Types and Applications of threaded gate valve

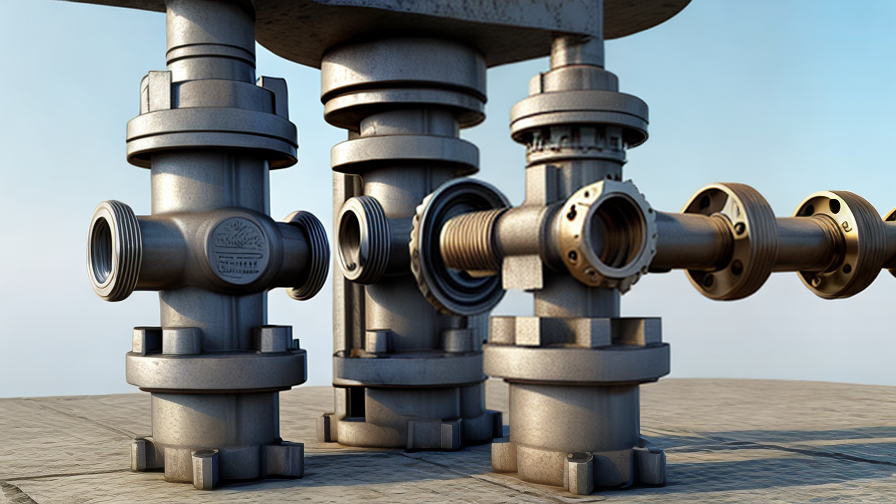

Threaded gate valve is a type of valve that is used to control the flow of fluids, gases, and other materials. It is designed with a gate or wedge that moves up and down to open or close the valve. Threaded gate valves are commonly used in various industries, including oil and gas, construction, manufacturing, and mining, among others.

There are different types of threaded gate valves, including rising stem and non-rising stem valves. The rising stem valve has a stem that moves up and down when the valve is opened or closed, while the non-rising stem valve has a fixed stem that does not move. Threaded gate valves can also be classified based on the material used to make them. For example, they can be made of stainless steel, bronze, or cast iron.

Applications of threaded gate valves include regulating the flow of fluids and gases in pipelines, controlling the flow of water and other liquids in plumbing systems, and isolating or shutting off the flow of gas or oil in tanks or storage vessels. Threaded gate valves are also used in fire protection systems to control the flow of water.

One advantage of threaded gate valves is that they have a low pressure drop, meaning that they do not cause a significant decrease in pressure as the fluid passes through the valve. They are also durable and can withstand high temperatures and pressure, depending on the material used to make them. Threaded gate valves are easy to operate, and they can be used in various positions, including horizontal and vertical.

In conclusion, threaded gate valves are essential components in various industries, and they play a critical role in regulating the flow of fluids and gases. They come in different types and materials, and their applications range from plumbing systems to oil and gas pipelines. Threaded gate valves are reliable and efficient, and they offer a practical solution for controlling the flow of fluids and gases in different environments.

Benefits and Feature of Utilizing threaded gate valve

Threaded gate valves are widely used for their various benefits and features. Some of the key advantages of utilizing a threaded gate valve are:

1. Easy to install: Threaded gate valves are easy to install as they do not require any welding. They can be installed using pipe threads, which makes the installation process quick and straightforward.

2. Durability: Threaded gate valves are made of high-quality materials such as brass, stainless steel, and bronze, making them durable and long-lasting.

3. Minimal leakage: Threaded gate valves have a tight mechanical seal that ensures minimal leakage. This makes them ideal for use in applications where leakage is not acceptable, such as in the oil and gas industry.

4. High flow rate: Threaded gate valves can handle high flow rates due to their low resistance to fluid flow. This makes them suitable for use in applications where high flow rates are required.

5. Easy to maintain: Threaded gate valves are easy to maintain as they can be easily disassembled for cleaning, inspection, and repair.

6. Versatile: Threaded gate valves are versatile and can be used in a wide range of applications, including water supply systems, gas pipelines, and HVAC systems.

In conclusion, threaded gate valves are a reliable and efficient choice for controlling fluid flow in various industrial applications. Their easy installation, durability, minimal leakage, high flow rate, easy maintenance, and versatility make them a popular choice for many industries.

The Process of threaded gate valve

A threaded gate valve is a type of valve that controls the flow of liquid or gas by using a gate-like mechanism to open or close the passageway. The valve is typically made of brass, stainless steel, or bronze and has a threaded connection for easy installation onto pipes.

The process of using a threaded gate valve involves several steps. First, the valve must be installed onto the pipe using the threaded connection. Once installed, the valve must be manually operated to open or close the gate mechanism. This is typically done by turning a handle or wheel that is attached to the top of the valve.

When the valve is closed, the gate mechanism seals off the passageway, preventing the flow of liquid or gas. When the valve is opened, the gate mechanism is lifted, allowing the liquid or gas to flow through the passageway.

One of the advantages of using a threaded gate valve is that it is a cost-effective option for controlling the flow of liquid or gas. It is also relatively easy to install and operate, making it a popular choice for residential and commercial applications.

However, threaded gate valves can be prone to leakage if they are not tightened properly during installation. This can result in a loss of pressure and reduced efficiency of the system. It is therefore important to follow the manufacturer’s instructions carefully when installing and operating a threaded gate valve.

How to use threaded gate valve

A threaded gate valve is a type of valve that is used to control the flow of fluid in a pipeline. It is designed with a threaded connection at both ends, which makes it easy to install and remove from the pipeline without needing any special tools. Here are some steps to use a threaded gate valve:

1. Firstly, ensure that the valve is the correct size for the pipeline and that it is rated for the appropriate pressure and temperature of the fluid that will be flowing through it.

