Introduce about who makes cummins engines guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

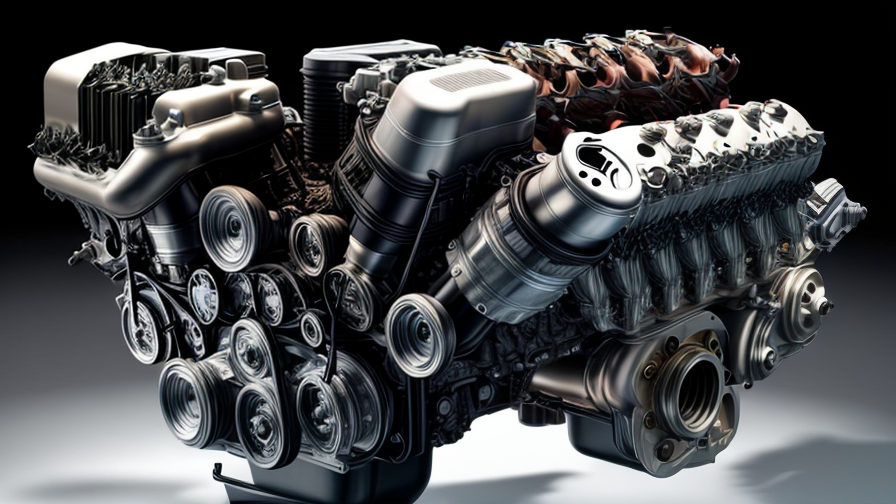

Cummins Inc. is a renowned American company that specializes in the manufacturing of engines, generators, and other power-related products. With over a century of experience, Cummins has established itself as a leader in the industry, producing engines that power a wide range of applications including commercial vehicles, construction equipment, marine vessels, and more.

When it comes to quality, Cummins engines are highly regarded for their reliability and performance. The company follows rigorous manufacturing processes and strict quality control measures to ensure that their engines meet the highest standards. Each engine undergoes extensive testing and inspection before leaving the production facility, guaranteeing optimal performance and durability.

In terms of cost, Cummins engines provide excellent value for money. While they may come at a slightly higher initial investment compared to some competitors, their long-lasting performance, fuel efficiency, and low maintenance requirements make them cost-effective in the long run.

Cummins engines are available through a vast network of authorized suppliers and distributors worldwide. This extensive distribution network ensures easy access to genuine Cummins products, spare parts, and service support.

Cummins holds various certifications, including ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. These certifications demonstrate Cummins’ commitment to delivering products that meet international quality and safety standards.

With a strong presence in both domestic and international markets, Cummins engines are widely utilized across various industries and geographical locations. Their engines have garnered a reputation for reliability and have established a significant market share globally.

For those considering purchasing a Cummins engine, here are a few useful tips:

1. Identify the specific power requirements and intended application to select the most suitable engine model.

2. Consult with authorized dealers or Cummins representatives to ensure optimal configuration and compatibility.

3. Regularly follow recommended maintenance schedules and use genuine Cummins parts for optimal performance and longevity.

Frequently Asked Questions (FAQ):

1. Are Cummins engines environmentally friendly? Yes, Cummins has made significant strides in producing engines that comply with stringent emission standards, reducing their environmental impact.

2. Can Cummins engines be used in marine applications? Absolutely, Cummins offers a range of marine engines that deliver reliable power for various vessel types.

3. Does Cummins provide warranty coverage for their engines? Yes, Cummins offers comprehensive warranty coverage for their engines, which may vary based on the specific model and application.

In conclusion, Cummins engines are renowned for their reliable performance, durability, and efficiency. With a global presence, quality certifications, and superior customer support, Cummins continues to be a trusted choice for a wide range of applications in various industries worldwide.

Types of who makes cummins engines

Cummins Inc. is a renowned American company that specializes in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. They are known to produce engines for various applications, including trucks, buses, agricultural machinery, construction equipment, and power generation.

One of the key types of engines manufactured by Cummins is their on-highway engines. These engines are specifically designed for trucks and buses that operate on highways and are built to deliver maximum performance, fuel efficiency, and reliability. Cummins on-highway engines are used by numerous leading truck manufacturers worldwide, such as Freightliner, International, Kenworth, Peterbilt, and Volvo, among others.

Cummins also produces off-highway engines that are used in a wide range of applications in industries like agriculture, construction, and mining. These engines are engineered to provide power and durability to tackle the toughest off-road conditions. Many well-known manufacturers choose Cummins engines to power their machines, including John Deere, Case, Hitachi, Komatsu, and Caterpillar.

In addition to on- and off-highway engines, Cummins manufactures engines for marine applications. Cummins marine engines are designed to meet the specific requirements of the boating industry, offering reliable and efficient power for recreational and commercial vessels. Many boat builders, such as Sea Ray, Boston Whaler, and Bertram, rely on Cummins engines to provide propulsion for their boats.

Furthermore, Cummins is a leader in the power generation sector. They produce engines specifically designed for stationary power generation, offering solutions for backup power, prime power, and continuous power. Their engines can be found in data centers, hospitals, factories, and other facilities around the world, providing reliable electricity in times of need.

Cummins engines are widely recognized for their high quality, durability, and fuel efficiency. The company’s commitment to innovation and technological advancements has made them a trusted choice for countless manufacturers across various industries. Whether it’s a truck, a construction machine, a boat, or a power generator, when it comes to engines, Cummins has a wide range of options to meet diverse needs.

Pros and Cons of Using who makes cummins engines

Cummins Inc. is a reputable manufacturer of engines, known for their durability and reliability. Here are some pros and cons of using Cummins engines:

Pros:

1. Performance and Power: Cummins engines are known for their excellent performance and power. They are designed to deliver high torque and horsepower, making them suitable for various applications including heavy-duty trucks, construction machinery, and marine vessels.

2. Fuel Efficiency: Cummins engines are engineered to be highly fuel-efficient. They have advanced technology that optimizes combustion, reduces friction, and enhances overall engine efficiency. This leads to lower fuel consumption and operating costs.

3. Durability and Longevity: Cummins engines are built to last. They are constructed with high-quality materials and undergo rigorous testing to ensure their durability. These engines can withstand harsh operating conditions and provide reliable performance for many years.

