Knowledge about Textile Printing Machine

Textile printing machine is an essential tool for textile industries. It is used to print vibrant and intricate designs onto fabrics using various printing techniques. A textile printing machine is capable of printing on fabrics of different types and thicknesses, including cotton, silk, polyester, and others. In this article, we will discuss some basic knowledge about textile printing machines.

Types of Textile Printing Machines

There are different types of textile printing machines, and they can be classified based on their printing method. The most common types of textile printing machines are screen printing machines, digital printing machines, and rotary printing machines.

Screen Printing Machines

Screen printing machines use stencils to print designs onto fabric. They are suitable for printing designs with few colors, and the prints are durable and long-lasting.

Digital Printing Machines

Digital printing machines use high-resolution images to print designs onto fabrics. They are suitable for printing intricate and detailed designs with many colors. Digital printing machines are expensive and usually used in high volume production.

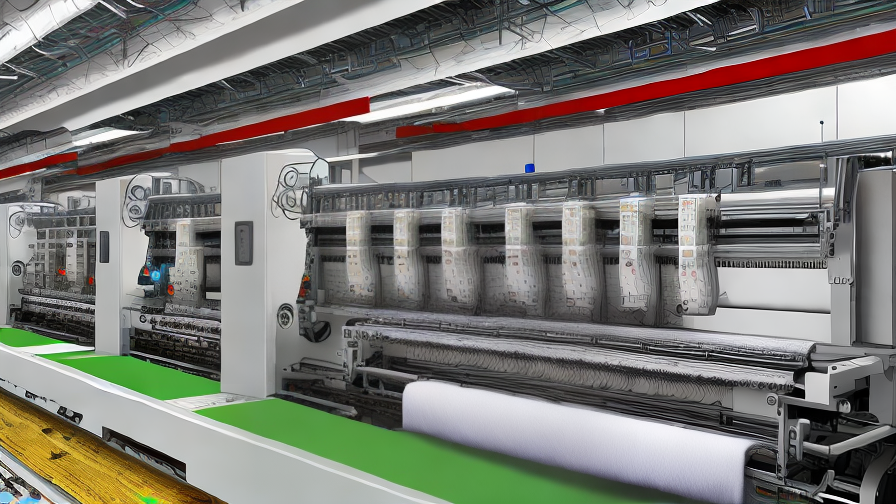

Rotary Printing Machines

Rotary printing machines use cylindrical rollers to print designs onto fabric. They are suitable for printing large quantities of fabric with repetitive designs. Rotary printing machines are efficient and cost-effective.

Factors to Consider When Choosing a Textile Printing Machine

When selecting a textile printing machine, there are several factors to consider. One of the most critical factors is the printing method. The printing method will determine the quality of the prints and the type of fabric you can print on. Other factors include the level of automation, printing speed, and cost.

Conclusion

Textile printing machines play a vital role in the textile industry. They are versatile and can print intricate designs onto fabrics using different printing techniques. When choosing a textile printing machine, it is essential to consider the printing method, level of automation, printing speed, and cost. A well-chosen textile printing machine can help your textile business thrive and produce high-quality prints.

Various Types of Textile Printing Machine

Textile printing machines have revolutionized the textile industry, allowing for intricate and complex designs to be printed on fabrics in a matter of minutes. There are various types of textile printing machines available, each with their own unique features and capabilities.

Screen printing machines, also known as silk screen printers, are one of the most popular textile printing machines. These machines use a stencil-like screen to apply ink onto the fabric, allowing for highly detailed and multicolored designs. However, the setup process can be time-consuming, and the screens require constant cleaning.

Heat transfer printing machines use heat to transfer a design from a paper or film onto the fabric. These machines are ideal for smaller-scale production and can be used on a variety of fabrics, including cotton, polyester, and even leather. However, the finished product may not be as durable as other printing methods.