2. Next, identify the flow direction of the fluid to ensure that the valve is installed in the correct orientation. Most gate valves have an arrow indicating the direction of flow.

3. Use a pipe wrench or similar tool to tighten the valve onto both sides of the pipeline. It is important not to over-tighten the valve as this can damage the threading on the valve body or the pipeline.

4. Once the valve is installed, use the operating handle to open or close the valve. To open the valve, turn the handle counterclockwise until it stops. To close the valve, turn the handle clockwise until it also stops.

5. In the event that the valve needs to be removed or replaced, the threaded connection makes it relatively easy to do so. Simply use a pipe wrench to loosen and remove the valve from the pipeline.

Overall, threaded gate valves are a reliable and simple way to control the flow of fluids in a pipeline. By following a few basic steps, they can be easily installed and operated by anyone with basic plumbing knowledge.

threaded gate valve Manufacturer,Supplier and Wholesale

A threaded gate valve is a type of valve that is widely used in various industries such as oil and gas, water treatment, and chemical processing. It is designed to control the flow of fluids by opening or closing a gate that moves up and down between the valve body. This valve operates by turning a handle or a handwheel that rotates a threaded stem, which causes the gate to move inversely.

As a leading manufacturer, supplier, and wholesaler of threaded gate valves, our company offers a wide range of products that are designed to meet different application needs. We use high-quality materials such as stainless steel, brass, and carbon steel to manufacture our valves. Moreover, we strictly adhere to international standards such as API, ANSI, and BS to ensure our valves are of superior quality.

Our threaded gate valves feature several advantages like durability, reliability, and easy maintenance. Additionally, they come in various sizes, ranging from ½ inch to 4 inches, and pressure ratings from 150lb to 600lb. We also offer customized valves to meet specific client requirements.

Our threaded gate valves are ideal for applications that require throttling and isolating services. They are used in pipelines carrying fluids such as water, gas, and oil, where the flow needs to be closely monitored. These valves are also an excellent choice for applications where zero leakage is essential, as they have a tight shut-off feature that ensures no fluid escapes.

In conclusion, our company provides high-quality threaded gate valves that are durable, reliable and meet diverse industry needs. We supply our products globally, and our commitment to quality and affordability has earned us a reputation as a trusted supplier in the valve industry.

threaded gate valve Price

Threaded gate valves provide an easy way to control the flow of fluids and gases in piping systems. These valves are commonly used in residential, commercial, and industrial applications. The prices of threaded gate valves vary depending on the size, material, and manufacturer.

The smallest threaded gate valves are typically 1/4 inch in size and are used in low-pressure applications. These valves are made of brass and are commonly found in residential plumbing systems. They usually cost between $10 and $20.

The prices of threaded gate valves increase with the size and the pressure rating. For instance, a 2-inch threaded gate valve that can handle up to 600 PSI can cost between $100 and $200. This valve is typically made of bronze or stainless steel and is suitable for industrial applications.

When purchasing a threaded gate valve, it’s important to consider the material of the valve body and the seat. The valve body can be made of brass, bronze, stainless steel, or cast iron. The seat can be made of brass, bronze, stainless steel, or rubber. The material selection depends on the fluid or gas being handled, the pressure and temperature requirements, and the compatibility with other materials in the piping system.

It’s also important to consider the manufacturer and the warranty when purchasing a threaded gate valve. Reputable manufacturers typically offer a longer warranty and provide technical support and customer service in case of any issues.

In summary, threaded gate valve prices range from $10 to $200 depending on the size, material, and manufacturer. When purchasing a valve, it’s important to consider the material selection, pressure and temperature requirements, and the manufacturer’s warranty and support.

FAQ sourcing threaded gate valve manufacturer from China with multiple answers

Q: How to source threaded gate valve manufacturers from China?

A: There are several ways to source threaded gate valve manufacturers from China:

1. Online search: Conduct an online search using search engines like Google or Alibaba. This will give you a list of potential manufacturers to choose from.

2. Trade shows: Attend China-based trade shows related to valves and other hardware products. This is an excellent opportunity to meet manufacturers and discuss your needs.

3. Referrals: Seek referrals from your peers, friends and family members who have experience sourcing products from China.

4. Direct contact: Contact the manufacturer directly via phone, email, or chat.

Q: How do I ensure a threaded gate valve manufacturer from China is reliable?

A: There are several factors to consider when selecting a reliable threaded gate valve manufacturer in China:

1. Certification: Look for manufacturers with relevant certifications such as ISO 9001:2015, CE, and RoHS.

2. Quality control: Inquire about their quality control processes to ensure that their products meet your expectations.

3. Production capacity: Make sure their production capacity meets your order requirements.

4. Communication: A reliable manufacturer should be easy to communicate with and respond promptly to your inquiries.

5. History: Look for manufacturers with a solid history of producing quality products and serving satisfied customers.

Q: What are the shipping and delivery terms for suppliers of threaded gate valve in China?

A: Shipping and delivery terms for suppliers of threaded gate valves in China may vary depending on the manufacturer and the customer’s requirements. Some common shipping and delivery terms include:

1. FOB: The supplier is responsible for delivery of the goods to the port of shipment. Once the goods are loaded onto a vessel, the buyer assumes responsibility for shipping them to their destination.

2. CIF: The supplier is responsible for delivering the goods to the port of destination. This includes all shipping, insurance, and other related expenses.

3. EXW: The customer is responsible for all transportation costs and assumes risk for the goods from the factory.

Before placing an order, it’s important to clarify shipping and delivery terms with the supplier to avoid any misunderstandings.