Benefits of Uht Sterilizer

UHT sterilization, also known as ultra-high-temperature sterilization, is a process that involves heating milk, juice, or any other liquid to an extremely high temperature for a short period of time. It is a reliable and effective way to eliminate harmful bacteria and other microorganisms that can cause spoilage and disease.

There are numerous benefits of UHT sterilization. First and foremost, it increases the shelf life of the product. By removing harmful bacteria and other microorganisms, it prevents spoilage and extends the product’s shelf life, which ultimately reduces food waste and saves money for both producers and consumers.

UHT sterilization also helps to preserve the nutrient value and taste of the product. Unlike other sterilization methods such as thermal sterilization, which require longer heating times, UHT sterilization heats the liquid for only a few seconds, minimizing the damage to the product’s nutritional value and taste.

Moreover, UHT sterilization is a more environmentally friendly option compared to other sterilization methods. It requires less energy and fewer resources, making it a more sustainable option for producers and consumers.

Another advantage of UHT sterilization is that it eliminates the need for additional preservatives. Since UHT treatment effectively kills off bacteria and other microorganisms, it reduces the need for chemical preservatives, making the product safer and healthier for consumption.

In summary, UHT sterilization offers a multitude of benefits, including extended shelf life, preserved nutritional value and taste, environmental friendliness, and reduced need for preservatives. It has become an essential process in the food and beverage industry, ensuring that consumers have access to safe and high-quality products.

Features of Uht Sterilizer

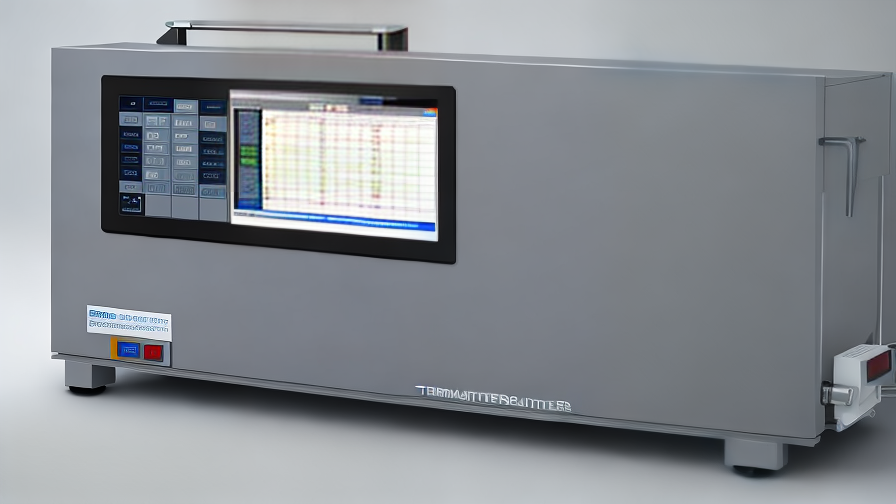

UHT sterilization is a process that is used to make food and beverages safe to consume by eliminating bacteria and other harmful microorganisms. UHT stands for Ultra High Temperature, and the UHT sterilizer is the machine used in this process.

The UHT sterilizer has a number of features that are important in ensuring that the sterilization process is effective and achieves the desired results. Some of the key features of a UHT sterilizer include:

1. High temperature: The UHT sterilizer reaches temperatures of up to 135°C, which is sufficient to kill all microorganisms in the product being sterilized.

2. Short processing time: The UHT sterilizer can complete the sterilization process in a matter of seconds, making it a highly efficient method of sterilization.

3. Continuous processing: The UHT sterilizer can process a continuous flow of product, which means that large volumes can be sterilized in a short amount of time.

4. Sterile environment: The UHT sterilizer creates a sterile environment within the machine, which helps to prevent recontamination of the product after sterilization.

5. Product safety: The UHT sterilizer ensures that food and beverage products are safe to consume by eliminating harmful bacteria and other microorganisms.

6. Minimal impact on product quality: The UHT sterilizer has minimal impact on the quality of the product being sterilized, which means that it can preserve the taste, texture, and nutritional value of the food or beverage.