Digital printing machines are a popular choice for high-quality, customizable designs. These printers use specialized software to transfer a digital image directly onto the fabric, allowing for precise color matching and sharp, detailed designs. However, these machines can be expensive to purchase, and the process can be slower than other printing methods.

Direct-to-garment printing machines are typically used for clothing production. These machines use specialized inkjet technology to print designs directly onto fabric, allowing for vibrant colors and intricate details. However, the ink can be expensive, and the finished product may require additional processing to ensure the design stays intact.

In conclusion, there are various types of textile printing machines available, each with their own unique features and benefits. Whether you’re looking to produce high-quality, customizable designs or need a method for mass production, there’s a textile printing machine that’s perfect for your needs.

FAQ sourcing Textile Printing Machine manufacturer from China

If you’re thinking about importing textile printing machines from China, you may have some questions. Here are some frequently asked questions (FAQs) with answers to help you start your sourcing journey.

Q: What are the types of textile printing machines available in China?

A: China offers a wide range of textile printing machines, including screen printing machines, digital textile printers, transfer printing machines, rotary screen printing machines, and more.

Q: Can I find reliable manufacturers in China?

A: Yes, there are many reliable textile printing machine manufacturers in China. However, it’s important to do your research and choose a manufacturer with a good reputation, quality products, and excellent customer service. You can check out online directories like Alibaba or attend trade shows like the Canton Fair to find potential manufacturers.

Q: What are the advantages of importing from China?

A: Importing from China can offer several advantages, including low manufacturing costs, diverse product options, and access to advanced technology. However, you should also consider the risks, such as communication barriers, shipping delays and quality control issues.

Q: How can I ensure the quality of the machines?

A: You can ensure the quality of the machines by visiting the factory, inspecting the machines, and requesting samples. You should also request the manufacturer to provide proof of certifications and testing (e.g. CE certification).

Q: What is the payment method?

A: There are several payment methods available, such as wire transfer, letter of credit and PayPal. You should discuss the payment terms with the manufacturer and choose a safe and reliable method that suits both parties.

Importing textile printing machines from China can be a profitable venture, but it’s important to do your due diligence and choose a reliable manufacturer. By researching and following the tips above, you can find a quality supplier and start your journey in the textile printing industry.

Applications of Textile Printing Machine

Textile printing machines are becoming increasingly popular across several industries thanks to their versatility and efficiency. They are widely used in the fashion, home decor, automobile, and advertising industries. The printing process involves applying ink or dye to fabrics to create unique and attractive designs.

One of the primary applications of textile printing machines is in the fashion industry. Clothing brands and designers use these machines to create unique patterns and designs on various fabrics. The machines can handle different types of fabrics ranging from cotton to silk, making them suitable for creating all kinds of designs. The machines make it easier to create bold and intricate designs, and they allow for quick turnaround times.

The home decor industry is another area where textile printing machines can be useful. With the machines, it is possible to print patterns and designs on a variety of products, including curtains, bed sheets, and cushion covers. This allows homeowners to customize their home decorations, and it provides home decor manufacturers with a cost-effective way of creating unique designs.

In the automobile industry, textile printing machines can be used to create custom car seat covers, floor mats, and other interior components. The machines allow manufacturers to create unique designs that match the brand and style of the vehicles. Additionally, the machines enable automobile manufacturers to produce customized interior components for specific car models easily.

Lastly, the advertising industry can also benefit from the use of textile printing machines. The machines are useful in creating banners, flags, and other advertising materials. The machines are capable of producing high-quality prints on different types of textiles, and they can handle large-scale printing projects.

In conclusion, textile printing machines are versatile and efficient tools that are useful in several industries. They allow manufacturers and designers to create unique and attractive designs on different types of fabrics, and they can handle both large and small-scale printing projects. With the advancements in technology, textile printing machines will undoubtedly continue to grow in popularity and applications in the future.

Manufactured Products made of Textile Printing Machine

Textile printing machines are widely used for the production of fabrics, clothing, and various other types of textiles. The machines use advanced printing technology to create high-quality and precise designs on the fabric. These machines are used by different manufacturers to produce various types of textile products.

