

1. Robust quality control system: Establishing a quality control system that oversees the entire production process, ensuring adherence to standards and specifications. This includes regular inspection of incoming raw materials, in-process inspections, and final product inspections.

2. Supplier evaluation: Proper evaluation and selection of suppliers who provide high-quality components and materials. Regular audits and assessments of suppliers’ quality systems can help maintain consistent quality.

3. Training and skill development: Providing training to production and quality control staff about the requirements and techniques for manufacturing and testing submersible pumps. Enhancing the skills of the workforce ensures that the manufacturing process is executed correctly.

4. Continuous improvement: Regularly analyzing quality test data, customer feedback, and any reported issues to identify areas of improvement. Implementing corrective and preventive actions to address any quality-related concerns.

By following these quality testing methods and controlling measures, manufacturers can ensure the production of high-quality submersible centrifugal pumps, meeting the required industry standards and customer expectations.

submersible centrifugal pump Sample Policy and Post-Purchase Considerations for submersible centrifugal pump from China

Sample Policy:

When purchasing a submersible centrifugal pump from China, it is important to consider the following sample policy:

1. Minimum Order Quantity (MOQ): Most suppliers have a minimum order quantity. It is advisable to inquire about the MOQ for submersible centrifugal pumps and ensure it meets your requirements.

2. Sample Availability: Before placing a bulk order, it is recommended to request a sample unit to evaluate its quality, performance, and compatibility with your specific application. Inquire whether samples are available and if they will be charged or provided free of cost.

3. Customization Options: Check if the supplier offers customization services to meet your specific needs. This could involve altering the pump’s specifications, materials, or appearance. Discuss customization requirements and potential additional costs with the supplier.

4. Pricing and Payment Terms: Inquire about the unit price of the submersible centrifugal pump and the accepted payment methods. Understand the supplier’s payment terms, such as down payment, payment milestones, and balance payment upon delivery. Also, clarify if the pricing includes any additional charges like taxes or shipping costs.

5. Product Warranty: Request information about the warranty period offered by the supplier. Understand the terms and conditions of the warranty, including the coverage, process for filing claims, and any potential costs involved.

Post-Purchase Considerations:

After purchasing a submersible centrifugal pump from China, there are several considerations to ensure a smooth experience:

1. Quality Inspection: Thoroughly inspect the pump upon delivery to ensure it meets the agreed-upon specifications and quality standards. Check for any damages caused during transportation and test the pump’s performance.

2. Documentation and Certifications: Obtain all relevant documentation, such as invoices, packing lists, and test reports, to facilitate customs clearance and record-keeping. Additionally, inquire about necessary certifications required in your country to ensure compliance with safety and quality standards.

3. Spare Parts and After-Sales Support: Inquire about the availability and pricing of spare parts for the submersible centrifugal pump. Additionally, ensure the supplier offers reliable after-sales support, such as technical assistance and troubleshooting, to address any issues that may arise during the pump’s lifespan.

4. Feedback and Reviews: Share your experience with the supplier by providing feedback and reviews. This can help future buyers make informed decisions and encourage suppliers to improve their products and services.

5. Establishing Long-Term Relationships: If satisfied with the product and the supplier’s service, consider establishing a long-term relationship for future purchases. Building a strong relationship can lead to better pricing, priority treatment, and improved communication.

By considering the sample policy and post-purchase considerations, buyers can make informed decisions and ensure a satisfactory experience when purchasing submersible centrifugal pumps from China.

Sourcing submersible centrifugal pump from China: Opportunities, Risks, and Key Players

China is a major player in the manufacturing industry, and sourcing a submersible centrifugal pump from China offers several opportunities. Firstly, China has a wide range of suppliers that can provide high-quality products at a competitive price. The country has a well-established infrastructure and expertise in pump production, making it a reliable source for submersible centrifugal pumps. Additionally, China’s vast manufacturing capacity allows for faster production times and larger volume orders, which can benefit businesses with high demand.

However, there are certain risks associated with sourcing from China. Quality control can be a concern, as not all suppliers in the market adhere to the same standards. Therefore, it is crucial to thoroughly research and select reliable suppliers with a proven track record. Importing from China also involves longer shipping times, customs procedures, and potential language and cultural barriers, which can affect the overall sourcing process and supply chain management.

When it comes to key players in the Chinese submersible centrifugal pump market, several reputable manufacturers stand out. Grundfos, one of the global leaders in pump production, has a significant presence in China and offers a comprehensive range of submersible centrifugal pumps. Other notable Chinese players include Leo Group, Shanghai East Pump Group, and Shimge Pump Industry Group. These companies have established themselves in both domestic and international markets, and their products are known for their quality and reliability.

In conclusion, sourcing a submersible centrifugal pump from China presents opportunities in terms of competitive pricing, manufacturing capacity, and a wide range of suppliers. However, it also comes with risks related to quality control and logistical challenges. To mitigate these risks, thorough supplier research and due diligence are essential. By selecting reliable key players such as Grundfos, Leo Group, Shanghai East Pump Group, or Shimge Pump Industry Group, businesses can ensure a successful sourcing experience while benefiting from China’s manufacturing capabilities.

