Benefits of Water Cooled TIG Welder

A water-cooled TIG welder provides several advantages over a traditional air-cooled unit. Firstly, the water-cooling system will extend the lifespan of the welder. The water-cooled TIG welder has a mechanism that circulates water throughout the machine to keep it cool. This lowers the risk of the welder overheating, which can lead to damage and costly repairs.

The water cooling also provides a more consistent weld. TIG welding produces intense heat that requires precise control. When the machine overheats, this can cause fluctuations in the arc, making it difficult to maintain a consistent weld. Water-cooled TIG welders prevent this issue, providing a stable welding environment.

Another advantage of water-cooled TIG welders is the ability to work for longer periods of time. With an air-cooled machine, the operator must often stop work to let the machine cool down. Water-cooled units can run for longer periods without stopping production. This makes them perfect for industrial applications that require consistent output.

Water-cooled TIG welders are also more efficient. The water cooling system reduces the amount of power required to maintain the welder’s internal temperature, which reduces the amount of energy used. This means that the machine will have a reduced operating cost and a lower impact on the environment.

Finally, water-cooled TIG welders are quieter than air-cooled machines. The water cooling system works more efficiently than a fan, leading to fewer vibrations and less noise. This can make a significant difference in the workplace, making for a more pleasant environment for welders and others in the area.

In conclusion, water-cooled TIG welders offer several advantages over air-cooled units. They offer a longer lifespan, more consistent welds, longer working periods, improved efficiency, and a quieter operation. These benefits make the water-cooled TIG welder an excellent choice for anyone looking for a reliable, efficient, and effective piece of welding equipment.

Features of Water Cooled TIG Welder

A water-cooled TIG welder is a powerful and versatile machine used for various welding applications. The primary benefit of a water-cooled TIG welder is that it can prevent the welder from overheating and extend the welding time, making this welding technique suitable for heavy-duty industrial applications.

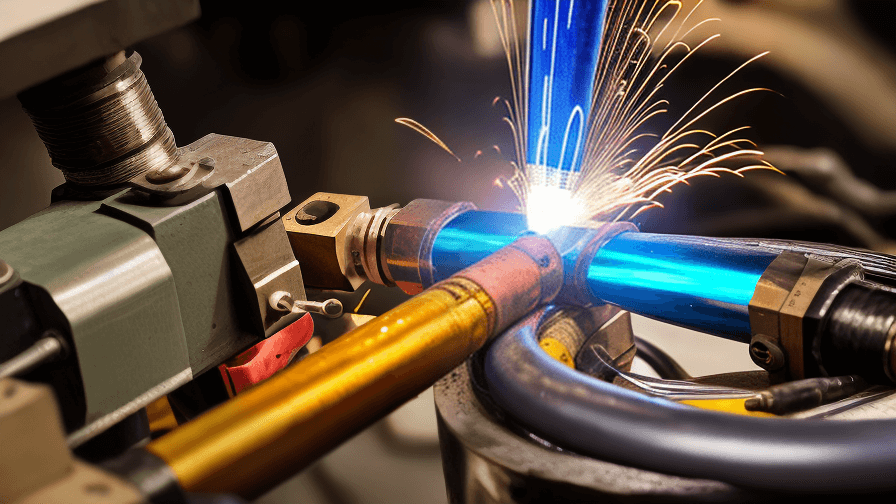

The key feature of a water-cooled TIG welder is the cooling system that allows the machine to operate efficiently and continuously without overheating. This type of welder allows operators to carry out extensive welding functions for extended periods, thus making it a preferred choice for welding operations in industries such as automotive, aerospace, and marine applications.

Another feature of a water-cooled TIG welder is the ability to weld metals like aluminum and stainless steel with consistent and precise quality. The welder uses a tungsten electrode to create a molten pool, and the cooling system helps to regulate the heat, which ensures that there is no warping or distortion in the metal.

Additionally, a water-cooled TIG welder has a more substantial output, and it can weld thicker metals. The welder can provide a current of up to 500 amps, allowing operators to weld metals with thicknesses of up to ½ inches. This provides versatility to welders to carry out different welding applications.

