Benefits of Tissue Paper Manufacturing

Tissue paper is a staple in every household and workplace as it serves several purposes. From cleaning surfaces to wiping noses, it has become an essential commodity. In recent times, the demand for tissue paper has increased significantly due to hygiene concerns, and this has led to the growth of the tissue paper manufacturing industry. Here are some benefits of tissue paper manufacturing:

1. Employment Opportunities

Tissue paper manufacturing requires a large workforce, ranging from operators to supervisors and managers. The industry provides employment opportunities for both skilled and unskilled workers, thereby reducing unemployment and improving the standard of living.

2. Revenue Generation

The tissue paper industry is a lucrative one as it has a vast local and international market. With the increasing demand for tissue paper, manufacturers stand to gain significant profits, leading to the growth of the economy.

3. Customer Satisfaction

Tissue paper manufacturers prioritize customer satisfaction by producing quality products that meet the needs of consumers. They ensure that the products are soft, absorbent, and of high quality, thereby ensuring customer loyalty and leading to the growth of the business.

4. Eco-Friendly

The tissue paper manufacturing industry has embraced sustainability by using eco-friendly materials in their production process. This has reduced the impact of tissue paper manufacturing on the environment, making it a green industry.

5. Easy to Recycle

Tissue paper is easy to recycle, ensuring that waste is reduced significantly. The use of recycled pulp in tissue paper production has reduced the dependence on wood pulp, leading to the preservation of forests and reducing environmental degradation.

In conclusion, the tissue paper manufacturing industry has numerous benefits that go beyond the production of tissue paper. It provides employment opportunities, generates revenue, ensures customer satisfaction, is eco-friendly, and easy to recycle, making it a valuable industry for any economy.

Features of Tissue Paper Manufacturing

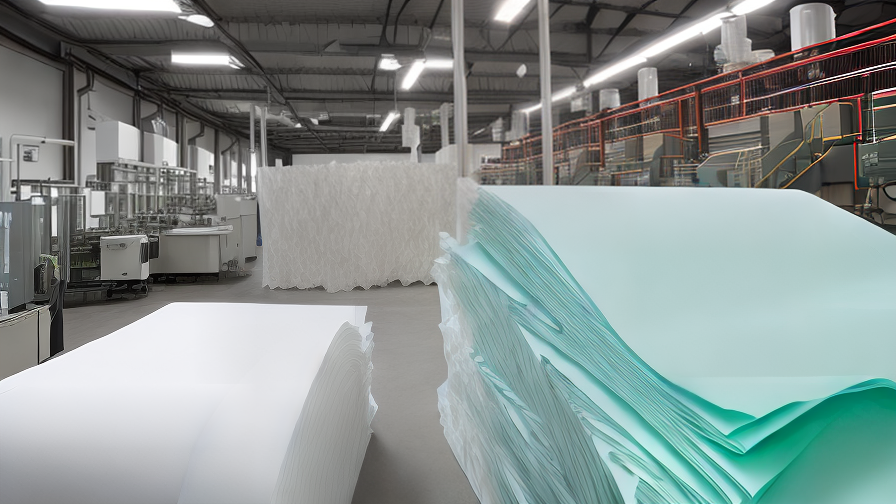

Tissue paper is a lightweight paper used for a wide range of purposes such as wiping, cleaning, and hygiene. The manufacturing process of tissue paper involves several stages, including converting wood into pulp, refining the pulp into fibers, and finally converting these fibers into tissue paper. There are a few key features involved in the tissue paper manufacturing process which we shall discuss in this article.

Firstly, tissue paper manufacturing involves the use of high-quality pulping technologies that ensure the pulp is well-refined to produce soft, strong, and absorbent fibers. This process starts by sourcing wood from sustainable forests and then subjecting it to a pulping process. Two common techniques used in pulping include chemical and mechanical pulping.

Once the pulp is refined, it is washed thoroughly to remove any impurities before proceeding to the next stage. The fibers are then treated with chemicals like bleaches, softeners, and other additives to enhance the paper’s properties such as strength, softness, and absorbency.

The paper is then produced by a paper machine, where the fibers are layered onto a moving wire mesh to form a sheet. Drying the sheet is the next stage of the process, which is typically conducted using steam-heated rollers that press out any remaining moisture.

Finally, the sheet is cut into rolls or sheets of different sizes, packaged, and shipped to customers.