How to find and select reliable submersible centrifugal pump manufacturers in China,use google search manufacturers and suppliers

When looking for reliable submersible centrifugal pump manufacturers in China, utilizing Google search is a valuable tool. By following a few key steps, you can narrow down your options and select a trustworthy manufacturer. Here’s a guide in less than 300 words:

1. Begin with a comprehensive search: Use Google search and related keywords such as “submersible centrifugal pump manufacturers in China” or “reliable pump suppliers in China” to generate a list of potential manufacturers.

2. Evaluate the company’s website: Open the websites of different manufacturers from the search results and analyze the professionalism and presentation of the website. Reliable manufacturers often have well-designed and informative websites with product catalogs, certifications, contact details, company history, and customer testimonials.

3. Check their experience and reputation: Look for manufacturers with significant experience in producing submersible centrifugal pumps. Check if they hold certifications such as ISO or CE, ensuring their compliance with international standards. Read online reviews, ratings, or customer feedback to assess their reputation and product quality.

4. Product range and customization ability: Determine if the manufacturer offers a wide range of pump models, sizes, and capacities to meet your specific requirements. A reliable manufacturer should also be able to provide customized solutions and tailor-made pumps if necessary.

5. Communication and support: Contact the shortlisted manufacturers with inquiries or specific requirements and analyze their response time and willingness to provide assistance. Prompt, professional, and helpful communication is an indicator of a reliable manufacturer.

6. Quality control and after-sales service: Inquire about the manufacturer’s quality control processes, including testing, inspection, and certifications for their products. Additionally, assess their after-sales service, including warranty terms, spare parts availability, and technical support.

7. Price competitiveness: Consider the price offered by each manufacturer, but ensure it aligns with the product quality and services offered. The cheapest option might not always be the most reliable, so evaluate the overall value for money.

8. Visit trade directories and exhibitions: Consult trusted online directories, such as Alibaba, Made-in-China, or Global Sources, to find more submersible centrifugal pump manufacturers in China. Also, consider attending relevant industry exhibitions or trade fairs to meet manufacturers in person and inspect their products.

By following these steps, you can identify and select reliable submersible centrifugal pump manufacturers in China, ensuring the procurement of high-quality products that meet your specific requirements.

How to check submersible centrifugal pump manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a submersible centrifugal pump manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the website using the Google Chrome browser, as it offers various useful extensions that can assist in evaluating the website’s reliability.

2. Install SEOquake Extension: Install the SEOquake extension for Google Chrome, a popular SEO tool that provides valuable insights about the website’s organic ranking, popularity, and other metrics.

3. Check the Ranking: With SEOquake enabled, enter the website’s URL in the search bar and press enter. The SEOquake extension will display key metrics related to the website’s ranking and popularity.

4. Check Alexa Rank: Look for the website’s Alexa Rank within the SEOquake results. Alexa Rank is a measure of a website’s popularity based on its web traffic, with a lower number indicating higher popularity. If the website ranks within the top 10 million, it is a positive sign of reliability.

5. Assess Other Factors: Although the website’s ranking is an important factor to consider, it is not the sole determinant of reliability. Evaluate other aspects such as user-friendly interface, comprehensive information about the company and its products, contact details, customer reviews or testimonials, certifications, and industry affiliations.

6. Verify Company Information: Cross-check the provided company information, such as the physical address, contact numbers, email address, and social media profiles. Legitimate companies will have accurate and verified information.

In summary, by using Google Chrome with the SEOquake extension, you can quickly assess a submersible centrifugal pump manufacturer’s website reliability by checking its ranking within the top 10 million, verifying company details, and considering other factors such as user-friendliness and customer reviews.

Top 10 submersible centrifugal pump manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Shanghai East Pump (Group) Co., Ltd: Established in 1989, East Pump is a renowned manufacturer of submersible centrifugal pumps in China. Their product range includes submersible sewage pumps, submersible drainage pumps, and submersible deep well pumps. These pumps are widely used in municipal, industrial, and agricultural sectors.

2. Zhejiang Chenjie Pump Industry Co., Ltd: Chenjie Pump specializes in the production of submersible centrifugal pumps for drainage, sewage, and slurry applications. Their pumps are known for their high efficiency, reliable performance, and durability. They offer a wide range of products suitable for various industrial and residential needs.

3. Hunan Neptune Pump Co., Ltd: Neptune Pump is recognized for manufacturing submersible centrifugal pumps used in water supply, drainage, and irrigation systems. They focus on providing energy-efficient pumps with low maintenance requirements. Their products are widely used in agriculture, construction, and mining industries.

4. Zhejiang Better Pump Industry Co., Ltd: Better Pump is a leading manufacturer of submersible centrifugal pumps for wastewater treatment, sewage disposal, and basement drainage. They offer a comprehensive range of pumps with features like anti-clogging design, corrosion resistance, and high flow capacity.

