Introduce about vertical sealing machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

A vertical sealing machine guide provides essential information about machinery used for sealing products in vertical packaging applications. These machines are commonly used in the food, pharmaceutical, and cosmetic industries to ensure product safety, freshness, and shelf-life.

Quality is an important factor when considering a vertical sealing machine. High-quality machines offer efficient and reliable sealing, reducing the risk of leaks or product spoilage. Look for machines made from durable materials that can withstand the demands of continuous production.

Cost is another crucial consideration. Vertical sealing machines come in a wide price range, depending on their features and capabilities. It’s important to balance cost with quality to ensure you invest in a machine that meets your production needs without compromising on performance.

Choosing a reputable supplier is vital to ensure a reliable purchase and after-sales service. Look for suppliers with a good track record, positive customer reviews, and excellent customer support. Verify if they offer warranty and maintenance services to prevent any potential issues.

Certification is an important aspect when purchasing a vertical sealing machine. Ensure that the machine meets industry standards and regulations such as CE, ISO, or FDA certifications. These certifications demonstrate that the machinery has been tested for safety and performance.

The market for vertical sealing machines is constantly expanding due to increased demand for efficient packaging solutions. With advancements in technology, modern machines offer enhanced automation features, further streamlining the packaging process.

Tips for choosing the right vertical sealing machine include considering the type of packaging materials, the size and shape of the packages, production capacity, and specific sealing requirements. It’s also important to assess your future needs to ensure the machine can accommodate any potential growth.

Frequently Asked Questions (FAQ) may include inquiries about the sealing process, maintenance procedures, troubleshooting, and compatibility with specific packaging materials. The supplier or manufacturer should provide detailed answers to commonly asked questions to assist customers.

In conclusion, a vertical sealing machine guide provides essential information about quality, cost, suppliers, certifications, market trends, tips, and frequently asked questions related to vertical sealing machines. Making an informed decision when choosing a machine ensures efficient and reliable packaging solutions for your products.

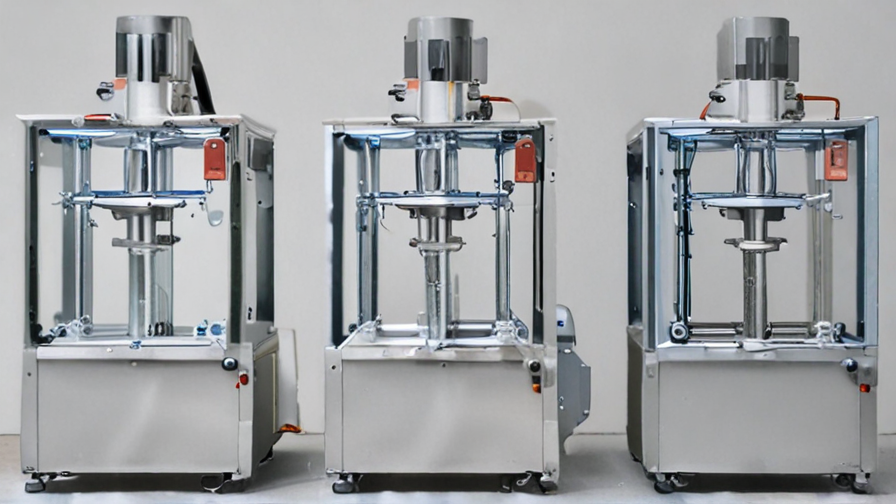

Types of vertical sealing machine

Vertical sealing machines are widely used in various industries to package products securely and efficiently. These machines can seal different types of bags, pouches, or films vertically, providing a tight, reliable seal to ensure the product’s freshness, protection, and tamper resistance. Here are some common types of vertical sealing machines:

1. Vertical Form Fill Seal (VFFS) Machines: VFFS machines are versatile and commonly used in the food, pharmaceutical, and agricultural industries. These machines can form, fill, and seal bags from a flat roll of film. They have a vertical bag-forming tube, and the product is weighed, measured, or counted before being introduced into the pouch. The machine then seals the bag and cuts it from the film roll.

2. Vertical Band Sealing Machines: These machines use a continuous band to create a heat seal on the bag or pouch. They are commonly used for sealing larger bags or packages that cannot be easily sealed using other methods. Vertical band sealers are widely employed in industries such as pet food, chemicals, and agriculture.

3. Vertical Hot Air Sealing Machines: Also known as hot air sealers, these machines use heated air to create a seal. The bag is placed between two sealing bars, and hot air is directed onto the seal area. The hot air softens the bag material, causing it to fuse together and form a strong seal. Vertical hot air sealers are commonly used for packaging products like snack foods, coffee, and powdered goods.

4. Vertical Ultrasonic Sealing Machines: Ultrasonic sealing machines use ultrasonic vibrations to create heat and pressure, enabling the sealing of bags and pouches. The vibrations generate friction, causing the two layers of bag material to melt and bond together. These machines are commonly used in the food, cosmetics, and pharmaceutical industries due to their ability to provide a strong, precise, and contamination-free seal.

5. Vertical Impulse Sealing Machines: Impulse sealers use a heating element to create a short burst of heat that fuses the bag materials together. These machines are quick and energy-efficient, making them suitable for a wide range of applications. Vertical impulse sealers are commonly used for sealing bags or pouches containing products like snacks, spices, and office supplies.

In conclusion, vertical sealing machines come in various types, each catering to specific packaging needs. These machines play a crucial role in maintaining product integrity and extending shelf life. The choice of a vertical sealing machine depends on factors such as the type of packaging material, product characteristics, production volume, and industry requirements.

Pros and Cons of Using vertical sealing machine

Using a vertical sealing machine, also known as a vertical form-fill-seal machine or VFFS, has several advantages and disadvantages. Let’s explore some of the pros and cons of using this type of packaging machinery:

Pros:

1. Efficiency: Vertical sealing machines have a high production output, allowing for fast packaging speeds. This can result in substantial cost savings due to increased productivity.

2. Versatility: These machines can handle a wide range of products, including solid, granulated, and powdered materials. They offer the flexibility to package various sizes and shapes, making them suitable for different industries and products.

3. Improved hygiene: With precise control over packaging, vertical sealing machines can provide a clean and hygienic environment for product packaging. This is crucial for industries such as food and pharmaceuticals that require high hygiene standards.

4. Reduced labor costs: Automation provided by vertical sealing machines reduces the need for manual labor, resulting in cost savings related to hiring, training, and managing employees.

5. Space-saving: Compared to horizontal machines, vertical sealing machines often require less floor space, making them suitable for small or compact production areas.

Cons:

1. Initial investment: Vertical sealing machines can be relatively expensive compared to other packaging equipment. This upfront cost might be a barrier for small businesses with limited budgets.

2. Maintenance and servicing: Like any machinery, vertical sealing machines require regular maintenance to ensure optimal performance. Repairs and maintenance costs may add to the total cost of ownership.

3. Complexity: Operating a vertical sealing machine often requires skilled personnel who are trained in operating and troubleshooting the machinery. The complexity of the equipment may result in longer learning curves for new operators.

4. Packaging limitations: While vertical sealing machines offer versatility, there may be limitations in packaging certain types of products that have unique shapes or characteristics. Additional customization or modifications may be required to accommodate such products.

5. Product waste: During initial setup or when switching products, there can be some product waste. This can negatively impact production efficiency and lead to higher material costs.

In conclusion, vertical sealing machines offer several advantages, including high efficiency and versatility. However, they also come with certain drawbacks, such as the initial investment cost and the need for skilled operators. Businesses considering the use of vertical sealing machines should carefully evaluate their specific needs and weigh the pros and cons before making a decision.

vertical sealing machine Reference Specifications (varies for different product)

The vertical sealing machine is a widely-used packaging equipment that is utilized in various industries for sealing different types of products. The specifications of this machine may vary depending on the product being packaged. Here we present a general reference specification for the vertical sealing machine.