4. Wide Range of Options: Cummins offers a diverse range of engines across different power outputs and applications. This allows customers to find the right engine that suits their specific needs, whether it’s for heavy-duty trucks, generators, or industrial equipment.

5. Global Support Network: Cummins has a vast network of authorized dealers and service centers worldwide. This ensures that customers can receive timely support and access genuine Cummins parts and service wherever they are located.

Cons:

1. Higher Initial Cost: Cummins engines tend to have a higher initial purchase cost compared to some other brands. However, this can be offset by their long-term durability and reliability.

2. Noise and Vibration: Some Cummins engines may generate more noise and vibration compared to certain competitors. While this may not be an issue in rugged applications, it could be a consideration for applications where noise reduction is crucial.

3. Emissions Compliance: While Cummins has made significant advancements in reducing engine emissions, their engines may not always meet the most stringent emission standards in certain regions. This could limit their use in certain applications or require additional emission control systems.

4. Size and Weight: Cummins engines are known for their robust construction, which can sometimes result in larger and heavier engines compared to competitors. This may be a factor to consider for applications with strict weight limitations.

In conclusion, Cummins engines offer excellent performance, durability, and fuel efficiency. However, potential drawbacks include higher initial costs, noise and vibration levels, emissions compliance, and size and weight considerations. Ultimately, the suitability of Cummins engines depends on the specific requirements and priorities of the application.

who makes cummins engines Reference Specifications (varies for different product)

Cummins Inc. is the company that designs, manufactures, and distributes Cummins engines. Founded in 1919, Cummins is known for its wide range of engines used in various applications. With its headquarters in Columbus, Indiana, Cummins operates globally and serves customers in over 190 countries.

Cummins specializes in the production of diesel and natural gas engines for a variety of industries, including automotive, construction, power generation, marine, mining, oil and gas, and rail. The engines are designed to deliver power, efficiency, reliability, and durability.

Cummins engines are developed with advanced technologies and undergo rigorous testing to ensure they meet or exceed industry standards. These engines are renowned for their fuel efficiency, low emission levels, and ability to operate in diverse conditions. They are also known for their reliability and long service life, making them a preferred choice for many customers.

Cummins offers a wide range of engines, each tailored to specific applications and market requirements. These engines come in various sizes, power ratings, and configurations to suit different needs. Some of Cummins’ popular engine series include the Cummins B Series, ISB, ISL, ISX, QSB, QSL, QSK, QSM, QSX, and the X Series.

In addition to engines, Cummins also provides related components, systems, and technologies such as turbochargers, exhaust aftertreatment systems, filtration solutions, fuel systems, electronics, and power generation systems.

Cummins’ commitment to innovation, quality, and customer satisfaction has made it a global leader in engine manufacturing. The company invests heavily in research and development to continuously improve its products and develop new technologies that meet evolving industry and environmental standards.

Overall, Cummins engines are relied upon by various industries worldwide for their exceptional performance, reliability, and efficiency. Cummins continues to be at the forefront of engine development, ensuring that its products meet the needs of customers in an ever-changing landscape.

Applications of who makes cummins engines

Cummins Inc. is an American multinational corporation that designs, manufactures, and distributes engines, filtration, and power generation products. They are well-known for their diesel engines, which are used in a variety of applications across different industries. Let’s explore some of the key applications of Cummins engines.

1. Automotive Sector: Cummins engines are widely used in various types of vehicles, including heavy-duty trucks, pickup trucks, buses, and recreational vehicles (RVs). Their engines are renowned for their reliability, durability, and fuel efficiency, making them a popular choice for commercial and personal transportation needs.

2. Construction and Mining: Cummins engines are prominently utilized in construction equipment and mining machinery due to their high torque output, fuel efficiency, and ability to perform in challenging operating conditions. These engines power equipment like excavators, bulldozers, loaders, and dump trucks, ensuring optimal performance and productivity in demanding environments.

3. Marine Industry: Cummins offers a range of marine engines for various vessels, such as yachts, fishing boats, tugboats, and commercial ships. Their engines provide reliable power and are designed to withstand the harsh operating conditions of marine environments, enabling smooth and efficient navigation.

4. Power Generation: Cummins is a leading provider of power generation solutions. Their engines are used in standby, prime, and continuous power applications to generate electricity. Cummins power generation systems are employed in hospitals, data centers, manufacturing facilities, residential buildings, and more, providing a reliable and uninterrupted power supply.

5. Agriculture and Farming: Cummins engines are utilized in agricultural equipment, including tractors, harvesters, irrigation systems, and grain elevators. These engines deliver high torque and fuel efficiency, facilitating maximum productivity for farmers and meeting the demands of modern agricultural practices.

6. Rail and Locomotive: Cummins engines power locomotives used for freight and passenger transportation. Cummins provides rail engines that meet emission regulations while ensuring reliable and efficient operation, contributing to the sustainable development of rail transportation.

7. Oil and Gas: In the oil and gas industry, Cummins engines are employed in drilling rigs, well-servicing equipment, and pumping units. Cummins’ engines are known for their durability, high power output, and ability to operate in remote and rugged environments, making them suitable for oil and gas exploration and production activities.

These are just a few examples of the numerous applications where Cummins engines are widely utilized. Cummins’ commitment to innovation, quality, and environmental consciousness has made them a trusted partner in various industries worldwide.

The Work Process and how to use who makes cummins engines

Cummins Inc. is a renowned global leader in manufacturing diesel engines and related technologies. The work process at Cummins involves several key stages that ensure high-quality engines are produced.

