Introduce about textile recycling machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

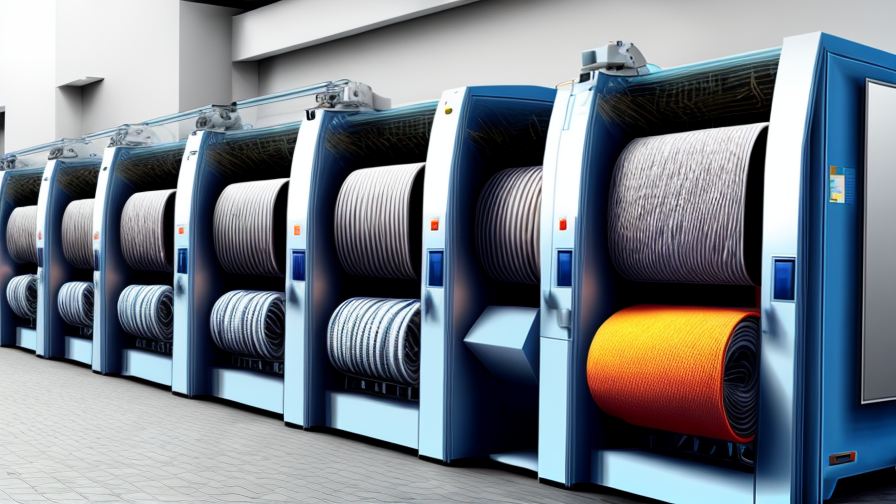

Textile recycling machines are innovative tools designed to transform discarded textiles into usable materials, reducing waste and promoting sustainability in the fashion industry. This guide aims to provide a comprehensive overview of these machines, including quality, cost, suppliers, certification, market, tips, and frequently asked questions (FAQs).

Quality is crucial when considering textile recycling machines. High-quality machines ensure efficient processing, minimal energy consumption, and superior output. Look for reputable manufacturers who offer durable and technologically advanced equipment that can handle various textile types and quantities.

Costs of textile recycling machines vary depending on factors such as capacity, automation level, and specific features. Prices may range from a few thousand to several hundred thousand dollars. Additionally, maintenance, operating costs, and any required infrastructure should be considered in the overall investment.

Finding reliable suppliers is essential for acquiring a suitable textile recycling machine. Extensive market research is advisable to identify reputable manufacturers with a track record of delivering robust and efficient machines.

Certification plays a crucial role in ensuring the quality and safety aspects of textile recycling machines. Look for machines that comply with internationally recognized standards and certifications such as ISO and CE. These certifications indicate adherence to quality control and safety regulations.

The market for textile recycling machines is growing steadily due to increased awareness of environmental issues in the fashion industry. Particularly, countries with robust textile manufacturing and consumption markets have witnessed a surge in demand for textile recycling technologies.

Here are some tips for successful textile recycling machine operation:

1. Properly sort textile waste before processing to achieve optimal results.

2. Ensure regular maintenance and servicing of the machine to maximize performance and longevity.

3. Consider the availability of trained personnel and technical support when choosing a machine.

4. Stay updated with emerging technologies and advancements in textile recycling for improved efficiency.

Frequently Asked Questions (FAQs):

Q: What types of textiles can be recycled using these machines?

A: Textile recycling machines can process various fabrics, including cotton, polyester, nylon, and blended materials.

Q: Is textile recycling sustainable?

A: Yes, textile recycling is a sustainable practice that helps reduce landfill waste and minimize the environmental impact of the fashion industry.

Q: Are textile recycling machines easy to operate?

A: Modern textile recycling machines are designed with user-friendly interfaces and may require minimal training for operation.

In conclusion, textile recycling machines offer an innovative solution to combat environmental challenges in the fashion industry. With proper research and consideration of quality, cost, suppliers, certification, and market trends, businesses can invest in these machines and contribute to a more sustainable future.

Types of textile recycling machine

Textile recycling machines play a crucial role in the process of converting waste textiles into reusable materials, reducing waste and promoting sustainability. There are several types of textile recycling machines, each designed to handle different stages or aspects of the recycling process. Here are three common types:

1. Textile shredders: These machines are used in the initial stage of textile recycling. They are designed to break down various types of textiles into smaller pieces or fragments. Shredders come in different models, such as single-shaft, double-shaft, or quad-shaft, depending on the level of fragmentation required. These machines help in preparing textiles for further processing by reducing their size and increasing their surface area, which facilitates subsequent separation and sorting processes.

2. Textile sorting machines: After the initial shredding stage, textile materials need to be sorted based on their type, color, and quality to optimize recycling processes. Textile sorting machines use various mechanisms like optical sensors, infrared technology, or manual inspection to differentiate between different types of textiles. These machines separate textiles based on their composition (e.g., cotton, polyester, nylon), color, and even specific textiles such as denim or wool. Sorting machines help streamline the recycling process by segregating textiles for subsequent processing.

3. Textile fiber recycling machines: Once the textiles are shredded and sorted, fiber recycling machines are used to convert them into reusable fibers or yarns. The most common type of fiber recycling machine is a mechanical granulator, also known as a carding machine. Carding machines comb and align the textile fibers, removing impurities and creating a continuous web of raw material. This web is then processed further to convert it into yarns or woven fabrics, which can be used to produce new textile products.

These three types of textile recycling machines collectively contribute to the efficient recycling of textiles and the reduction of textile waste. By breaking down, sorting, and converting waste textiles into reusable materials, these machines support the circular economy and the goal of sustainable textiles production.

Pros and Cons of Using textile recycling machine

Textile recycling machines have been gaining popularity as a sustainable solution for the textile industry. These machines offer several advantages and disadvantages, which are outlined below:

Pros of Using Textile Recycling Machines:

1. Environmental Benefits: Textile recycling machines help reduce environmental pollution by diverting textile waste from landfills. This reduces the demand for virgin resources and minimizes the energy, water, and chemical usage associated with textile manufacturing.

2. Energy Savings: Recycling textiles requires significantly less energy compared to producing new fibers from raw materials. By utilizing textile recycling machines, energy consumption can be reduced, leading to a decrease in greenhouse gas emissions and a smaller carbon footprint.

3. Conservation of Resources: Textile recycling machines enable the recovery of valuable resources, such as cotton, polyester, and nylon. By reusing these materials, the demand for virgin resources decreases, preserving natural resources and reducing the environmental impact associated with their extraction.

4. Job Creation: The textile recycling industry has the potential to generate new job opportunities. As the demand for recycled textiles increases, more workers will be needed to operate and maintain recycling machines, sort and process textiles, and develop innovative recycling techniques.

Cons of Using Textile Recycling Machines:

1. Insufficient Collection Systems: One of the major challenges in textile recycling is the lack of effective collection systems. If the supply of textile waste is insufficient, textile recycling machines may not operate at their full potential, leading to underutilization of resources and limited environmental benefits.