7. Flexibility: The UHT sterilizer can be used to sterilize a wide range of food and beverage products, including dairy, juices, soups, and sauces.

In conclusion, the UHT sterilizer is an efficient and effective method of sterilizing food and beverages. Its key features include high temperature, short processing time, continuous processing, sterile environment, product safety, minimal impact on product quality, and flexibility. These features make the UHT sterilizer an important tool in the food processing industry, ensuring that products are safe to consume while preserving their taste, texture, and nutritional value.

Various Types of Uht Sterilizer

UHT sterilizer is an equipment used to treat food products such as dairy and juice products. Different types of UHT sterilizers are available in the market to meet the needs of different food processors. The three main types of UHT sterilizers are direct, indirect, and combination UHT sterilizers.

Direct UHT Sterilizer: The direct UHT sterilization process heats the product directly to its required temperature and holds it there for a specific time to achieve effective sterilization. Direct UHT sterilizers are widely used because they are simple to operate, compact, and have low energy consumption.

Indirect UHT Sterilizer: The process of indirect UHT sterilization is where the heat exchanger heats the product indirectly. This is done by passing the cold product through a heat exchanger that is heated by steam. The hot exchanger transfers the heat from steam to the cold product, causing it to warm up to the sterilization temperature. The sterilization temperature is maintained for a specific time. Indirect UHT sterilizers are useful for products containing particles or high viscosity.

Combination UHT Sterilizer: Combination UHT sterilizers combine both direct and indirect heating methods. The combination UHT sterilizer provides high flexibility by combining the best features of both direct and indirect UHT sterilizers, and it is suitable for processing a wide range of products.

Other types of UHT Sterilizer include the tubular type, where the sterilization process takes place inside a long tube that the product flows through. The product continuously moves through from one end of the tube to the other end, and it achieves high efficiency, yield, and productivity.

In conclusion, UHT sterilizers are essential for food processing industries to maintain safety and extend product shelf life. The type of UHT sterilizer depends on the characteristics of the product, such as viscosity, particle size, and thermal properties. The choice of UHT sterilizer is dependent on the manufacturer’s preference, budget, and the end quality of the processed product.

Applications of Uht Sterilizer

UHT (Ultra High Temperature) sterilization is a method of sterilizing food products that involves heating them to a very high temperature of around 135°C for about 1-2 seconds. This process completely kills all microorganisms in the product, making it shelf-stable for many months without the need for refrigeration.

The applications of UHT sterilization are many and varied, and include a wide range of food products such as milk, cream, soups, sauces, fruit juices, and more. One of the main benefits of UHT sterilization is that it allows food manufacturers to produce products with longer shelf lives, reducing waste and increasing efficiency.

UHT sterilization is particularly popular in the dairy industry, where it is used to produce long-lasting milk and cream products that can be stored at room temperature. This makes it possible for these products to be transported and stored more easily, making them more accessible to consumers around the world.

Another important application of UHT sterilization is in the production of ready-to-eat meals, which can be sterilized and packaged in sealed containers. These meals can then be stored at room temperature, making them ideal for distribution in areas where refrigeration is not available or where access to a hot meal is limited.

UHT sterilization is also widely used in the production of fruit juices and other beverages, where it allows manufacturers to produce long-lasting products without the use of preservatives. This makes it possible for consumers to enjoy fresh-tasting juices and other beverages without the need for refrigeration or other forms of preservation.

In conclusion, the applications of UHT sterilization are many and varied, and this method of food processing has become an important tool for food manufacturers around the world. From dairy products to ready-to-eat meals and fruit juices, UHT sterilization has revolutionized the way we produce and consume food, making it possible to enjoy fresh, high-quality products with a longer shelf life.

The Process of Uht Sterilizer

UHT sterilization is a method used in the food industry for the preservation of milk, cream, and other dairy products. UHT, which stands for ultra-high temperature, refers to the process in which the product is heated to a temperature of 135-150°C for a short period of time, usually 2-5 seconds, before being rapidly cooled and packaged in a sterile container.