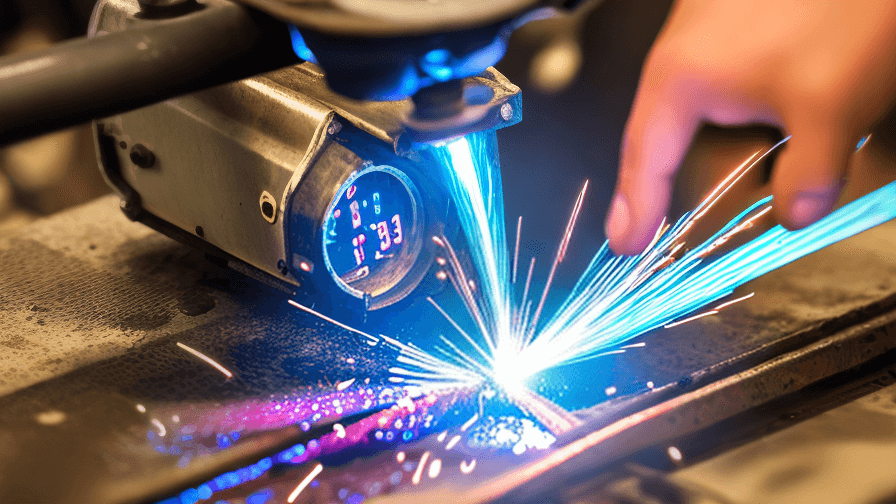

Lastly, a water-cooled TIG welder is easy to set up and operate, with its intuitive displays and simple control panel. This makes it ideal for welders, even those who are not experienced in using the machine. This feature, combined with the faster cooling times of water-cooled machines, makes them more efficient and saves time.

In conclusion, a water-cooled TIG welder is an efficient and versatile welding tool that is used in various industries. Its cooling system, precision, and power output make it a preferred tool for welding operations where quality and consistency are essential. With the ability to weld thicker metals and its intuitive control system, welders can carry out diverse applications while achieving consistent high-quality results.

Various Types of Water Cooled TIG Welder

The water-cooled TIG welding machine is a popular choice for welders in various industries. Welders use water-cooled TIG machines for welding stainless steel, aluminum, and other exotic metals. There are various types of water-cooled TIG welders.

The first type of water-cooled TIG welder is the inverter-based machine. This type is more energy-efficient than the transformer type because it combines a transformer with an inverter to increase the welding capacity of the machine. The machine is portable, and its cooling system uses a coolant flow, which circulates around the welding torch.

The second type of water-cooled TIG welder is air-cooled. This type uses an air-cooled torch that uses gas for cooling, rather than water. This type of machine is useful for light welding tasks where there is no need for heavy-duty welding.

The third type of water-cooled TIG welder is the transformer-based machine. This machine uses a transformer to connect the electrode to the material being welded. The machine is ideal for heavy-duty welding tasks, as it provides a constant supply of power, allowing for deeper penetration into the metal being welded.

The fourth type of water-cooled TIG welder is the AC/DC machine. This machine is useful for welding both aluminum and stainless steel metals. The machine is versatile and provides a constant supply of AC and DC power to aid in the welding process, thereby ensuring that the welder achieves a consistent welding depth.

Finally, the fifth type of water-cooled TIG welder is the hybrid machine. This machine combines the features of the inverter-based and transformer-based machines to provide more power and control to the welder.

In conclusion, there are various types of water-cooled TIG welders available in the market. If you are in the market for a water-cooled TIG welding machine, you should look out for the type that will meet your welding needs.