2. Limited Efficiency: While textile recycling machines have improved significantly in recent years, the efficiency of these machines may still not match that of traditional textile production processes. Issues such as contamination, uneven fiber lengths, and compromised quality can affect the final output.

3. High Initial Investment: Setting up a textile recycling facility with the necessary machinery requires a significant upfront investment. The cost of purchasing and maintaining textile recycling machines, along with the infrastructure needed to support operations, can be challenging for small businesses or developing countries with limited financial resources.

4. Technological Challenges: The proper functioning and maintenance of textile recycling machines require skilled technicians and appropriate technological infrastructure. In some regions, access to such expertise and equipment may be limited, posing challenges to establishing and operating textile recycling facilities.

In conclusion, textile recycling machines offer numerous environmental benefits, including resource conservation and reduced energy usage. However, their effectiveness relies on having an efficient collection system and appropriate operational infrastructure. While these machines have advantages, considerations must be made regarding investment costs, technological challenges, and overall efficiency.

textile recycling machine Reference Specifications (varies for different product)

The textile recycling machine is a state-of-the-art technology designed to efficiently recycle various types of textile waste and convert them into usable materials. The machine’s reference specifications may vary depending on the specific product being recycled, but it generally operates under the following principles.

The machine consists of a feed system that takes in textile waste, such as scraps, post-consumer garments, or industrial remnants. The waste is then sorted and processed to remove any non-recyclable elements, such as zippers or buttons. The sorted textiles are shredded into smaller fragments, ensuring maximum surface area for subsequent processes.

Next, the shredded materials undergo a cleaning process that effectively removes any contaminants, such as dirt, dyes, or chemicals. This ensures that the recycled textile will have a high level of purity, suitable for various end-uses. The cleaned materials are then dried to remove any moisture, optimizing the efficiency of the subsequent recycling processes.

The dried textile fragments go through a mechanical breakdown process, which further reduces their size and converts them into fibers. These fibers are then refined and spun into yarns using specialized machines. The resulting yarns possess properties similar to those of virgin yarns, making them suitable for various textile applications.

To enhance the sustainability aspect of the recycling process, the machine employs energy-efficient technologies, including advanced filtration systems to minimize emissions and reduce the carbon footprint.

Moreover, the machine incorporates smart technologies and automation, allowing for precise control and monitoring of the recycling process. This ensures optimal output quality and reduces human error.

The specific reference specifications of the textile recycling machine may vary depending on the desired end products, the capacity of the machine, and the specific waste materials being processed. However, it is designed to operate with minimal power consumption, high efficiency, and maximum reliability.

In summary, the textile recycling machine is an advanced technology that effectively recycles textile waste into usable materials. Its reference specifications may vary depending on the specific product being recycled, but the machine generally involves processes such as sorting, shredding, cleaning, refining, and spinning. It emphasizes sustainability, employs smart technologies, and aims to achieve high efficiency and reliability in its operations.

Applications of textile recycling machine

Textile recycling machines are technologically advanced equipment that play a pivotal role in the sustainable management of textile waste. These machines have various applications that contribute to environmental conservation and the circular economy. Below are some of the key applications of textile recycling machines:

1. Fiber and Yarn Production: One of the primary uses of textile recycling machines is to transform discarded textiles into fibers and yarns. These machines processes different types of textile waste, including clothing scraps, fabric remnants, and post-consumer garments. By breaking down these materials into fibers or shredding them into smaller pieces, the machine enables the production of new yarns, which can then be used for making various textile products.

2. Nonwoven Production: Textile recycling machines are also used in the manufacturing of nonwoven textiles. Nonwovens are widely used in the automotive, construction, and healthcare industries. These machines can convert textile waste into nonwoven fabrics through processes like carding, air-laying, and needle punching. This application contributes to minimizing the need for virgin materials and reducing waste generation.

3. Insulation Materials: Textile recycling machines can process textile waste into insulation materials, mainly used in the construction sector. The recycling process involves shredding and compressing textiles to produce insulation materials like fiberboards, batts, and rolls. These materials offer thermal and acoustic insulation properties, thereby enhancing energy efficiency and reducing environmental impact.

4. Geotextiles: Geotextiles are structures made from textile materials used for soil stabilization, erosion control, and waste management in civil engineering projects. Textile recycling machines can transform discarded textiles into geotextiles through processes like weaving, knitting, and needle punching. This application helps in reducing the demand for virgin materials while providing an eco-friendly solution for various construction projects.

5. Upcycling and Repurposing: In addition to conventional recycling methods, textile recycling machines enable upcycling and repurposing of textile waste. Upcycling involves transforming old or unused textiles into new products with higher value and functionality. The machines can convert waste materials into items like bags, accessories, or even new garments, prolonging their lifespan and reducing the need for new production.

Textile recycling machines offer numerous possibilities for repurposing and reusing textile waste, thereby contributing to the reduction of landfill waste, conserving resources, and minimizing the environmental impact of the textile industry. These applications demonstrate the potential of textile recycling machines in creating a more sustainable and circular textile economy.

The Work Process and how to use textile recycling machine

Textile recycling is an important process that involves converting old or unwanted textiles into new products or materials. One of the key components in this process is a textile recycling machine, which plays a crucial role in breaking down and repurposing textiles. Here is an overview of the work process involved in using a textile recycling machine.

Firstly, the textiles to be recycled are collected and sorted based on their color, type, and condition. This step helps in ensuring efficient processing and maintaining the quality of the final product. Textiles can be in the form of clothes, fabrics, bedding, or any other material made from fibers.

Once the textiles are sorted, they are fed into the textile recycling machine. The machine operates by shredding and cutting the textiles into small pieces or fibers. This can be achieved through various methods such as mechanical shredding, shearing, or tearing.

After the initial shredding process, the machine separates the fibers from any contaminants like buttons, zippers, or dirt. This is usually done through a combination of methods like sieving, magnetic separation, and air-blowing. Removing contaminants ensures the resultant fibers are clean and ready for further processing.

Next, the separated fibers undergo a process called carding, where they are aligned and straightened to form a web-like structure. Carding helps in improving the quality and consistency of the fibers, making them easier to handle and process further.

Once carded, the fibers can undergo additional processes such as blending, combing, or spinning, depending on the desired end product. Blending involves mixing fibers of different types or colors to create new materials with desired properties. Combing, on the other hand, further aligns and removes shorter fibers from the longer ones, resulting in a smoother and more uniform fiber.

Finally, the processed fibers can be used to create new textiles, insulation materials, upholstery, or even recycled yarns for knitting or weaving. They can also be combined with other materials like plastics or paper to produce composite materials with unique characteristics.

It is important to note that different textile recycling machines may vary in terms of their specific processes or capabilities. Therefore, it is crucial to follow the manufacturer’s instructions and guidelines while operating the machine to ensure safe and efficient usage.