The UHT process is carried out in a sterilizer machine, which is made up of a series of heat exchangers, heaters, and coolers. The process begins with the preheating of the raw product, which is then sent to a holding tube where it is subjected to high temperature for the required duration. The holding time is crucial, as it ensures that all the bacteria and pathogens in the product are destroyed.

After holding, the product is then rapidly cooled down to a temperature of approximately 4°C by passing it through a series of heat exchangers. This ensures that the product is not overcooked and maintains its nutritional value and taste.

One of the advantages of UHT sterilization is that it allows for long shelf life of the products, usually up to six months, without the need for refrigeration. Another advantage is that it ensures that the product is free from bacteria and pathogens, thus reducing the risk of food poisoning.

The process of UHT sterilization is widely used in the food industry, particularly in the production of milk and dairy products. It has become an important method in the preservation and packaging of dairy products, allowing for the distribution of high-quality, safe and nutritious products to consumers around the world.

How to use Uht Sterilizer

UHT sterilizer, also known as ultra-high temperature sterilizer, is a machine that is used to sterilize liquid products. It is a widely used method in the food and pharmaceutical industries to preserve the products for a long time.

Using a UHT sterilizer involves a few simple steps that need to be followed to ensure the effective sterilization of the liquid products. Here is a step-by-step guide on how to use a UHT sterilizer:

1. Pre-heat the sterilizer: Before using the UHT sterilizer, it is essential to pre-heat the machine to the desired temperature. This will ensure that the product is heated uniformly and thoroughly during the sterilization process.

2. Fill the product into the sterilizer: Once the machine is pre-heated, it is time to fill the liquid product to be sterilized into the sterilizer. Ensure that the product is filled up to the recommended level to avoid overfilling or underfilling.

3. Sterilize the product: The sterilization process begins once the product is filled into the sterilizer. The UHT sterilizer heats the liquid product to an ultra-high temperature of around 135-150°C for a short period of 2-5 seconds. This process destroys all the microorganisms present in the product, ensuring the product’s long shelf life.

4. Cool down the product: After the sterilization process is completed, it is essential to cool down the product quickly. This can be done by passing the product through a cooling unit, which rapidly cools the product to the desired temperature. This process helps to prevent the denaturation of the product and maintain its quality.

5. Fill the product into packaging: Once the product is cooled down, it is ready to be filled into the packaging. Ensure that the packaging is clean and sterile to avoid contamination of the sterilized product.

Following these steps will ensure effective sterilization of the liquid product and provide a longer shelf life. It is essential to maintain the UHT sterilizer and perform regular checks to ensure that it is functioning correctly.

In conclusion, UHT sterilization is an effective method for preserving liquid products’ quality and safety. By following the steps outlined above, you can effectively use a UHT sterilizer to sterilize your liquid products.

Selecting the Ideal Manufacturer Uht Sterilizer

When it comes to selecting the ideal manufacturer for an UHT sterilizer, there are several important factors to consider. The UHT sterilizer is a machine that utilizes high-temperature processes to kill microorganisms in liquid products, extending their shelf life and ensuring they are safe for consumption.

One of the most critical factors to consider when choosing a manufacturer for an UHT sterilizer is experience. A manufacturer with a long history of producing high-quality sterilizers is more likely to provide a reliable and effective product.

Another important factor in choosing a manufacturer for an UHT sterilizer is the level of customization available. Different industries and products may require different settings and features, so a manufacturer that can customize their machines to meet specific needs is essential.

Quality and reliability are also vital considerations. Look for a manufacturer that uses high-quality materials and has rigorous quality control procedures in place to ensure that their machines are built to last and function effectively.

The available service and support offerings are also essential factors to consider when selecting an UHT sterilizer manufacturer. A manufacturer that offers ongoing support, maintenance, and training can ensure that the machine continues to operate correctly and effectively over the long term.

Finally, price is always an important consideration, but don’t make it the only factor. While it’s important to find a manufacturer that offers a competitive price, choosing the cheapest option may not provide the level of quality and reliability required for your specific needs.

In conclusion, when choosing a manufacturer for an UHT sterilizer, consider experience, customization, quality, service and support, and price to make an informed decision that will ensure long-term success.

list FAQ with answer about Uht Sterilizer

Uht Sterilizer is a system used to sterilize liquid food products by heating them at ultra-high temperatures. This process ensures that the products are free from bacteria and other harmful microorganisms, and can be stored for an extended period.