Applications of Water Cooled TIG Welder

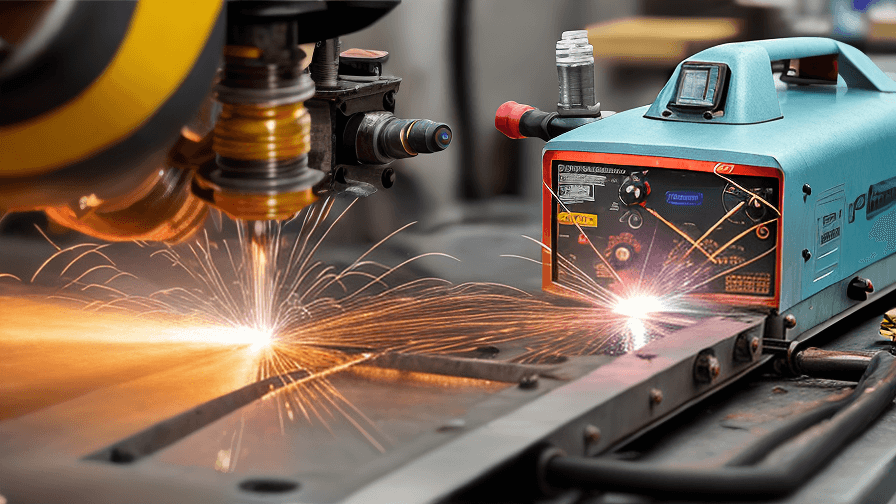

A water-cooled TIG welder is a type of welding equipment that uses water as a cooling agent to reduce the heat generated during the welding process. This type of welding system is widely used in various industries due to its numerous advantages over traditional welding techniques.

One of the primary applications of water-cooled TIG welder is in the aerospace industry. This type of welding system is used for welding various complex parts in aircraft, such as fuel tanks, landing gear, and fuselage components. The water-cooled TIG welding system allows welders to produce high-quality welds with minimal distortion, making it ideal for welding critical components in aircraft.

Another application of water-cooled TIG welder is in the automotive industry. This type of welding system is used for welding complex components in vehicles, such as engine blocks, transmissions, and exhaust system parts. Water-cooling the TIG welder also allows for extended welding times, which is essential in the case of welding larger components.

The construction industry also benefits greatly from water-cooled TIG welders. They are used for welding various components in buildings, such as aluminum window frames, steel beams, and HVAC systems. The water-cooled TIG welding system allows for precise welding control, producing high-quality welds that can withstand the harsh outdoor environment.

Lastly, the manufacturing industry also utilizes water-cooled TIG welders. This type of welding system is used for welding various components in manufacturing plants, such as piping systems, tanks, and conveyor systems. Water-cooling the TIG welder also reduces the risk of overheating, reducing the possibility of equipment damage and downtime.

In conclusion, water-cooled TIG welders are a versatile welding system that is widely utilized in various industries. Its ability to produce high-quality welds with minimal distortion, precise control, and extended welding times makes it an attractive option for critical welding applications in industries such as aerospace, automotive, construction, and manufacturing.