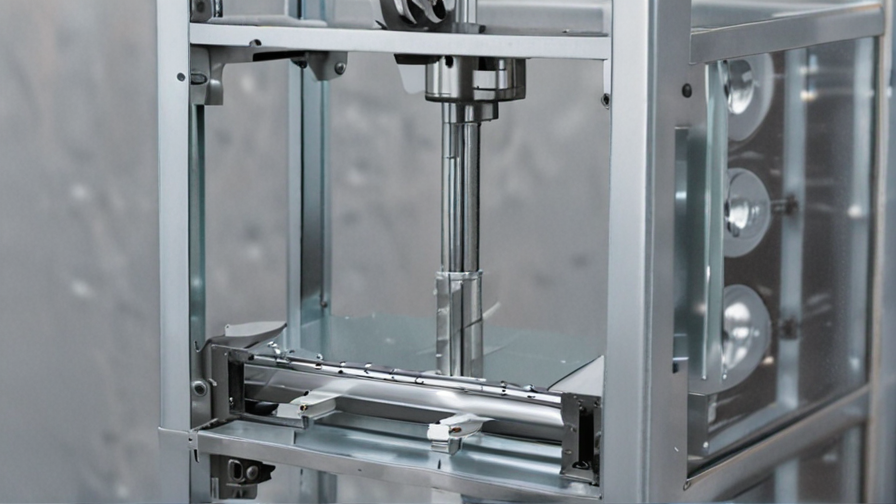

The machine is constructed with a sturdy stainless steel frame, ensuring durability and longevity. It features a vertical sealing mechanism that is designed to efficiently seal bags or pouches filled with products. The sealing mechanism consists of heated sealing jaws that apply heat and pressure to create a secure and airtight seal.

The sealing machine is equipped with adjustable parameters to accommodate different types of bags and products. These parameters include sealing time, sealing temperature, and pressure settings. The flexibility to adjust these parameters allows for optimal sealing performance and ensures that the machine can handle various product requirements.

For ease of operation, the machine incorporates a user-friendly control panel. The control panel provides a clear interface where operators can easily set the desired sealing parameters. Additionally, the machine is equipped with sensors and indicators that monitor the sealing process, alerting operators of any errors or malfunctions.

To enhance productivity, the vertical sealing machine is designed to operate at high speeds. It can seal a significant number of bags per minute, depending on the size and complexity of the product being packaged. The machine can also be integrated into an automated production line, allowing for continuous and efficient packaging operations.

Furthermore, the vertical sealing machine ensures product safety and hygiene. It is built with features that prevent contamination and ensure that the products remain in a clean and sterilized environment during the sealing process. These features include dust covers, easy-to-clean surfaces, and compliance with industry regulatory standards.

In conclusion, the vertical sealing machine is a versatile packaging equipment that offers customizable specifications to meet the needs of different products. Its sturdy construction, adjustable parameters, user-friendly interface, high-speed operation, and emphasis on product safety make it an essential tool in various industries.

Applications of vertical sealing machine

Vertical sealing machines, also known as vertical form-fill-seal machines, are versatile machines used in various industries for packaging purposes. These machines have numerous applications due to their ability to efficiently seal different types of flexible packaging materials. Some of the common applications of vertical sealing machines include:

1. Food packaging: Vertical sealing machines are widely used in the food industry for packaging various types of products such as chips, snacks, chocolates, biscuits, cookies, grains, spices, and powdered products. These machines ensure the safety and freshness of the packed food items while increasing their shelf life.

2. Pharmaceutical packaging: Vertical sealing machines are used in the pharmaceutical industry for packaging tablets, capsules, medicines, and medical devices. These machines maintain the integrity of the packaging, ensuring that the products are free from contamination and remain in their original state.

3. Personal care and cosmetics: Vertical sealing machines are utilized for packaging products in the personal care and cosmetics industry, including creams, lotions, shampoos, gels, and various beauty and skincare products. These machines provide a tight seal, preventing leakage and preserving the quality of the packaged items.

4. Pet food packaging: Vertical sealing machines are commonly used for packaging pet food products such as dry kibbles, treats, and snacks. These machines offer efficient packaging solutions that maintain the freshness and quality of the pet food, extending its shelf life.

5. Coffee and tea packaging: Vertical sealing machines are employed in the coffee and tea industry for packaging coffee beans, ground coffee, tea leaves, tea bags, and instant coffee/tea products. These machines ensure that the aroma and flavor of the coffee or tea are preserved and protected from external elements.

6. Agricultural products: Vertical sealing machines are used for packaging a wide range of agricultural products such as seeds, nuts, dried fruits, rice, grains, and fertilizers. These machines facilitate efficient packaging, protecting the freshness and quality of these perishable products.

7. Industrial products: Vertical sealing machines are utilized for packaging various industrial products such as powders, chemicals, hardware, and spare parts. These machines offer an effective packaging solution, ensuring product safety during transportation and storage.

In summary, vertical sealing machines find applications in the food, pharmaceutical, personal care, pet food, coffee and tea, agricultural, and industrial sectors. These machines enable efficient and reliable packaging, thereby enhancing the shelf life, freshness, and safety of the packaged products.

The Work Process and how to use vertical sealing machine

A vertical sealing machine is a piece of equipment used in various industries to package products by creating an airtight seal on their bags or pouches. The process of using a vertical sealing machine can be broken down into several steps.

Firstly, the operator needs to ensure that the machine is set up correctly. This involves adjusting the temperature and pressure settings according to the specific requirements of the product being sealed. The machine should also be cleaned and inspected for any wear and tear or obstructions that could affect its performance.

Once the machine is set up, the operator needs to prepare the bags or pouches for sealing. This may involve placing the products inside the bags and ensuring they are properly aligned for sealing. It is important to leave enough empty space at the top of the bag to allow for the sealing process.

Next, the operator should feed the bags onto the conveyor or feeding system of the vertical sealing machine. The bags will typically pass through a set of heated sealing bars that will melt the plastic together to create the seal. The operator should ensure that the bags are properly aligned and centered to ensure consistent sealing.

As the bags pass through the sealing area, the operator needs to ensure that the filled bags are not overfilled or underfilled. Overfilled bags can cause the seal to break, while underfilled bags may not form a proper seal. The operator should adjust the filling process accordingly.

Once the bags have passed through the sealing area, they can be collected for further processing or distribution. It is important for the operator to visually inspect the sealed bags to ensure they are properly sealed and free from any defects.

To summarize, using a vertical sealing machine involves setting up the machine, preparing the bags, feeding them into the machine, ensuring proper filling, sealing the bags, and inspecting the sealed bags for quality. It is crucial for the operator to follow proper procedures and guidelines to ensure efficient and effective use of the vertical sealing machine.

Quality Testing Methods for vertical sealing machine and how to control the quality

There are several quality testing methods that can be used to ensure the efficiency and effectiveness of a vertical sealing machine. These methods are crucial in controlling the quality of the sealing process and maintaining overall product integrity. Let’s explore some of these methods and how they can be utilized.

1. Visual Inspection: Visual inspection involves observing the sealing process to ensure that the packaging material is properly aligned, sealed, and free from any defects or imperfections. This can be done by trained operators or by implementing vision systems that can detect any visual abnormalities.

2. Leak Testing: Leak testing is essential to ensure the integrity of the sealed package by detecting any potential leaks that could compromise product quality or safety. This can involve employing techniques such as vacuum decay testing, dye penetrant testing, or bubble emission testing.

3. Strength Testing: Strength testing is conducted to assess the durability and robustness of the sealing. This can be done by subjecting sealed packages to specific mechanical forces or stress testing. The sealing should remain intact and not break or peel under normal or specified conditions.