Another important feature of tissue paper manufacturing is quality control. Manufacturers have to ensure that the tissue paper meets specific quality standards like strength, softness, thickness, and absorbency. To achieve this, quality control processes are implemented throughout the entire manufacturing process such as testing for consistency, adjusting chemical formulas, and testing product performance properties.

In conclusion, the tissue paper manufacturing process is an intricate process that requires several steps to achieve the desired attributes of the tissue product. With modern technology and stringent quality control measures, tissue manufacturers can ensure that they produce high-quality tissue paper products that meet customer requirements.

Various Types of Tissue Paper Manufacturing

Tissue paper is one of the most commonly used paper products across the world. The production process of tissue papers is similar to that of regular paper, but it requires additional processing to create a soft, absorbent and flexible product. There are various types of tissue paper manufacturing used in the industry, and each of them has its unique characteristics.

The first and most common method used in tissue paper manufacturing is the dry crepe tissue paper. In this method, the pulp used in papermaking is treated with chemicals to break down the fibers, which is then formed into sheets using a wire mesh. The sheets are then pressed and dried before a final creping process, which creates the unique softness and flexibility of tissue paper.

Another type of tissue paper manufacturing is the wet-laid nonwoven process. This method involves the use of multiple layers of pulp, which are bonded together using a water jet process. The resulting tissue paper is thick and strong, making it ideal for use in hygiene products such as diapers and sanitary napkins.

Another method is the through-air-drying (TAD) tissue paper manufacturing process. The TAD process involves the pulping of long fibers, which are then formed into sheets using a wire mesh. The sheets are then fed through a drying cylinder, which uses hot air to dry the paper. The final product is soft and strong, making it suitable for use in facial tissues, paper towels, and napkins.

The fourth type of tissue paper manufacturing is the embossed tissue paper. This is created by using a roll of paper, which is embossed with a pattern or design. The embossed paper is then cut into sheets, which are then folded into the compact size required for packaging.

In conclusion, the tissue paper manufacturing process has evolved to cater to the growing demand for high-quality tissue products in hygiene, household, and industrial markets. Each manufacturing process has its specific benefits, which make it suitable for use in different products. As the tissue paper continues to play a crucial role in our daily lives, advancements in manufacturing processes will continue to drive innovation in the industry.

Applications of Tissue Paper Manufacturing

Tissue paper manufacturing has numerous applications. It is used in personal and institutional hygiene, as well as for wiping and cleaning surfaces. Moreover, tissue paper is a popular material for gift-wrapping, crafting, and decorations. In this article, we will discuss some of the most common applications of tissue paper manufacturing.

One of the most significant applications of tissue paper manufacturing is in personal hygiene. Facial tissue and toilet tissue are the most common tissue products used for personal hygiene. Facial tissue mainly serves to wipe and clean the face with utmost delicacy, while toilet tissue is used to clean up after using the toilet. This type of tissue is generally softer, more absorbent, and disposable. For this reason, the market for these products is massive, and manufacturers continue to innovate products that cater to the varying demands of users.

Another application of tissue paper manufacturing is in institutional hygiene. Tissue papers are used by institutions such as hospitals, schools, restaurants, and offices to maintain cleanliness and hygiene. Paper towels, napkins, and toilet paper are some of the tissue products used in institutional settings. These products are essential for cleaning spills and other messes, maintaining hand hygiene, and in creating a comfortable and clean environment for customers and staff.

Tissue paper is also used in wrapping, packing, and decorations. Many people use tissue paper in gift-wrapping and crafting because of its pliability, lightness, and versatility. It is also available in a range of colors, making it an ideal decorative material. Moreover, it is widely used in floral arrangements as a lightweight filler and to add volume and color to the arrangement.

In conclusion, tissue paper manufacturing has numerous applications in personal and institutional hygiene, as well as in gift-wrapping and decorations. The demand for tissue products continues to grow, and manufacturers continue to innovate products that cater to the different needs of users. Tissue paper is a versatile and functional product that benefits different industries and has become a staple in many households.

The Process of Tissue Paper Manufacturing

Tissue paper is a common household product that is used for cleaning, wiping, and sanitary purposes. The process of tissue paper manufacturing involves several steps, from preparing the wood pulp to packaging the finished product.

The first step in tissue paper manufacturing is preparing the wood pulp. Wood chips are turned into pulp using a grinding process that breaks down the wood fibers. The wood pulp is then treated with chemicals to remove impurities and improve the quality of the tissue paper.