One of the most popular manufactured products made with textile printing machines is clothing. Textile printing machines are used by clothing manufacturers to create unique and stylish patterns on fabrics. The machines are also used to create custom designs for specific customers. Clothing manufacturers use these machines to create a range of products ranging from t-shirts to high-end fashion items.

Another popular product manufactured using textile printing machines is home textiles. Textile printing machines are used to print different designs on various home textile products such as curtains, bed linen, and pillowcases. The machines are also used to add decorative prints and motifs to tablecloths, napkins, and other types of fabrics used in the home.

Industrial textiles are also manufactured using textile printing machines. These textiles are used for various industrial applications such as safety clothing, banners, and tents. Textile printing machines are used to add logos, branding, and other designs to the industrial textiles.

In conclusion, textile printing machines play a vital role in the manufacturing of different types of textile products. From clothing to home textiles and industrial textiles, these machines are used by different manufacturers to produce unique and high-quality products. With the advanced technology used in textile printing machines, the possibilities for creating innovative designs are endless.

The Evolution history of Textile Printing Machine

Textile printing has been practiced for thousands of years, but it wasn’t until the Industrial Revolution that the process was automated. The evolution of textile printing machines has gone through a series of significant innovations over the years, empowering this industry to produce beautiful and unique fabric designs.

In the early 19th century, manual silk-screen printing was the primary method used for printing on textiles. It was a slow and tedious process, requiring skilled workers to hand carve stencils and apply ink manually.

The first automated screen-printing machine was invented in 1907 by Samuel Simon of Manchester, England. Simon’s machine used flatbed printing and was one of the major breakthroughs in textile printing technology.

The rotary screen printing machine, which came into existence in 1947, was another game-changer in the textile printing industry. This machine enabled faster printing speeds due to the continuous movement of the fabric. It also allowed for larger-scale printing of more intricate designs.

The introduction of digital printing is one of the most significant advancements in textile printing machinery. It uses digital technology, making it possible to print full-color images with incredible accuracy and detail. Digital printing is cost-effective, and has eliminated the need for printing plates, reducing lead time between designing and production.

Today, textile printing machines use a range of advanced techniques, including rotary, flatbed, and digital printing. The machines also use different types of inks, including pigment and reactive dyes, and printing on natural and synthetic fibers.

In conclusion, the evolution of textile printing machinery has undergone significant advancements over the years, making it easier and more efficient to produce beautiful fabric designs. Today, the combination of innovative technologies and skilled human labor plays a crucial role in this industry, making it possible to create unique and beautiful fabric designs that can be used in an array of industries.

The Process of Textile Printing Machine

Textile printing machine is a complex process that involves various techniques and stages to produce high-quality printed fabrics. The process starts with a design, which is either manually drawn or created using design software. The design is then transferred to a printing cylinder or screen using photo emulsion or wax.

The printing cylinder or screen is then placed on the textile printing machine and prepared for printing. The fabric to be printed is then passed through the machine, and the printing cylinder or screen is pressed onto it with the help of pressure rollers. The ink is then transferred onto the fabric through the openings on the printing cylinder or screen.

The process of textile printing machine is not only limited to printing, but it also involves various other stages such as washing, steaming, and drying. After the printing is complete, the fabric is washed to remove any excess ink, and then steamed to set the ink onto the fabric. The fabric is then dried to ensure that the ink is completely set.

Textile printing machine also involves various types of printing techniques, such as direct printing, discharge printing, resist printing, and screen printing. Each technique has its own advantages, and the choice of technique depends on several factors such as the type of fabric, the type of ink used, and the design requirements.

In conclusion, textile printing machine is a complex process that involves various stages and techniques to produce high-quality printed fabrics. It requires precision and expertise to ensure that the final product meets the desired standards. With the advancement of technology, textile printing machine has become more efficient and versatile, and it continues to play a crucial role in the textile industry.