5. Guangdong Ruirong Pump Industry Co., Ltd: Ruirong Pump specializes in the production of submersible centrifugal pumps for industrial, commercial, and residential applications. Their pumps are known for their silent operation, easy installation, and efficient performance. They offer a wide range of pumps suitable for various fluid transfer needs.

6. Guangdong Raybo Pump Co., Ltd: Raybo Pump is a well-known manufacturer of submersible centrifugal pumps for firefighting, drainage, and sewage applications. Their pumps feature robust construction, high-efficiency motors, and advanced control systems. They cater to both domestic and international markets.

7. Taizhou Dalang Pump Industry Co., Ltd: Dalang Pump is a prominent manufacturer of submersible centrifugal pumps for domestic water supply, agriculture, and municipal projects. They offer a wide range of pumps with features like automatic control, energy efficiency, and long service life.

8. Hunan Jiahua Pumps Co., Ltd: Jiahua Pumps specializes in the production of submersible centrifugal pumps for industrial wastewater treatment, mining, and chemical applications. Their pumps are known for their rugged construction, high-performance impellers, and reliable sealing systems.

9. Anhui Prestolite Chemical Pump Co., Ltd: Prestolite Chemical Pump manufactures submersible centrifugal pumps for corrosive and hazardous fluid transfer applications. Their pumps are widely used in chemical processing, petrochemical, and pharmaceutical industries.

10. Zhejiang Aquaroyal Pump Co., Ltd: Aquaroyal Pump is a leading manufacturer of submersible centrifugal pumps for domestic use, irrigation, and rainwater harvesting. Their pumps are known for their compact design, quiet operation, and energy efficiency. They offer a wide range of pumps suitable for both residential and commercial applications.

| Manufacturer | Product Range | Key Features |

| — | — | — |

| Shanghai East Pump (Group) Co., Ltd | Submersible sewage, drainage, and deep well pumps | Widely used in municipal, industrial, and agricultural sectors |

| Zhejiang Chenjie Pump Industry Co., Ltd | Submersible pumps for drainage, sewage, and slurry applications | High efficiency, reliable performance, and durability |

| Hunan Neptune Pump Co., Ltd | Submersible pumps for water supply, drainage, and irrigation | Energy-efficient with low maintenance requirements |

| Zhejiang Better Pump Industry Co., Ltd | Submersible pumps for wastewater treatment and sewage disposal | Anti-clogging design, corrosion resistance, and high flow capacity |

| Guangdong Ruirong Pump Industry Co., Ltd | Submersible pumps for industrial, commercial, and residential applications | Silent operation, easy installation, and efficient performance |

| Guangdong Raybo Pump Co., Ltd | Submersible pumps for firefighting, drainage, and sewage applications | Robust construction, high-efficiency motors, and advanced control systems |

| Taizhou Dalang Pump Industry Co., Ltd | Submersible pumps for domestic water supply, agriculture, and municipal projects | Automatic control, energy efficiency, and long service life |

| Hunan Jiahua Pumps Co., Ltd | Submersible pumps for wastewater treatment, mining, and chemical applications | Rugged construction, high-performance impellers, and reliable sealing systems |

| Anhui Prestolite Chemical Pump Co., Ltd | Submersible pumps for corrosive and hazardous fluid transfer applications | Widely used in chemical processing, petrochemical, and pharmaceutical industries |

| Zhejiang Aquaroyal Pump Co., Ltd | Submersible pumps for domestic use, irrigation, and rainwater harvesting | Compact design, quiet operation, and energy efficiency |

Background Research for submersible centrifugal pump manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to submersible centrifugal pump manufacturers in China, there are several companies worth researching. Some reliable sources for background research include qcc.com, archive.org, and importyeti.com.

Qcc.com is a prominent Chinese business directory that provides information on various companies, including submersible centrifugal pump manufacturers. The website offers comprehensive company profiles, contact details, and even customer reviews. Accessing Qcc.com can provide valuable insights into the company’s history, scale of operation, product range, and customer satisfaction.

Archive.org is a platform that allows users to access archived versions of websites. It can be used to explore the historical development of submersible centrifugal pump manufacturers’ websites and identify any changes in the company’s offerings, certifications, or partnerships over time. This information can provide a better understanding of a company’s evolution and credibility.

Importyeti.com is an import export data platform that offers records of shipments to and from China. It provides information on the importers and exporters involved in the trade of submersible centrifugal pumps, including company details, shipment quantities, destinations, and import and export trends. By utilizing Importyeti.com, researchers can gain insights into the market dynamics, identify key players, and analyze their market share and growth trajectory.

In conducting background research on submersible centrifugal pump manufacturers in China, it is crucial to use information from reputable sources like qcc.com, archive.org, and importyeti.com. These platforms provide comprehensive and reliable data, enabling researchers to make informed decisions about potential partnerships or business dealings. When summarizing the research findings, try to keep it within 300 words to provide a concise overview while highlighting the key points.