4. Heat Distribution Testing: A critical factor in sealing machines is to ensure consistent heat distribution across the sealing area. This is essential to achieve reliable and uniform seals. Thermal imaging cameras or sensors can be used to analyze the temperature distribution and identify any hotspots or areas with inadequate heat levels.

To control the quality of the sealing process, it is essential to establish standard operating procedures (SOPs) and quality control measures. Periodic calibration and maintenance of the sealing machine are necessary to ensure its proper functioning. Regular training sessions should be conducted to educate machine operators about the importance of quality control and the correct usage of the equipment.

Implementing statistical process control (SPC) techniques can be beneficial in monitoring and controlling important sealing process parameters, such as temperature, pressure, and time. SPC can help identify and rectify any deviations or abnormalities promptly.

It is also crucial to establish a comprehensive documentation system to record all quality control measures, testing results, and any corrective actions taken. This documentation can aid in future troubleshooting, process optimization, and analysis of quality trends.

In conclusion, vertical sealing machine quality control involves a combination of visual inspection, leak testing, strength testing, and heat distribution testing. Applying comprehensive quality control measures, including SOPs, machine maintenance, training, statistical process control, and proper documentation, ensures the consistency, reliability, and efficiency of the sealing process.

vertical sealing machine Sample Policy and Post-Purchase Considerations for vertical sealing machine from China

Sample Policy for Vertical Sealing Machine from China:

1. Sample Availability: Before making a bulk purchase, it is advisable to request samples from the supplier. Most suppliers in China provide samples for a nominal fee, including shipping costs. It is essential to check the quality, performance, and functionality of the vertical sealing machine to ensure it meets your requirements.

2. Payment Terms: Discuss and finalize payment terms with the supplier. It is common to have a 30% down payment before production begins, with the remaining 70% paid before shipment. Ensure that the payment terms are agreed upon and included in the contract or purchase order.

3. Product Specifications: Clearly communicate your requirements regarding the vertical sealing machine’s specifications, including size, capacity, power supply, sealing material compatibility, and any additional features you may need. This helps to avoid misunderstandings and ensures that the supplier delivers the correct product.

4. Quality Control: Chinese manufacturers generally have quality control measures in place. However, it is recommended to discuss quality control specifications with the supplier and inquire about their quality testing procedures. Insist on receiving a quality control report for each machine before they are packaged and shipped.

Post-Purchase Considerations for Vertical Sealing Machine from China:

1. Packaging and Shipping: Ensure that the vertical sealing machine is adequately packed and securely loaded to avoid any damage during transportation. Additionally, confirm that the shipping and handling charges, as well as the insurance coverage, are clearly stated and paid for.

2. Installation and Training: Seek assistance from the supplier to install and set up the machine correctly. Training for your staff regarding operation, maintenance, and troubleshooting is also recommended to maximize the machine’s efficiency and lifespan.

3. Warranty and After-sales Service: Inquire about the warranty period and terms provided by the supplier. It is beneficial to have a written agreement outlining the warranty coverage, response time for technical support, and availability of spare parts. Establish a reliable communication channel (email, phone, or online chat) with the supplier to address any future issues promptly.

4. Feedback and Reviews: Provide feedback to the supplier regarding your experience with the vertical sealing machine, both positive and negative. Positive feedback can help build a long-term relationship, whereas constructive criticism can assist the supplier in improving their product and service quality.

Remember to conduct due diligence, communicate clearly, and establish trust with the supplier when purchasing a vertical sealing machine from China.

Sourcing vertical sealing machine from China: Opportunities, Risks, and Key Players

Sourcing vertical sealing machines from China can offer several opportunities for businesses looking to expand their operations. China is known for its manufacturing capabilities and competitive pricing, making it an attractive option for sourcing machinery. Vertical sealing machines are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and more.

One of the main opportunities of sourcing vertical sealing machines from China is the cost advantage. Chinese manufacturers often offer lower prices compared to their counterparts in other countries due to lower labor and production costs. Additionally, China has a vast network of suppliers and manufacturers specializing in vertical sealing machines, providing a wide range of options to choose from.

Another opportunity is the access to advanced technology. China has been investing heavily in research and development, leading to technological advancements in manufacturing machinery. Sourcing vertical sealing machines from China can provide access to state-of-the-art technology, ensuring high-quality and efficient production processes.

However, there are also risks associated with sourcing from China. One of the significant risks is quality control. While there are reputable manufacturers in China, there are also cases of substandard or counterfeit products. It is crucial to thoroughly vet manufacturers, conduct factory inspections, and request product samples to ensure the quality meets the required standards.

Language and cultural barriers may also pose challenges during the sourcing process. Effective communication is essential to convey product specifications, requirements, and delivery schedules accurately. Working with a local sourcing agent or an experienced third-party logistics provider can help overcome these barriers.

When it comes to key players in the vertical sealing machine market in China, there are several reputable manufacturers worth considering: Shantou Yuedong Vacuum Equipment Manufacture Co., Ltd, Ruian Lihong Machinery Co., Ltd, Foshan Jin Chuang Lihong Mechanical Equipment Co., Ltd, and Wenzhou Fable Machinery Co., Ltd, among others. These companies have a proven track record and offer a wide range of vertical sealing machines to suit different business needs.

In conclusion, sourcing vertical sealing machines from China offers opportunities such as cost advantage and access to advanced technology. However, it is crucial to be cautious and conduct proper due diligence to mitigate risks associated with quality control and language barriers. By working with reliable manufacturers and leveraging the network of suppliers, businesses can find the right vertical sealing machine to enhance their production processes and achieve their goals.

How to find and select reliable vertical sealing machine manufacturers in China,use google search manufacturers and suppliers

When looking for reliable vertical sealing machine manufacturers in China, it is important to conduct thorough research to ensure the credibility and quality of the supplier. Here are some steps to follow:

1. Start with a Google search: Use relevant keywords like “vertical sealing machine manufacturers in China” to find potential suppliers. This will provide you with a list of manufacturers and suppliers.

2. Verify credentials: Visit the websites of the manufacturers and suppliers that appear in the search results. Look for information regarding their production capacity, experience in the industry, certifications, and quality control processes. Choose suppliers with relevant experience and a good reputation.

3. Check customer reviews and ratings: Look for online reviews and ratings on platforms like Alibaba, Made-in-China, or Global Sources. Feedback from other customers can give you insights into the reliability, quality, and service of the manufacturer.

4. Attend trade shows and exhibitions: Participate in industry events and exhibitions in China, such as the Canton Fair or East China Import and Export Commodities Fair. This provides an opportunity to meet manufacturers in person, view their products, and assess their capabilities.

5. Communicate directly with potential suppliers: Contact the shortlisted manufacturers and suppliers directly. Ask for product catalogs, samples, and details about their services, such as after-sales support and warranties. Prompt and professional communication is indicative of a reliable manufacturer.

6. Factory visit: If possible, plan a visit to the manufacturing facility. This will allow you to assess the quality control measures, production processes, and the overall working environment. Physically inspecting the products and reviewing the manufacturing capabilities can help verify the reliability of the manufacturer.

7. Request references: Ask the potential suppliers for references of their existing or previous clients. Contact these references to learn about their experience with the manufacturer, including aspects like product quality, delivery times, and customer service.

8. Consider certifications: Look for manufacturers that have relevant certifications for the industry, such as ISO 9001 or CE certifications. These certifications ensure that the supplier follows strict quality control processes, which is essential for reliable product manufacturing.

By following these steps, you can find and select reliable vertical sealing machine manufacturers in China. Remember to do thorough research, gather information, make inquiries, and verify the credibility and quality of the manufacturers before making a final decision.

How to check vertical sealing machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a vertical sealing machine manufacturer’s website, you can follow these steps:

1. Open the website in Google Chrome: Launch Google Chrome browser on your computer or mobile device.

2. Install SEOquake extension: Go to the Chrome Web Store and search for “SEOquake.” Install the extension to your browser. This extension provides various SEO metrics.