Benefits Advantages of Utilizing Textile Printing Machine

Textile printing machines have become popular in the textile industry as they offer a variety of benefits and advantages over traditional print methods. With the advancement of technology, textile printing machines have improved in quality and are now more efficient, cost-effective, and eco-friendly. Here are some of the benefits of utilizing textile printing machines:

1. High-Quality Prints: Textile printing machines offer high-quality printing that can be very detailed and accurate. They produce vibrant colors and precise designs that do not fade easily. The images printed using these machines appear sharp and vivid.

2. Cost-Effective: Traditional printing methods can be costly, especially if they involve a high volume of printing. Using textile printing machines is more cost-effective as they use less ink and produce less waste material. They also require less maintenance, which means lower costs of operation.

3. Time-Saving: Textile printing machines are faster than traditional printing methods. They can print a large number of designs within a short time, which saves time and increases productivity. This makes it possible to meet deadlines and achieve production targets within the required time frame.

4. Eco-Friendly: The use of textile printing machines is more eco-friendly as they consume less energy and produce less waste. They also use eco-friendly ink, which is biodegradable and does not harm the ecosystem.

5. Versatile: Textile printing machines can print on a variety of materials, including cotton, polyester, and nylon. They can also be used for printing on t-shirts, backpacks, and other textiles, making them versatile and suitable for various applications.

In conclusion, utilizing textile printing machines offers a range of benefits and advantages that can save time, reduce costs, and produce high-quality prints. They are also eco-friendly and versatile, making them a go-to option for the textile industry. It’s important to invest in the latest technology to stay competitive in the industry and meet customer demands.

Disadvantages Textile Printing Machine

Textile printing machines are widely used in the textile industry to implement patterns and designs onto fabrics. However, despite being highly efficient, these machines come with a few disadvantages that are worth considering.

First and foremost, textile printing machines require a significant amount of capital to acquire and maintain. The cost of purchasing a machine can be quite steep, and the cost of repair and maintenance can add up over time. This makes it difficult for small-scale textile businesses to invest in the technology.

Secondly, most textile printing machines can only handle specific types of fabrics such as cotton, polyester, and silk, which limits their versatility. The need for different machines to handle different fabrics can increase capital expenditure, and the process may ultimately become more expensive than manually printing the fabrics.

Thirdly, the machines need to be operated by highly skilled personnel, which can increase labor costs. The training required to operate these machines may also take some time, and this may lead to losses during the learning process.

Fourthly, the complex nature of textile printing machines can lead to frequent breakdowns, making it necessary to halt production. This can be detrimental to any manufacturer as it can result in delays and additional losses.

Finally, textile printing machines are not environmentally friendly. Water, electricity, and chemicals are heavily used in the textile printing process, leading to pollution and environmental degradation. Moreover, because the machines are not easily recycled, they can contribute to electronic waste and disposal-related problems.

In conclusion, while textile printing machines are highly effective, they come with their fair share of disadvantages. These factors should be considered when deciding whether to invest in a textile printing machine or opt for traditional printing methods.

Selecting the Ideal Manufacturer Textile Printing Machine

When it comes to choosing the ideal textile printing machine manufacturer, there are a variety of factors that need to be taken into account. These factors will vary depending on the specific needs of your business and the type of textile printing machine you are looking for. Here are some important considerations to keep in mind when selecting your ideal manufacturer:

Quality of Equipment: It’s important to choose a manufacturer that produces high-quality equipment that provides reliable and accurate printing. Look at the materials that are used in the construction of the machine, as well as the reputation of the manufacturer in the industry.

Price: Price can often be a deciding factor when selecting a manufacturer. However, it is important not to prioritize price over quality when it comes to selecting a textile printing machine manufacturer. Look for a manufacturer that offers competitive pricing without sacrificing quality.

Reputation: Research the reputation of the manufacturer before making your final selection. Look for reviews and feedback from other customers to see what their experiences have been with the manufacturer’s equipment and customer service.