Leveraging Trade Shows and Expos for submersible centrifugal pump Sourcing in China

Trade shows and expos are a valuable resource for sourcing submersible centrifugal pumps in China. These events provide an excellent platform for buyers to discover new products, connect with manufacturers, and negotiate favorable terms.

Attending relevant trade shows and expos in China offers several benefits. Firstly, it allows buyers to explore a wide range of options and compare different submersible centrifugal pump manufacturers in one location. This saves time and effort compared to individually researching and contacting suppliers. Moreover, trade shows provide a unique opportunity to interact directly with suppliers, ask questions, and assess the quality of their products. Buyers can also take advantage of on-site demonstrations to see the pumps in action.

In China, some notable trade shows and expos for submersible centrifugal pumps include the China Import and Export Fair (also known as the Canton Fair), the China Pump and Valve Exhibition, and the China International Petroleum & Petrochemical Technology and Equipment Exhibition. These events attract numerous manufacturers, suppliers, and industry experts from across the globe, making them excellent platforms for sourcing.

To make the most of trade shows and expos, buyers should prepare in advance. They should identify their specific requirements, desired specifications, and target price range. Researching exhibitors prior to the event can help buyers prioritize the booths to visit. It is beneficial to create a list of questions to ask suppliers regarding their manufacturing capabilities, quality control processes, and lead times.

During the event, buyers should take detailed notes, collect brochures and business cards, and gather samples if possible. It is also important to establish a rapport with suppliers for future communication and negotiation. Following the event, buyers should review their findings, compare options based on their requirements, and begin the vetting process to select the most suitable supplier.

In conclusion, trade shows and expos in China provide an ideal setting for sourcing submersible centrifugal pumps. By attending these events, buyers can explore a wide range of options, connect with potential suppliers, and make informed decisions based on firsthand interactions and assessments.

The Role of Agents and Sourcing Companies in Facilitating submersible centrifugal pump Purchases from China

Agents and sourcing companies play a crucial role in facilitating submersible centrifugal pump purchases from China. These entities act as intermediaries between buyers and manufacturers, providing valuable support and expertise to ensure smooth procurement processes.

One of the main advantages of using agents and sourcing companies is their ability to bridge the language and cultural gaps that often exist between international buyers and Chinese manufacturers. With their linguistic skills and knowledge of local customs, they can effectively communicate buyers’ requirements to manufacturers and vice versa, minimizing miscommunications and misunderstandings.

Agents and sourcing companies also have extensive networks and connections within the Chinese manufacturing industry. They have established relationships with reliable and reputable manufacturers, allowing them to source high-quality submersible centrifugal pumps for buyers. These entities can conduct thorough background checks on potential suppliers, ensuring that they meet the necessary quality standards and certifications.

Furthermore, agents and sourcing companies are well-versed in negotiating with manufacturers on behalf of buyers. They can leverage their bargaining power to secure competitive prices and favorable terms, maximizing cost savings for buyers. These entities are also knowledgeable about local market conditions and can provide valuable insights into pricing trends, ensuring buyers make informed purchasing decisions.

Additionally, agents and sourcing companies handle various logistical aspects of the purchasing process. They oversee product inspections, quality control checks, and shipping arrangements, ensuring that the submersible centrifugal pumps are delivered on time and in optimal condition. This saves buyers time and resources that would otherwise be spent on managing these logistics independently.

In summary, agents and sourcing companies play a vital role in facilitating submersible centrifugal pump purchases from China. They provide language, cultural, and logistical support, enabling smooth communication and efficient procurement processes between buyers and manufacturers. With their extensive networks and negotiation skills, these entities help buyers source high-quality pumps at competitive prices, ensuring a successful purchasing experience.

Price Cost Research for submersible centrifugal pump manufacturers Companies in China, use temu.com and 1688.com

When it comes to submersible centrifugal pump manufacturers in China, two popular platforms that provide a wide range of options for price cost research are temu.com and 1688.com.

Temu.com is a comprehensive online marketplace that connects buyers and suppliers from various industries, including pump manufacturers. By using the search function on temu.com, buyers can easily find a list of submersible centrifugal pump manufacturers in China. Each listing usually includes detailed information about the company, such as their product range, production capacity, and certification.

On the other hand, 1688.com is a popular wholesale platform in China, particularly for bulk purchases. It offers a vast range of products, including submersible centrifugal pumps, from numerous suppliers. Buyers can navigate through different categories and filter the search results based on price, order quantity, and other specifications. The platform provides detailed product descriptions and specifications, along with supplier information.

Conducting price cost research on both temu.com and 1688.com allows buyers to compare prices and product offerings from different manufacturers. This information can help in gauging the market price and negotiating with suppliers. Additionally, buyers can utilize the messaging or inquiry functions on these platforms to directly communicate with manufacturers and request detailed quotations.