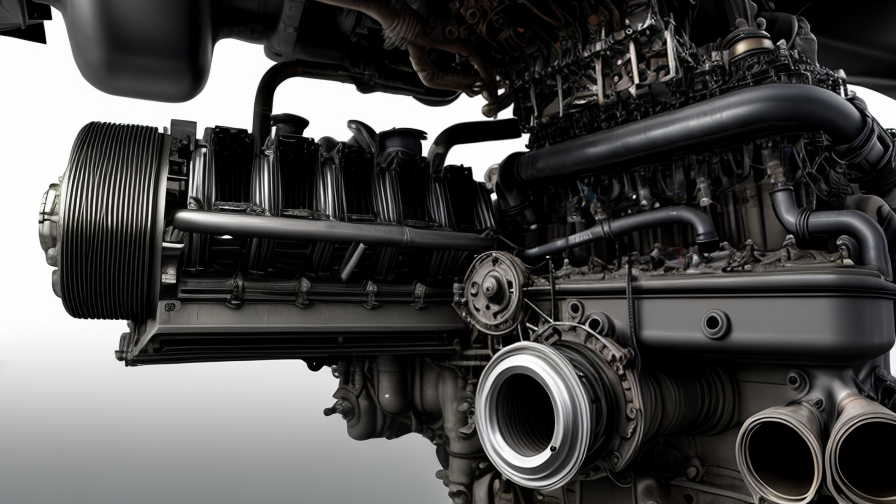

Firstly, the process starts with product engineering and design. Cummins’ team of experts and engineers conducts extensive research and development to create innovative engine designs that meet industry demands and regulatory standards. This phase includes computer-aided design, simulation, and testing to optimize engine performance and efficiency.

Once the design is finalized, the production phase begins. Cummins operates advanced manufacturing facilities worldwide, each equipped with state-of-the-art technologies and processes. The company utilizes automated assembly lines and precision machinery to construct various engine components. These components are manufactured to precise tolerances, ensuring consistent quality and reliability.

After component production, the components are assembled together to form a complete engine. This step involves skilled technicians who meticulously fit and connect the various pieces, following strict quality and safety protocols. Cummins’ focus on quality control guarantees that every engine leaving their facilities meets rigorous standards.

Once assembled, the engines undergo thorough testing. Cummins employs a range of tests to ensure optimal performance, durability, and emissions compliance. These tests involve subjecting the engines to extreme conditions, assessing their ability to withstand stress and fulfill operational requirements. Through extensive testing, any issues are identified and rectified, safeguarding the quality of the final product.

Finally, Cummins engines are shipped to various customers and industries, including automotive, construction, marine, and power generation. The company has an extensive global distribution network, ensuring timely delivery and support services wherever their engines are required.

Overall, Cummins’ work process involves design, component production, engine assembly, rigorous testing, and global distribution. Their commitment to quality, innovation, and customer satisfaction has made them a trusted provider of engines worldwide.

Quality Testing Methods for who makes cummins engines and how to control the quality

Cummins Inc. is a global manufacturer of engines and power generation equipment, known for its high-quality products. To ensure the quality of Cummins engines, several testing methods are employed throughout the production process.

Firstly, Cummins performs rigorous material testing to ensure the components used in engine manufacturing meet the required standards. This includes conducting chemical analysis, mechanical tests, and non-destructive testing methods such as ultrasonic and magnetic particle inspections.

During the manufacturing process, Cummins employs advanced testing techniques like dimensional analysis to ensure the precise dimensions and tolerances of engine components. This is vital to ensure proper fit, form, and function of the parts.

Functional testing is another crucial method used by Cummins to control quality. Engines undergo extensive performance tests, such as endurance runs, where the engines are operated under demanding conditions for extended durations. This allows for the identification of any potential issues related to performance, efficiency, or durability.

Cummins also utilizes emissions testing to ensure its engines comply with environmental regulations. Various emission control technologies are incorporated, and engines are tested to verify the reduction of harmful pollutants in accordance with applicable standards.

To further control quality, Cummins emphasizes continuous improvement processes and a robust quality management system. This includes inspections throughout the production line and thorough auditing of suppliers to maintain consistent quality of raw materials.

Furthermore, Cummins closely monitors customer feedback and conducts post-sales inspections and evaluations. This enables the identification of any quality issues that may have occurred during manufacturing or usage, allowing for targeted improvements.

In summary, Cummins employs a range of quality testing methods to ensure the production of reliable and high-performing engines. These methods include material testing, dimensional analysis, functional testing, emissions testing, and continuous improvement processes. Through these measures, Cummins successfully maintains its reputation for delivering quality engines to customers worldwide.

who makes cummins engines Sample Policy and Post-Purchase Considerations for who makes cummins engines from China

Sample Policy and Post-Purchase Considerations for Cummins Engines from China

When purchasing Cummins engines from China, it is essential to consider certain policies and post-purchase factors to ensure a smooth and satisfactory transaction. Here is a sample policy and post-purchase considerations guide:

1. Supplier Evaluation: Before making a purchase, thoroughly evaluate the supplier’s reputation, experience, and product quality. Look for certifications like ISO 9001 to ensure compliance with international quality standards. Check customer reviews and ratings to assess the supplier’s credibility.

2. Quality Assurance: Request detailed information about the product specifications, technical parameters, and performance standards of the Cummins engines. Seek evidence of rigorous quality control procedures, such as inspections and tests during manufacturing. Ensure the supplier is reliable and committed to delivering superior-quality engines.

3. Warranty and After-Sales Service: Inquire about the warranty period offered by the supplier. A reputable supplier should provide a reasonable warranty period, typically no less than 12 months, to ensure any manufacturing defects or operational issues are covered. Additionally, ensure that the supplier offers efficient after-sales service, including technical support and spare part availability.

4. Customs and Import Regulations: Familiarize yourself with the customs and import regulations of your country to avoid any legal issues or unexpected expenses. Confirm that the supplier can provide necessary documentation, such as certificates of origin, to facilitate smooth customs clearance.

5. Shipping and Logistics: Discuss shipping options, delivery times, and transportation costs with the supplier. Ensure that the chosen logistics provider is experienced in handling engine shipments and can provide secure packaging to prevent any damage during transit.

6. Payment Terms: Negotiate payment terms based on your preferences and the supplier’s policies. Be cautious of excessively low prices, as they may indicate compromised product quality or poor service. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment.

7. Communication and Language: Establish effective communication channels with the supplier, ensuring a clear understanding of your requirements. Confirm that the supplier has English-speaking representatives or interpreters available to facilitate smooth communication during the negotiation and post-purchase stages.

8. Tracking and Feedback: Once the order has been placed, request regular updates on the manufacturing progress, shipping details, and estimated delivery dates. Maintain open communication with the supplier to address any concerns and offer feedback on the product’s performance after its installation.

By following these policy and post-purchase considerations, you can enhance your chances of successfully procuring Cummins engines from a reliable supplier in China. A thorough evaluation, clear communication, and adherence to policies will help you mitigate potential risks and ensure a smooth and satisfactory purchase experience.

