Benefits of Vacuum Filler

Vacuum fillers are a great tool in the food industry for packaging and processing products like meats, cheeses, and soups. They work by removing air from the product and then filling it, leaving no empty spaces. This ensures that the product stays fresh for a longer period of time, and bacteria growth is minimized.

The benefits of vacuum fillers are numerous, and here are a few of them:

1. Product Quality: Vacuum fillers are designed to fill products with minimal exposure to air. This means that they help maintain the quality of the product, especially when it comes to meat products. Without oxygen, the meat doesn’t oxidize, so the meat’s color, flavor, and texture remain intact.

2. Cost-Effective: Vacuum fillers are cost-effective in the long run. When product quality is maintained, the product lasts longer and has less waste. This means that less product is wasted, which helps reduce overall costs.

3. Hygienic: Vacuum fillers are great for maintaining hygienic standards in the food industry. They are designed to reduce the risk of contamination of the product, which can be a significant problem in the food production industry.

4. Increased Production: By processing and packaging products with greater efficiency, vacuum fillers save time, labor, and ultimately increase production. This is especially important in time-sensitive production environments where a faster pace is required to meet customer demands.

5. Sustainability: Vacuum filling can also help companies reduce their carbon footprint by reducing packaging material waste. Moreover, products that are vacuum filled tend to last longer, which means that they are less likely to end up in landfills.

In conclusion, the use of vacuum fillers make a significant impact on the food industry. It helps maintain product quality, reduce costs, improve hygiene, increase production rates, and promote sustainability.

Features of Vacuum Filler

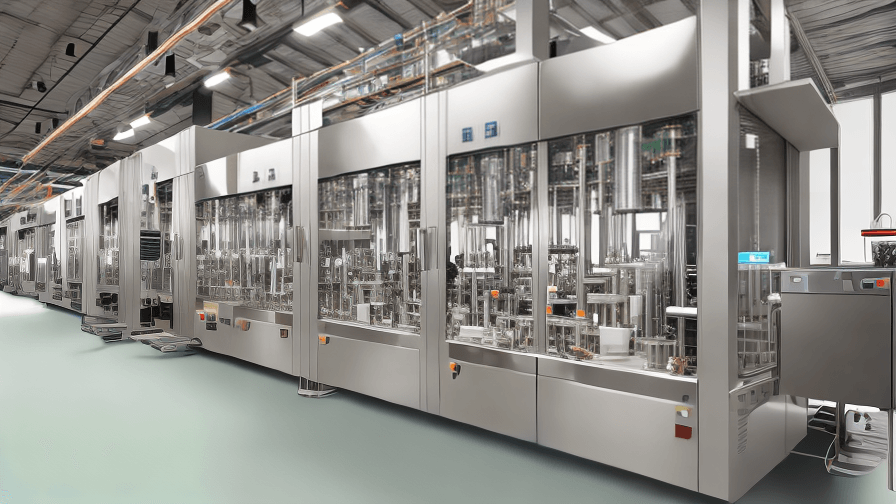

A vacuum filler is a piece of equipment that is widely used in the packaging industry. It is used to fill various types of liquids, such as oils, syrups, and chemicals, in glass and plastic bottles, as well as other containers. Here are the main features of a vacuum filler:

1. Precision Filling

Vacuum fillers are designed to fill containers with precise amounts of liquid, which can be set using the machine’s controls. This ensures that each container is filled accurately and consistently, reducing waste and maximizing efficiency.

2. Automatic Filling

Vacuum fillers are fully automated, making them easy to operate and maintain. Once a container is placed on the machine, the filling process is initiated automatically, and the machine will stop filling once the preset amount is reached.

3. High-Speed Filling

Vacuum fillers are capable of filling containers at a high speed, which is important for large-scale production. This saves time and money while ensuring that production targets are met.