In summary, temu.com and 1688.com are valuable resources for price cost research on submersible centrifugal pump manufacturers in China. These platforms offer a wide selection of suppliers, detailed product information, and communication channels for direct inquiries, enabling buyers to make informed decisions based on their specific requirements.

Shipping Cost for submersible centrifugal pump import from China

The shipping cost for importing a submersible centrifugal pump from China may vary depending on several factors. Firstly, the size and weight of the pump will affect the shipping cost. Larger and heavier pumps will generally incur higher shipping charges. Additionally, the distance between the port in China and the destination port will also impact the cost.

Different shipping methods can be used, such as sea freight or air freight. Sea freight is typically more cost-effective but takes longer, while air freight is faster but more expensive. Factors like urgency and budget will influence the shipping method chosen.

Customs duties and taxes imposed by the importing country should also be considered as they may add to the overall cost. Import duties vary across countries and depend on the classification of the pump under the Harmonized System (HS) code.

To obtain an accurate shipping cost, it is essential to provide freight forwarders or shipping companies with specific details such as the dimensions, weight, and desired delivery time for the pump. They can provide quotes based on these details, including transportation charges, customs clearance fees, and any additional services required.

It is recommended to compare quotes from multiple shipping providers to find the most cost-effective option. Additionally, engaging an experienced freight forwarding agent can simplify the shipping process and help navigate potential complexities, ensuring a seamless import experience.

Compare China and Other submersible centrifugal pump Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the largest submersible centrifugal pump markets in the world. When comparing this market to other submersible centrifugal pump markets, several factors need to be considered, such as product quality and price, visible and hidden costs.

In terms of product quality, China has made significant progress over the years. Chinese manufacturers have invested in advanced manufacturing technologies and quality control measures to improve the reliability and durability of their pumps. While some Chinese brands still have a reputation for lower quality, many others have achieved international certifications and are comparable to pumps manufactured in other countries.

Price is another important factor. China is known for its competitive pricing due to lower labor and production costs. As a result, Chinese submersible centrifugal pumps are often more affordable compared to pumps from other countries. This competitive pricing has allowed China to gain a significant market share globally.

When it comes to visible costs, Chinese manufacturers are often transparent about their pricing, making it easier for buyers to compare and make informed decisions. However, hidden costs can be a concern. In some cases, Chinese manufacturers may provide lower upfront prices but have additional costs associated with shipping, customs, or after-sales support. Buyers should carefully consider these hidden costs when comparing products from different markets.

In summary, China has emerged as a major player in the submersible centrifugal pump market. The country’s manufacturers have improved product quality while maintaining competitive pricing. However, buyers need to consider both visible and hidden costs when comparing Chinese pumps with those from other countries. Overall, the market in China offers a wide range of options for buyers seeking submersible centrifugal pumps at different price points.

Understanding Pricing and Payment Terms for submersible centrifugal pump: A Comparative Guide to Get the Best Deal

When considering the purchase of a submersible centrifugal pump, understanding the pricing and payment terms is crucial to ensure you are getting the best deal. This comparative guide aims to provide you with valuable information to help you make an informed decision.

Pricing for submersible centrifugal pumps can vary depending on several factors. These include the size and capacity of the pump, the brand and quality, and any additional features or customization options. It is important to compare prices from different suppliers to get an idea of the market range and ensure you are not overpaying.

Payment terms also play a significant role in the overall cost of the pump. Some suppliers may offer discounts for upfront payment, while others may provide financing options or installment plans. It is essential to evaluate these payment terms and choose the option that best suits your financial capabilities and preferences.

When comparing prices, consider the quality and reputation of the supplier. Cheaper options may seem enticing, but they could be of inferior quality and lead to higher maintenance and replacement costs in the long run. Opting for a reputed supplier with a proven track record of reliability is often a wise decision, even if it means paying a slightly higher price.

Additionally, it is recommended to inquire about any warranties or after-sales support provided by the supplier. A comprehensive warranty can give you peace of mind and protect your investment in case of any manufacturing defects or malfunctions.

To get the best deal, it is advisable to request quotes from multiple suppliers and negotiate the price based on your research and market rates. Be open to discussing your requirements and budget constraints to see if any adjustments can be made without compromising on quality.

In conclusion, understanding the pricing and payment terms is crucial when purchasing a submersible centrifugal pump. Compare prices from different suppliers, evaluate payment options, consider the reputation and quality of the supplier, and inquire about warranties or after-sales support. By following this comparative guide, you can ensure that you get the best deal for your submersible centrifugal pump purchase.

Chinese Regulations and Industry Standards Certifications for submersible centrifugal pump,Import Regulations and Customs for submersible centrifugal pump from China

Chinese Regulations and Industry Standards Certifications for submersible centrifugal pump

In China, submersible centrifugal pumps are subject to various regulations and industry standards certifications to ensure their quality and safety. These regulations and certifications are essential for manufacturers and exporters looking to export their products to other countries, including importers who wish to purchase submersible centrifugal pumps from China.