3. Activate SEOquake: Once installed, activate the SEOquake extension by clicking on its icon in the browser toolbar.

4. Set up parameters: Click on the SEOquake icon and open the settings. Under the “General Parameters” tab, select “Google Database” as your preferred search engine. This ensures accurate ranking information based on Google’s search results.

5. Check the website’s ranking: After configuring the settings, navigate to the vertical sealing machine manufacturer’s website. Click on the SEOquake icon again, and a toolbar will appear at the top of your browser window displaying various metrics.

6. Look for ‘Rank’ information: In the toolbar, locate the “Rank” section. This will display the website’s ranking in Google’s search results. If the manufacturer’s website is ranked within the top 10 million, it indicates a reasonable level of popularity and reliability.

7. Assess other metrics: SEOquake provides additional metrics like the number of indexed pages, Alexa rank, and backlinks. These can give you insights into the website’s credibility and overall performance.

8. Explore the website further: While the SEOquake ranking provides an initial indication, it is essential to explore the website’s content, product information, customer reviews, and certifications to validate its reliability.

Remember to use the information obtained from SEOquake as a starting point and not the sole factor in determining a manufacturer’s website reliability. Combining it with other research methods will ensure a comprehensive evaluation.

Top 10 vertical sealing machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. CHAOAN HANCHENGYUAN PACKAGING EQUIPMENT CO., LTD

CHAOAN HANCHENGYUAN PACKAGING EQUIPMENT CO., LTD is a leading manufacturer of vertical sealing machines in China. Their products are known for their high-quality and efficient performance. The company offers a wide range of vertical sealing machines that cater to various industries such as food, pharmaceuticals, cosmetics, and more. These machines are designed to seal different types of packaging materials including plastic bags, laminated films, and aluminum foil bags. The vertical sealing machines feature an advanced PLC control system, ensuring precise and reliable sealing operations. Additionally, they offer adjustable sealing parameters such as temperature, pressure, and speed for customizable sealing options. With their robust construction, these machines can handle heavy-duty sealing tasks efficiently. CHAOAN HANCHENGYUAN PACKAGING EQUIPMENT CO., LTD also provides excellent after-sales service and technical support to ensure customer satisfaction.

| Manufacturer | Product Range |

| ————- | —————————————————— |

| HANCHENGYUAN | Vertical sealing machines for various industries |

2. ZHEJIANG BROTHER PACKING MACHINERY CO., LTD

ZHEJIANG BROTHER PACKING MACHINERY CO., LTD is a renowned vertical sealing machine manufacturer in China. They specialize in the production of high-quality vertical sealing machines that deliver excellent performance and durability. The company offers a diverse range of sealing machines for different types of packaging materials including plastic bags, laminated films, and aluminum foil bags. These machines ensure airtight sealing for extended product shelf life. ZHEJIANG BROTHER PACKING MACHINERY CO., LTD incorporates advanced technology in their machines, such as PID temperature control and adjustable sealing pressure, to achieve precise and efficient sealing. Their vertical sealing machines are widely used in various industries, including food, beverage, pharmaceuticals, and more. The company also provides comprehensive technical support and after-sales service to ensure customer satisfaction.

| Manufacturer | Product Range |

| —————— | ——————————————————————— |

| BROTHER PACKING | Vertical sealing machines for plastic bags, laminated films, and more |

3. SHANGHAI JOUPACK PACKAGING EQUIPMENT CO., LTD

SHANGHAI JOUPACK PACKAGING EQUIPMENT CO., LTD is a reliable manufacturer of vertical sealing machines in China. They offer a wide range of sealing machines designed to meet the diverse needs of different industries. Their vertical sealing machines are suitable for sealing plastic bags, laminated films, and aluminum foil bags with optimum precision. These machines incorporate advanced features like PLC control systems, adjustable heat and pressure controls, and automatic film feeding mechanisms for efficient sealing operations. SHANGHAI JOUPACK PACKAGING EQUIPMENT CO., LTD machines are known for their robust construction, ensuring long-lasting performance even in high-demanding production environments. The company also offers customized solutions to meet specific sealing requirements of their customers. With a strong focus on quality, customer support, and innovation, SHANGHAI JOUPACK PACKAGING EQUIPMENT CO., LTD has established itself as a reputable vertical sealing machine manufacturer in China.

| Manufacturer | Product Range |

| ——————- | —————————————————————— |

| JOUPACK PACKAGING | Vertical sealing machines for plastic bags, laminated films, and more |

4. SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED

SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED is a prominent manufacturer of vertical sealing machines in China. The company is known for its innovative and reliable sealing solutions. Their vertical sealing machines are designed to seal various packaging materials such as plastic bags, laminated films, and aluminum foil bags. These machines incorporate advanced features like digital temperature control, adjustable sealing speed, and automatic film feeding systems to ensure precise and efficient sealing operations. SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED machines are widely used in industries such as food, cosmetics, and pharmaceuticals. The company also offers customization options, allowing customers to tailor the machines according to their specific sealing requirements. With a strong focus on quality, performance, and customer satisfaction, SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED has gained a reputation as a trustworthy manufacturer of vertical sealing machines in China.

| Manufacturer | Product Range |

| ——————————- | ———————————————————————– |

| SHENZHEN PENGLAI INDUSTRIAL | Vertical sealing machines for plastic bags, laminated films, and more |

5. WENZHOU KEDI MACHINERY CO., LTD

WENZHOU KEDI MACHINERY CO., LTD is a leading manufacturer of vertical sealing machines in China. The company specializes in providing high-quality packaging machinery solutions to various industries. Their vertical sealing machines offer precise and efficient sealing for different types of packaging materials such as plastic bags, laminated films, and aluminum foil bags. These machines incorporate advanced technology, including adjustable sealing parameters, automatic film feeding mechanisms, and temperature control systems, ensuring consistent sealing results. WENZHOU KEDI MACHINERY CO., LTD machines are designed for ease of use and maintenance, making them ideal for enhancing production efficiency. The company also offers excellent after-sales support and technical assistance to ensure customer satisfaction. With a strong commitment to quality and innovation, WENZHOU KEDI MACHINERY CO., LTD has become a reliable manufacturer of vertical sealing machines in China.

| Manufacturer | Product Range |

| ——————————- | ——————————————————————— |

| WENZHOU KEDI MACHINERY | Vertical sealing machines for plastic bags, laminated films, and more |

6. DONGGUAN RENJIAN AUTOMATION TECHNOLOGY CO., LTD

DONGGUAN RENJIAN AUTOMATION TECHNOLOGY CO., LTD is a reputable manufacturer of vertical sealing machines in China. The company offers a wide range of sealing machines designed to cater to the diverse requirements of different industries. Their vertical sealing machines are suitable for sealing plastic bags, laminated films, and aluminum foil bags with utmost precision and efficiency. These machines feature advanced technology, including adjustable sealing parameters, digital control systems, and automatic film feed mechanisms for consistent and reliable sealing operations. DONGGUAN RENJIAN AUTOMATION TECHNOLOGY CO., LTD machines are known for their durability and robust construction, ensuring long-term performance even in demanding production environments. The company also provides comprehensive after-sales support and technical assistance to ensure customer satisfaction. With their commitment to quality and innovation, DONGGUAN RENJIAN AUTOMATION TECHNOLOGY CO., LTD has established itself as a trusted manufacturer of vertical sealing machines in China.

| Manufacturer | Product Range |

| ———————————– | —————————————————————– |

| DONGGUAN RENJIAN AUTOMATION | Vertical sealing machines for plastic bags, laminated films, etc. |