The Process of Water Cooled TIG Welder

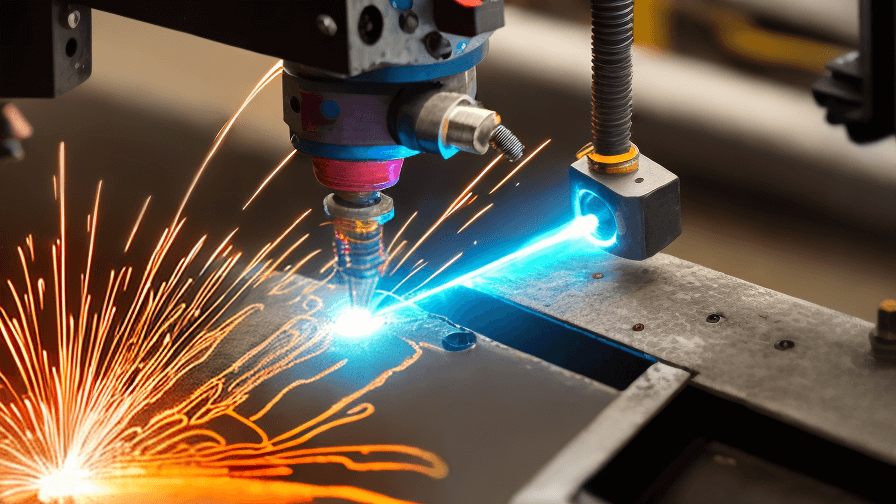

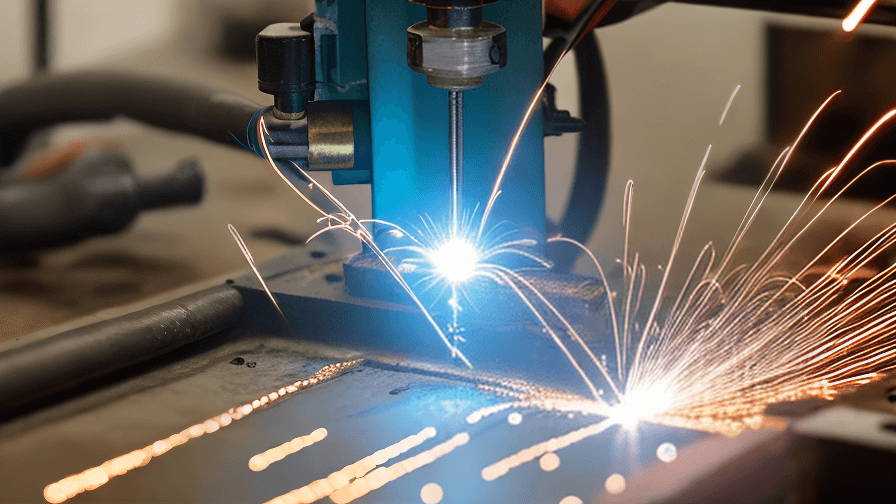

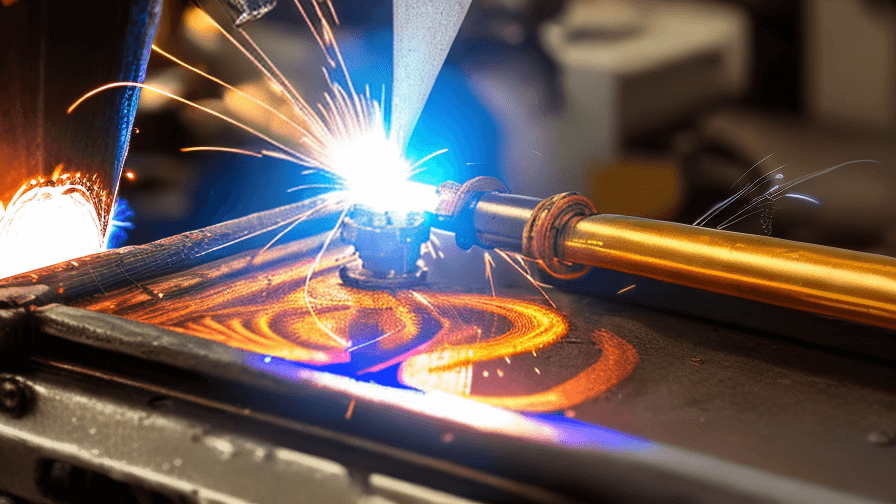

Water-cooled TIG welding is a process of fusing materials together using an arc of electricity that passes between a tungsten electrode and the workpiece. The process is highly advanced and requires precision control over the amount of heat applied to the materials.

The primary advantage of this welding process is that it allows welders to weld thick materials without overheating them. This is achieved by circulating water through the torch head, effectively reducing the temperature of the electrode, thus reducing the heat in the weld.

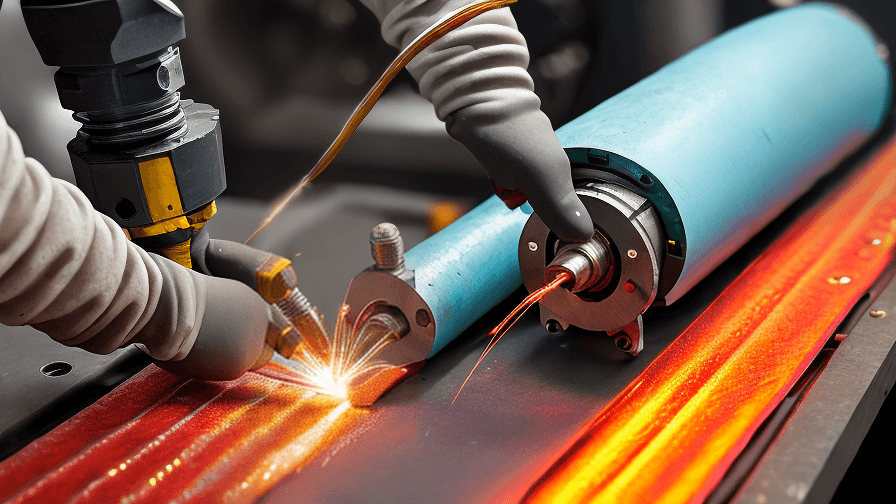

The process is carried out using a TIG welding machine that features a water-cooled torch head. The torch head, in turn, is connected to a water-cooled cooler assembly, which circulates water through the head and cools it down.