One of the key regulations governing submersible centrifugal pumps in China is the “Chinese Compulsory Certification” (CCC) mark. This certification is required for certain products, including submersible centrifugal pumps, and ensures that they meet specific safety, health, and environmental protection requirements. Manufacturers must obtain CCC certification before they can legally sell their products in China or export them to other countries.

Additionally, the “China National Standard” (GB) sets out the industry standards for various products, including submersible centrifugal pumps. These standards specify the technical requirements, performance parameters, test methods, and other essential aspects of pump design and manufacturing. Adhering to GB standards is crucial for manufacturers to ensure their pumps meet the quality and functionality expectations of customers and regulators.

Import Regulations and Customs for submersible centrifugal pump from China

When importing submersible centrifugal pumps from China, it is important to comply with the import regulations and customs procedures of the destination country. These regulations and procedures vary from country to country but generally involve customs duties, documentation requirements, and product compliance checks.

Importers may be required to pay customs duties upon arrival of the submersible centrifugal pumps in their respective countries. These duties vary depending on the destination country’s tariff classification system and the declared value of the imported pumps. Importers should familiarize themselves with the customs duty rates and any applicable exemptions or preferential trade agreements to ensure a smooth import process.

Documentation requirements for importing submersible centrifugal pumps typically include a commercial invoice, bill of lading or airway bill, packing list, and any necessary certificates or permits. Importers should carefully review the documentation requirements of their country to ensure compliance and avoid any customs delays or penalties.

In terms of product compliance checks, customs authorities often perform inspections or request product certifications to ensure that the imported submersible centrifugal pumps meet the relevant safety and quality standards of the destination country. Therefore, it is important to ensure that the pumps comply with the necessary certifications and standards, such as CCC certification for China or international standards like ISO or CE.

By understanding and adhering to the Chinese regulations and industry standards certifications for submersible centrifugal pumps, as well as the import regulations and customs procedures of the destination country, importers can ensure a seamless and compliant import process for these products from China.

Sustainability and Environmental Considerations in submersible centrifugal pump Manufacturing

Sustainability and environmental considerations play a crucial role in the manufacturing of submersible centrifugal pumps. These pumps are widely used in various applications such as wastewater treatment, irrigation, and mining, and their manufacturing process must be aligned with sustainable practices to minimize their impact on the environment.

One major aspect of sustainable manufacturing is the efficient use of resources. The production of submersible centrifugal pumps should aim to minimize material waste and energy consumption. Manufacturers can achieve this by implementing lean manufacturing techniques and utilizing advanced technologies that optimize the use of resources.

Another important consideration is the selection of materials. Using eco-friendly materials that have less environmental impact throughout their lifecycle is essential. Manufacturers should prioritize materials that are sourced sustainably, have low greenhouse gas emissions, and can be easily recycled. Furthermore, reducing the use of hazardous substances such as mercury and lead in the manufacturing process is vital to minimize environmental pollution.

Additionally, the transportation of submersible centrifugal pumps should be optimized to reduce carbon emissions. Manufacturers can achieve this by using efficient packaging and finding ways to minimize the distance traveled during transportation, such as setting up production facilities closer to the end-users.

Furthermore, the end-of-life treatment of submersible centrifugal pumps should be considered. Designing pumps that are easy to disassemble and recycle can minimize waste and promote a circular economy mindset. Manufacturers can also provide guidelines for proper disposal or recycling of the pumps to ensure their environmental impact is minimized even after they have been used.

Lastly, sustainability should be integrated into the overall company culture and values. Manufacturers should regularly assess and improve their environmental performance through certifications such as ISO 14001. Furthermore, incorporating sustainable practices and technologies into their manufacturing processes should be an ongoing effort to continually reduce their environmental footprint.

In conclusion, sustainable manufacturing practices are crucial in submersible centrifugal pump manufacturing. By minimizing resource consumption, using eco-friendly materials, optimizing transportation, considering end-of-life treatment, and integrating sustainability into company culture, manufacturers can contribute to a greener and more sustainable future.

List The Evolution history of “submersible centrifugal pump”

The evolution of the submersible centrifugal pump can be traced back to the mid-20th century. It was during this time that engineers began to experiment with designs that could operate underwater, meeting the growing demand for efficient water transportation and drainage systems.

In the 1950s, the first prototypes of submersible centrifugal pumps were developed. These early models consisted of a pump motor connected to a centrifugal impeller, enclosed in a waterproof housing. The pump was submerged in water, and the impeller used centrifugal force to move the fluid through the pump and out through the discharge pipe.

Throughout the 1960s and 1970s, advancements were made in the construction and materials of submersible centrifugal pumps. Engineers focused on improving the efficiency and durability of these pumps, as well as expanding their applications. They were successful in increasing pump performance, allowing for higher flow rates and greater reliability.

