Knowledge about Tube Filling Machine

A tube filling machine is a vital piece of equipment used in the packaging industry. It plays a significant role in the cosmetic and pharmaceutical industries, where it is used for filling different types of creams, gels, and pastes into tubes.

The process of filling tubes with creams, gels, and pastes can be costly, time-consuming, and error-prone when done manually. Tube filling machines automate the process and enable the packaging of different products with high efficiency and accuracy. They are designed to handle different tube sizes and shapes, depending on the products being filled.

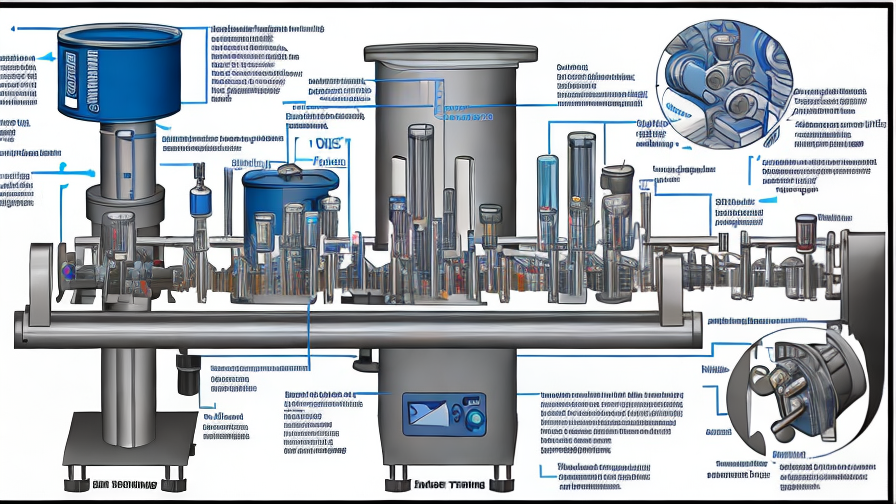

It is essential to have knowledge about a tube filling machine’s working principle to maximize its potential. A tube filling machine consists of various components, including the hopper, tube orientation module, filling station, sealing station, and tube-ejection system. The hopper is responsible for feeding the product into the machine. The tube-orientation module ensures that the tubes are in the correct position for filling. The filling station measures the predetermined amount of the product and fills it into the tube. The sealing station seals the tubes after filling, while the tube-ejection system removes the tubes ready for the final packaging stage.

The type of filling system in a tube filling machine may vary from one machine to another. The filling system could be either piston or peristaltic. A piston filling system uses a piston to dispense the product accurately and precisely, while a peristaltic system uses rollers to squeeze the product through a tube.

Tube filling machines come with different features and capabilities, with some being fully automated or semi-automated. Fully automated machines have robotic systems responsible for handling the tubes and efficiently filling them. Semi-automated machines would require some human intervention to adjust the settings.

In conclusion, a tube filling machine is an important investment for any manufacturer involved in the production of cosmetic and pharmaceutical products. Therefore, ensuring that the user is knowledgeable about the machine’s capabilities and operating principles is crucial to maximize its performance and ensure the

Various Types of Tube Filling Machine

Tube filling machines are widely used in the pharmaceutical, cosmetic, food, and chemical industries for improving efficiency and productivity. These machines are designed to fill different types of tubes with products such as creams, gels, lotions, pastes, and ointments.

The most common types of tube filling machines are automatic, semi-automatic, manual, and plastic tube filling machines.

Automatic tube filling machines are the most advanced and sophisticated type of tube filler. They are fully automatic and designed to fill and seal up to 400 tubes per minute. The machine comes with an automatic tube loading system and is programmable with a touch screen, making it easy to operate with minimal labor intervention.

Semi-automatic tube filling machines, on the other hand, are a more cost-effective option for those looking for a less advanced tube filler. The machine can fill up to 30 tubes per minute, and the operator needs to load tubes manually.

Manual tube filling machines are perfect for small-volume production when filling is typically done by a single operator using a hand-operated lever. They are also useful in scenarios where products contain sensitive ingredients that may be prone to damage when exposed to mechanical pressure.