In conclusion, textile recycling machines are essential in the process of transforming old textiles into new products or materials. They contribute to the sustainability of the textile industry by reducing waste and conserving resources. By understanding the work process of a textile recycling machine, one can effectively utilize it to recycle textiles and contribute to a greener and more circular economy.

Quality Testing Methods for textile recycling machine and how to control the quality

When it comes to quality testing methods for textile recycling machines, there are several approaches that can be adopted to ensure optimum performance and output:

1. Visual Inspection: This method involves a thorough visual examination of the textile recycling machine to detect any defects, damages, or abnormalities. It allows for the identification of any visible issues that can impact the quality of the recycled textiles.

2. Control Samples: The use of control samples involves comparing the output of the textile recycling machine with pre-defined standards or samples. This helps ensure that the quality of the recycled textiles meets the desired requirements.

3. Physical Testing: Various physical tests can be performed on the recycled textiles to assess their quality. These tests may include evaluating the tensile strength, colorfastness, shrinkage, and dimensional stability, among others. By conducting these tests, any deviations from the required quality parameters can be identified and addressed.

4. Chemical Testing: Chemical analysis can be performed on the recycled textiles to ensure that they do not contain any harmful substances or chemicals. This testing method helps control the quality of the recycled textiles by verifying their compliance with safety and regulatory standards.

In order to control the quality of the textile recycling machine, the following measures can be taken:

1. Regular Maintenance: Regular and timely maintenance of the machine is crucial to ensure its optimal performance and extend its lifespan. This includes cleaning, lubricating, and inspecting the machine regularly to identify and address any potential issues.

2. Calibration: Calibrating the machine periodically helps maintain its accuracy and consistency in delivering the desired quality of recycled textiles. This involves adjusting the machine’s settings and parameters based on the specific requirements.

3. Operator Training: Providing comprehensive training to the operators of the textile recycling machine is essential. This ensures that they are equipped with the necessary knowledge and skills to operate the machine correctly, minimize errors, and maintain the desired quality standards.

4. Documentation and Record-Keeping: Maintaining detailed documentation and records of the machine’s operations, maintenance, and testing results is important for quality control. This enables the identification of patterns or trends that may affect the machine’s performance and allows for corrective measures to be implemented.

By implementing these quality testing methods and control measures, textile recycling machines can consistently produce high-quality recycled textiles that meet the required standards.

textile recycling machine Sample Policy and Post-Purchase Considerations for textile recycling machine from China

Sample Policy and Post-Purchase Considerations for Textile Recycling Machine from China

When purchasing a textile recycling machine from China, it is important to set clear expectations in terms of product quality, warranty, and after-sales support. The following sample policy and post-purchase considerations will help guide your decision-making process:

Sample Policy:

1. Quality Assurance: Ensure that the supplier can provide certifications such as ISO 9001 to confirm their commitment to quality standards. Request samples or visit their manufacturing facility if possible.

2. Product Warranty: Obtain a written agreement specifying the warranty period and any limitations. Verify if the warranty covers parts, labor, or both. It is recommended to opt for longer warranty periods.

3. Spare Parts Availability: Inquire about the availability and cost of spare parts for the machine. A reliable supplier should be able to provide spare parts quickly to minimize downtime.

4. Technical Support: Ensure that the supplier offers technical support via email, phone, or on-site visits, if required. Prompt and efficient technical support is crucial for troubleshooting and maintenance.

5. Training and Installation: Confirm whether the supplier offers training and installation services. This will help ensure correct machine setup and operation.

Post-Purchase Considerations:

1. Communication and Follow-up: Stay in touch with the supplier to address any issues or queries promptly. Maintain open and regular communication to ensure a smooth post-purchase experience.

2. Machine Performance: Regularly monitor and evaluate the machine’s performance to ensure it meets your expectations. Identify any issues early and take appropriate actions.

3. Routine Maintenance: Follow the supplier’s recommended maintenance schedule to ensure optimal performance and maximize the machine’s lifespan. Regularly clean and inspect the machine for wear and tear.

4. Upgrades and Improvements: Stay updated with the latest technology and advancements in textile recycling. Inquire if the supplier offers upgrades or improvements that can enhance your machine’s efficiency and capabilities.

5. User Feedback: Provide constructive feedback to the supplier regarding the machine’s performance, reliability, and ease of use. This will enable them to improve their products and services.

By implementing these policies and considerations, you can maximize the efficiency and longevity of your textile recycling machine while ensuring satisfactory post-purchase support.

Sourcing textile recycling machine from China: Opportunities, Risks, and Key Players

Sourcing textile recycling machines from China presents several opportunities and risks in the market. China is known for its vast manufacturing capabilities and competitive prices, making it an attractive destination for sourcing machinery. Moreover, the textile industry is increasingly focused on sustainability, creating a growing demand for textile recycling machines.

One of the main opportunities of sourcing from China is the cost advantage. Chinese manufacturers can offer machinery at lower prices due to their economies of scale and lower labor costs. This can significantly benefit businesses looking to invest in textile recycling machines while optimizing their budget.

Furthermore, China has a well-established supply chain infrastructure for manufacturing textile machinery. This allows for faster production and delivery times, ensuring efficient procurement processes. Additionally, Chinese manufacturers often have experience in exporting their products, providing convenient logistics solutions to global buyers.

However, sourcing from China also entails certain risks. One of the main concerns is ensuring the quality of the machines. While China has many reputable manufacturers, there are also cases of subpar or counterfeit products. It is essential to thoroughly research and verify the reputation and certifications of potential suppliers before making a purchasing decision.

Intellectual property theft is another risk that should be considered. China has faced criticism for its inadequate enforcement of intellectual property rights, creating concerns about the potential replication or misuse of technologies. Businesses must protect their intellectual property through patents, trademarks, or other legal mechanisms to mitigate this risk.

Despite the challenges, there are several key players in the Chinese textile recycling machine market. Companies such as Tianyuan Group, Jiangsu Yingyang Nonwoven Machinery, and Shang Hai BEF are renowned manufacturers with extensive experience in textile recycling technology. These key players offer a variety of machines for different stages of textile recycling, including sorting, shredding, and spinning.

In conclusion, sourcing textile recycling machines from China offers significant opportunities in terms of cost, manufacturing capabilities, and efficient supply chains. However, risks such as quality assurance and intellectual property theft need to be carefully addressed. By conducting thorough research and partnering with reputable manufacturers, businesses can successfully source textile recycling machines from China to enhance their sustainability efforts.

How to find and select reliable textile recycling machine manufacturers in China,use google search manufacturers and suppliers

To find and select reliable textile recycling machine manufacturers in China, using Google search manufacturers and suppliers, follow these steps:

1. Begin by conducting a Google search using keywords like “textile recycling machine manufacturers in China.” This will provide you with a list of manufacturers and suppliers in the industry.

2. Visit the websites of the manufacturers listed in the search results. Look for detailed information about their company, such as their history, experience, certifications, and product range.

3. Check if the manufacturer has a dedicated page for textile recycling machines on their website. This indicates their specialization in this particular field.