Next, the pulp is fed into a paper machine, which turns the pulp into tissue paper. The paper machine is a large piece of industrial equipment that consists of several components, including a headbox, a press section, and a dryer section.

The headbox is the first component of the paper machine, where the pulp is fed into the machine and distributed evenly onto a wire mesh. The wire mesh moves through the press section, where the pulp is pressed to eliminate excess water and improve the strength of the tissue paper.

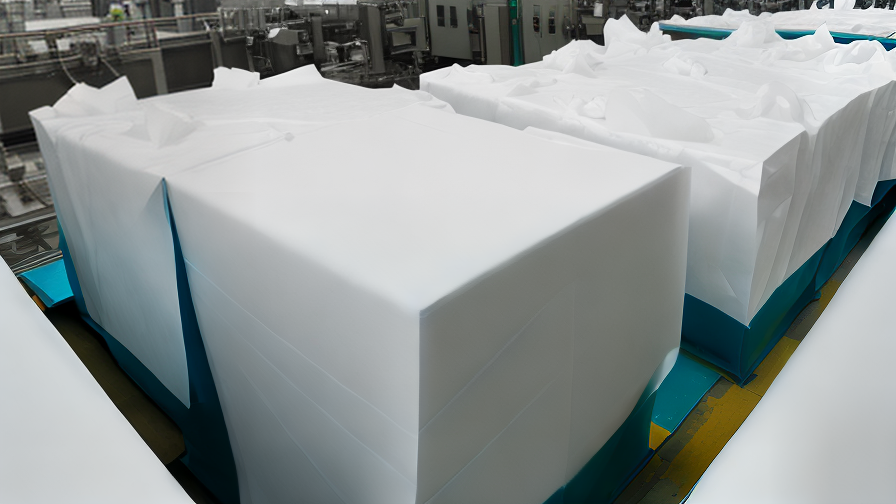

After the press section, the paper travels through the dryer section, which uses hot air to dry the tissue paper. The tissue paper is then wound onto large rolls or cut into smaller sheets, depending on the manufacturer’s preference.

The final step in tissue paper manufacturing is packaging the finished product. Tissue paper can be packaged in several ways, including bulk packaging, individually wrapped, or in decorative packaging.

Overall, the process of tissue paper manufacturing involves several steps and requires large pieces of industrial equipment. However, the end result is a product that is essential for everyday use in households and businesses around the world.

How to use Tissue Paper Manufacturing

Tissue paper manufacturing is a crucial process in the production of tissues that are used for personal hygiene, cleaning and wiping surfaces, and packaging items. This article outlines how to use tissue paper manufacturing to produce high-quality tissue products.

The first step is to choose the appropriate raw materials, which include pulp, water, and chemicals that aid in the formation and bonding of fibers. The pulp can be obtained from wood, recycled paper, or a combination of both. Once the raw materials are assembled, they are thoroughly mixed to form a slurry that is then cleaned of impurities and passed through a refining process.

Next, the slurry is fed into a machine called a Fourdrinier machine. This machine separates the fibers and distributes them evenly onto a moving wire mesh that forms a continuous sheet of tissue. The sheet is then pressed and dried to remove excess water.

To improve the strength and softness of the tissue paper, it is creped using a serrated knife or blade that scrapes the surface of the paper as it falls off the machine rollers. This process creates a wrinkled appearance that is characteristic of tissue paper.

After creping, the tissue paper is rolled onto large spools that are then cut into smaller rolls depending on the intended use. The rolls can be embossed to enhance softness and absorbency or colored to suit different preferences.

In conclusion, tissue paper manufacturing is a complex process that requires careful selection of raw materials, attention to detail during production, and adherence to rigorous quality standards. By keeping these aspects in mind, manufacturers can produce high-quality tissue products that meet the needs of consumers.

Selecting the Ideal Manufacturer Tissue Paper Manufacturing

Selecting the ideal manufacturer for tissue paper manufacturing is crucial for businesses that rely on tissue paper as a vital component of their operations. With the increasing competition in the tissue paper market, selecting the right manufacturer helps ensure that a business will receive quality tissue paper products that can meet specific needs at a reasonable price.

When selecting a tissue paper manufacturer, it is critical to consider a manufacturer’s reliability, reputation, and expertise. A reliable manufacturer is one that can meet the commitments made and fulfill orders timely. The reputation of tissue paper manufacturers is crucial as it helps to establish the overall quality of their products. Expertise is also vital as it demonstrates their level of knowledge and competence in the industry.