Plastic tube filling machines are designed to be used with plastic tubes. These machines can fill both plastic and metal tubes and are perfect for filling products that are prone to contamination. They are mostly used in the food and cosmetic industries.

In conclusion, selecting the right tube filling machine is crucial for any manufacturing process that involves the production of a high volume of tubes. It is essential to consider the type of product, the volume of production, and the level of automation needed when deciding which machine to choose. With these considerations, manufacturers can select the right tube filler to streamline their processes and optimize production.

FAQ sourcing Tube Filling Machine manufacturer from China

If you’re looking to source a tube filling machine from China, you likely have a few questions. Here are some frequently asked questions with multiple answers to help guide your search:

1. What type of tube filling machines are available from Chinese manufacturers?

Chinese manufacturers offer a variety of tube filling machines, including fully-automatic, semi-automatic, and manual machines. These machines may fill tubes with creams, gels, pastes, or liquids.

2. What features should I consider when choosing a tube filling machine from China?

Consider the capacity of the machine, the materials used in manufacturing the machine, its power source, its ease of use and maintenance, and its compatibility with the type of tube you plan to fill.

3. What materials are typically used to manufacture tube filling machines from China?

Manufacturers use a variety of materials to manufacture filling machines, including stainless steel, aluminum, and other alloys.

4. Is it easy to obtain spare parts and service for tube filling machines from China?

Yes, most manufacturers offer spare parts and service for their machines. However, it’s always important to check with the manufacturer to determine their specific policy.

5. How long does it take to receive a tube filling machine from China?

Delivery times can vary depending on the manufacturer, but it typically takes between four and six weeks for delivery.

In summary, there are many factors to consider when sourcing a tube filling machine from China, including the type of machine, its features and compatibility, the materials used in manufacturing, and the availability of service and spare parts. With careful research and communication with the manufacturer, it’s possible to find a machine that meets your specific needs.

Applications of Tube Filling Machine

Tube filling machines are vital equipment in the packaging industry. They are widely used to fill various products such as ointments, creams, gels, glue, adhesives, toothpaste, cosmetics, and food products. The machine has several features that allow for the accurate, efficient, and precise filling of products.

The tube filling machine is commonly used in pharmaceutical companies in the production of various medical and cosmetic products. They are also used in food processing industries to prepare various sauces, jelly, cheese spread, and other products. Apart from these industries, the machine is also used in personal care items such as toothpaste, shampoo, and lotion.

The tube filling machine is designed in such a way that it can accommodate various types of tubes, including plastic, metal, and laminate. This component is essential as it enables the packaging of different products in tubes that suit their specific requirements. Moreover, different tube filling technologies are available, including hot-air sealing, ultrasonic, and hot-jaw sealing, among others, that cater to specific product requirements.

The tube filling machine also comes equipped with an automatic feeding system that ensures continuous and seamless filling of the tubes. The system also ensures accuracy in the filling process, which reduces material wastage, a critical feature in the current world economy. The filling process can be calibrated to meet different product viscosity, texture, and color requirements, which is another vital benefit of the tube filling machine.

The tube filling machine is also environmentally friendly as it enables the packaging of products in tubes that are recyclable. It also ensures that the products are free from contamination by keeping them sealed in the tubes.

In conclusion, the significance of the tube filling machine in the packaging industry cannot be overstated. Its ability to fill different products accurately, efficiently, and precisely is essential in the production of quality and safe products. The machine’s versatility means that it is used in different sectors of the economy, including pharmaceuticals, food processing, and personal care products. Therefore, businesses that

Manufactured Products made of Tube Filling Machine

Tube filling machines are essential equipment in the manufacturing process of a wide array of processed products. These machines are crucial for businesses that require precise filling of their products. The use of tube filling machines can improve production efficiency, reduce production costs, and guarantee product quality.

There are a wide variety of manufactured products that require the use of tube filling machines. These machines are frequently used in the production of consumer products such as toothpaste, creams, gels, and lotions. Additionally, tube filling machines play an important role in the manufacturing process of pharmaceutical products such as ointments, creams, and gels.