4. Look for customer reviews or testimonials on their website or other online platforms. Positive reviews indicate customer satisfaction and reliability.

5. Evaluate the manufacturer’s production capacity and technological capabilities. This can be inferred from their production facilities, research and development efforts, and investment in advanced machinery.

6. Check if the manufacturer complies with international quality standards such as ISO certification. This ensures that their products meet international quality requirements.

7. Inquire about the manufacturer’s after-sales service and technical support. Reliable manufacturers provide comprehensive support and maintenance services to their customers.

8. Contact the shortlisted manufacturers and request additional information like product catalogs, pricing, lead time, and customization capabilities.

9. Assess the manufacturer’s responsiveness and professionalism in their communication. Prompt and informative responses are indicative of their reliability.

10. Finally, consider their pricing, payment terms, and delivery options. Compare these factors among different manufacturers to make an informed decision.

By following these steps and considering factors such as company information, customer reviews, quality standards, technical support, and pricing, you can effectively find and select reliable textile recycling machine manufacturers in China.

How to check textile recycling machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of a textile recycling machine manufacturer’s website, you can follow these steps using Google Chrome and the SEOquake extension:

1. Install SEOquake: Start by installing the SEOquake extension on your Google Chrome browser. You can find and install this extension from the Chrome Web Store.

2. Search for the Manufacturer: Go to the Google Search homepage and enter the name of the textile recycling machine manufacturer. Click on the search button to view the results.

3. Analyze Search Ranking: Scan through the search results and check if the manufacturer’s website appears in the top 10 million websites. To do this, hover your mouse cursor over the website link of the manufacturer and look for the SEOquake bar at the bottom of the page. The SEOquake bar provides information about the website’s estimated monthly visitors, Alexa Rank, and more.

4. Assess Website Information: Click on the manufacturer’s website link in the search results to visit their website. Look for essential information such as contact details, company history, product specifications, and certifications. A reliable manufacturer’s website typically provides comprehensive and accurate information about their products and services.

5. Check for Customer Reviews/Testimonials: Look for customer reviews or testimonials on the website. Genuine and positive reviews indicate a manufacturer’s credibility and customer satisfaction. You can also search for external review websites or forums to gather more insights from actual users.

6. Verify Certifications and Partnerships: Look for any certifications or partnerships displayed on the manufacturer’s website. Recognitions from reputable organizations or collaborations with established industry partners can suggest reliability and trustworthiness.

7. Contact the Manufacturer: If you have any doubts or questions, consider reaching out to the manufacturer directly. Reliable manufacturers will promptly respond to inquiries and provide accurate information.

It’s essential to exercise caution and conduct comprehensive research before making any significant purchases from a textile recycling machine manufacturer. By following these steps and considering the information gathered, you can evaluate the reliability of a manufacturer’s website effectively.

Top 10 textile recycling machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Wuxi Shunlida Plastic Machinery Co., Ltd. specializes in manufacturing textile recycling machines, including waste fabric tearing machines, waste cotton recycling machines, and fiber opening machines. These machines are designed to efficiently process various types of textile waste, leading to reduced fabric waste and increased recycling rates.

2. Qingdao Huaruijiahe Machinery Co., Ltd. offers a range of textile recycling machines that include high-speed fabric cutting machines, fabric recycling machines, and industrial fabric cutting machines. With their innovative technology, these machines ensure precise cutting and effective recycling of textile waste.

3. Emin Machinery provides advanced textile waste recycling solutions with their cutting-edge textile waste opening machines. These machines effectively open and separate various kinds of textile waste, enabling efficient recycling and reuse of the materials.

4. Jinan Morinte Machinery Co., Ltd. specializes in manufacturing textile recycling machines like fabric tearing machines and waste yarn recycling machines. These machines are designed to facilitate the recycling process by tearing or separating textile waste into smaller fibers for further processing.

5. Changshu Shouyu Machinery Co., Ltd. offers a comprehensive range of textile recycling machines, including waste fabric shredders, waste yarn recycling lines, and fiber waste compactors. Their machines are known for their durability, efficiency, and minimal maintenance requirements.

6. Zhangjiagang Sevenstars Machinery Co., Ltd. manufactures textile recycling machines, such as waste fabric shredders and fabric cutting machines. These machines are designed to effectively shred and cut textile waste into smaller pieces, facilitating the recycling process.

7. Jiangsu Fangsheng Machinery Co., Ltd. provides innovative textile recycling solutions with their textile waste tearing machines and textile shredders. These machines effectively tear or shred textile waste, enabling easy recycling and reuse of the materials.

8. Jinan Runsen Machinery Co., Ltd. specializes in manufacturing textile recycling machines, including waste fabric shredders and fiber opening machines. These machines are designed to efficiently process textile waste, reducing the overall carbon footprint and promoting sustainable practices.

9. Dongguan Haibao Machinery Technology Co., Ltd. offers a wide range of textile recycling machines, including fabric cutting machines and waste textile recycling lines. These machines ensure precise cutting and effective recycling of textile waste, contributing to a greener environment.

10. Suzhou Youlian Textile Equipment Technology Co., Ltd. manufactures textile recycling machines like fabric tearing machines and waste yarn recycling machines. These machines are designed to effectively tear and recycle textile waste, helping to reduce environmental pollution caused by fabric waste.

|Manufacturer |Main Products |

|—————————————-|————————————————————————-|

|Wuxi Shunlida Plastic Machinery Co., Ltd.|Waste fabric tearing machines, waste cotton recycling machines, fiber opening machines |

|Qingdao Huaruijiahe Machinery Co., Ltd. |High-speed fabric cutting machines, fabric recycling machines, industrial fabric cutting machines|

|Emin Machinery |Textile waste opening machines |

|Jinan Morinte Machinery Co., Ltd. |Fabric tearing machines, waste yarn recycling machines |

|Changshu Shouyu Machinery Co., Ltd. |Waste fabric shredders, waste yarn recycling lines, fiber waste compactors|

|Zhangjiagang Sevenstars Machinery Co., Ltd.|Waste fabric shredders, fabric cutting machines |

|Jiangsu Fangsheng Machinery Co., Ltd. |Textile waste tearing machines, textile shredders |

|Jinan Runsen Machinery Co., Ltd. |Waste fabric shredders, fiber opening machines |

|Dongguan Haibao Machinery Technology Co., Ltd.|Fabric cutting machines, waste textile recycling lines |

|Suzhou Youlian Textile Equipment Technology Co., Ltd.|Fabric tearing machines, waste yarn recycling machines|

These textile recycling machine manufacturers in China offer a wide range of products to cater to various textile waste recycling needs. Each manufacturer specializes in different types of machines that effectively process textile waste, reducing fabric waste and promoting sustainability. By incorporating these machines into their operations, textile manufacturers can contribute to a greener environment and promote a circular economy in the textile industry.