Here are some frequently asked questions about Uht Sterilizers and their answers.

Q: What is Uht Sterilization?

A: Uht Sterilization stands for Ultra-High Temperature Sterilization. It is a process of heating liquid food products at extremely high temperatures for a short amount of time to kill all the bacteria and other harmful microorganisms.

Q: What are the benefits of Uht Sterilization?

A: Uht Sterilization enhances the shelf life of liquid food products, eliminates the need for refrigeration, and ensures that the products remain safe for consumption.

Q: How long does the Uht Sterilization process take?

A: The Uht Sterilization process typically takes between 2-5 seconds, depending on the product being sterilized.

Q: What types of food products can be sterilized using Uht Sterilization?

A: Uht Sterilization can be applied to a wide range of liquid food products such as milk, juices, soup, sauces, and other liquid foods.

Q: What is the required temperature for Uht Sterilization?

A: The required temperature for Uht Sterilization is typically between 130-150°C.

Q: What are the challenges associated with Uht Sterilization?

A: The primary challenge associated with Uht Sterilization is the high cost of equipment required to perform the process. Additionally, some liquid food products may not be compatible with the high temperatures required for Uht Sterilization.

Q: Are there any alternatives to Uht Sterilization?

A: Yes, there are several alternative methods for sterilizing liquid food products such as pasteurization, sterilization by irradiation, and sterilization by chemicals.

In conclusion, Uht Sterilization is a process that has become increasingly popular in the food industry due to its ability to extend the shelf life of liquid food products. However, it is essential to understand the process’s requirements and challenges before incorporating it into a production process.

Things to Consider When Purchasing Uht Sterilizer

When it comes to buying UHT sterilizers, it is crucial to consider several factors. These factors can help ensure that you get the right sterilizer that perfectly fits your needs. Here are some things you need to keep in mind when buying a UHT sterilizer.

Firstly, consider the sterilization process of the device. You want a UHT sterilizer that can eliminate all microorganisms from the product without affecting its quality. Go for a sterilizer that allows you to adjust the temperature, flow rate, and time according to the sensitivity of the product.

Secondly, the capacity and throughput of the sterilizer should also play a significant role in your decision-making process. This involves the volume of product your sterilizer can process per hour. Make sure that you select a UHT sterilizer that can handle your production capacity.

Thirdly, the type of product you are manufacturing and its viscosity are essential points to consider when purchasing a UHT sterilizer. Some products may require specialized sterilizers to remain viable, while others will need a sterilizer with specific accessories such as pumps, pipes, valves, and filters.

Fourthly, you should also factor in the cost of purchasing and maintaining the UHT sterilizer over the long term. Consider the warranty period, replacement parts, and preventive maintenance costs. A high-quality UHT sterilizer may be more expensive initially but will save more on maintenance and repairs later on.

Lastly, make sure to buy from a reputable supplier with high-quality UHT sterilizers. Check for reviews and testimonials from previous customers to get an idea of the supplier’s reputation in the industry.

In conclusion, purchasing a UHT sterilizer requires careful consideration of many factors such as sterilization process, capacity, product viscosity, cost, and supplier reputation. By keeping these factors in mind, you can get the right UHT sterilizer that can help you produce high-quality, safe, and shelf-stable products.

Properties of Uht Sterilizer

UHT sterilizers are commonly used in food and beverage processing to preserve and extend the shelf life of products. UHT stands for ultra-high temperature, which refers to the process of heating liquid products to extremely high temperatures, usually between 135°C and 150°C, for a very short duration, typically a few seconds. This high-temperature treatment inactivates any microorganisms present in the product, ensuring that it remains safe and stable for a long period.

One of the most significant properties of UHT sterilizers is their ability to achieve a high level of microbial destruction. The short-time, high-temperature process destroys virtually all microorganisms present in the product, including bacteria, yeasts, and molds. This makes UHT sterilization an effective way to ensure the safety and stability of liquid products, even at room temperature.