One of the advantages of using tube filling machines is the accuracy with which they can fill products. This reduces product waste, eliminates the need for manual labor, and reduces the risk of contamination to the products. The machines are designed to dispense precise amounts of product at high speed, which makes them ideal for use in mass production.

Tube filling machines are versatile machines that can handle a wide range of products with different viscosities. The machines can process products with thick or thin consistency, ensuring that the products are well-filled.

One key benefit of using tube filling machines is the reduction in production costs. The machines are designed to work seamlessly without human intervention, making them more efficient and cost-effective compared to manual methods. Also, the machines require minimal maintenance, which makes them a practical option for small and large businesses.

In conclusion, tube filling machines play a significant role in the manufacturing process of a wide range of consumer and pharmaceutical products. Their accuracy, speed, versatility, and cost-effectiveness make them an essential piece of equipment for businesses. As the demand for processed products continues to grow globally, manufacturers must invest in modern tube filling machines to meet this increasing demand.

The Evolution history of Tube Filling Machine

The history of tube filling machines dates back to the early 1900s when they were first introduced to fill the toothpaste into plastic tubes. The early models of tube filling machines were manual and required a lot of physical effort to operate. In the 1920s, the first automatic tube filling machine was introduced. However, these machines were still relatively primitive and had limited capabilities.

During the 1950s, the technology of tube filling machines began to advance rapidly. The introduction of toothpaste in aluminum tubes saw the advent of laminated tubes. The demand for tube filling machines soon grew as an increasing number of manufacturers began using these tubes for packaging their products.

In the 1960s, tube filling machines became more sophisticated with the introduction of rotary filling machines. The use of modern stainless steel materials in the production of tube filling machines ensured rust-free operation for a long time.

The 1980s saw the introduction of computer-controlled tube filling machines. This technology allowed for greater accuracy in filling tubes with more complex materials such as creams and ointments. The use of servo motors also ensured that tube filling machines could handle more significant volumes of product with greater precision.

In recent years, tube filling machines have become more advanced, incorporating technologies such as automatic cleaning systems, improved digital displays, and even robotics. These machines have become more compact and efficient, offering high-speed production with minimum wastage.

In conclusion, the evolution of tube filling machines over the past century has been remarkable. From the early manual models to the sophisticated, computer-controlled machines of today, tube filling machines have come a long way. These machines have revolutionized the packaging industry, making it possible to package a wide range of products more efficiently and cost-effectively.

The Process of Tube Filling Machine

The process of tube filling machine involves a series of steps to fill tubes with various substances, including creams, gels, ointments, and lotions. The process is essential for the pharmaceutical, cosmetic, and food industries, among others.

The first step in the process is to prepare the tubes for filling. This involves cleaning and sanitizing the tubes to ensure they are free from dirt, dust, or any other contaminants. The tubes are then loaded onto the machine, ready for filling.

The next step involves the actual filling of the tubes with the desired substance. This is an automated process that uses a nozzle to dispense the product into the tubes accurately. The quantity of the product dispensed is controlled to ensure consistency in the amount of product in each tube.

Once the tubes are filled, the next step is to seal them. The sealing process involves heating the tube ends to melt an adhesive that seals the tube, preventing any leakage of the product inside. The type of sealing used depends on the type of tube, with some using crimping, folding, or twisting to seal.

After sealing, the tubes are labeled and coded for traceability purposes. This makes it possible to identify the contents of each tube, the production date, and the batch number.

The last step in the process is to package the tubes. This involves placing the tubes in cartons or boxes ready for shipment or storage. The packaging is done carefully to prevent damage to the tubes or the contents inside.

In conclusion, the process of tube filling machine is an essential process for various industries that require the filling of tubes with various products. By understanding the steps involved, manufacturers can ensure that their products are filled accurately, sealed correctly, and packaged safely for transportation or storage.

Benefits Advantages of Utilizing Tube Filling Machine

Tube filling machines are an increasingly popular option for companies that need efficient and reliable packaging solutions. These machines can fill products such as creams, pastes, and gels into tubes, making them ideal for use in industries such as cosmetics, pharmaceuticals, and food production. Here are some of the benefits and advantages of utilizing tube filling machines.