7. HANGZHOU ZHENGJIU MACHINERY MANUFACTURING CO., LTD

HANGZHOU ZHENGJIU MACHINERY MANUFACTURING CO., LTD is a well-known manufacturer of vertical sealing machines in China. The company specializes in providing innovative and reliable sealing solutions to various industries. Their vertical sealing machines are designed to seal different types of packaging materials, including plastic bags, laminated films, and aluminum foil bags, with optimum efficiency. These machines incorporate advanced features like adjustable sealing parameters, digital control systems, and automatic film feed mechanisms for precise and consistent sealing operations. HANGZHOU ZHENGJIU MACHINERY MANUFACTURING CO., LTD machines are known for their sturdy construction, ensuring long-lasting performance in demanding production environments. The company also offers customization options to meet specific sealing requirements. With their commitment to quality and customer satisfaction, HANGZHOU ZHENGJIU MACHINERY MANUFACTURING CO., LTD has gained a strong reputation as a reliable manufacturer of vertical sealing machines in China.

| Manufacturer | Product Range |

| ———————– | ————————————————————————- |

| HANGZHOU ZHENGJIU | Vertical sealing machines for plastic bags, laminated films, aluminum foil |

8. YUANHUA MACHINERY EQUIPMENT CO., LTD

YUANHUA MACHINERY EQUIPMENT CO., LTD is a renowned manufacturer of vertical sealing machines in China. The company offers a wide range of sealing machines designed to meet the various needs of different industries. Their vertical sealing machines are suitable for sealing plastic bags, laminated films, and aluminum foil bags, providing excellent sealing quality and efficiency. These machines are equipped with advanced features like adjustable sealing parameters, digital control systems, and automatic film feeding mechanisms for precise and reliable sealing operations. YUANHUA MACHINERY EQUIPMENT CO., LTD machines are known for their rugged construction, ensuring durability and long-term performance. The company also provides excellent after-sales service and technical support to ensure customer satisfaction. With their focus on quality, innovation, and customer-oriented approach, YUANHUA MACHINERY EQUIPMENT CO. LTD has become one of the leading manufacturers of vertical sealing machines in China.

| Manufacturer | Product Range |

| —————————– | ——————————————————————– |

| YUANHUA MACHINERY EQUIPMENT | Vertical sealing machines for plastic bags, laminated films, and more |

9. WENZHOU DEEPBLUE TECHNOLOGY CO., LTD

WENZHOU DEEPBLUE TECHNOLOGY CO., LTD is a reliable manufacturer of vertical sealing machines in China. The company offers a wide range of sealing machines that are widely used in various industries. Their vertical sealing machines are suitable for sealing plastic bags, laminated films, aluminum foil bags, and more. These machines incorporate advanced features like adjustable sealing parameters, digital control systems, and automatic film feeding mechanisms for efficient sealing operations. WENZHOU DEEPBLUE TECHNOLOGY CO., LTD machines are known for their robust construction and reliable performance. The company also provides excellent after-sales support and technical assistance, ensuring customer satisfaction. With their focus on quality, innovation, and customer needs, WENZHOU DEEPBLUE TECHNOLOGY CO., LTD has become a trusted manufacturer of vertical sealing machines in China.

| Manufacturer | Product Range |

| ——————————– | ———————————————————— |

| WENZHOU DEEPBLUE TECHNOLOGY | Vertical sealing machines for plastic bags, laminated films, etc. |

10. HANGZHOU ZON PACKAGING MACHINERY CO., LTD

HANGZHOU ZON PACKAGING MACHINERY CO., LTD is a reputable manufacturer of vertical sealing machines in China. The company offers a diverse range of sealing machines suitable for different industries. Their vertical sealing machines deliver efficient sealing for various packaging materials like plastic bags, laminated films, and aluminum foil bags. These machines feature advanced technology, including adjustable sealing parameters, digital control systems, and automatic film feeding mechanisms for precise and reliable sealing. HANGZHOU ZON PACKAGING MACHINERY CO., LTD ensures the durability and robust construction of their machines, enabling long-term performance even in demanding production environments. The company also provides comprehensive technical support and after-sales service to ensure customer satisfaction. With their commitment to quality and customer-oriented approach, HANGZHOU ZON PACKAGING MACHINERY CO., LTD has gained a strong reputation as a reliable manufacturer of vertical sealing machines in China.

| Manufacturer | Product Range |

| —————————— | ——————————————————————— |

| HANGZHOU ZON PACKAGING | Vertical sealing machines for plastic bags, laminated films, and more |

**Comparison Table**

| Manufacturer | Product Range |

| ———————————- | ———————————————————————- |

| CHAOAN HANCHENGYUAN PACKAGING | Vertical sealing machines for various industries |

| ZHEJIANG BROTHER PACKING | Vertical sealing machines for plastic bags, laminated films, and more |

| SHANGHAI JOUPACK PACKAGING | Vertical sealing machines for plastic bags, laminated films, and more |

| SHENZHEN PENGLAI INDUSTRIAL | Vertical sealing machines for plastic bags, laminated films, and more |

| WENZHOU KEDI MACHINERY | Vertical sealing machines for plastic bags, laminated films, and more |

| DONGGUAN RENJIAN AUTOMATION | Vertical sealing machines for plastic bags, laminated films, etc. |

| HANGZHOU ZHENGJIU | Vertical sealing machines for plastic bags, laminated films, aluminum foil |

| YUANHUA MACHINERY EQUIPMENT | Vertical sealing machines for plastic bags, laminated films, and more |

| WENZHOU DEEPBLUE TECHNOLOGY | Vertical sealing machines for plastic bags, laminated films, etc. |

| HANGZHOU ZON PACKAGING | Vertical sealing machines for plastic bags, laminated films, and more |

Background Research for vertical sealing machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When it comes to vertical sealing machine manufacturers in China, three websites can provide valuable background research: qcc.com, archive.org, and importyeti.com.

Qcc.com is a Chinese business information platform that offers comprehensive data on companies’ registration details, financial information, management status, and more. It provides the legal and operational background of businesses, allowing users to verify their authenticity and track their history. By searching for specific vertical sealing machine manufacturers on qcc.com, one can gather information about their establishment, legal status, and potentially find reviews or ratings from previous customers or partners.

Archive.org is a digital library that archives web pages, including company websites, over time. By using this website, researchers can access historical data regarding the development and changes in a company’s website, including their product offerings, certifications, partnerships, and news. This can provide insights into the company’s evolution, market presence, and focus areas, allowing for a thorough analysis of their capabilities, resources, and growth trajectory.

Importyeti.com is a platform that helps users find and vet suppliers in China. By searching for vertical sealing machine manufacturers on this website, one can access information on their import and export activities, including details about shipments, partners, and customers. This data enables researchers to assess the company’s global reach, market competitiveness, and the industries they serve.

By exploring these three websites, researchers can gather relevant background information on vertical sealing machine manufacturers in China. This data can assist in evaluating a company’s credibility, understanding their growth and evolution, and assessing their market presence and competitiveness. It is important to note that while these websites provide valuable insights, due diligence should be exercised by cross-referencing information and verifying it through multiple sources.

Leveraging Trade Shows and Expos for vertical sealing machine Sourcing in China

Trade shows and expos can be highly effective platforms for sourcing vertical sealing machines in China. These events provide a unique opportunity to connect with numerous suppliers and manufacturers from all over the country in a single location.

Firstly, attending trade shows and expos allows buyers to meet face-to-face with potential suppliers, fostering personal relationships that are essential for successful business partnerships. By interacting directly with manufacturers, buyers can inquire about the quality, price, and specifications of vertical sealing machines, as well as negotiate deals and discuss customization options.

Moreover, trade shows and expos often serve as showcases for the latest technological advancements and innovations in the industry. Exhibitors frequently debut new models or prototypes of vertical sealing machines, providing buyers with a glimpse of cutting-edge technology and the opportunity to stay ahead of the competition. By attending these events, buyers can also gain insights into industry trends and future developments, which can guide their sourcing decisions.