Sourcing who makes cummins engines from China: Opportunities, Risks, and Key Players

Cummins Inc. is a renowned American manufacturer that produces engines of various sizes and applications. While Cummins operates globally, it also has manufacturing facilities in China. These Chinese plants predominantly cater to the domestic market, but they also contribute to Cummins’ supply chain for engines worldwide.

Sourcing Cummins engines from China presents both opportunities and risks for buyers. The primary opportunity lies in cost effectiveness. Manufacturing in China allows for lower labor and production costs, which can result in competitive pricing for Cummins engines. This can be advantageous for businesses looking to reduce their overheads or capitalize on lower purchasing costs. Additionally, sourcing from China enables companies to tap into the extensive manufacturing capabilities and supply chain network present in the country.

However, there are also several risks associated with sourcing Cummins engines from China. Quality control can be a concern, as there have been cases of counterfeit and inferior products in the Chinese market. It is crucial for buyers to ensure that they are sourcing genuine Cummins engines from authorized dealers or manufacturers. Engaging in thorough due diligence and verifying credentials can mitigate this risk.

Key players involved in manufacturing Cummins engines in China include Cummins itself and its joint venture partners. Cummins has formed several joint ventures with Chinese companies, such as Dongfeng Motor Corporation, Chongqing Machinery & Electric Co., Ltd., and Xi’an Cummins Engine Co., Ltd. These partnerships allow Cummins to access localized expertise, better navigate Chinese regulations, and establish a stronger presence in the domestic market.

In conclusion, sourcing Cummins engines from China offers opportunities in terms of cost effectiveness and access to an extensive supply chain network. However, risks related to quality control must be carefully managed. Cummins, along with its joint venture partners, is the key player in manufacturing Cummins engines in China. Thorough due diligence is essential to ensure sourcing from authorized channels and to mitigate any potential risks.

How to find and select reliable who makes cummins engines manufacturers in China,use google search manufacturers and suppliers

When searching for reliable manufacturers of Cummins engines in China, using Google can be an effective approach. Here are some steps to find and select the right manufacturer while staying within the word limit:

1. Begin the search by entering relevant keywords like “reliable Cummins engine manufacturers in China” or “China Cummins engine suppliers.” Google will generate a list of results related to your search.

2. Filter the search results by assessing the website’s credibility. Look for well-designed websites with professional layouts, product details, certifications (such as ISO or CE), and contact information.

3. Check the manufacturer’s reputation by visiting their website’s “About Us” or “Company Profile” section. Look for information on their experience, production capacity, quality control measures, and client base. Reliable manufacturers often highlight their achievements and provide comprehensive details.

4. Explore their product range and determine if they specialize in manufacturing Cummins engines. Check if they offer a wide variety of engine models and sizes, as it demonstrates expertise and capability.

5. Assess the manufacturer’s manufacturing capabilities and facilities. Look for details on their production lines, equipment, and quality control processes. Consider if they have modern technologies and adhere to international manufacturing standards.

6. Look for client reviews or testimonials on the manufacturer’s website. Genuine feedback from previous clients can provide insights into their product quality, reliability, and customer service.

7. Contact the manufacturer directly to gather additional information. Inquire about their production time, pricing, customization options, and after-sales support. Reliable manufacturers typically respond promptly and provide comprehensive information.

8. Verify their ability to export and comply with international trade regulations. Ensure they have experience exporting Cummins engines to your desired location and have a clear understanding of export requirements.

By following these steps and utilizing Google’s search results, you can find and select reliable manufacturers of Cummins engines in China. Remember to evaluate their credibility, reputation, product range, manufacturing capabilities, customer feedback, and export experience.

How to check who makes cummins engines manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To determine the reliability of a manufacturer’s website for Cummins engines, you can follow these steps:

1. Open Google Chrome: Ensure that you have Google Chrome browser installed on your computer. It provides useful tools for analyzing the website’s reliability.

2. Install SEOquake extension: Visit the Chrome Web Store and search for the “SEOquake” extension. Install it on your browser.

3. Access the manufacturer’s website: Search for the manufacturer of Cummins engines using Google search. Click on their official website to access it.

4. Analyze website ranking: With SEOquake installed, you will find a new toolbar in your browser. Directly above the website, you’ll see various SEO parameters. Look for the “Alexa Rank” or “Rank” value, which indicates the website’s traffic rank globally or within a specific country.

5. Check the website’s rank: If the manufacturer’s website has an Alexa Rank within the top 10 million, it generally suggests a decent amount of traffic and popularity. This implies that the website is likely reliable.

6. Consider other factors: While checking rankings provides a basic understanding, several other factors contribute to a website’s reliability. Check for clear contact information, including a physical address and phone number. Look for testimonials, certifications, and partnerships that showcase industry recognition and trustworthiness. Evaluate the website design and organization for a professional appearance.

7. Limit the word count: Make sure your analysis remains concise and within the given word limit of 300 words. Focus on the most critical aspects mentioned above, such as the website’s ranking and presence of trust signals.

By following these steps and analyzing the manufacturer’s website for Cummins engines using Google Chrome’s SEOquake extension, you can effectively assess its reliability.

Top 10 who makes cummins engines manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Dongfeng Cummins Engine Co., Ltd: Dongfeng Cummins is a joint venture between Dongfeng Motor Group and Cummins Inc. They specialize in manufacturing medium to heavy-duty engines for various applications including trucks, construction machinery, and power generation. Their engines are known for their durability, efficiency, and environmental friendliness.

2. Chongqing Cummins Engine Co., Ltd: Chongqing Cummins is also a joint venture between Cummins Inc. and Chongqing Machinery and Electric Co., Ltd. They produce a wide range of engines that are renowned for their reliability and performance. Their products include engines for commercial vehicles, buses, and marine applications.

3. Xi’an Cummins Engine Co., Ltd: Xi’an Cummins focuses on manufacturing engines for off-highway equipment, such as mining machinery and construction equipment. They offer powerful and efficient engines that are designed to withstand harsh operating conditions.

4. Beijing Foton Cummins Engine Co., Ltd: This joint venture between Cummins Inc. and Beiqi Foton Motor Co. specializes in producing engines for light-duty trucks, pickups, and SUVs. Their engines are known for their excellent fuel economy, low emissions, and reliable performance.