Another crucial factor to consider when selecting a tissue paper manufacturer is their product range. A good manufacturer should offer various grades and types of tissue paper customized to meet varying customer needs. Whether it is small or large pieces of tissue paper or a wide range in thickness, colors, or prints, the manufacturer must have a broad range of products that can satisfy all demands.

Furthermore, the quality of the tissue paper produced by the manufacturer is critical. A good manufacturer must use quality control measures that ensure manufactured products meet or exceed the industry standards, particularly with respect to product safety, hygiene, and environmental regulations.

Finally, pricing is also essential when selecting a manufacturer. It is good to work with a manufacturer that can offer quality tissue paper at a reasonable price, ensuring businesses save on their budgets.

In conclusion, selecting the ideal manufacturer for tissue paper manufacturing requires careful consideration of a manufacturer’s reputation, reliability, expertise, product range, quality, and pricing. It is essential to take the necessary steps to assess a manufacturer and ensure that they can meet the requirements of the business at an affordable price.

list FAQ with answer about Tissue Paper Manufacturing

Tissue paper is one of the most used paper products in the world. It has various uses, including wiping, cleaning, and drying. Tissue paper manufacturing is a complex process that involves different stages. Here are some frequently asked questions about tissue paper manufacturing.

1. What are the raw materials used in tissue paper manufacturing?

The raw materials used in tissue paper manufacturing include wood pulp, recycled paper, and water.

2. What is the process of making tissue paper?

The tissue paper manufacturing process involves pulping, refining, blending, sheet formation, pressing, and drying.

3. What is the difference between virgin and recycled tissue paper?

Virgin tissue paper is made from wood pulp, while recycled tissue paper is made from recycled paper.

4. What is the importance of refining in tissue paper manufacturing?

Refining is a critical stage in tissue paper manufacturing, as it helps to break down the wood fibers to make them softer and more absorbent.

5. How is tissue paper made softer?

Tissue paper can be made softer by using a softer wood fiber, adding softening agents, and creating a softer sheet structure.

6. What is the role of pressing in tissue paper manufacturing?

Pressing is the stage where excess water is removed from the sheet to make it stronger and more stable.

7. What is the importance of drying in tissue paper manufacturing?

Drying is a crucial stage in tissue paper manufacturing, as it helps to remove the remaining moisture in the sheet and make it ready for use.

In conclusion, tissue paper manufacturing is a complex process that involves different stages. The raw materials used in the process include wood pulp, recycled paper, and water. The process involves pulping, refining, blending, sheet formation, pressing, and drying. Refining is a critical stage in tissue paper manufacturing, and it helps to break down the wood fibers to make them softer and more absorbent. Pressing and drying are also important stages in the process.

Things to Consider When Purchasing Tissue Paper Manufacturing

When it comes to purchasing tissue paper manufacturing equipment, there are several important things to consider. Here are some key factors to keep in mind:

1. Capacity: Before making any purchases, determine the capacity of the equipment you require. This will depend on the amount of tissue paper you plan to produce, as well as your budget and available space.

2. Quality: Look for tissue paper manufacturing equipment that produces high-quality products. You want to ensure that your tissue paper will be soft, strong, and absorbent, so it’s important to invest in equipment that can meet these requirements.

3. Efficiency: Efficiency is important for reducing operating costs and maximizing productivity. Make sure the equipment you purchase is energy-efficient and has the capacity to produce tissue paper quickly and with minimal waste.

4. Maintenance: Like any machinery, tissue paper manufacturing equipment will require maintenance and repairs. Look for equipment that is easy to maintain and has spare parts readily available.

5. Cost: Finally, consider the cost of the equipment. While it’s important to invest in high-quality equipment, you also want to ensure that you’re getting a good value for your money. Research different brands and models, and compare prices to find the best deal for your budget.

By considering these factors, you can make an informed decision when purchasing tissue paper manufacturing equipment. With the right equipment in place, you can produce high-quality tissue paper efficiently and cost-effectively, helping to grow your business and increase profitability.

Properties of Tissue Paper Manufacturing

Tissue paper is a widely used product for personal hygiene and household cleanliness, and it’s manufactured with different properties to meet various consumer needs. One of the most crucial properties of tissue paper is its absorbency, which requires the use of high-quality pulp fibers. The manufacturing process involves several steps, including pulp refining, sheet formation, pressing, drying, and converting.