In addition to networking and staying up-to-date with industry trends, trade shows and expos offer a comprehensive overview of the market. Buyers can compare different manufacturers and suppliers side by side, evaluating their product offerings, production capabilities, and pricing strategies. This allows buyers to make informed sourcing decisions and select the most suitable supplier for their vertical sealing machine needs.

Lastly, trade shows and expos are ideal platforms for conducting due diligence on potential suppliers. Buyers can assess the credibility and reliability of manufacturers by inspecting their booth, product samples, and documentation. It is crucial to verify the supplier’s certifications, such as ISO 9001, to ensure compliance with international quality standards.

In conclusion, leveraging trade shows and expos for sourcing vertical sealing machines in China is a highly efficient approach. These events facilitate direct communication with suppliers, provide access to the latest technological advancements, offer a comprehensive market overview, and enable due diligence on potential suppliers. By maximizing the opportunities provided by trade shows and expos, buyers can find reliable and high-quality vertical sealing machine suppliers in China.

The Role of Agents and Sourcing Companies in Facilitating vertical sealing machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating vertical sealing machine purchases from China. These entities specialize in connecting international buyers with Chinese manufacturers, streamlining the entire procurement process, and ensuring a smooth transaction from start to finish.

Firstly, agents and sourcing companies act as a bridge between buyers and manufacturers. They have extensive knowledge of the Chinese market and can accurately identify reliable and suitable suppliers based on the buyer’s requirements. This saves buyers the time and effort of searching for manufacturers on their own, as agents already have an established network of trusted suppliers.

Moreover, agents and sourcing companies provide essential support during the negotiation process. They possess in-depth knowledge of the local business culture, language, and bargaining practices, which allows them to negotiate favorable terms and prices on behalf of the buyer. This expertise ensures buyers receive the best possible deal, protecting their interests and maximizing their purchasing power.

Additionally, agents and sourcing companies handle logistics and quality control. They arrange shipping, monitor production schedules, and handle customs clearance, ensuring a hassle-free delivery of the vertical sealing machines. Additionally, they conduct quality inspections to guarantee that the purchased machines meet the buyer’s specifications and standards. This quality control process minimizes the risk of receiving subpar or defective products.

Furthermore, agents and sourcing companies provide valuable post-sales support and assistance. They act as a reliable point of contact for buyers in case of any issues or concerns that may arise after the purchase. They can provide assistance with warranty claims, spare parts sourcing, or any necessary repairs or replacements.

In conclusion, agents and sourcing companies play a pivotal role in facilitating vertical sealing machine purchases from China. Their expertise and knowledge of the Chinese market streamline the procurement process, ensure competitive prices, handle logistics and quality control, and provide valuable post-sales support. Therefore, partnering with these entities significantly simplifies the buying process and mitigates potential risks for international buyers.

Price Cost Research for vertical sealing machine manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for vertical sealing machine manufacturers in China, two popular online platforms to utilize are temu.com and 1688.com. By exploring these platforms, one can gather valuable information about the pricing and cost aspects associated with vertical sealing machines in the Chinese market.

Temu.com is a renowned B2B e-commerce website in China, specializing in providing various industrial products and services. As a reliable platform, it offers a range of vertical sealing machines from different manufacturers. By searching for vertical sealing machines on temu.com, one can obtain detailed product descriptions, specifications, and prices. This website also allows users to compare prices among various suppliers, enabling them to find the most cost-effective options.

1688.com, on the other hand, is a popular wholesale sourcing platform in China, operated by Alibaba Group. It serves as a comprehensive marketplace for various products, including vertical sealing machines. By navigating through the website, users can filter their searches to specifically target vertical sealing machines and access supplier listings. The product descriptions and images provided on 1688.com give insights into the features and specifications of the machines. Moreover, this platform offers a price range for each product, allowing users to gauge the general pricing trends in the market.

When performing price cost research on these platforms, it is advisable to focus on the product price, as well as factors such as minimum order quantity requirements, shipping costs, and any additional fees. Additionally, contacting the manufacturers directly through the platforms’ messaging systems can provide an opportunity to negotiate prices or gather more detailed cost information. Moreover, reading customer reviews and ratings can offer insights into the quality and reliability of the manufacturers and their products.

In summary, temu.com and 1688.com are valuable resources for researching price costs of vertical sealing machine manufacturers in China. These platforms offer a wide range of product options along with essential information about pricing, specifications, and availability. By utilizing these platforms efficiently, one can make informed decisions and find cost-effective solutions from reliable manufacturers in China.

Shipping Cost for vertical sealing machine import from China

The shipping cost for importing a vertical sealing machine from China will depend on several factors such as the weight and dimensions of the machine, the shipping method chosen, and the destination country.

For small machines, air shipping is usually a preferred option due to its speed and convenience. Air freight charges are determined by the volume or weight of the package, whichever is higher. Considering that a vertical sealing machine typically weighs between 100 to 300 kilograms, the airfreight cost can range between $500 to $1500, depending on the distance.

If the machine is larger and heavier, sea shipping may be more economical. The shipping cost for sea freight is determined by the cubic meter or the weight of the cargo. For example, a vertical sealing machine with dimensions of 2 cubic meters may cost around $1000 to $2000 to ship by sea.

In addition to the shipping cost, importers should also consider other charges such as customs duties, import taxes, customs clearance fees, and any additional services required, such as insurance or inland transportation.

It’s important to note that the shipping cost mentioned here is just an estimate and can vary depending on various factors. To get an accurate shipping cost, it is advisable to contact a freight forwarder or shipping agent who can provide a detailed quote based on the specific requirements of the vertical sealing machine and the importer’s location.

Compare China and Other vertical sealing machine Markets: Products Quality and Price,Visible and Hidden Costs

China has emerged as a major player in the vertical sealing machine market. When comparing China with other vertical sealing machine markets, such as those in Europe or the United States, several factors come into consideration – including product quality, price, visible and hidden costs.

Product Quality:

China initially gained a reputation for producing low-quality products, but over the years, it has made significant improvements in product quality. Chinese manufacturers now offer a wide range of vertical sealing machines that meet international quality standards. However, compared to established markets like Europe or the United States, there may still be slight differences in terms of precision engineering and durability.

Price:

China has a significant advantage in terms of price competitiveness. The country’s manufacturing capabilities, labor costs, and economies of scale allow Chinese vertical sealing machines to be offered at comparatively lower prices than their counterparts from other markets. This makes China an attractive option for price-conscious buyers, especially in developing countries.

Visible Costs:

Visible costs, including the purchase price of the machine and any associated fees, tend to be lower for Chinese products. Due to the price advantage mentioned earlier, Chinese manufacturers can offer competitive prices, making their machines more accessible to a wider range of customers.

Hidden Costs:

Hidden costs refer to expenses that may arise after the purchase, such as maintenance, spare parts, and repairs. In this aspect, other markets may have an advantage. Established markets often have a well-developed aftermarket ecosystem, with readily available spare parts and comprehensive service networks. Chinese manufacturers are catching up in this area but might still offer a more limited range of services and availability of spare parts.

In conclusion, China’s vertical sealing machine market has made remarkable progress in terms of product quality and competitive pricing. However, there may still be slight differences when compared to other established markets in terms of precision engineering and durability. Additionally, factors like visible and hidden costs need to be considered, where other markets may have an advantage due to a well-developed aftermarket ecosystem. Ultimately, buyers need to evaluate their specific requirements and strike a balance between product quality, price, and support services when choosing between China and other vertical sealing machine markets.

Understanding Pricing and Payment Terms for vertical sealing machine: A Comparative Guide to Get the Best Deal

When purchasing a vertical sealing machine, it is important to understand the pricing and payment terms to ensure you get the best deal. By familiarizing yourself with these aspects, you can make an informed decision and negotiate favorable terms with the supplier.