4. Minimal Drip Losses

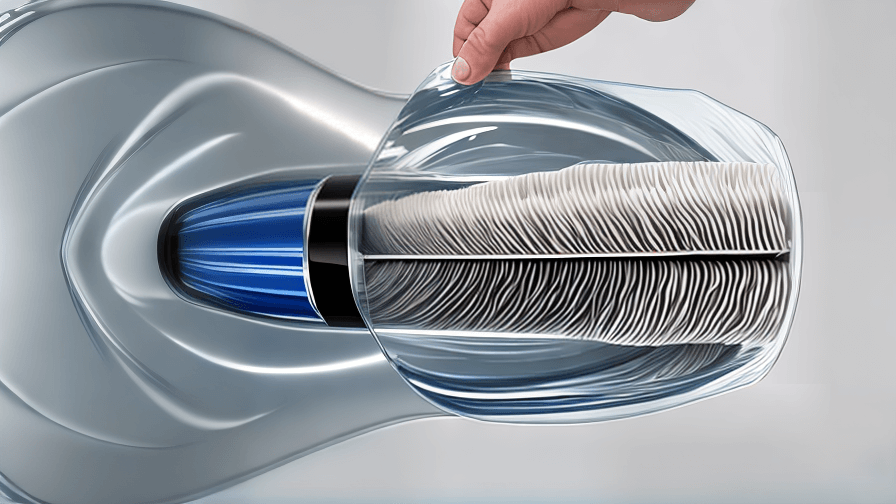

Vacuum fillers are designed to minimize the amount of liquid that is lost due to drips and spills. This is achieved by using specialized nozzles and valves that control the flow of liquid, and by using a vacuum to remove any excess liquid from the container after filling.

5. Versatile

Vacuum fillers are versatile machines that can be used to fill a wide range of liquids, including viscous and foamy liquids. They can also be used with a variety of container types and sizes, making them a great choice for businesses that need to fill different types of containers.

6. Easy to Clean

Vacuum fillers are easy to clean, which is essential for maintaining hygiene standards in the food and beverage industry. The machine can be disassembled and cleaned thoroughly, ensuring that there is no buildup of residue or other contaminants.

In conclusion, vacuum fillers are an essential piece of equipment for any business that needs to fill containers with liquid quickly, accurately, and consistently. With precision filling, automatic filling, and high-speed filling capabilities, vacuum fillers are versatile and efficient machines that can help businesses meet production targets and maintain high-quality standards.

Various Types of Vacuum Filler

A vacuum filler is a popular packing machine used to fill various liquids like water, oil, and beverages, among others, into containers like bottles, jars, and cans. It works by creating a vacuum in the container, which sucks in the liquid from a reservoir. Here are different types of vacuum fillers:

1. Piston Vacuum Filler: This type is ideal for viscous liquids like syrups and oils. It uses a piston to draw the fluids into the container.

2. Overflow Vacuum Filler: It is used for fill container fully without any air pockets. It overflows the container with liquid to ensure that it’s completely filled while sucking in any excess into the reservoir. It is useful for non-viscous liquids like water and beverages.

3. Gravity Vacuum Filler: This type is ideal for containers that have a narrow opening. It uses gravity to fill the containers while ensuring that there are no spills. It is perfect for filling wine bottles and perfume containers.

4. Pressure Vacuum Filler: It is suitable for filling products that need a high level of accuracy, like pharmaceuticals. It uses pressure to fill the containers, ensuring that the amount of liquid filled is consistent.

5. Vacuum Overflow Filler: Here, a vacuum pump is tied with the filling nozzle which helps to vacuum the container before fill the liquid which reduces the amount of Oxygen inside the jar.

In conclusion, vacuum fillers are versatile that cater to the needs of many industries. The choice of the vacuum filler largely depends on the product being filled and the container being used. The selection should be based on factors like viscosity, accuracy, and the size of the opening, among others.

Applications of Vacuum Filler

Vacuum fillers are machines that are used to fill products such as liquid, paste, or meat in packaging. They are widely used in the food industry to fill different products, including sausages, cold cuts, cream, and other kinds of foods. These machines use vacuum technology to fill the packaging with the product, ensuring that there is no air trapped in the package, which can compromise the product’s quality. There are many different applications of vacuum fillers, which make them an essential part of various industries.