During welding, the operator manually guides the tungsten electrode across the surface of the workpiece, creating the arc. As the arc heats the workpiece, the operator adds a filler material to fuse the materials together. This process requires careful monitoring of the heat and the input of filler material to ensure a strong and uniform weld.

Water-cooled TIG welding requires a high level of skill and training, and the process is typically used for precision fabrication applications, such as aerospace and medical device manufacturing, as well as in the automotive and construction industries.

In conclusion, water-cooled TIG welding is a highly advanced process that requires precision and expertise. It is used in a wide range of applications to create strong, precise, and uniform welds, and is particularly useful for welding thick and challenging materials. With the proper training and equipment, water-cooled TIG welding can produce excellent results in even the most demanding applications.

How to use Water Cooled TIG Welder

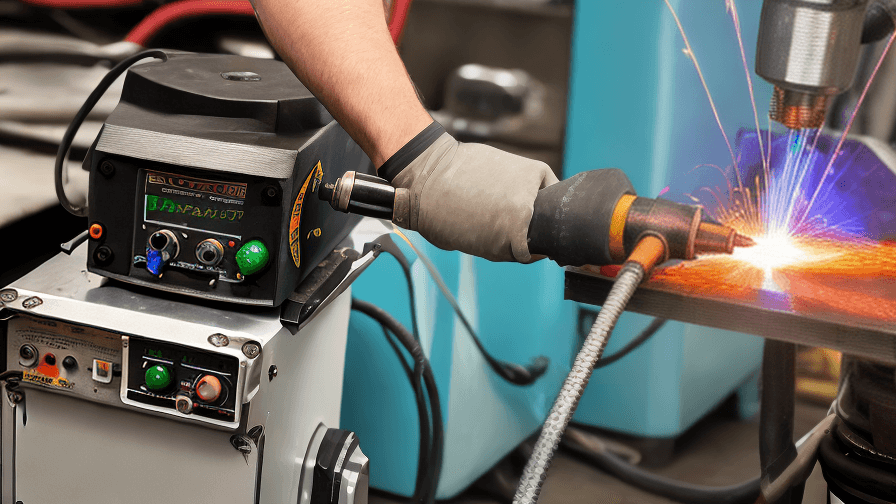

A water cooled TIG welder is a powerful welding tool that requires precise handling. Here are some tips on how to use a water cooled TIG welder:

1. First, ensure that the machine is well-maintained and powered up. Check the cables and torch for any damage, and ensure that the coolant level is adequate.

2. Set up your workspace. Ensure that you have enough space to maneuver around and that the welding area is clean and free from any flammable materials.

3. Secure the workpiece and clamp it firmly in place to avoid any vibrations during the welding process.

4. Adjust the settings on the machine. The appropriate settings will vary bу job, so consult the machine’s instruction manual for guidance.

5. Turn on the gas supply; a flow rate of around 15-25 cubic feet per hour is optimal. The shielding gas will protect the weld area from contaminants as you work.

6. Before starting the weld, make a practice run to ensure you have the right settings and torch angle.

7. Begin welding, keeping the torch angle at about 15 degrees. Use the foot pedal to adjust the amperage as you weld.

8. After finishing the weld, allow the material to cool before removing any clamps or supports.

9. Turn off the machine and clean up your workspace.

In conclusion, a water cooled TIG welder is a powerful tool that can deliver precise and high-quality welds. By following these simple guidelines, you can safely and effectively use a water cooled TIG welder and achieve great results.

Selecting the Ideal Manufacturer Water Cooled TIG Welder

Selecting the ideal manufacturer for a water-cooled TIG welder is necessary to ensure that you get the best quality product that suits your needs. Here are some factors to consider:

1. Reputation and Experience

The first factor to consider is the reputation and experience of the manufacturer. The ideal manufacturer should have a good reputation in the market for producing high-quality water-cooled TIG welders. They should also have considerable experience in manufacturing these types of welders.