1. Increased Production Efficiency

One of the main benefits of using tube filling machines is their ability to increase production efficiency. These machines have the capacity to fill tubes at a high speed, ensuring that companies can create more products within a shorter period. This, in turn, can lead to increased profitability, as businesses can generate more revenue and reduce the cost of production.

2. Reduced Waste

Another significant advantage of using tube filling machines is that they can significantly reduce waste. These machines are designed to be precise and accurate, ensuring that only the correct amount of product is dispensed into each tube. This eliminates the need for excessive overfilling or spillages, which can both be costly and harmful to the environment.

3. Improved Product Quality

Tube filling machines use advanced technology to ensure that products are of high quality. The machines can control the filling and sealing process, ensuring that the products are sealed correctly and that air is eliminated from the tubes. This helps to preserve the quality and integrity of the products, making them more appealing to customers.

4. Customization

Another benefit of utilizing tube filling machines is that they offer a high level of customizability. The machines can handle a range of tube sizes, allowing companies to choose the best size for their products. Additionally, they can be designed to meet specific requirements such as labeling or color-coding, enabling businesses to tailor their packaging to their needs.

In conclusion, the benefits and advantages of utilizing tube filling machines are numerous, ranging from increased production efficiency and reduced waste to improved product quality and customization. These machines are a sound investment for businesses looking to streamline their packaging processes and boost their bottom line.

Disadvantages Tube Filling Machine

Tube filling machines are highly specialized machines designed to quickly and accurately fill tubes with a wide range of products, from cosmetics to adhesives. However, like any machine, they are not without their disadvantages.

One major disadvantage of tube filling machines is their high cost. These machines are often expensive to purchase and maintain, which can be a significant barrier to entry for small businesses or startups. Additionally, their complex design means they require skilled operators and specialized training, which can also add to their overall cost.

Another disadvantage of tube filling machines is their limited range of products they can fill. These machines work best with products that have a uniform consistency and viscosity, ruling out the ability to fill high-viscosity products such as gels and creams, which require specialized machines. The machine may also not be able to accommodate small quantities of materials, which is challenging when filling less commonly used products.

Tube filling machines also have the potential to be less accurate than other types of filling machines. Their design can make it difficult to fill a specified quantity of product every time, which can be a problem for industries that require precisely measured products. In such cases, the need to adjust and calibrate the machine frequently may arise, and this can be both time-consuming and expensive.

In conclusion, while tube filling machines offer many advantages, such as speed and efficiency, they are not without their downsides. Their high cost, limited range of product types, and sometimes less precise filling process are all potential disadvantages of using tube filling machines. However, if the benefits outweigh these drawbacks in your specific case, then a tube filling machine can provide significant time and cost savings.

Selecting the Ideal Manufacturer Tube Filling Machine

Tube filling machines are essential for any company that specializes in producing tubes. These machines simplify the process of filling tubes with products, which in turn increases productivity and efficiency. However, not all tube filling machines are created equal. Therefore, it is essential to select the ideal manufacturer tube filling machine that suits your needs. In this article, we will discuss the necessary factors to consider when selecting the best tube filling machine manufacturer.

1. Purpose: The first factor to consider is the purpose of the tube filling machine. Before selecting a manufacturer, you need to determine the type of product you intend to fill in the tubes. In essence, different tube filling machines are designed for different products. Therefore, if you are filling liquids, semi-solids, or gels, there is a need to select a machine that suits your specific needs.

2. Capacity: Capacity is also an essential factor to consider when selecting a tube filling machine manufacturer. The capacity of a tube filling machine is determined by how many tubes it can fill per minute. Therefore, it is important to determine the amount of products you need to fill and select a machine that can handle that capacity.

3. Quality: Quality should be at the top of your priorities when selecting a tube filling machine manufacturer. Look for a manufacturer who has a reputation for producing high-quality machines that last longer. Quality machines will ensure that your production line runs smoothly, with minimal interruptions.