5. Yuchai Cummins Industrial Power Co., Ltd: Yuchai Cummins is a collaboration between Cummins Inc. and Guangxi Yuchai Machinery Group. They manufacture engines for power generation, industrial applications, and marine vessels. Their engines are highly efficient, low in emissions, and have a strong power output.

6. FAW Jiefang Automotive Co., Ltd: FAW Jiefang is one of China’s leading manufacturers of heavy-duty trucks. They produce trucks equipped with Cummins engines, which offer exceptional reliability, excellent fuel efficiency, and robust performance.

7. Shaanxi Automobile Group Co., Ltd: Shaanxi Automobile Group is a major producer of heavy-duty trucks in China. They partner with Cummins to equip their trucks with engines that deliver high torque, low fuel consumption, and low emissions.

8. Sinotruk (Hong Kong) Limited: Sinotruk is a well-known manufacturer of heavy-duty trucks under the brand name “Howo.” They collaborate with Cummins to offer trucks with engines that are fuel-efficient, powerful, and meet international emission standards.

9. Dayun Automobile Co., Ltd: Dayun Automobile is a leading manufacturer of light, medium, and heavy-duty trucks. They use Cummins engines in their vehicles to provide customers with reliable and technologically advanced transportation solutions.

10. Chang’an Automobile Co., Ltd: Chang’an Automobile is one of China’s largest automakers and produces a wide range of vehicles. They utilize Cummins engines in their lineup to provide customers with durable, high-performance options.

| Manufacturer | Products |

| —————————————— | ———————————————————— |

| Dongfeng Cummins Engine Co., Ltd | Medium to heavy-duty engines for trucks, construction machinery, power generation |

| Chongqing Cummins Engine Co., Ltd | Engines for commercial vehicles, buses, marine applications |

| Xi’an Cummins Engine Co., Ltd | Engines for off-highway equipment (mining machinery, construction) |

| Beijing Foton Cummins Engine Co., Ltd | Engines for light-duty trucks, pickups, SUVs |

| Yuchai Cummins Industrial Power Co., Ltd | Engines for power generation, industrial applications, marine vessels |

| FAW Jiefang Automotive Co., Ltd | Heavy-duty trucks |

| Shaanxi Automobile Group Co., Ltd | Heavy-duty trucks |

| Sinotruk (Hong Kong) Limited | Heavy-duty trucks |

| Dayun Automobile Co., Ltd | Light, medium, and heavy-duty trucks |

| Chang’an Automobile Co., Ltd | Various vehicles |

In summary, these top 10 Cummins engine manufacturers in China offer a diverse range of products that cater to different industries and applications. Whether it’s heavy-duty trucks, construction equipment, power generation, or marine vessels, these manufacturers provide engines that are known for their reliability, efficiency, and performance.

Background Research for who makes cummins engines manufacturers Companies in China, use qcc.com archive.org importyeti.com

Cummins Inc. is a well-known American manufacturer of engines, power generation equipment, and related components. While Cummins primarily operates out of the United States, it also has a strong presence in China. To identify the manufacturers of Cummins engines in China, we can refer to the websites qcc.com, archive.org, and importyeti.com for background research.

QCC.com is a Chinese business database that provides information about companies in China. By searching for Cummins or related keywords on this platform, we can find a list of Chinese companies involved in manufacturing Cummins engines or engine components. However, since access to detailed information may require a subscription, it is recommended to sign up and explore the database further for a comprehensive analysis.

Archive.org is a website that offers access to archived versions of web pages. We can utilize this platform to explore websites of Cummins’ authorized dealers, partners, or distributors in China. By accessing archive.org, we can review historical information about Chinese companies associated with Cummins and potentially identify engine manufacturers.

Importyeti.com is a global trade data platform that provides information on import and export activities, including details about products, suppliers, and buyers. Using Importyeti.com, we can search for shipments and suppliers associated with Cummins engines imported into China. This will enable us to identify the manufacturers or suppliers of Cummins engines in China based on their import records.

To sum up, by using qcc.com, archive.org, and importyeti.com, we can conduct background research on companies involved in manufacturing Cummins engines in China. Although access to detailed information may vary, these platforms offer valuable insights into the Chinese manufacturers associated with Cummins engines.

Leveraging Trade Shows and Expos for who makes cummins engines Sourcing in China

Trade shows and expos provide valuable opportunities for sourcing Cummins engines in China. These events specifically cater to the manufacturing industry and bring together a multitude of suppliers, manufacturers, and industry professionals in one place. By leveraging these platforms, businesses can effectively source Cummins engines from reliable Chinese manufacturers, while also gaining insights into the latest industry trends and innovations.

One prominent trade show to consider is the China International Import Expo (CIIE), which is held annually in Shanghai. This event provides a platform for both Chinese and international companies to showcase their products and services. It attracts a wide range of domestic and international suppliers, including those specializing in engine manufacturing. By attending CIIE, businesses can establish contacts with Cummins engine suppliers, negotiate deals, and explore new partnership opportunities.

Additionally, participating in relevant expos and trade shows focused on the automotive or machinery industry in China can be beneficial. For instance, the China International Exhibition on Internal Combustion Engine (ICE China) is a prominent trade show that specifically caters to the engine manufacturing sector. Numerous Cummins engine suppliers, including those in China, participate in this event. By engaging with these suppliers directly, businesses can evaluate product quality, negotiate prices, and assess manufacturing capabilities.

To maximize the benefits of trade shows and expos, businesses should make proper preparations. This includes identifying their specific sourcing needs, conducting thorough research on potential suppliers, and scheduling appointments with targeted manufacturers in advance. It is also crucial to have a clear understanding of the market dynamics, industry regulations, and any potential risks associated with sourcing from China.

In conclusion, trade shows and expos provide an excellent platform for sourcing Cummins engines in China. By strategically participating in these events, businesses can identify reliable suppliers, establish partnerships, and gain valuable industry insights. However, proper preparation and research are necessary to make the most out of these opportunities.

The Role of Agents and Sourcing Companies in Facilitating who makes cummins engines Purchases from China

Agents and sourcing companies play a crucial role in facilitating the purchase of Cummins engines from China. Their role can be summarized into three main aspects: research and identification, negotiation and communication, and quality control.