Food industry: Vacuum fillers are widely used in the food industry, especially in the meat processing industry. The machines are used to fill packaging with meat, sausages, and hot dogs, among other types of foods. These machines use vacuum technology to ensure that the product is filled evenly, and there is no air trapped in the package. This helps to preserve the quality and freshness of the food.

Pharmaceutical industry: Vacuum fillers are also widely used in the pharmaceutical industry to fill different products, including syrups, ointments, and creams. The machines are designed to provide a high level of accuracy and precision, which is critical in the pharmaceutical industry. The vacuum technology used in the machines helps to ensure that the products are filled evenly and consistently to meet the required quality standards.

Cosmetic industry: Vacuum fillers are also used in the cosmetic industry to fill different products, including lotions, creams, and gels. The machines are designed to ensure that the product is filled accurately and consistently, without any air pockets or bubbles. This helps to ensure that the product is of high-quality and that the customer receives a great experience.

In conclusion, vacuum fillers are machines that are widely used in different industries, including the food, pharmaceutical, and cosmetic industries. These machines use vacuum technology to fill packaging with different products accurately and consistently, ensuring that the quality of the products is not compromised. The importance of vacuum fillers cannot be overstated because they play a critical role in ensuring that products are filled correctly, meeting the required quality standards.

The Process of Vacuum Filler

Vacuum fillers are widely used in the food industry for filling liquids such as sauces, gravies, and jams. The process involves removing air from the container to create a vacuum and then filling it with the product. Vacuum filling is an efficient way to fill containers with liquids because it reduces the amount of air in the container, which in turn increases the amount of product that can be filled in a single cycle.

The vacuum filling process begins with the container being placed on the filling nozzle of the machine. The nozzle is connected to a vacuum pump that creates a vacuum in the container by drawing out the air. Once the vacuum is created, the machine begins to fill the container with the liquid product. The filling process is controlled by a sensor that monitors the level of the product and stops the filling process once the desired level is reached.

The vacuum filling process is efficient, reliable, and safe. The machine is designed to fill containers with minimal spillage and wastage, which reduces costs and increases productivity. Additionally, the process is safe because the machine is equipped with safety features such as automatic shutoff and emergency stop buttons.

One of the key benefits of vacuum filling is that it allows for accurate filling of the container. The sensor in the machine ensures that the container is filled to the desired level, which eliminates the need for manual adjustments and reduces the risk of overfilling. As a result, the product quality is consistent, and the risk of contamination is minimized.

In conclusion, vacuum filling is a widely used process in the food industry for filling liquids such as sauces, gravies, and jams. The process is efficient, reliable, and safe, and it allows for accurate filling of the container. Vacuum filling machines are designed to reduce spillage and wastage, increase productivity, and ensure consistent product quality.

How to use Vacuum Filler

A vacuum filler is a useful tool for filling products like jams, jellies, and other thick substances. It operates based on the principle of vacuum, which pulls the product into its container. To make the most of your vacuum filler, you must use it right. Here are a few step-by-step instructions to help you get started:

1. Assemble your vacuum filler. Ensure you have all the components, including the filling nozzle, hopper, and pumps. Make sure that the machine is clean and lubricated before use.

2. Prepare the product. The product to be filled needs to be the correct consistency to work correctly. Ensure that it’s warmed up and mixed well. You should also check that the product has not started to set or congeal.

3. Fill the hopper with the product. The hopper is the container where the product sits before flowing into the filling chamber. Be cautious not to overfill the hopper.

4. Open the vacuum valve. The vacuum valve will be located near the filling chamber. Turn it on, so the vacuum is created in the filling chamber.

5. Insert the filling nozzle into the product. Be sure to set the nozzle to the correct height, so the product remains at the right level in the filling chamber.

6. Open the filling valve. The filling valve is what allows the product to flow into the container. It should be opened slowly to prevent splashing and overfilling.