2. Technology and Innovation

The second factor to consider is the technology and innovation used by the manufacturer. The ideal manufacturer should be innovative and use the latest technology to produce the water-cooled TIG welders. This ensures that the welders are efficient, reliable, and have the latest features that meet the needs of the user.

3. Price

Another important factor to consider is the price of the water-cooled TIG welder. The ideal manufacturer should offer competitive prices that match the quality of the product. Avoid manufacturers that offer cheap products as they are likely to be of low quality and may not last long.

4. Customer Support

The ideal manufacturer should offer excellent customer support to their customers. If you encounter any issues with the welder, the manufacturer should be able to provide you with prompt and reliable support. This includes technical support, repairs, and replacement of parts.

5. Warranty

Finally, it is crucial to consider the warranty offered by the manufacturer. The ideal manufacturer should offer a comprehensive warranty that covers all faults and issues that may arise with the water-cooled TIG welder within a reasonable time frame.

In conclusion, selecting the ideal manufacturer for a water-cooled TIG welder requires careful consideration of various factors. Choosing a reputable and experienced manufacturer that uses the latest technology and offers competitive prices, excellent customer support, and a comprehensive warranty is essential to ensure you get the right product that meets your needs.

list FAQ with answer about Water Cooled TIG Welder

A water-cooled TIG welder is a powerful tool used for joining metals with precision. If you’re new to using this type of equipment or simply want to brush up on commonly asked questions, we’ve assembled a list of FAQs with answers that can help guide you through the process.

Q: What is a water-cooled TIG welder, and how is it different from other types of welders?

A: A water-cooled TIG welder uses water to cool the torch and electrode, allowing for longer welding sessions at higher temperatures. It’s different from other welders like MIG and stick welders, which use different methods to melt and join metal.

Q: What materials can be welded with a water-cooled TIG welder?

A: Water-cooled TIG welders are used primarily for welding thin and exotic metals like stainless steel, aluminum, and copper.

Q: What are the benefits of using a water-cooled TIG welder?

A: A water-cooled TIG welder provides more control and precision during the welding process, resulting in stronger and more consistent welds. It also allows for longer welding sessions without needing to pause and let the equipment cool down.

Q: What are some of the drawbacks of using a water-cooled TIG welder?

A: One of the main drawbacks of using a water-cooled TIG welder is the extra equipment required, such as a water-cooled torch and a cooling system. Additionally, it may not be necessary for all welding projects, so there may be an unnecessary expense for some.

Q: How do I choose the right water-cooled TIG welder?

A: When choosing a water-cooled TIG welder, consider the materials you’ll be welding, the thickness of the metal, and your budget. It’s important to invest in a high-quality machine that will provide consistent results over time.

In conclusion, a water-cooled TIG welder can be a useful and precise tool for welding thin and exotic metals. By understanding its benefits and drawbacks, as well as how to choose the right machine, you can confidently navigate using this equipment in your welding projects.

Things to Consider When Purchasing Water Cooled TIG Welder

When purchasing a water-cooled TIG welder, there are a few key factors to consider. First and foremost is the amperage range of the welder. You want to make sure that the amperage range of the machine is suitable for the types of welding projects you plan on tackling. If you aren’t sure what your amperage needs are yet, consider purchasing a welder with a broad amperage range to give you flexibility as you gain experience.

Another important consideration is the size and weight of the welder. If you’ll be moving the machine from job site to job site, it’s important to choose a model that is compact and easy to transport. If the welder will be stationary, however, you may want to prioritize a larger, heavier machine that can handle longer welding runs without overheating.

The cooling system is another key factor to consider. Water-cooled welders are designed to run for longer periods of time than air-cooled models, but the cooling system will only be effective if it is properly maintained. Consider the availability of replacement cooling components when choosing a welder, as these components can wear out over time and require replacement.

Finally, be sure to compare the prices of different models from various manufacturers to find the best value. While a higher-priced welder may offer more advanced features or better performance, it may not be necessary for your specific needs. On the other hand, a cheaper welder may be lacking in quality or certain features that you require. Researching and comparing different models will help you find the most suitable water-cooled TIG welder for your needs and budget.

Properties of Water Cooled TIG Welder

A water-cooled TIG welder is a welding machine that uses water to cool down the components of the torch. TIG welding is a process that involves the use of a tungsten electrode, which creates an arc to melt the metal and form a weld. This process generates a lot of heat, which can cause damage to the torch and other components of the welding machine if it is not cooled down.