Firstly, agents and sourcing companies conduct research and identify potential suppliers of Cummins engines in China. They have in-depth knowledge of the Chinese market and can easily identify reliable and reputable manufacturers. This saves buyers time and effort in searching for suppliers on their own.

Once potential suppliers are identified, agents and sourcing companies negotiate on behalf of the buyers. They have expertise in navigating business transactions in China and are skilled in price negotiation, ensuring that buyers secure the best possible deals. They also facilitate communication between the buyer and the supplier, overcoming language and cultural barriers that may exist.

Furthermore, agents and sourcing companies are responsible for quality control. China has a diverse marketplace, and not all manufacturers meet the required quality standards. Agents and sourcing companies conduct thorough inspections, audits, and quality checks to ensure that the Cummins engines being purchased meet the buyer’s specifications. This reduces the risk of receiving subpar or faulty products.

Additionally, agents and sourcing companies handle logistics and shipping arrangements, ensuring that the purchased Cummins engines are transported safely and efficiently to the buyer’s location. They take care of all necessary documentation and customs procedures, making the import process hassle-free for the buyer.

In summary, agents and sourcing companies play a vital role in facilitating purchases of Cummins engines from China. They conduct research, negotiate deals, handle communication, ensure quality control, and manage logistics. Their expertise and experience in the Chinese market streamline the procurement process, allowing buyers to source high-quality Cummins engines efficiently and effectively.

Price Cost Research for who makes cummins engines manufacturers Companies in China, use temu.com and 1688.com

When it comes to researching the price and cost of Cummins engines, manufacturers companies in China offer a wealth of information. Two popular platforms for conducting this research are Temu.com and 1688.com.

Temu.com is a renowned B2B website in China that provides comprehensive product information and allows direct communication with suppliers. By searching for Cummins engines on Temu.com, one can find a wide range of manufacturers offering their products. The platform provides detailed specifications, pricing, and contact information for each supplier, facilitating easy communication and negotiation.

1688.com, on the other hand, is a popular online marketplace operated by Alibaba Group in China. It boasts a vast collection of manufacturers and suppliers, enabling users to explore a variety of Cummins engine options. Similar to Temu.com, this platform provides essential product details, pricing information, and the possibility to interact with suppliers.

By utilizing these websites, users can find the most up-to-date pricing and cost-related details for Cummins engines manufactured in China. They can compare prices among different suppliers to find the best deal that suits their specific requirements. Additionally, these platforms enable direct communication, allowing users to negotiate prices and obtain customized quotes.

In conclusion, Temu.com and 1688.com are valuable resources for conducting price cost research on manufacturers of Cummins engines in China. These platforms provide comprehensive product information, pricing details, and the opportunity to communicate directly with suppliers, making it easier to find the most suitable and cost-effective options.

Shipping Cost for who makes cummins engines import from China

The shipping cost for importing Cummins engines from China can vary depending on several factors. These factors include the size and weight of the shipment, the shipping method and carrier chosen, the destination country, and any additional services required.

When importing Cummins engines from China, it is essential to choose a reliable and experienced freight forwarder or shipping agent who can handle the logistics efficiently. They can help navigate through customs procedures and arrange transportation to ensure a smooth and cost-effective shipping process.

The shipping method selected will greatly impact the shipping cost. Options include air freight, sea freight, or a combination of both. Air freight is typically faster but more expensive, while sea freight is slower but generally more affordable, especially for heavy or bulky shipments like engines. The choice of which method to use will depend on factors such as urgency, budget, and transportation requirements.

Another factor influencing the shipping cost is the destination country and the distance from China. Shipping to nearby countries or regions may incur lower costs compared to long-haul destinations. Additionally, customs duties, taxes, and import regulations specific to the destination country should be considered when calculating the overall shipping cost.

To keep the shipping cost within budget, it is advisable to optimize the packaging of the Cummins engines. Using the right packaging materials and dimensions helps to reduce the overall weight and size of the shipment, potentially lowering shipping expenses.

Lastly, negotiating favorable shipping rates and terms with the selected carrier can also help control costs. Factors such as volume of shipments, established relationships, and competitive quotes can contribute to obtaining more cost-effective shipping rates.

Considering these factors, it is challenging to provide an exact shipping cost without specific details. Therefore, it is recommended to consult with a freight forwarder or shipping agent who can provide accurate cost estimates based on the specific requirements of importing Cummins engines from China.

Compare China and Other who makes cummins engines Markets: Products Quality and Price,Visible and Hidden Costs

China and other markets differ in various aspects when it comes to Cummins engines.

Products Quality: Cummins engines offered in China and other markets generally maintain the same level of quality, as the company upholds its global standards across all locations. Cummins is renowned for their reliable and durable engines, ensuring high performance and longevity in both markets.

Price: In terms of price, there might be slight variations between China and other markets due to factors like taxes and production costs. However, Cummins strives to maintain competitive pricing globally, offering engines at a reasonable cost in both China and other markets.

Visible and Hidden Costs: Visible costs comprise the visible expenses associated with purchasing Cummins engines, such as the initial purchase price and any additional services or features. These costs are generally consistent between China and other markets. However, hidden costs may vary due to factors like import and export duties or transportation expenses. These costs can differ between China and other markets based on local regulations and logistical factors.

It’s important to note that Cummins engines are commonly used globally in various applications, from automotive to industrial sectors. Thus, while markets like China may have particular requirements or regulations specific to their region, the overall quality and performance of Cummins engines remain consistent.

In conclusion, when comparing China and other markets for Cummins engines, the products’ quality and price tend to be similar, with slight variations in visible and hidden costs due to factors specific to each market. However, Cummins strives to maintain a standardized level of excellence and competitive pricing across all locations worldwide.

Understanding Pricing and Payment Terms for who makes cummins engines: A Comparative Guide to Get the Best Deal

When it comes to purchasing engines, particularly those made by Cummins, understanding pricing and payment terms is crucial in order to secure the best deal. This comparative guide aims to provide insights into effectively navigating the process, offering tips and considerations to keep in mind.

1. Research and Compare Prices: Begin by researching the current market prices for Cummins engines. This can be done online by visiting official Cummins websites, authorized dealers, and reputable third-party seller platforms. Take note of the different engine models, specifications, and associated pricing options.