7. Clean the machine after filling. Make sure you have removed any leftover product from the hopper, filling chamber, and nozzle. Ensure everything is fully cleaned and disinfected before storage.

In conclusion, using a vacuum filler might require some learning. Nonetheless, following the steps outlined above can help you fill products correctly. Besides, practice makes perfect, and with time, you’ll enjoy using this useful tool and perfect your filling skills.

Selecting the Ideal Manufacturer Vacuum Filler

When it comes to selecting a manufacturer vacuum filler for your business, there are several factors that need to be considered. With so many options available in the market, choosing the ideal vacuum filler can be confusing, time-consuming, and even costly. The right choice can create an efficient, productive, and cost-effective filling process, which in turn translates to higher profits. Here are some tips to help you select the ideal manufacturer vacuum filler.

Capacity: Determine the amount of product that needs to be filled at any given time. Select a vacuum filler that can handle the required volume efficiently and quickly.

Functionality: Look for vacuum fillers that offer versatility in its functionality. An ideal vacuum filler should be suitable for different types of products ranging from liquids to viscous substances.

Accuracy: Select a vacuum filler with the precision to deliver exact measurements of the product with minimal wastage.

Ease of Use: An easy-to-use vacuum filler does more than just increase productivity, it also reduces the risk of errors and potential accidents.

Reliability: Choose a reliable vacuum filler that will reduce downtime, minimize breakdowns, and have low maintenance costs.

Cost: While cost is a key factor, it should not be the only factor considered when selecting a manufacturer vacuum filler. Look for vacuum fillers with a reasonable price tag without compromising on quality, reliability or functionality.

In conclusion, selecting the ideal vacuum filler can be a daunting task, but taking the time to consider the above factors will help in making an informed decision. It can also provide you with the necessary tools needed to make your business more efficient and productive, which ultimately leads to higher profits and customer satisfaction.

list FAQ with answer about Vacuum Filler

FAQ with Answers About Vacuum Filler

What is a vacuum filler?

A vacuum filler is a machine used to fill liquids into containers or bottles. It utilizes vacuum technology to draw out the air from the container during the filling process.

What are the advantages of using a vacuum filler?

The primary advantage of using a vacuum filler is the elimination of air in the containers, which prevents product spoilage by reducing the risk of bacterial or fungal growth. Additionally, it can improve product consistency and reduce waste by accurately measuring the amount of liquid filled in each container.

What types of liquids can be filled using a vacuum filler?

A vacuum filler can be used for filling various liquids, such as juices, sauces, syrups, oils, and cosmetic products like shampoos and lotions. However, it is not suitable for carbonated or foaming beverages.

How accurate is a vacuum filler?

Most vacuum fillers have high accuracy levels, with filling variations typically less than or equal to 1%. It depends on the machine model and the type of product.

Do vacuum fillers require special maintenance?

Vacuum fillers require regular maintenance, such as cleaning and inspecting the machine before and after use. It would be best if you also lubricated the machine parts to prevent wear and tear. Regular maintenance ensures the machine is functioning efficiently and prolongs its lifespan.

What capacity of vacuum filler is ideal for my business?

The ideal vacuum filler capacity depends on the volume of the product you want to fill and your production capacity. It is best to choose a machine that can accommodate your production needs.

Where can I buy a vacuum filler?

You can purchase vacuum fillers from manufacturers, suppliers, or distributors of industrial packaging equipment. Consider comparing prices, features, and after-sales services of various suppliers before making a purchase.

Conclusion

Vacuum fillers are beneficial for businesses that produce liquids as they provide accurate and efficient filling while reducing product spoilage. Regular maintenance is necessary to prolong machine life and ensure efficient operations. Consider the product volume and production capacity to determine the appropriate vacuum filler for your business.

Things to Consider When Purchasing Vacuum Filler

When it comes to choosing the right vacuum filler, there are several factors you need to consider. The vacuum filling machine technology has advanced and there is a wide range of machines available in the market. Here are some things you need to keep in mind when purchasing a vacuum filler.