One of the main benefits of a water-cooled TIG welder is that it can operate at a higher amperage for a longer period of time. This is because the water cooling system helps to dissipate the heat generated by the welding process, which can prolong the life of the welding machine. It also makes it easier to maintain a consistent arc during the welding process, which can result in a higher quality weld.

Another advantage of a water-cooled TIG welder is that it is typically smaller and lighter than a conventional air-cooled TIG welder. This makes it easier to transport to job sites and to maneuver in tight spaces. It is also less noisy than an air-cooled welder, which can be beneficial in residential areas or other areas where noise is a concern.

In addition, water-cooled TIG welders are designed to be more efficient than air-cooled welders. This is because they use less energy to maintain a consistent welding temperature, which can result in lower electricity bills over time. They also produce less waste heat, which can help to reduce the overall environmental impact of welding operations.

Overall, there are many benefits to using a water-cooled TIG welder for your welding needs. Whether you are a professional welder or a DIY enthusiast, this type of welding machine can help you to achieve high-quality welds and to work more efficiently. If you are in the market for a new TIG welder, be sure to consider the advantages of a water-cooled system before making your purchase.

Technical Parameters Terms for Water Cooled TIG Welder

Water-cooled TIG welders are specialized machines that are utilized in the welding process. These remarkable machines provide a variety of welding techniques that make welding more effortless than it was done previously. Welding can be challenging, and that is why the technical parameters of water-cooled TIG welders are essential to be aware of. Understanding the technical parameters of water-cooled TIG welders is crucial in choosing the right one for your welding needs.

One of the primary technical parameters of water-cooled TIG welders is the welding current, represented in amperes (amps). The welding current is the amount of electric current passing through the tungsten electrode used in TIG welding. The intensity of the welding current depends on the type of metal being worked on, its thickness, and the welding position.

Another technical parameter is the duty cycle. The duty cycle is the amount of time that the welder can operate continuously without overheating. Typically, 100 amps welders should be operated in shorter cycles than the 250-amp machines. The duration a particular water cooled TIG welder can operate varies depending on its capabilities. Furthermore, the duty cycle is influenced by the ambient temperature, the air supply, and the operator technique.

Another essential technical parameter to consider is the Arc Force Control. Arc force control is the measurement of the arc’s stability and its ability to maintain the arc’s length. This is particularly important when working with longer welds, as it ensures that the weld does not run out of control and cause damage to the job.

Finally, the gas flow rate is another critical technical parameter that determines the quality of a water-cooled TIG welder. The gas flow rate is the quantity of shielding gas that should surround the tungsten electrode while performing welding operations. The right gas flow rate will ensure that you get a clean, uniform weld that is free from defects.

In conclusion, the technical parameters of a water-cooled TIG welder are vital in deciding which welder to utilize for specific welding tasks. By taking into consideration the welding current, duty cycle, arc force control, and gas flow rate, you can select the right machine that meets your needs and helps you achieve high quality, precise welds.

Water Cooled TIG Welder Price

Water cooled TIG welders are a popular choice among professional welders as they offer better performance than a standard TIG welder. They are designed to handle high-amperage welding and provide consistent results throughout the entire weld.

The price of a water cooled TIG welder varies depending on several factors such as brand, features, and specifications. Generally speaking, a water cooled TIG welder can range from $1,500 to $5,000 or more.

When it comes to pricing, it’s important to consider what features and specifications you need in a machine. For instance, a higher amperage output will cost more than a lower one, so consider the type of welding projects you’ll be working on and the amount of power you’ll need.

Other factors that can affect the price include the type of cooling system, the amount of portability, and additional features like pulse welding or an AC/DC power supply.

It’s important to keep in mind that while a water cooled TIG welder may be more expensive upfront, it can save you money in the long run. The water cooling system keeps the machine at a consistent temperature, reducing wear and tear on the parts and extending the lifespan of the machine.

In conclusion, the price of a water cooled TIG welder may seem steep, but it’s important to consider the investment in terms of performance, longevity, and the type of welding projects you’ll be undertaking. Research brands and models and always choose a machine that meets your specific welding and budget needs.