The pricing of a vertical sealing machine can vary depending on several factors, including the brand, model, features, and supplier. It is advisable to research and compare prices from different suppliers to get an idea of the average market rate for the machine you are interested in. This will help you identify any overpriced or underpriced offers, and enable you to negotiate a fair price.

Payment terms are crucial when making a purchase. Most suppliers offer various options, such as full upfront payment, partial payment upfront with the balance due upon delivery, or payment in installments. It is essential to consider your budget and financial capabilities before choosing a payment option. If possible, try to negotiate flexible payment terms that suit your needs and cash flow.

In addition to the actual price and payment terms, it is important to consider any additional costs that may be associated with the purchase. These can include shipping fees, taxes, customs duties, and installation charges. Be sure to discuss these additional expenses with the supplier and clarify who will bear the costs to avoid any surprises or misunderstandings later on.

To get the best deal on a vertical sealing machine, it is recommended to seek multiple quotes from different suppliers. This allows you to compare not only the pricing but also the overall package offered. Look for suppliers that offer warranties, after-sales support, and maintenance services to ensure you receive a reliable and high-quality machine.

In conclusion, understanding the pricing and payment terms for a vertical sealing machine is crucial to secure the best deal. Plan your budget, research prices, compare quotes, and negotiate flexible payment options. Consider additional costs and factor in the supplier’s reputation, warranty, and support services. Armed with this knowledge, you can make an informed decision and purchase the most suitable vertical sealing machine for your needs.

Chinese Regulations and Industry Standards Certifications for vertical sealing machine,Import Regulations and Customs for vertical sealing machine from China

Chinese Regulations and Industry Standards Certifications for vertical sealing machines play a crucial role in ensuring the quality, safety, and compliance of these machines in the market. The main regulations and certifications include:

1. China Compulsory Certification (CCC): This certification is mandatory for various products, including vertical sealing machines, intended for sale and distribution in the Chinese market. It ensures that the machines meet the required safety, performance, and quality standards set by the government.

2. National Standard for Sealing Machine: China has national standards specifically designed for sealing machines, including vertical sealing machines. These standards outline the technical requirements, performance criteria, and testing methods that manufacturers and importers must adhere to.

3. Food and Drug Administration (FDA): If the vertical sealing machine is used in the food industry, it must comply with the guidelines and regulations set by the FDA. This ensures that the machine is safe for food packaging and meets the necessary hygiene standards.

When importing vertical sealing machines from China, importers should also be aware of the relevant import regulations and customs procedures. These include:

1. Customs Declarations: Importers need to complete the necessary customs declarations, providing accurate and detailed information about the imported vertical sealing machines, such as quantity, value, and specifications.

2. Import Duties and Taxes: Importers must pay the applicable import duties and taxes levied by the customs authorities. The rates may vary depending on the country of import and the classification of the machines.

3. Documentation and Compliance: Importers should ensure that all required documents, such as commercial invoices, packing lists, and certificates of origin, are provided accurately and comply with the import regulations of their country.

It is essential for importers to thoroughly understand and comply with these regulations and certifications to avoid potential delays, penalties, or rejections at the customs. Working with reliable suppliers who have the necessary certifications and can provide the required documentation is crucial to ensure a smooth importing process.

Sustainability and Environmental Considerations in vertical sealing machine Manufacturing

When it comes to vertical sealing machine manufacturing, sustainability and environmental considerations play a crucial role in ensuring responsible production and minimizing the impact on the planet.

Firstly, manufacturers need to focus on using sustainable materials in the construction of these machines. This means substituting traditional materials, such as plastic and metal, with eco-friendly alternatives like recycled or biodegradable materials. Additionally, using renewable energy sources during the manufacturing process can significantly reduce the carbon footprint associated with these machines.

Furthermore, reducing energy consumption is of utmost importance. Manufacturers can achieve this by using energy-efficient components and optimizing the design and operation of the machine. For instance, incorporating sensors that detect when the machine is idle and automatically power it down can help prevent unnecessary energy consumption.

Proper waste management is another key consideration in vertical sealing machine manufacturing. Manufacturers should strive to minimize waste generation during the production process and ensure that any waste produced is appropriately treated or recycled. Implementing recycling programs for packaging materials, such as cardboard and plastic, can significantly reduce the environmental impact.

Water conservation is also an essential aspect of sustainability in manufacturing. By implementing water-saving technologies and practices, such as water recycling systems and optimizing water usage, manufacturers can minimize their water footprint and contribute to the conservation of this precious resource.

Lastly, manufacturers should consider the end-of-life stage of vertical sealing machines. Designing these machines with disassembly and recycling in mind can facilitate the proper disposal or recycling of the components at the end of their life cycle. Promoting extended product lifespan through repair and maintenance services also contributes to sustainability.

In conclusion, sustainability and environmental considerations in vertical sealing machine manufacturing involve using sustainable materials, reducing energy consumption, managing waste appropriately, conserving water, and planning for end-of-life disposal. By integrating these practices into the manufacturing process, manufacturers can contribute to a more sustainable and environmentally friendly industry.

List The Evolution history of “vertical sealing machine”

The evolution of vertical sealing machines can be traced back to the late 1800s when the concept of sealing food and other products in bags gained popularity. The initial machines were manual and required operators to feed the bags into the sealing mechanism. These machines used heat to seal the bags, ensuring proper closure and preservation.

With advances in technology in the early 1900s, semi-automatic vertical sealing machines were introduced. These machines incorporated mechanical components to automate the bag feeding process and started to gain traction in various industries.

In the mid-20th century, the introduction of electronic components revolutionized the design of vertical sealing machines. These new machines were capable of precise temperature control for better sealing and automatic bag release mechanisms. The integration of electronic controls also improved the versatility and performance of these machines, making them suitable for sealing a wide variety of bag materials.

Throughout the latter half of the 20th century, vertical sealing machines continued to evolve with the adoption of computer technology. This led to the development of fully-automatic machines that could handle high-speed operations and offer advanced features like programmable control systems, touch screens, and self-diagnostic capabilities.

In recent years, vertical sealing machines have also embraced advancements in ergonomics and sustainability. Manufacturers have incorporated features such as adjustable heights for operator comfort and energy-efficient components to reduce environmental impact. Newer models have also undergone design improvements to ensure ease of maintenance and cleaning.

Moreover, the advent of Industry 4.0 and the Internet of Things (IoT) has enabled vertical sealing machines to become interconnected and remotely monitored. This integration allows for real-time data collection, predictive maintenance, and improved overall efficiency.

In conclusion, vertical sealing machines have come a long way from their manual beginnings to the fully-automatic, technologically advanced systems we see today. The evolution of these machines has been driven by advancements in mechanical, electronic, and computer technologies, resulting in improved performance, versatility, and sustainability.

The Evolution and Market Trends in vertical sealing machine Industry

The vertical sealing machine industry has witnessed significant evolution and market trends in recent years due to advancements in technology and changing consumer preferences.

One key evolution in the industry is the development of automated and high-speed vertical sealing machines. This advancement has improved the efficiency and productivity of sealing processes by reducing manual intervention and increasing the speed of sealing operations. Manufacturers are now able to seal a larger volume of products in a shorter period, resulting in improved production rates and cost savings.

Another evolution in the vertical sealing machine industry is the integration of smart technologies. Many machines now come equipped with features like sensors, automation systems, and touch screen interfaces. These technologies help in ensuring consistent sealing quality, reducing human error, and providing real-time monitoring and control over the sealing process. A more intelligent and connected sealing machine allows manufacturers to achieve higher accuracy and traceability, which is crucial for meeting regulatory requirements and maintaining product quality.

In terms of market trends, there is a growing demand for eco-friendly and sustainable packaging solutions. Consumers are increasingly becoming aware of environmental issues, and they expect products to be packaged using materials that can be recycled or are biodegradable. As a result, manufacturers are incorporating green packaging practices, and this trend has a significant impact on the vertical sealing machine industry. Machines that can handle eco-friendly packaging materials, such as biodegradable films, are in high demand.