1. Type of product: Different vacuum fillers are designed for different types of products. Some fillers work great with heavy and thick products such as creams and sauces, while others are better suited for liquids such as juices and water. Before making a purchase, ensure that the vacuum filler can handle the type of product that you plan on filling.

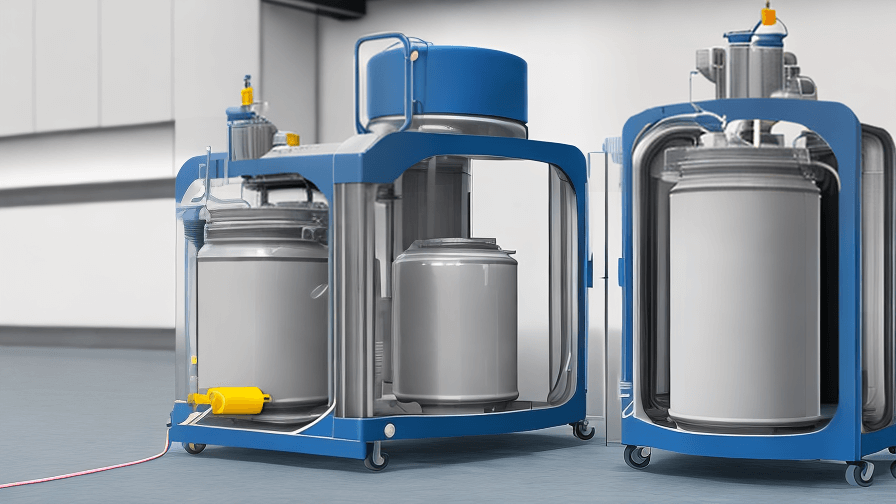

2. Capacity: Depending on the size of your operation, you will need a vacuum filler with a certain capacity. If you are running a small-scale operation, you may not need a high-capacity vacuum filler. However, if you are filling large quantities of products, you will need a machine with a high capacity to keep up with the demand.

3. Quality: Ensure that you invest in a high-quality vacuum filler that will last for years. A low-quality filling machine may break down quickly, leading to costly repairs and downtime.

4. Ease of use: Look for a vacuum filler that is easy to operate and maintain. If you have a small team or are handling the filling process on your own, it is essential that you do not waste time learning how to use the machine.

5. Cost: The cost of a vacuum filler varies depending on the features and capacity. Ensure that you choose a machine that meets your needs without breaking the bank. A higher-priced machine is not always the best option, but an affordable one may not have the features you need.

In conclusion, purchasing a vacuum filler requires careful consideration of various factors. By taking into account these factors, you will find a machine that meets your requirements and fits your budget. Additionally, it is vital to purchase a vacuum filler from a reliable supplier to ensure quality and efficiency.

Properties of Vacuum Filler

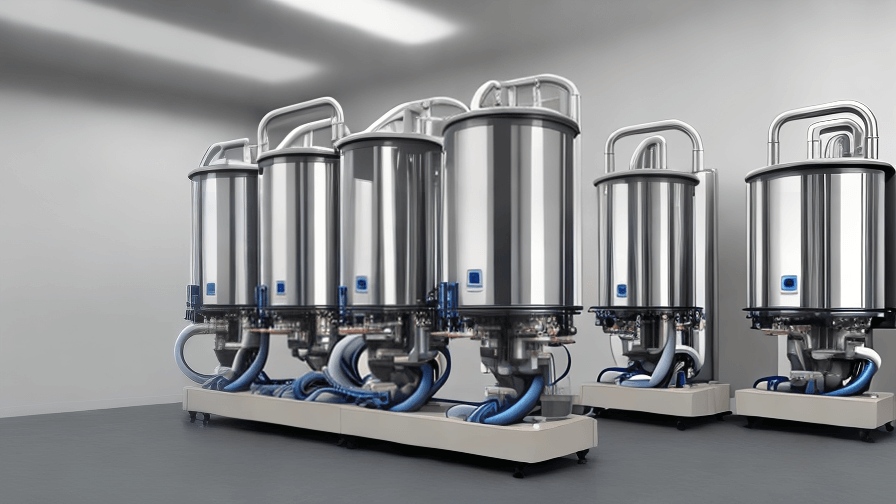

Vacuum fillers are machines that are used in filling products into bags, bottles, and other containers. They work by creating a vacuum in the container, which removes all the air, leaving it empty. The product is then pumped into the container, and the vacuum is released, closing the container. Vacuum fillers come with several properties that make them ideal for various industries, including food, pharmaceuticals, and cosmetics.