2. Evaluate Your Needs: Determine the specific requirements for your engine. Consider factors such as power output, fuel efficiency, and intended use. This will help you identify the appropriate Cummins engine model that meets your needs, aiding in the negotiation phase.

3. Reach Out to Multiple Suppliers: Contact various Cummins engine suppliers, including authorized dealers and independent sellers, to obtain quotes. It’s important to request written quotes that outline the engine model, its specifications, and the offered price. This will help you make accurate comparisons.

4. Negotiate the Price: Once you have received multiple quotes, engage in negotiation to secure the best deal. Emphasize your knowledge of competing prices and demonstrate your willingness to explore other options if needed. This may encourage suppliers to provide more competitive pricing. Keep in mind that bargaining power may vary depending on factors such as the engine model’s demand and availability.

5. Consider Payment Terms: While negotiating the price, don’t overlook payment terms. Evaluate the suppliers’ offerings regarding down payments, installment plans, or bulk purchase discounts. Assessing these terms will enable you to determine the most viable payment option that aligns well with your financial capabilities.

6. Warranty and After-Sales Support: In addition to price and payment terms, consider warranty coverage and after-sales support. Cummins offers different warranty options, and it’s essential to understand what each supplier includes and the duration provided. Evaluate the supplier’s reputation for providing reliable after-sales support, including maintenance services and spare parts availability.

7. Seek Recommendations and Customer Feedback: To ensure a satisfactory purchasing experience, seek recommendations and read customer reviews. Engage with others who have purchased Cummins engines to gain valuable insights into their experiences with different suppliers. This information will offer a broader perspective and help inform your decision-making process.

By following this comparative guide, you can enhance your chances of obtaining the best deal for Cummins engines. Adequate research, evaluation of pricing and payment terms, and consideration of warranty and after-sales support will empower you to make an informed purchase and achieve optimum value for money.

Chinese Regulations and Industry Standards Certifications for who makes cummins engines,Import Regulations and Customs for who makes cummins engines from China

Chinese Regulations and Industry Standards Certifications for Cummins Engines:

In China, the production and distribution of Cummins engines need to comply with several regulations and industry standards certifications. These regulations are aimed at ensuring product quality, environmental protection, and safety. The main regulations and certifications include:

1. Quality Management System Certification (GB/T19001-2016/ISO 9001:2015): This certification ensures that the manufacturing processes and operations of Cummins engines meet international quality standards. It focuses on improving customer satisfaction, product quality, and continual improvement.

2. Environmental Management System Certification (GB/T24001-2016/ISO 14001:2015): This certification guarantees that the manufacturing facilities and operations of Cummins engines are environmentally friendly. It ensures compliance with laws and regulations concerning environmental protection, pollution prevention, and resource conservation.

3. Occupational Health and Safety Management System Certification (GB/T45001-2020/ISO 45001:2018): This certification emphasizes the health and safety of workers involved in the production of Cummins engines. It focuses on creating a safe working environment, improving accident prevention, and minimizing occupational hazards and risks.

Import Regulations and Customs for Cummins Engines from China:

When importing Cummins engines from China, several import regulations and customs procedures need to be followed. These regulations are designed to ensure smooth trade, proper documentation, and compliance with customs regulations. The key points to consider are:

1. Import Tariffs and Duties: The importing country may impose import tariffs and duties on Cummins engines from China. Importers must be aware of these charges and factor them into their cost calculations.

2. Custom Clearance: Importers need to complete the necessary customs clearance procedures to comply with local regulations. This involves providing accurate documentation, such as commercial invoices, packing lists, and airway bills or bill of lading, to customs authorities.

3. Product Inspection: Imported Cummins engines may be subject to product inspection by customs authorities to ensure compliance with technical regulations and safety standards. Random inspections may occur, and importers should be prepared to provide the necessary certifications and test reports.

4. Import Licensing: Some countries require importers to obtain specific import licenses or permits to bring in Cummins engines. Importers should check with their local authorities to determine if such licenses are required.

By adhering to these regulations and certifications, both the producer of Cummins engines in China and the importers can ensure smooth trade, compliance with local laws, and the delivery of high-quality products to the market.

Sustainability and Environmental Considerations in who makes cummins engines Manufacturing

Cummins, a global manufacturing company that specializes in diesel engines, recognizes the importance of sustainability and environmental considerations in its manufacturing processes. The company acknowledges that its operations can have a significant impact on the environment and seeks to minimize this impact through various initiatives.

One of the key focuses of Cummins’ sustainability efforts is reducing its carbon footprint. The company is committed to improving energy efficiency in its manufacturing facilities by implementing advanced technologies and practices. It invests in energy-efficient equipment, upgrades its infrastructure, and optimizes production processes to minimize energy consumption and greenhouse gas emissions. This not only helps Cummins meet its environmental goals but also results in cost savings for the company.

Cummins also strives to conserve water resources in its manufacturing operations. The company has implemented water management strategies, including the reuse and recycling of water, to reduce its water consumption. By employing innovative technologies, such as water-efficient fixtures and closed-loop cooling systems, Cummins aims to minimize its impact on freshwater resources and protect local ecosystems.

Waste reduction and proper disposal are also crucial aspects of Cummins’ sustainability approach. The company implements waste management practices that aim to minimize waste generation, promote recycling, and ensure proper treatment and disposal of hazardous materials. Cummins prioritizes the use of recycled or recyclable materials in its manufacturing processes and encourages suppliers to adopt similar practices.

To support sustainable mobility, Cummins is actively involved in the development of low-emission technologies and alternative fuel solutions. The company invests in research and development to create more efficient and environmentally friendly engine designs. By offering hybrid and electric power solutions, Cummins aims to reduce emissions and dependence on fossil fuels in various industries.

Cummins recognizes that sustainability is a continuous journey, and it continually seeks to improve its environmental performance. The company actively engages with stakeholders, including employees, customers, suppliers, and communities, to raise awareness and develop innovative solutions. By integrating sustainability and environmental considerations into its manufacturing processes, Cummins aims to create a positive impact on the environment and contribute to a more sustainable future.

List The Evolution history of “who makes cummins engines”

Cummins Inc., a prominent American manufacturer of diesel engines, has a rich history in the development of its engines. Originally founded in 1919 by Clessie Cummins and William Irwin, the company started as the Cummins Engine Company, primarily producing diesel engines for road vehicles.