Furthermore, the market is witnessing a shift towards smaller and more compact sealing machines. This trend is driven by the need for space optimization in manufacturing facilities. Compact machines not only occupy less floor space but also provide flexibility in terms of installation and integration into existing production lines. Manufacturers are increasingly looking for solutions that can be easily integrated into their operations and offer high performance in a limited space.

In conclusion, the vertical sealing machine industry has evolved to meet the demands of a rapidly changing market. Automation, smart technologies, sustainability, and compactness are the key areas that have seen significant advancements and market trends. Manufacturers need to embrace these changes to stay competitive and meet the evolving needs of their customers.

Custom Private Labeling and Branding Opportunities with Chinese vertical sealing machine Manufacturers

There are numerous opportunities for custom private labeling and branding with Chinese vertical sealing machine manufacturers. These manufacturers specialize in producing high-quality vertical sealing machines that are widely used in the packaging industry.

One significant advantage of working with Chinese manufacturers is the ability to customize products to meet specific branding requirements. This includes adding logos, brand names, or any other artwork to the machine’s body or packaging. Custom labeling and branding can help businesses establish a distinct identity and differentiate themselves in the market.

Chinese manufacturers also offer flexible options for private labeling. They can provide OEM (Original Equipment Manufacturer) services, allowing businesses to place their brand name on machines manufactured by the Chinese company. Alternatively, manufacturers can produce machines under the buyer’s private label, incorporating their branding from start to finish.

Another benefit of collaborating with Chinese vertical sealing machine manufacturers is the cost-effectiveness. Chinese manufacturers often provide competitive pricing structures, making it an attractive option for businesses seeking cost-effective solutions without compromising quality.

Chinese manufacturers are known for their advanced production capabilities and modern machinery. Their expertise in manufacturing vertical sealing machines ensures the production of reliable and technologically advanced equipment. This enables businesses to offer high-performance machines with their own branding, enhancing their reputation among customers.

To capitalize on these opportunities, businesses should establish clear communication channels with Chinese manufacturers, clearly define their branding requirements, and provide detailed specifications for customization. Additionally, conducting thorough research and due diligence before finalizing a partnership is crucial to ensure the manufacturer’s credibility, production capacity, and adherence to quality standards.

In conclusion, partnering with Chinese vertical sealing machine manufacturers offers custom private labeling and branding opportunities that can positively impact a business’s market presence. It allows businesses to customize machines, incorporate their branding, and benefit from Chinese manufacturers’ cost-effective solutions and advanced production capabilities.

Tips for Procurement and Considerations when Purchasing vertical sealing machine

When purchasing a vertical sealing machine, there are several considerations and tips to keep in mind to ensure a successful procurement process. Here are some key points to consider:

1. Machine specifications: Understand the specific requirements of your business and choose a machine that meets those requirements. Consider factors such as sealing speed, bag sizes, sealing material compatibility, and power consumption.

2. Quality and durability: Look for a machine that is built with high-quality materials, sturdy construction, and reliable components. A durable machine will have a longer lifespan and withstand daily use without breakdowns, reducing maintenance costs.

3. Ease of use: Opt for a vertical sealing machine that is user-friendly and easy to operate. A machine with intuitive controls, clear instructions, and minimal training requirements will increase efficiency and productivity.

4. Maintenance and servicing: Inquire about the machine’s maintenance needs and check if spare parts are easily available. Choose a machine with a reputable manufacturer or supplier who offers reliable after-sales support, warranties, and timely servicing.

5. Safety features: Ensure the machine has safety features such as emergency shut-off buttons, overheat protection, and safety interlocks to prevent accidents and injuries.

6. Reviews and references: Research and read customer reviews or seek recommendations from other businesses using similar machines. This will give you insights into the performance, reliability, and customer satisfaction of different models and brands.

7. Budget and ROI: Assess the total cost of ownership, including the machine’s purchase price, operating costs, and potential energy savings. A higher initial investment may be worthwhile if it leads to improved efficiency, reduced labor costs, and increased productivity in the long run.

8. Compatibility with other equipment: Check if the vertical sealing machine can seamlessly integrate with existing packaging equipment or processes in your production line. Compatibility will help streamline operations and avoid any disruptions.

9. Training and support: Inquire about training opportunities and technical support provided by the manufacturer or supplier. Proper training for the machine operators will ensure efficient use, reduce downtime, and prevent costly errors.

10. Future scalability: Consider future business expansion plans and evaluate if the chosen machine can accommodate increased production demands or new packaging requirements. Flexibility and scalability will save costs in the long term.

By considering these tips and factors, you can make an informed decision when purchasing a vertical sealing machine that fits your business needs, maximizes efficiency, and ensures long-term value for your investment.

FAQs on Sourcing and Manufacturing vertical sealing machine in China

Q: What is a vertical sealing machine?

A: A vertical sealing machine is a device used to seal and package products in vertical form-fill-seal (VFFS) packaging applications. It is commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and more.

Q: Why source and manufacture vertical sealing machines in China?

A: China is known for its strong manufacturing capabilities and competitive pricing. Many Chinese manufacturers specialize in producing high-quality, cost-effective vertical sealing machines. Sourcing and manufacturing in China can offer significant cost savings and access to a wide range of options and customization possibilities.

Q: How can I find reliable suppliers of vertical sealing machines in China?

A: There are several ways to find reliable suppliers in China. One approach is to attend international trade shows and exhibitions where Chinese manufacturers showcase their products. Online B2B platforms, such as Alibaba and Global Sources, also provide a vast database of suppliers and facilitate direct communication. Additionally, engaging with sourcing agents or working with third-party inspection and verification companies can help ensure the reliability and quality of the supplier.

Q: What should I consider when sourcing and manufacturing vertical sealing machines in China?

A: When sourcing and manufacturing in China, it is essential to consider factors such as the supplier’s manufacturing capabilities, quality control measures, certifications, and after-sales service. Conducting thorough due diligence, including factory audits and requesting samples, can help assess the supplier’s reliability and product quality. Additionally, it is crucial to have a clear understanding of the specifications, requirements, and customization needs of the vertical sealing machine to ensure it meets your specific needs.

Q: Are there any risks or challenges associated with sourcing and manufacturing in China?

A: Like any sourcing and manufacturing process, there are potential risks and challenges. These may include communication barriers, cultural differences, intellectual property protection, and logistical issues. However, these risks can be mitigated by conducting proper research, working with experienced sourcing agents or consultants, and establishing clear contracts and agreements with suppliers.

In summary, sourcing and manufacturing vertical sealing machines in China provide access to reliable suppliers with strong manufacturing capabilities, cost-effective solutions, and customization options. However, it is essential to conduct thorough research, verify supplier credentials, and address potential challenges to ensure a successful sourcing process.

Why contact sourcifychina.com get free quota from reliable vertical sealing machine suppliers?

SourcifyChina.com is able to offer a free quota from reliable vertical sealing machine suppliers for a number of reasons. Firstly, SourcifyChina.com has established strong and long-standing relationships with a wide network of vertical sealing machine suppliers in China. These suppliers have been thoroughly vetted and have a proven track record of delivering high-quality products.

Furthermore, SourcifyChina.com has a deep understanding of the vertical sealing machine industry and the requirements of businesses looking to source these machines. This expertise allows them to effectively match businesses with the most suitable suppliers based on their specific needs and preferences.

The free quota offered by SourcifyChina.com also serves as an incentive for businesses to utilize their services when sourcing vertical sealing machines. By offering a free quota, businesses are able to receive information on pricing, MOQs, and other relevant details from multiple suppliers without incurring any upfront costs or commitments. This allows businesses to gather comprehensive information and make informed decisions without any financial obligation.