Customer Support: The level of customer support provided by a manufacturer is an important consideration. Look for a manufacturer that provides ongoing support and maintenance services for their equipment.

Compatibility: Ensure that the equipment you select is compatible with the textiles and inks you plan on using in your business. Some manufacturers specialize in certain types of printing equipment, so it’s important to select a manufacturer that offers the specific type of machine that your business needs.

In conclusion, selecting the ideal manufacturer for your textile printing machine is important for ensuring the success of your business. Keep these factors in mind when selecting a manufacturer to ensure that you are choosing high-quality equipment, competitive pricing, reliable customer support, and equipment that is compatible with your business needs.

Things to Consider When Purchasing Textile Printing Machine

When considering purchasing a textile printing machine, there are several things to keep in mind. The following tips can help ensure that you select a machine that will meet your needs and provide the best possible results.

1. Purpose: Determine the primary use of the machine. Are you looking for a machine for personal use or commercial use? Do you want to print on a small scale or a large scale? This will help you narrow down your options.

2. Quality: Look at the quality of prints the machine produces. Check for the resolution, clarity, and vibrancy of the colors. Ensure that the colors do not bleed or fade, and that the prints are sharp and clear.

3. Durability: Consider the durability of the printing machine. It should be able to withstand heavy use without breaking down, and should be capable of handling different types of fabrics.

4. Ease of use: The machine should be easy to use and operate, with a clear user manual and instructions. Consider the time it takes to set up, load fabrics, and clean the machine.

5. Compatibility: Check if the machine is compatible with the type of ink and fabric you plan to use. Some machines work better with certain types of ink or fabrics, so ensure that the one you choose is compatible.

6. Cost: Consider the initial cost of the machine as well as maintenance and repair costs. Look for machines with a good warranty and support from the manufacturer. Also, consider the cost of ink and other supplies that will be needed over time.

7. Size: Evaluate the size of the machine. It should fit your workspace without taking up too much room.

By keeping these factors in mind, you can select a textile printing machine that meets your needs and provides high-quality prints.

Properties of Textile Printing Machine

Textile printing machines are used to put color and pattern on fabrics. These machines play an essential role in textile manufacturing, as they are responsible for producing textiles with diverse designs and colors. Some of the features that make these machines unique include their speed, accuracy, and versatility.

One of the most crucial properties of textile printing machines is their speed. These machines work at a much faster pace than manual printing processes, making it possible to produce a high volume of printed textiles in a short amount of time. This speed increases the efficiency of the textile manufacturing process, thereby reducing costs and increasing productivity.

Another important property of textile printing machines is their accuracy. These machines are equipped with advanced technology that ensures the precise placement of colors and patterns on textile surfaces. This accuracy helps to create high-quality prints that are clear, detailed, and visually appealing to consumers.

The versatility of textile printing machines is another critical property. These machines can print on a wide range of fabrics, including natural and synthetic textiles. This versatility expands the range of textiles that manufacturers can produce, giving them the ability to diversify their product lines and cater to a wider range of customers.

In summary, the properties of textile printing machines make them essential in the textile manufacturing process. Their speed, accuracy, and versatility help to increase efficiency, reduce costs, and produce high-quality textiles. As technology advances, these machines will continue to improve and evolve, leading to more advanced and efficient textile manufacturing processes.

How to use Textile Printing Machine

Textile printing is a method of applying color to fabrics or textiles using various techniques. The most commonly used technique is screen printing, which involves pressing ink through a stencil to create a design or pattern. Textile printing machines have made this process much easier, efficient, and precise.

To begin using a textile printing machine, you will need to prepare the artwork or design you want to print. This can be done using graphic design software such as Adobe Illustrator or CorelDRAW. Once your design is ready, you will need to transfer it onto a stencil or screen. This can be done using a photo emulsion kit or by exposing the stencil directly onto the screen.