Background Research for textile recycling machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to textile recycling machine manufacturers in China, several companies stand out in terms of their expertise, experience, and product quality. Using platforms like qcc.com, archive.org, and importyeti.com, we can gather background information on some prominent manufacturers in this industry.

One such company is Qingdao New Shun Xing Co., Ltd, which specializes in the production of textile recycling machinery. Established in 2003, they have developed a range of advanced machines that are used for recycling various textiles, including cotton, polyester, nylon, and more. Their products are known for their high efficiency and excellent performance in the recycling process.

Another notable manufacturer is Jinjiang Hanwei Machinery Manufacturing Co., Ltd. Founded in 2006, they have gained a strong reputation for producing textile recycling machines that are widely used in garment factories and textile recycling facilities. Their range of machines includes cotton waste recycling machine, fabric cutter machine, and yarn waste recycling machine.

We can also find relevant information on manufacturers such as Gaomi Rongda Machinery Co., Ltd. With over two decades of experience, they specialize in the production of textile recycling machines, including fiber opening machines, textile cutting machines, and fiber tearing machines. Their products are highly regarded for their durability and precision.

An additional company worth mentioning is Qingdao Joint Machinery Co., Ltd. They have been manufacturing textile recycling machines since 1997 and offer a comprehensive range of products that cater to the needs of the industry. Their machines are designed to efficiently process textile waste, turning it into reusable materials.

In conclusion, China is home to several reputable textile recycling machine manufacturers. Companies like Qingdao New Shun Xing Co., Ltd, Jinjiang Hanwei Machinery Manufacturing Co., Ltd, Gaomi Rongda Machinery Co., Ltd, and Qingdao Joint Machinery Co., Ltd have established themselves as leading players in this field. Their expertise, experience, and commitment to producing high-quality machines make them valuable contributors to the textile recycling industry.

Leveraging Trade Shows and Expos for textile recycling machine Sourcing in China

Trade shows and expos are excellent platforms for sourcing textile recycling machines in China. These events bring together manufacturers, suppliers, and industry professionals, making it easier to connect with potential suppliers and evaluate their products and services.

Attending trade shows and expos dedicated to textile recycling machines can provide several benefits. Firstly, it allows buyers to have a hands-on experience with the machines on display. This enables them to assess the quality, functionality, and efficiency of the equipment. Buyers can examine the machines’ components, durability, and overall build quality to ensure that they meet their specific requirements.

Furthermore, trade shows and expos create opportunities for face-to-face interactions and networking with suppliers. Engaging in direct conversations with manufacturers and sales representatives allows buyers to ask questions, seek clarification, and negotiate pricing and terms. These personal connections can help establish trust and build strong relationships with potential suppliers in China.

Another advantage of trade shows and expos is the ability to explore a wide range of options. These events bring together numerous exhibitors offering different types of textile recycling machines. Buyers can compare the features, specifications, and pricing of various machines in a single location, saving time and effort.

To maximize the benefits of attending trade shows and expos, buyers should come prepared. Researching the exhibitors beforehand and identifying the key machines of interest can help streamline the sourcing process. Taking note of specific questions, concerns, and requirements ensures that buyers can make informed decisions.

In sum, leveraging trade shows and expos for textile recycling machine sourcing in China provides an effective way to connect with potential suppliers, assess machine quality, and explore a wide range of options. These events facilitate personal interactions with manufacturers and allow buyers to negotiate favorable terms. By adequately preparing for these events, buyers can optimize their sourcing efforts and find the most suitable textile recycling machine for their needs.

The Role of Agents and Sourcing Companies in Facilitating textile recycling machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating textile recycling machine purchases from China. These intermediaries act as a bridge between buyers and manufacturers, helping to streamline the procurement process and ensure smooth transactions.

One of the primary functions of agents and sourcing companies is to identify suitable suppliers in China who specialize in manufacturing textile recycling machines. They have an extensive network of contacts and a deep understanding of the Chinese market, enabling them to connect buyers with reliable and reputable manufacturers. By conducting thorough due diligence, these intermediaries ensure that the selected suppliers meet the buyer’s requirements in terms of quality, price, and delivery timeframes.

Additionally, agents and sourcing companies assist buyers in negotiating favorable terms and conditions with the manufacturers. They leverage their industry knowledge and bargaining power to secure competitive prices, favorable payment terms, and other advantageous contractual arrangements. This helps buyers to obtain the best possible value for their investment in textile recycling machines from China.

Furthermore, agents and sourcing companies provide assistance with the logistical aspects of the purchase. They coordinate shipping and customs clearance, ensuring that the machines are transported safely and efficiently to the buyer’s location. This expertise in international logistics helps to minimize any potential delays or disruptions that may arise during the transportation process.

Moreover, agents and sourcing companies also play a crucial role in quality control and assurance. They conduct regular inspections and monitoring of the production process to ensure that the textile recycling machines are manufactured to the required specifications. This helps to mitigate any risks of substandard products and facilitates the timely resolution of any quality issues that may arise.

In summary, agents and sourcing companies are instrumental in facilitating textile recycling machine purchases from China. Their expertise in supplier identification, negotiation, logistics, and quality control streamlines the procurement process and ensures that buyers can acquire high-quality machines that meet their specific requirements. By acting as trusted intermediaries, these professionals contribute to building strong business relationships between buyers and Chinese manufacturers.

Price Cost Research for textile recycling machine manufacturers Companies in China, use temu.com and 1688.com

When it comes to textile recycling machine manufacturers in China, two prominent websites for conducting price cost research are temu.com and 1688.com.

temu.com is an online marketplace specifically dedicated to recycled textile machinery. It provides a vast range of options from various manufacturers in China. The website allows users to search for specific machinery, browse through different categories, and analyze product specifications. The platform also features filters to refine searches based on price range, production capacity, and other desired criteria. By exploring the listings on temu.com, researchers can gain insights into the price ranges and features offered by different textile recycling machine manufacturers.

1688.com, on the other hand, is a popular B2B online marketplace in China that offers a wide range of products, including textile recycling machines. It functions as a wholesale platform, providing users with access to manufacturers, wholesalers, and suppliers directly. Researchers can leverage the search bar on 1688.com to look for textile recycling machines, filter results by price, view product details, and compare prices among different manufacturers. This platform can provide valuable information on pricing trends, allowing researchers to make informed decisions regarding costs.

By utilizing these platforms, researchers can access price comparisons, explore different manufacturers’ offerings, and gain knowledge about the features and specifications of textile recycling machines. This research can help potential buyers or investors make informed decisions based on their budget, quality requirements, and production needs.

Shipping Cost for textile recycling machine import from China

The shipping cost for importing a textile recycling machine from China will depend on various factors such as the size and weight of the machine, the shipping method, and the distance between the origin and destination. Generally, there are two primary methods of shipping: air freight and sea freight.