One of the key properties of vacuum fillers is their versatility. They can be used to fill various types of products, including liquids, semi-solids, and powders. This means that they can be utilized in multiple industries, providing an efficient and cost-effective solution to different filling requirements. Additionally, the fillers can handle a range of container sizes and shapes, making them ideal for packing irregularly shaped products.

Another essential property of vacuum fillers is their accuracy and precision. They are equipped with advanced sensors and controls that allow them to measure the exact amount of product to be filled into each container, ensuring consistency and avoiding product waste. The fillers can also adjust to flow rates and viscosity, making them suitable for products with varying fluidity.

Vacuum fillers are also known for their ease of cleaning and maintenance. They are designed to have smooth surfaces that can easily be wiped clean, eliminating the risk of bacterial growth. Moreover, the machines have few moving parts, which reduces wear and tear and the need for frequent repairs. This lowers maintenance costs and minimizes downtime, ultimately increasing productivity and profitability.

Lastly, vacuum fillers are incredibly efficient in terms of energy consumption. They use a small amount of air pressure to create a vacuum, which reduces power consumption and operating costs. Additionally, the machines are eco-friendly, as they reduce product waste, minimize packaging material usage, and maximize product shelf life.

In conclusion, vacuum fillers are an essential filling machine for various industries globally. Their versatility, accuracy and precision, ease of cleaning and maintenance, and energy efficiency are properties that have made them popular across different market segments. With continued technological advancements, it’s expected that vacuum fillers will continue to play a significant role in the manufacturing industry.

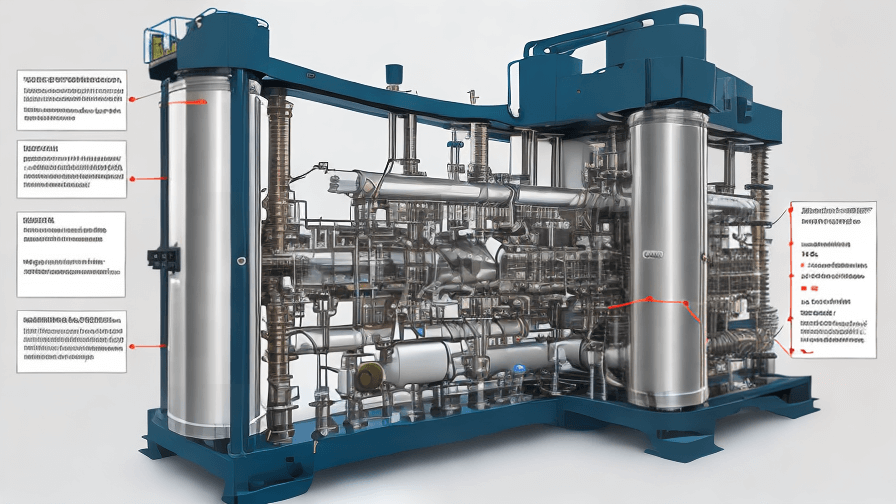

Technical Parameters Terms for Vacuum Filler

When it comes to purchasing or using a vacuum filler, it’s important to have a solid understanding of the technical parameters that come with it. These parameters help to define the machine’s capabilities, performance, and efficiency.

One of the most important technical parameters of a vacuum filler is its filling speed. This refers to how much product the machine can fill in a given period of time. Depending on the application, filling speed can range from a few hundred packs per hour to thousands.