4. Budget: The cost of the machine is also a significant factor to consider. However, you should not compromise on the quality of the machine for the cost. Instead, look for a manufacturer who offers quality machines at a reasonable price.

5. After-sales service: Finally, select a manufacturer who offers after-sales service. There might be times when your tube filling machine breaks down, and you will need a manufacturer who provides repair and maintenance services.

In conclusion, selecting the ideal tube filling machine manufacturer goes beyond the features of the machines. It also involves considering the purpose, capacity,

Things to Consider When Purchasing Tube Filling Machine

Tube filling machines are an essential tool for any manufacturing company involved in the production of toothpaste, ointments, creams, and other viscous products. Choosing the right tube filling machine for your business can be overwhelming, considering the many models and brands available in the market. Here are some things to consider when purchasing a tube filling machine.

Capacity: The quantity of tubes you intend to fill per hour is a critical consideration when purchasing a tube filling machine. If you have a small operation, a semi-automatic machine may suffice, while more substantial businesses will require an automatic tube filling machine.

Type of Product: The type of product you want to fill will determine the type of filling machine to choose. For instance, for liquids, a peristaltic pump filling machine would be an excellent choice while for paste-like products, a piston filling machine would be best.

Accuracy: The accuracy of filling is paramount for the quality of the final product. Choose a machine that has a high measure of accuracy to ensure every tube is filled to perfection.

Ease of Maintenance: Maintenance and cleaning of the machine is also an important consideration since this will extend the machine’s lifespan. Look for a machine that is easy to clean, maintain, and repair when need arises.

Speed: Filling machines come in different filling speeds. Depending on your production and filling requirements, choose a machine with the right speed.

Price: Price is also an important consideration. Always have a set budget and choose a machine that fits within your budget while meeting your requirements.

The Bottom Line

Choosing the right tube filling machine is critical to the success of any manufacturing company involved in the production of viscous products. Take into account the capacity, the product you want to fill, accuracy, maintenance, speed, and price, among other factors that may be important to your business. It’s recommended that you purchase from a reputable supplier who offers warranties and aftersales services to ensure smooth operations of your tube filling machine.

Properties of Tube Filling Machine

A tube filling machine is an essential packaging equipment used extensively in the manufacturing of a variety of products such as toothpaste, ointments, creams, and gels. The machine works by filling products into various types of tubes such as aluminum, plastic, and laminate. Here are some of the properties of tube filling machines that make them a popular choice for manufacturers.

Versatility: Tube filling machines are incredibly versatile and capable of filling products of different viscosities, densities, and textures. The machines also have the ability to fill various tube sizes, shapes, and materials, making them suitable for an array of products.

Accuracy: Tube filling machines are designed to deliver precise and accurate product filling. The machines are equipped with instrumentation that ensures accurate filling by regulating the fill weight, volume or length of the tube to meet the desired specifications.

Efficiency: Tube filling machines are fast and efficient, capable of filling large volumes of tubes in a short time. This not only maximizes production but also results in significant cost savings by reducing labor requirements.

Durability: Tube filling machines are designed to withstand harsh operating conditions such as dust and moisture, making them durable and long-lasting. The machines’ robust construction ensures continuous operation with minimal downtime.

Ease of use: Tube filling machines are user-friendly and easy to operate, requiring minimal training to run effectively. Manufacturers can easily adjust the machines to suit their specific production needs and maintain them with ease.

In conclusion, tube filling machines are an essential tool in the manufacturing of various products. The machines’ versatility, accuracy, efficiency, durability, and ease of use make them a top choice for manufacturers. By investing in a tube filling machine, manufacturers can improve their production rates while maintaining maximum accuracy in the filling process.

How to use Tube Filling Machine

A tube filling machine is a piece of equipment that is used to fill tubes with a variety of products, including toothpaste, cream, and liquid gel. If you have just purchased a tube filling machine, you might be wondering how to use it correctly. Here are a few essential tips on how to use a tube filling machine effectively to get the best results.

1. Understand the requirements of the product: Before using a tube filling machine, you must understand the type of product you are going to fill, the consistency, and the viscosity. It will help you choose the right filling nozzle and adjust the settings on the machine accordingly.