For air freight, the cost will be higher but the delivery time will be significantly shorter. The cost will be calculated based on the weight and dimensions of the machine. Additionally, other charges such as handling fees, customs duties, and taxes may also apply. On average, the cost for air freight can range from $2 to $10 per kilogram, excluding additional charges.

On the other hand, sea freight is a more cost-effective option for large and heavy machinery. The cost will be calculated based on the volume and weight of the machine, as well as the shipping route. Sea freight options include full container load (FCL), where a whole container is dedicated to the shipment, and less than container load (LCL), where the machine will be consolidated with other shipments. The cost for sea freight can range from $500 to $3,000 or more, depending on the size and distance.

It is important to mention that these costs are estimates and can vary significantly depending on factors such as the shipping company, current market conditions, and any extra services required, such as insurance or customs clearance.

To ensure a smooth shipping process and accurate cost estimation, it is recommended to contact shipping companies or freight forwarders for detailed quotes and guidance based on the specific requirements of the machine and the intended destination.

Compare China and Other textile recycling machine Markets: Products Quality and Price,Visible and Hidden Costs

China is a dominant player in the textile recycling machine market, competing against other countries such as the United States, Germany, and India. When it comes to product quality, China often offers a wide range of options, including both high-quality machines and cheaper, lower-quality alternatives. This variety gives customers the flexibility to choose based on their specific needs and budget.

In terms of price, China generally has a competitive edge over other markets. The country’s ability to mass-produce machines efficiently and cost-effectively allows manufacturers to offer more affordable prices compared to their counterparts in other countries. However, this lower price point sometimes comes at the expense of product quality, as cheaper machines may not operate as efficiently or have the same lifespan as higher-priced alternatives.

When assessing the costs associated with textile recycling machines, it is essential to consider both visible and hidden costs. Visible costs include the initial purchase price, delivery charges, and any additional accessories or features. China’s competitive pricing often makes these visible costs more attractive to customers.

However, hidden costs such as maintenance, repairs, and replacement parts need to be factored in as well. China’s lower-priced machines might require more frequent maintenance or replacement parts, increasing long-term costs. Purchasing a higher-priced machine from a different market might result in lower hidden costs over time due to better quality and durability.

It is important for customers to carefully evaluate their priorities – whether they prioritize short-term affordability or long-term reliability and durability – when comparing China’s textile recycling machines to those in other markets. The decision ultimately depends on their specific needs, budget, and their willingness to pay more upfront to potentially save on hidden costs in the long run.

In conclusion, China’s textile recycling machine market offers a diverse range of products with both high and low-quality options. The competitive pricing makes these machines attractive initially, but hidden costs such as maintenance and replacement parts should be carefully considered. Customers should evaluate their priorities and long-term goals to make an informed decision between China and other markets.

Understanding Pricing and Payment Terms for textile recycling machine: A Comparative Guide to Get the Best Deal

When it comes to purchasing a textile recycling machine, understanding pricing and payment terms is crucial to ensure you get the best deal. This comparative guide aims to highlight important factors to consider and provide insights into getting the most value for your investment.

Firstly, pricing for textile recycling machines can vary significantly depending on various factors such as the machine’s capacity, efficiency, brand reputation, and additional features. It is important to research different manufacturers and suppliers to get a better understanding of the market prices. Comparing multiple quotes and evaluating the quality of the machines will help you identify the most reasonable price range.

In addition to the initial cost, it is essential to consider the long-term expenses related to the machine. This includes maintenance, spare parts, and operational costs. Some manufacturers may offer warranty packages or after-sales services, which can minimize unexpected expenses and provide greater peace of mind. Evaluating the overall cost of ownership will give a more accurate understanding of the machine’s value.

Payment terms also play a vital role in securing the best deal for a textile recycling machine. Generally, suppliers offer two main options: upfront payment or financing. While upfront payment might seem financially burdensome, it can often lead to lower overall costs as it eliminates interest charges. However, financing options allow businesses to spread the cost over time, making it more manageable for those with limited capital.

When considering financing, it is important to compare interest rates, repayment schedules, and any additional fees or charges. Some suppliers might have partnerships with financial institutions, allowing them to offer more favorable terms. Carefully assessing the payment terms and associated costs will enable you to make an informed decision.

Lastly, it is crucial to negotiate and communicate with suppliers effectively. Engage in discussions about pricing, payment terms, and any customizations you require. Be open to exploring alternative options or additional perks that can enhance the value of your purchase. Building a strong relationship with the supplier can also lead to future benefits such as discounted rates or priority access to new technologies.

In conclusion, understanding pricing and payment terms for textile recycling machines is vital to obtain the best deal. Conduct thorough research, compare quotes, evaluate long-term expenses, and carefully assess payment options. Negotiate with suppliers to ensure you get the most value for your investment. By following these guidelines, you can make an informed decision and contribute to sustainable textile recycling initiatives.

Chinese Regulations and Industry Standards Certifications for textile recycling machine,Import Regulations and Customs for textile recycling machine from China

Chinese Regulations and Industry Standards Certifications for textile recycling machine:

In China, the textile recycling machine must adhere to certain regulations and obtain industry standards certifications before they can be sold or imported. The main regulatory body responsible for setting standards and issuing certifications is the General Administration of Quality Supervision, Inspection, and Quarantine (AQSIQ).

One of the key certifications required for textile recycling machines is the China Compulsory Certification (CCC). This certification ensures that the machine complies with the mandatory safety and quality requirements as specified by the Chinese government. It is intended to protect consumers and prevent substandard or unsafe machines from entering the market.

Additionally, textile recycling machines may need to conform to specific industry standards for different aspects, such as performance, energy efficiency, and environmental protection. These standards are set by various standard organizations and associations, including the National Textile Machinery Standardization Technical Committee.

Import Regulations and Customs for textile recycling machines from China:

Importing textile recycling machines from China requires compliance with specific regulations and customs procedures. The import regulations and customs policies vary depending on the country of import, and it is advisable to consult the customs authorities of the importing country for detailed requirements. However, there are some general procedures that are commonly followed:

1. Import permit or license: In some countries, an import permit or license may be necessary to import textile recycling machines. This requirement is aimed at controlling imports and ensuring compliance with safety and quality standards.

2. Customs documentation: The importer needs to provide necessary customs documents, including the commercial invoice, packing list, bill of lading or airway bill, and any other relevant certificates or licenses.

3. Customs duties and taxes: Importers are required to pay customs duties, import taxes, and other applicable fees upon importation. The customs authorities of the importing country will determine the exact amount based on the declared value of the machines.

4. Customs clearance: To clear the textile recycling machines through customs, the importer needs to submit all required documentation and pay any applicable duties or taxes. The customs authorities will inspect the goods and verify the conformity with regulations and standards.

In conclusion, to sell or import textile recycling machines from China, manufacturers and importers must ensure compliance with Chinese regulations and obtain industry standards certifications. Importers need to be aware of the specific import regulations and customs procedures of their country to successfully import these machines.