Another property of UHT sterilizers is that they are very versatile and can be used to sterilize a wide range of liquid products. UHT sterilizers are commonly used in the production of milk and other dairy products, such as cream, yogurt, and ice cream. They are also used in the processing of fruit juices, soft drinks, and alcoholic beverages.

UHT sterilizers have minimal impact on the quality and nutritional value of the product being processed. Unlike other sterilization methods that can alter the flavor and texture of the food, UHT sterilization has a minimal impact on the quality, taste, and nutrient content of the product. This means that UHT sterilized products retain their flavor, texture, and nutritional value for longer periods, making them more appealing to consumers.

In conclusion, UHT sterilizers are an important tool in the food and beverage industry that helps to ensure the safety, stability, and quality of liquid products. With their high level of microbial destruction, versatility, and minimal impact on the nutritional value and quality of the product, UHT sterilizers are an ideal sterilization method for a wide range of liquid products.

Technical Parameters Terms for Uht Sterilizer

UHT Sterilizers are commonly used in the food and beverage industry to sterilize products before packaging. The sterilization process involves heating the product to a high temperature for a short period of time, killing any bacteria or microorganisms present in the product. The technical parameters used in UHT sterilization include temperature, holding time, flow rate, and pressure.

Temperature is one of the most important technical parameters in UHT sterilization. The product needs to be heated to a certain temperature for a specific amount of time to ensure complete sterilization. The temperature range for UHT sterilization is typically between 135°C and 150°C, with most applications between 135°C and 140°C for a holding time of 4-6 seconds.

Holding time refers to the amount of time the product is held at the sterilization temperature. Longer holding times are required for thicker or viscous products to ensure that all parts of the product are heated to the sterilization temperature. Generally, holding time ranges from 2 to 15 seconds depending on the product.

Flow rate determines the speed at which the product is moved through the UHT sterilizer. Faster flow rates require higher temperatures or longer holding times to ensure complete sterilization. The flow rate also varies according to the viscosity of the product, with thicker products requiring slower flow rates.

Pressure is a less common technical parameter in UHT sterilization, but it can affect the efficiency of the process. Higher pressures can help to lower the sterilization temperature or reduce the holding time required for complete sterilization. However, higher pressures can also damage sensitive products, so it is important to find the right balance depending on the product.

In conclusion, understanding the technical parameters in UHT sterilization is important to ensure the sterilization process is efficient and effective. Temperature, holding time, flow rate, and pressure are all important parameters that must be balanced properly to produce a high-quality, safe product.

Uht Sterilizer Price

Uht sterilizers are crucial equipment in the food and beverage industry that ensure the quality of products by sterilizing them through the ultra-high temperature process. As food safety and hygiene become mandatory concerns in the industry, investing in quality Uht sterilizers is vital.

When considering purchasing a Uht sterilizer, the price is an essential factor for any business operator. Uht sterilizers’ prices vary, and several factors determine the price range. The sterilizer’s size, material, and features can determine the cost, and larger models tend to be more expensive. Additionally, the material making up the sterilizer can also impact the price, with stainless steel models being more expensive than their counterparts.

The average price range for Uht sterilizers typically ranges from $5000 to $70,000, but specific factors can cause the cost to vary. For instance, a small-scale Uht sterilizer will cost relatively less than a larger commercial sterilizer capable of handling high production volumes. Similarly, a basic Uht sterilizer with fewer features may cost significantly less than a more advanced model with complex control systems.

It’s essential to consider the cost of maintaining the Uht sterilizer in the long term, such as cleaning and maintenance. These expenses can vary depending on the type of sterilizer and the amount of production. It is essential to read the manufacturer’s instructions for maintenance and cleaning to ensure the equipment functions properly, ultimately reducing the cost of repairs and maintenance.

In conclusion, investing in a Uht sterilizer is vital for businesses in the food and beverage industry. The price for a Uht sterilizer can vary depending on the size, material, and features. When making a purchase decision, it’s essential to consider several factors that impact the Uht sterilizer’s price and the maintenance costs in the long run. Ultimately, the goal is to obtain a high-quality Uht sterilizer that can operate efficiently while ensuring quality standards of the final product.