Another important parameter is accuracy. This is measured in terms of how closely the filler is able to match the target weight or volume of the product being filled. A good quality machine should have an accuracy of at least +/-0.5%.

Machine changeover time is another important parameter that can directly impact productivity. This refers to the time it takes to switch from filling one product to another. A faster changeover time enables the machine to increase the variety of products it can handle, without sacrificing productivity.

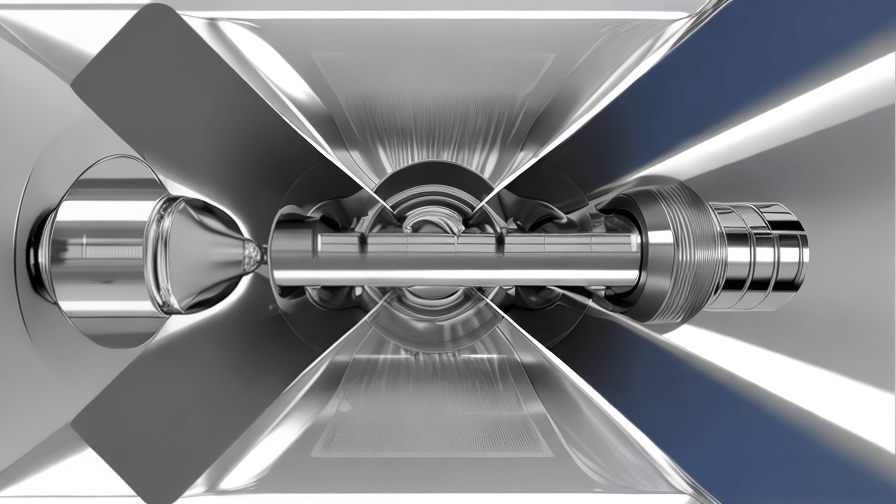

Vacuum pressure is another key parameter that affects the quality of the filled product. It refers to the level of vacuum created inside the filler during the filling process. It determines the degree of air removal and product compaction, which can affect product integrity, texture, and appearance.

Finally, the size of the filler is an essential parameter that should be considered. This includes the dimensions of the machine itself, its weight and capacity. It is important to ensure that the machine will fit into the production line and be able to handle the volume of production required.

Overall, having a solid understanding of these technical parameters can help to ensure that the vacuum filler selected is best suited to the specific production needs of the business.

Vacuum Filler Price

Vacuum filling machines are an essential piece of equipment for any food or pharmaceutical manufacturing company that requires the efficient and accurate filling of liquid and viscous products. The cost of a vacuum filler can vary depending on several factors, including the machine’s size, model, and make. Below are some essential considerations when determining the vacuum filler price.

Size: The size of the machine affects its price. To determine the size of a vacuum filler, manufacturers consider the volume of the filling chamber. Larger filling chambers are generally more expensive than smaller filling chambers, but they provide a higher level of efficiency and speed when filling a substantial amount of products.

Model: Different models have different functions and features and come at varying prices. For instance, the vacuum filler machines range from semi-automatic, automatic, and fully automatic models. Automated models are more expensive than the manual models since they offer higher accuracy and efficiency while providing more features.

Make: The manufacturer of the vacuum filler can also affect its price. Some manufacturers offer cost-effective machines with essential features while others offer industrial-grade equipment for hefty prices. Some manufacturers also offer customized machines that come at a higher cost than standard models.

Additional features: Vacuum filling machines offer a range of features that affect the cost. For example, some machines offer adjustable filling speed, sanitization options, and CIP (cleaning in place) capabilities to ensure sanitary standards. The additional features come at an extra cost and should be considered when determining the overall price.

In conclusion, the cost of a vacuum filler machine varies depending on the size, model, make, and additional features. However, the overall cost should be viewed as an investment rather than just a purchase. The machine’s accuracy and efficiency increase the productivity of a manufacturing company, thereby boosting profits and reducing waste. Therefore, when making a decision about a vacuum filler, one should consider the benefits of a higher-priced machine over lower-priced alternatives.