Sustainability and Environmental Considerations in textile recycling machine Manufacturing

Sustainability and environmental considerations play a crucial role in textile recycling machine manufacturing. Such machines are designed to recycle textile waste and convert it into reusable materials, minimizing the environmental impact caused by the textile industry.

One important aspect of sustainability in textile recycling machine manufacturing is the use of eco-friendly materials. Manufacturers strive to incorporate recycled and biodegradable materials in the production of these machines, reducing the consumption of virgin materials and promoting a circular economy. Additionally, energy-efficient components and systems are implemented to minimize energy consumption during the machine’s operation.

Another significant consideration is the reduction in water usage. Textile recycling machines often involve washing and treating textile waste to remove impurities. To make the process sustainable, manufacturers are increasingly utilizing innovative technologies that enable efficient water management. Techniques like water recycling, advanced filtration systems, and low-water consumption designs are implemented to minimize water wastage and reduce the environmental impact.

Furthermore, the integration of smart technologies and automation in textile recycling machines helps optimize the recycling process. These technologies enable precise control and monitoring of various parameters, ensuring minimal material loss and maximizing the recycling efficiency. By reducing waste and increasing recycling rates, manufacturers contribute to a more sustainable and environmentally friendly textile industry.

Sustainability and environmental considerations also extend to the end-of-life of these machines. Manufacturers strive to design machines that are easy to dismantle and recycle. This ensures that the components and materials of the machines can be recovered efficiently, minimizing waste and promoting the concept of a circular economy.

In conclusion, sustainability and environmental considerations are integral to textile recycling machine manufacturing. By incorporating eco-friendly materials, minimizing water usage, utilizing smart technologies, and designing for end-of-life recyclability, manufacturers contribute to a more sustainable textile industry and help reduce its environmental impact.

List The Evolution history of “textile recycling machine”

Textile recycling machines have evolved significantly over the years, adapting to changing technology and environmental needs. The history of textile recycling machines can be traced back to the early 19th century when the first mechanized spinning mills were introduced. These mills revolutionized the textile industry by enabling large-scale production of textiles.

In the early 20th century, with the proliferation of synthetic fibers like nylon and polyester, the need for textile recycling became apparent. The first textile recycling machines were simple sorting mechanisms that separated different types of textiles based on their fiber composition. These early machines laid the foundation for future developments in textile recycling technology.

Throughout the mid-20th century, advances in automation and machinery led to the development of more sophisticated textile recycling machines. These machines were capable of shredding, cutting, and processing textile waste into fibers that could be reused in the production of new textiles. The goal was to minimize the amount of textile waste ending up in landfills and to reduce the demand for raw materials.

In recent decades, technological advancements have played a crucial role in the evolution of textile recycling machines. Improved sensors and sorting technologies now allow for more accurate separation of different fiber types, enabling a higher quality of recycled textiles. Additionally, advancements in material science have led to the development of innovative recycling processes like chemical dissolution and mechanical depolymerization, which further increase the efficiency and effectiveness of textile recycling machines.

The introduction of artificial intelligence and robotics has also had a significant impact on textile recycling machines. AI-powered systems can now automate many aspects of the recycling process, improving efficiency and reducing labor costs. Robots are increasingly being used in textile recycling facilities to perform tasks such as sorting, cutting, and packaging.

Looking to the future, the evolution of textile recycling machines will likely continue. Innovations in nanotechnology and biotechnology hold the potential to further improve the recycling process by developing new materials and methods. Additionally, the integration of renewable energy sources into textile recycling machines will contribute to a more sustainable and environmentally friendly recycling process.

In summary, the evolution of textile recycling machines has seen a progression from simple sorting mechanisms to sophisticated, automated systems. Advancements in technology, material science, and automation have all played a role in improving the efficiency and effectiveness of these machines. With further advancements on the horizon, textile recycling machines will continue to contribute to a more sustainable textile industry.

The Evolution and Market Trends in textile recycling machine Industry

The textile recycling machine industry has experienced significant growth and evolution over the years, driven by increasing awareness about sustainability and the need to reduce textile waste. These machines play a crucial role in the recycling process by sorting, shredding, and converting textile waste into reusable fibers or materials.

One of the key market trends in this industry is the adoption of advanced technology. Textile recycling machines are now equipped with state-of-the-art sensors and sorting algorithms, enabling more efficient sorting and processing of different types of textiles. This not only improves the overall recycling process but also increases the quality and value of the recycled materials.

Another important trend is the shift towards automation and robotics. As the textile recycling industry continues to grow, the demand for faster and more efficient machines is increasing. Automated machines can handle larger volumes of textile waste and require minimal manual intervention, leading to higher productivity and cost-effectiveness.

Furthermore, there is a growing trend towards the development of compact and mobile textile recycling machines. These machines are designed to be small in size and easy to transport, allowing textile recycling to be conducted on-site or in remote areas. This is particularly beneficial for businesses or organizations that generate a significant amount of textile waste, as it eliminates the need for transportation and storage of bulky waste materials.

In addition to these trends, there is also a rising demand for recycled textile materials. With a growing focus on sustainability and circular economy principles, many industries are looking for eco-friendly alternatives to traditional textile materials. This has created a market for recycled textiles, driving the need for more efficient and advanced recycling machines.

Overall, the textile recycling machine industry is witnessing a transformation driven by technological advancements, automation, and the growing demand for sustainable materials. As the industry continues to evolve, it is expected that more innovative and efficient machines will be developed, further revolutionizing the textile recycling process.

Custom Private Labeling and Branding Opportunities with Chinese textile recycling machine Manufacturers

There are abundant custom private labeling and branding opportunities available with Chinese textile recycling machine manufacturers. Chinese manufacturers have comprehensive capabilities to produce high-quality machines that can efficiently recycle textile waste. By partnering with these manufacturers, businesses can leverage their expertise to create a unique and specialized brand image in the textile recycling industry.

Chinese manufacturers offer flexible custom private labeling options, allowing businesses to prominently display their own branding and logos on the machines. This helps establish a strong brand identity and increases brand recognition among potential customers. Through custom labeling, businesses can effectively differentiate themselves from competitors and build customer trust and loyalty.

Furthermore, Chinese manufacturers are well-versed in textile recycling machine technology and can provide tailor-made solutions to meet specific business requirements. They have a wide range of models and designs, ensuring businesses can select the most suitable machine for their operational needs. Manufacturers also offer the opportunity to customize machine features, such as size, capacity, and performance, allowing businesses to create unique selling points for their branded machines.

In addition to private labeling, Chinese manufacturers provide branding opportunities through customized packaging and marketing materials. Packaging can be personalized with business logos, colors, and design elements, which not only enhances the overall brand experience but also helps attract attention and stand out on the market. Marketing materials like brochures, catalogs, and advertisements can also be branded, ensuring consistent messaging and reinforcing brand awareness.