After your stencil is ready, it’s time to set up the textile printing machine. First, make sure to choose the right type of ink for your fabric. There are different types of inks available, such as water-based, discharge, and plastisol inks. Once you have selected the right ink, set up the machine according to the manufacturer’s instructions.

Next, load the fabric onto the textile printing machine. Ensure that it is positioned correctly and secured tightly. If you are using a carousel machine, you can print multiple colors or designs simultaneously. Once you are ready to print, load your stencil onto the screen and apply the ink onto the fabric.

Finally, allow the fabric to dry completely, and then cure the ink using a heat press or tunnel dryer. This ensures that the ink is set and will not fade over time.

In conclusion, textile printing machines are an efficient way to produce high-quality prints on fabrics or textiles. With the right equipment, software, and techniques, anyone can learn how to use a textile printing machine to create stunning designs and patterns with ease.

Glossary Terminology Terms for Textile Printing Machine

When it comes to the textile printing industry, there are many technical terms and jargon that may be unfamiliar to those who are new to the industry. To fully understand the workings of textile printing machines, it’s essential to know some basic glossary terminology terms for textile printing machine. Here are some of the common ones.

1. Fabric Feed: Refers to the process of supplying fabric to the textile printing machine’s printing platform. Depending on the machine, this can be done either manually or automatically.

2. Registration: This is the process of aligning each color or design element perfectly. Accurate registration ensures that the resultant design is clean and free of overlap and smudges.

3. Drying: Once the ink is applied to the fabric, it must be left to dry. This drying process can take several minutes or hours, depending on the printing process.

4. Squeegee: This is a tool used to apply ink onto the fabric. By applying pressure to the ink and pressing it against the printing screen, the squeegee forces the ink into the fabric.

5. Printing Speed: This refers to the speed at which the machine prints the design on the fabric. This variable can be adjusted depending on the complexity of the design, the type of fabric, and other factors.

6. Retention Time: This is the amount of time that the ink is left in contact with the fabric. The retention time can vary, depending on the ink’s thickness, complexity of the design, and other factors.

7. Reactive Dye: Reactive dyes are water-soluble dyes used for printing patterns that need to be long-lasting and withstand regular washing.

8. Pigment Dye: Pigment dyes are insoluble in water and are ideal for printing designs that need to stand out, particularly on dark fabrics.

These are just some of the essential terms used in a textile printing machine, and there are many more. Understanding these terms is critical when it comes to creating

Textile Printing Machine Price

Textile printing is an essential process in the textile industry, which enables designers to create stunning designs on a range of fabrics. The textile printing machine is the most crucial tool to achieve this objective, and it’s worth mentioning that its price can vary significantly.

When it comes to purchasing a textile printing machine, it’s important to consider your budget, the type and quality of the machine, and the supplier’s reputation. A high-end machine may be more expensive than a basic one, but it can produce high-quality prints and get the job done faster, leading to increased productivity and profitability.

The price range of textile printing machines can vary from as low as $5,000 to as high as $150,000, depending on your requirements, like the size of the printing area, the type of ink, the printing speed, and the level of automation. Manual machines that use screen-printing techniques are the most affordable, and their price varies from $5,000 to $10,000. While automatic machines that are equipped with computerized systems and advanced printing technologies, are more expensive and their price ranges from $40,000 to $150,000.

In addition to the machine’s initial cost, you should consider other expenses like installation, training, and maintenance costs. Installation cost varies based on the type of machine and location; it may range from $400 to $1,500. Machine training is essential to ensure that your staff can operate the printer correctly and effectively. On average, it costs between $200 and $1,500, depending on the supplier’s location.

Finally, maintenance is crucial to keep the machine in good condition and ensure optimal productivity. The maintenance cost is dependent on the machine type and its usage. You should be prepared to spend around $100 to $1,000 annually on maintenance.

In conclusion, the price of a textile printing machine can vary significantly, depending on various factors. It’s crucial to determine your budget and requirements before selecting a suitable machine. Additionally