2. Prepare the machine: Once you know the product requirements, you need to prepare the tube filling machine. First, fill the hopper with the product you want to fill. Secondly, ensure that the machine is clean and sanitized, and all the components are correctly assembled.

3. Adjust the settings: Depending on the type of product you are filling, adjust the settings on the tube filling machine, including volume, speed, and filling temperature.

4. Fill the tubes: Once you have made the necessary adjustments and the machine is ready to use, start filling the tubes. Ensure that the tubes are appropriately positioned in the machine, and the filling nozzle is precisely aligned with the opening.

5. Seal the tubes: After filling the tubes, use the sealing unit of the machine to seal them. You can use different sealing methods, including folding and crimping, depending on the type of tube and product.

6. Package and label: Once the tubes are filled and sealed, package them into boxes, and label them with the necessary product information.

In conclusion, using a tube filling machine requires careful attention to detail and a good understanding of the product requirements. Follow the above steps, and you will be able to use a tube filling machine correctly to achieve the best results.

Glossary Terminology Terms for Tube Filling Machine

A tube filling machine is a piece of equipment that is used to fill tubes with different types of products such as cream, lotion, ointment, and toothpaste. There are a number of different terminologies related to tube filling machines. Understanding these terms can help in making an informed decision when purchasing a tube filling machine. In this article, we will discuss the glossary terminology terms for tube filling machines.

1. Hopper: The hopper is a container that is used to hold the material that will be filled into the tubes. It is located at the top of the machine.

2. Nozzle: The nozzle is the part of the tube filling machine that dispenses the material into the tube.

3. Sealing: Sealing refers to the process of sealing the tube after it has been filled with the material.

4. Air Compression: Air compression is a mechanism that is used in tube filling machines to regulate the pressure of air used during the filling process.

5. Heat Sealing: Heat sealing is a process that involves using heat to seal the tube once it has been filled with the material.

6. PLC: A Programmable Logic Controller (PLC) is a device that is used to control various activities of the tube filling machine.

7. Dosing: Dosing refers to the measurement of the material that will be filled into the tube. The dosing system in the tube filling machine ensures that the correct amount of material is dispensed into the tube.

8. Changeover: Changeover refers to the process of changing the tube filling machine from filling one type of product to another.

In conclusion, understanding the terminology related to tube filling machines is crucial in helping you make an informed decision. It enables you to make appropriate and informed choices when purchasing or operating a tube filling machine. Knowing the glossary terminology terms for tube filling machine such as sealing, dosing, heat sealing, PLC, air compression, changeover, nozzle and hopper is valuable in enhancing productivity and

Tube Filling Machine Price

Tube filling machines are essential equipment for pharmaceutical and cosmetic industries. They are machines used to produce tubes for packaging in different capacities, designs and shapes. With the rise of automated technology, the cost of tube filling machines has come into question. The tube filling machine price can vary according to factors such as brand, performance, capacity, and technology involved.

When it comes to tube filling machine price, there are two types of machines in the market. The first one is the fully automatic machine, and the second is the semi-automatic machine. Fully automatic tube filling machines are more expensive than semi-automatic tube filling machines because they require less manual labor and are more efficient. However, the semi-automatic machines are still preferred by many small-scale manufacturers because of their lower cost and easier operation.

The price of tube filling machines varies depending on the size and complexity of the machine. In general, smaller machines with lower production capacities are less expensive than bigger machines with high production capacity. The price can start from a few thousand dollars for small capacity machines to tens of thousands for fully automated machines with high production capacity.

Another factor that influences the tube filling machine price is the technology involved. The newer the technology, the more expensive the machine will be. High-tech machines can reduce the production time and provide better quality products, but they come at a higher price.

In conclusion, tube filling machine prices may vary according to many factors. For those who want to invest in these machines, it is essential to compare different brands and models, production capacity, and technology used. There are many online platforms where you can get information about different types of tube filling machines and their prices. It is wise to consult a professional before making a purchase to get the most suitable machine for your specific needs.