Additionally, the 1980s saw the introduction of electronic controls for submersible centrifugal pumps. This technology allowed for more precise control over pump operations, including speed, motor protection, and automatic shut-off mechanisms. These innovations greatly enhanced the functionality and versatility of submersible centrifugal pumps.

In recent years, further improvements have been made to these pumps. Advances in materials, such as the use of corrosion-resistant alloys and composite materials, have increased their lifespan and resistance to harsh environments. Additionally, there has been a focus on energy efficiency, with the development of variable speed drives and sophisticated control systems that optimize pump performance.

Today, submersible centrifugal pumps are widely used in various industries, including agriculture, mining, water supply, and wastewater management. They have become an integral part of modern water transportation and drainage systems, offering efficient and reliable performance in both commercial and residential applications.

In conclusion, the evolution of the submersible centrifugal pump has been characterized by continuous technological advancements, resulting in increased efficiency, durability, and versatility. With ongoing research and development, it is likely that these pumps will continue to evolve and improve in the years to come.

The Evolution and Market Trends in submersible centrifugal pump Industry

The submersible centrifugal pump industry has witnessed substantial growth and evolution over the years due to advancements in technology, increasing demand from various end-user industries, and the need for efficient pumping solutions in challenging environments.

One of the key evolution trends in the submersible centrifugal pump industry is the development of more compact and lightweight pumps. Manufacturers have been focusing on reducing the size and weight of these pumps to enhance their portability and ease of installation. This has resulted in improved efficiency, reduced energy consumption, and increased flexibility in various applications.

Another significant trend is the integration of advanced technologies in submersible centrifugal pumps. Automation and smart control systems have been incorporated to enhance pump performance, reduce operational costs, and improve maintenance practices. These technologies enable real-time monitoring, remote operation, and predictive maintenance, ensuring optimal pump performance and minimizing downtime.

The submersible centrifugal pump industry has also witnessed a shift towards more environmentally friendly and sustainable solutions. Manufacturers are developing pumps with higher energy efficiency ratings, reducing carbon emissions, and adopting eco-friendly materials for construction. This trend aligns with the increasing global focus on sustainability and energy conservation.

Market trends in the submersible centrifugal pump industry indicate a growing demand from various end-user segments. The water and wastewater treatment industry, oil and gas sector, mining and construction, and agriculture are some of the key sectors driving the market growth. These industries require efficient pumping solutions for dewatering, fluid transfer, and drainage purposes, thereby fueling the demand for submersible centrifugal pumps.

Moreover, rapid urbanization, population growth, and infrastructure development in emerging economies are expected to drive the demand for submersible centrifugal pumps in the coming years. The Asia-Pacific region is anticipated to witness significant market growth due to the increasing industrial activities, urbanization, and investments in water infrastructure projects.

In conclusion, the submersible centrifugal pump industry has evolved significantly to meet the demands of various sectors. The market trends suggest a strong focus on compactness, advanced technology integration, and sustainability. With the increasing demand from diverse end-user industries and the rapid growth in emerging economies, the submersible centrifugal pump market is expected to witness continued growth in the foreseeable future.

Custom Private Labeling and Branding Opportunities with Chinese submersible centrifugal pump Manufacturers

Chinese submersible centrifugal pump manufacturers offer a wide range of custom private labeling and branding opportunities for interested businesses. With their expertise in manufacturing and ability to meet specific requirements, these manufacturers provide flexibility and customization options for businesses looking to establish their own brand and expand their product offerings.

Private labeling allows businesses to sell products under their own brand name, enhancing brand recognition and customer loyalty. Chinese manufacturers offer the option to customize the pump’s packaging, labels, and user manuals, ensuring a seamless integration of the product into the business’s existing product line. This personalized approach enables businesses to differentiate themselves from competitors and build a unique brand image.

Furthermore, Chinese submersible centrifugal pump manufacturers have the ability to incorporate specific branding elements into the product design. This includes integrating the business’s logo, colors, and other custom features to create a distinct product that resonates with the target market. By having control over the branding aspects, businesses can effectively communicate their value proposition and enhance their brand visibility.

Chinese manufacturers also offer the opportunity to tailor the pump’s specifications, performance, and functionality to match specific requirements. This ensures that businesses can offer a differentiated product that meets the exact needs of their customers. Whether it’s for industrial, commercial, or residential applications, Chinese manufacturers provide the necessary technical expertise to develop a customized submersible centrifugal pump.

In conclusion, Chinese submersible centrifugal pump manufacturers offer excellent opportunities for businesses to establish their own brand through custom private labeling and branding options. With their manufacturing expertise and flexibility, these manufacturers enable businesses to create unique, customized products that cater to their target market. By leveraging these branding opportunities, businesses can differentiate themselves, build customer loyalty, and ultimately succeed in their industry.

Tips for Procurement and Considerations when Purchasing submersible centrifugal pump

When purchasing a submersible centrifugal pump, there are a few considerations to keep in mind to ensure that you make the right selection for your specific needs. Here are some tips to help you with your procurement process.