The pulp refining process involves the use of mechanical, chemical, or a combination of both methods to break down the wood fiber into small fibers. This step helps to improve the absorbent properties of the tissue paper and make it softer. The sheet formation process uses a papermaking machine that produces tissue paper in a continuous web. The fibers are pre-distributed evenly across the forming surface with the help of a headbox, which controls the fiber’s distribution.

During pressing, water is squeezed out of the tissue paper and enhances its thickness and strength. The drying process involves the use of heated drums or cylinders, which evaporate the remaining moisture in the tissue paper. After drying, the paper is wound onto large rolls, which are then converted into the desired tissue paper products, such as facial tissues, toilet papers, and paper towels.

The properties of tissue paper can be modified by adding materials such as chemicals, dyes, and fragrances. Chemicals like bleach can increase the tissue paper’s brightness, while fragrances can improve its scent. Adding lotion or other emollients can enhance the tissue paper’s softness, making it suitable for sensitive skin.

In conclusion, tissue paper manufacturing is a complex process that involves several stages and requires the use of high-quality pulp fibers for optimal absorbency. The properties of tissue paper can be customized to meet various consumer needs, such as softness, absorbency, and fragrance. As tissue paper is an essential product in our daily lives, the manufacturing process continues to evolve to meet the ever-changing consumer demands.

Technical Parameters Terms for Tissue Paper Manufacturing

Tissue paper manufacturing involves a range of technical parameters that need to be carefully considered to ensure optimal production efficiency and quality. Here are some essential terms and parameters to be familiar with.

1. Basis Weight: This refers to the weight of the tissue paper per unit area, typically measured in grams per square meter (gsm). It affects the thickness and absorbency of the final product.

2. Fiber type: Tissue paper can be made from various types of fibers, including virgin pulp, recycled paper, and a blend of both. The fiber type impacts the strength and softness of the paper.

3. Crepe ratio: Creping is a process where the paper is stretched and compressed to create wrinkles, giving the tissue paper a soft and fluffy texture. The crepe ratio is the ratio of the stretch length to the original length of the paper.

4. Wet strength: This is the ability of the paper to maintain its strength when wet. It is important for tissue paper used in applications such as cleaning and wiping.

5. Ply count: Tissue paper can be single-ply, two-ply, or three-ply, depending on the number of layers it has. The ply count affects the softness and absorbency of the final product.

6. Caliper: This refers to the thickness of the paper, measured in microns or thousandths of an inch. It impacts the bulk and absorbency of the paper.

7. Tensile strength: This is the force required to break the paper, measured in newtons or pounds. It is crucial for tissue paper that needs to withstand stretching and tearing during use.

By understanding these technical parameters, tissue paper manufacturers can optimize their production processes to achieve the desired quality and functionality of their products.

Tissue Paper Manufacturing Price

Tissue paper is a commonly used everyday item that is essential in every household. It is a thin, soft and lightweight paper that is used for a variety of purposes such as wiping, cleaning, and blowing our noses. Tissue paper is made from pulp, which can come from various sources such as wood, recycled paper, or a combination of both.

The price of tissue paper manufacturing depends on several factors, including the type of tissue paper being produced, the quality of raw materials used, and the manufacturing process used to produce it. For instance, if the tissue paper is made from high-quality raw materials and through an advanced manufacturing process, the manufacturing price will be relatively high.

Among the primary factors that impact the price of tissue paper manufacturing is the cost of raw materials. Wood pulp, which is widely used as the main raw material in the production of tissue paper, is affected by supply and demand factors. The price of wood pulp can also be influenced by environmental and regulatory policies, such as legislation that restricts deforestation.

The manufacturing process is also a significant determinant of the price of tissue paper. Advanced manufacturing technologies that can produce high-quality tissue paper faster, and more efficiently are generally more expensive. This is because they require more capital investment in machinery, equipment, and labor.

Despite these factors, tissue paper manufacturers need to keep the price of their products competitive. This is because the tissue paper market is highly competitive, and consumers are sensitive to price variations. Manufacturers need to employ innovative strategies in sourcing raw materials, optimizing production processes, and managing costs to produce tissue paper at a reasonable price.

In conclusion, the price of tissue paper manufacturing is influenced by several factors such as the type and quality of raw materials used, and the production process employed. This means that tissue paper manufacturers need to balance the production costs while still producing high-quality tissue paper at a reasonable price.