The extensive manufacturing infrastructure in China and the cost-effectiveness of production make it a favorable destination for businesses looking to establish their own branded textile recycling machines. Chinese manufacturers are capable of producing high volumes, ensuring scalability for businesses as they grow. Additionally, the competitive pricing of Chinese manufactured products offers a significant advantage in the global market.

In conclusion, Chinese textile recycling machine manufacturers offer businesses endless possibilities for custom private labeling and branding. By partnering with these manufacturers, businesses can create a distinct brand identity, differentiate themselves from competitors, and establish a strong market presence in the textile recycling industry.

Tips for Procurement and Considerations when Purchasing textile recycling machine

1. Define your requirements: Start by identifying the specific type and capacity of the textile recycling machine you require. Consider factors such as the types of fabrics you will be processing, the desired output capacity, and any specific features or functionalities you need.

2. Research reputable suppliers: Look for suppliers with a strong reputation in the industry and a track record of delivering high-quality machines. Consider factors such as their experience, customer reviews, and whether they offer after-sales service and technical support.

3. Evaluate machine capabilities: Ensure that the machine you are considering can handle the types of textiles you will be recycling. Check if it can process different fabric weights and compositions effectively. Look for features such as adjustable settings for different fabric types and options for customization to meet your specific needs.

4. Consider production capacity: Determine the desired output capacity of the machine, and choose a model that can meet your production requirements. Take into account factors such as processing speed, efficiency, and the potential for expansion if your production needs change in the future.

5. Ensure energy efficiency: Look for a textile recycling machine that is energy-efficient to reduce operational costs and minimize environmental impact. Consider features such as energy-saving modes, low-power consumption, and efficient heat recovery systems.

6. Assess maintenance and support: Inquire about the availability of spare parts, maintenance requirements, and service contracts. A reliable supplier should provide comprehensive technical support and be able to quickly address any issues that arise during machine operation.

7. Consider space requirements: Evaluate the space available in your facility and choose a machine that can fit within those constraints. Take into account factors such as the machine’s dimensions, clearance requirements for maintenance, and space for loading and unloading raw materials.

8. Request demonstrations or trials: Ask suppliers if they offer demonstrations or trials of their textile recycling machines. This will allow you to assess the machine’s performance, functionality, and ease of operation before making a purchase.

9. Consider the total cost of ownership: Look beyond the initial purchase price and consider the long-term costs associated with the machine, including maintenance, energy consumption, and potential downtime. Opt for a machine that offers a good balance of upfront cost and ongoing expenses.

10. Seek references: Ask the supplier for references from other customers who have purchased their textile recycling machine. Contact these references to learn about their experience with the machine and supplier, helping you make an informed decision.

By following these key considerations when purchasing a textile recycling machine, you can select a reliable and efficient machine that meets your specific requirements and supports sustainable textile recycling practices.

FAQs on Sourcing and Manufacturing textile recycling machine in China

Q1: What is textile recycling?

Textile recycling refers to the process of converting unwanted or old textiles into new textile products or other materials. This sustainable method helps reduce the amount of waste generated by the textile industry and minimizes the environmental impact associated with textile production.

Q2: Why source textile recycling machines from China?

China is one of the leading countries when it comes to textile recycling technology and machinery. It has a well-established manufacturing industry with numerous specialized suppliers and manufacturers offering various types of textile recycling machines. Chinese manufacturers often provide cost-effective options without compromising on quality.

Q3: What types of textile recycling machines are available in China?

China offers a wide range of textile recycling machines that cater to different processes of recycling. Some common types include textile shredders, textile balers, fiber openers, carding machines, spinning machines, and needle punching machines. These machines perform specific functions such as cutting, baling, separating fibers, and producing new textile materials.

Q4: How to source textile recycling machines from China?

To source textile recycling machines from China, you can follow these steps:

1. Identify your specific requirements and determine the type and capacity of the machine you need.

2. Conduct thorough market research to find reputable suppliers or manufacturers in China. Online platforms, trade shows, and industry associations can be valuable resources.

3. Shortlist potential suppliers and compare their products, pricing, certifications, and after-sales services.

4. Request detailed quotations from the selected suppliers, ensuring they include specifications, warranty terms, delivery options, and payment methods.

5. Arrange a visit to the suppliers’ facilities in China, if feasible, to assess their manufacturing capabilities and product quality.

6. Once confident with a supplier, negotiate the contract terms, including price, delivery time, payment terms, and quality assurance.

7. Arrange shipment logistics and monitor the manufacturing and delivery progress closely.

Q5: How can I ensure the quality of textile recycling machines from China?

To ensure the quality of textile recycling machines, consider the following:

1. Choose suppliers with a good reputation, preferably with certifications such as ISO 9001.

2. Request product samples or visit the manufacturer’s facility to inspect the machine’s build quality and performance.

3. Verify if the supplier follows strict quality control measures during manufacturing and testing.

4. Check if the supplier offers warranty and after-sales support, indicating their commitment to product quality.

5. Seek customer references or reviews from other buyers who have previously sourced machines from the supplier.

By following these steps and conducting due diligence, you can minimize the risk and source reliable and high-quality textile recycling machines from China.

Why contact sourcifychina.com get free quota from reliable textile recycling machine suppliers?

Sourcifychina.com, a sourcing platform focused on connecting businesses with reliable suppliers in China, offers free quota to businesses looking for textile recycling machines for several reasons. By obtaining a free quota from reliable suppliers, businesses can benefit in the following ways:

1. Access to a Wide Network: Sourcifychina.com has established connections with numerous reliable textile recycling machine suppliers in China. By obtaining a free quota, businesses gain access to this extensive network, increasing their chances of finding the right supplier for their specific requirements.

2. Cost Savings: Sourcing from China often brings cost advantages due to competitive pricing. Accessing free quotas from reliable suppliers enables businesses to explore cost-saving opportunities without the need for upfront financial commitment.

3. Supplier Verification: Sourcifychina.com thoroughly verifies the reliability and credibility of its suppliers. By obtaining a free quota from these trusted suppliers, businesses can be assured of working with reputable manufacturers, minimizing the risk of scams or low-quality products.

4. Competitive Advantage: Textile recycling is becoming increasingly important as companies strive for sustainable and environmentally friendly practices. By utilizing the services of Sourcifychina.com and obtaining a free quota, businesses can stay ahead of their competitors by integrating textile recycling machines in their production processes.

5. Customization and Compatibility: Each business has unique requirements when it comes to textile recycling machines. By connecting with reliable suppliers through Sourcifychina.com and acquiring a free quota, businesses can discuss their specific needs and explore customization options, ensuring compatibility with their existing machinery and processes.

In conclusion, Sourcifychina.com offers free quotas from reliable textile recycling machine suppliers to help businesses in accessing a wide network of trusted suppliers, achieve cost savings, ensure supplier verification, gain a competitive advantage, and explore customization possibilities. This service simplifies the sourcing process, minimizing risks and maximizing opportunities for businesses in the textile recycling industry.