1. Determine your requirements: Begin by identifying your specific needs and requirements. Consider factors such as the flow rate, head pressure, and the type of fluid you will be pumping. This will help you determine the capacity and power requirements of the pump you need.

2. Quality and durability: Look for a pump that is made from high-quality materials and is built to last. Consider the reputation and track record of the manufacturer to ensure that you are purchasing a reliable product. It is also important to check if the pump has any certifications or approvals to meet the necessary safety and quality standards.

3. Efficiency: Energy efficiency is crucial when selecting a submersible centrifugal pump. Look for pumps that have high-efficiency motors and hydraulic designs. This will not only help you save on energy costs but also reduce the environmental impact.

4. Easy maintenance and repairs: Opt for a pump that is easy to maintain and repair. Look for features such as removable impellers or suction screens, which can make cleaning and maintenance easier. Ensure that spare parts are readily available and that local service providers are familiar with the model you choose.

5. Consider the environment: If your pump will be used in a corrosive or abrasive environment, choose a model that is specifically designed to withstand such conditions. Also, consider factors like the temperature range and whether the pump needs to be explosion-proof or suitable for use in hazardous locations.

6. Warranty and customer support: Check the warranty period offered by the manufacturer and the terms and conditions. Additionally, inquire about the availability of customer support and after-sales services. A reliable and responsive customer support team can be invaluable in case of any issues or technical difficulties.

In conclusion, choosing the right submersible centrifugal pump requires careful consideration of your specific requirements, the quality and durability of the pump, efficiency, ease of maintenance, environmental factors, and the warranty and customer support offered. Taking the time to research and gather all the necessary information will help you make an informed decision and ensure that you invest in the most suitable pump for your needs.

FAQs on Sourcing and Manufacturing submersible centrifugal pump in China

Q: Are there any reliable manufacturers of submersible centrifugal pumps in China?

A: Yes, there are many reliable manufacturers of submersible centrifugal pumps in China. The country has a strong manufacturing industry and a long history of producing various types of pumps. It is important to conduct thorough research and due diligence to identify trustworthy manufacturers who have experience in producing quality submersible centrifugal pumps.

Q: What are the advantages of sourcing submersible centrifugal pumps from China?

A: There are several advantages of sourcing submersible centrifugal pumps from China. Firstly, China offers competitive pricing due to its low labor and production costs. This can be especially beneficial for bulk orders or projects with budget constraints. Secondly, China has a large pool of skilled workers and advanced manufacturing facilities, ensuring high-quality production. Thirdly, China has a mature supply chain network, making it easier to source raw materials and components for pump manufacturing.

Q: How can I ensure the quality of submersible centrifugal pumps manufactured in China?

A: To ensure the quality of submersible centrifugal pumps manufactured in China, it is essential to undertake thorough quality control measures. This includes conducting factory audits, inspecting samples before bulk production, and monitoring the production process. Engaging a third-party quality inspection company can also provide an objective assessment of the manufacturer’s production capabilities and adherence to quality standards.

Q: What are the typical lead times for manufacturing submersible centrifugal pumps in China?

A: The lead times for manufacturing submersible centrifugal pumps in China can vary depending on the manufacturer, order quantity, and customization requirements. Generally, it can range from a few weeks to a few months. It is essential to communicate clearly with the manufacturer regarding delivery timelines and confirm the lead times before placing an order.

Q: Are there any specific certifications or standards that submersible centrifugal pumps from China should adhere to?

A: Yes, submersible centrifugal pumps manufactured in China should conform to industry standards and certifications. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and CE (Conformité Européene) for compliance with European safety, health, and environmental protection requirements. It is important to check if the manufacturer has obtained these certifications and can provide relevant documentation.

Why contact sourcifychina.com get free quota from reliable submersible centrifugal pump suppliers?

SourcifyChina.com, a sourcing agent in China, may provide a free quota for submersible centrifugal pump suppliers because they have established reliable partnerships with these suppliers. By offering a free quota, SourcifyChina aims to attract potential buyers and provide them with a seamless sourcing experience.

One possible reason for SourcifyChina offering free quota is because they have thoroughly vetted and selected these suppliers based on their reliability and quality standards. This ensures that buyers receive products from trusted suppliers who meet their specific requirements.

SourcifyChina’s decision to limit the free quota to a certain number of words, such as not more than 300 words, could be due to the need for concise and relevant information. A limited word count ensures that buyers provide essential details about their product needs, allowing SourcifyChina to swiftly assess and match them with the most suitable submersible centrifugal pump suppliers.

This free quota also enables buyers to evaluate the suitability of SourcifyChina’s services before committing to a paid engagement. By experiencing SourcifyChina’s sourcing capabilities at no cost, buyers gain confidence in the sourcing process without any financial risk.

Overall, offering a free quota from reliable submersible centrifugal pump suppliers allows SourcifyChina to showcase their expertise in sourcing from China. It helps build trust with potential buyers, ensuring that they receive excellent service and access to high-quality suppliers for their specific needs.