In its early years, Cummins faced various challenges but managed to establish itself as a reputable engine manufacturer. Their engines gained recognition for their durability, fuel efficiency, and reliability. As the company grew, it gradually expanded into different market sectors, including construction, agriculture, and industrial applications.

In the 1930s, Cummins introduced engines for buses and trucks, solidifying its presence in the transportation industry. This marked the beginning of collaborations with renowned vehicle manufacturers such as Dodge, Mack Trucks, and Kenworth.

However, it wasn’t until 1988 that Cummins entered into a significant partnership with Chrysler Corporation (now the FCA US LLC). This collaboration led to Cummins engines being installed in Dodge Ram trucks, elevating the company’s status as a leading diesel engine supplier for pickup trucks. This partnership strengthened over the years, with Cummins engines becoming a popular choice among truck enthusiasts for their performance and fuel efficiency.

In recent years, Cummins has continued to evolve and diversify its range of engines. With the rise of environmental concerns, the company has focused on developing engines that meet stringent emissions standards. This led to the introduction of Cummins’ clean diesel technology, advanced aftertreatment systems, and the development of natural gas-powered engines.

Cummins has also embraced electrification and alternative power solutions. They launched their first fully electric commercial vehicle powertrain in 2017, showcasing their commitment to becoming a leader in electric mobility.

Throughout its evolution, Cummins has remained dedicated to innovation, quality, and providing solutions to meet the ever-changing needs of customers. The company’s engines have consistently earned a reputation for their performance, durability, and technological advancements, making Cummins a trusted brand in the global engine manufacturing industry.

The Evolution and Market Trends in who makes cummins engines Industry

Cummins Inc. is a globally recognized manufacturer of engines, power systems, and related technologies. It has been a key player in the industry for over a century, and its products have evolved significantly over time to meet changing market demands.

In the earlier years, Cummins primarily focused on producing diesel engines for the heavy-duty trucking sector. However, over time, the company expanded its product range to cater to diverse industries such as construction, mining, agriculture, and power generation. This diversification has allowed the company to mitigate market risks and tap into different segments, ensuring its sustained growth.

One notable evolution in the Cummins engine industry is the shift towards cleaner and more sustainable technologies. Stricter emission regulations and increasing environmental concerns have influenced market trends, leading Cummins to invest in research and development of alternative fuel options, such as natural gas and electric engines. Cummins’ commitment to environmental sustainability has not only positioned the company as an industry leader but also helped it cater to the evolving needs of customers who prioritize eco-friendly solutions.

Furthermore, Cummins has embraced digitalization and connectivity to meet the demands of a rapidly changing market. The integration of advanced technologies, such as telematics and data analytics, has enabled Cummins engines to be more efficient, reliable, and connected. This trend towards interconnectedness has simplified maintenance and improved overall performance, allowing customers to gain better insights into their operations while reducing downtime.

The market trends in the Cummins engine industry also reflect a growing demand for power solutions that support autonomous and electrified vehicles. With the advent of electric and hybrid technologies, there is an increasing focus on electrification in various transportation sectors. Cummins has responded to this trend by developing electric power systems and partnering with other industry leaders to deliver integrated solutions.

In conclusion, the Cummins engine industry has experienced significant evolution and market trends over the years. From its beginnings in diesel engines for heavy-duty trucks, Cummins has expanded its product range, diversified into different industries, and embraced sustainable technologies. The shift towards cleaner fuels, digitalization, and electrification reflects the changing demands of customers and environmental considerations. By adapting to these market trends, Cummins has maintained its industry leadership and continues to be a trusted provider of innovative engine solutions.

Custom Private Labeling and Branding Opportunities with Chinese who makes cummins engines Manufacturers

There are numerous custom private labeling and branding opportunities available with Chinese manufacturers who produce Cummins engines. These opportunities allow businesses to establish their own unique brand identity and cater to the specific needs and preferences of their target market.

Chinese manufacturers provide a range of services to facilitate private labeling and branding. These include customizing the design and packaging of the Cummins engines with the client’s logo, colors, and branding elements. This enables businesses to showcase their brand consistently across their product line and create a recognizable image in the market.

By collaborating with Chinese manufacturers, businesses can also access a vast pool of expertise in engine manufacturing. Chinese manufacturers have extensive experience in producing Cummins engines and can provide guidance on optimizing engine specifications to meet specific performance, efficiency, and emission requirements.

Additionally, partnering with Chinese manufacturers offers cost advantages. These manufacturers often have lower production costs compared to manufacturers in Western countries, allowing businesses to reduce their manufacturing expenses. This cost efficiency can be channeled towards marketing and promotional activities to strengthen brand positioning and increase market reach.

Furthermore, Chinese manufacturers can offer flexible minimum order quantities, allowing businesses of different sizes to engage in private labeling and branding. This flexibility provides opportunities for startups and small businesses to enter the market with their own branded Cummins engines without the need for significant upfront investments.

In conclusion, collaborating with Chinese manufacturers who produce Cummins engines presents a range of custom private labeling and branding opportunities. These opportunities allow businesses to establish their unique brand identity, access expertise in engine manufacturing, benefit from cost advantages, and cater to varied market demands.

Tips for Procurement and Considerations when Purchasing who makes cummins engines

When it comes to procurement and purchasing decisions involving Cummins engines, there are several tips and considerations to keep in mind. Cummins Inc., a global power leader, is renowned for manufacturing engines used in a wide range of applications, such as trucks, buses, generators, construction equipment, and marine vessels. Here are some essential tips to consider:

1. Identify your specific engine requirements: Determine the power, size, and any additional features you need for your intended application. Cummins offers a comprehensive line-up of engines, each designed for different purposes, so understanding your requirements is crucial.

2. Research Cummins engine models: Explore the various engine models available from Cummins. This includes engines from their different series, such as the X, L, B, and QSK series. Compare performance specifications, fuel efficiency, maintenance requirements, and emission controls to find the optimal fit.

3. Consider support and warranty: Evaluate the level of support and warranty provided by Cummins. Ensure that there are authorized service centers in your vicinity, knowledgeable technicians, and readily available spare parts to maintain and repair the engines effectively.

4. Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price and analyze the TCO. Consider maintenance costs, fuel efficiency, longevity, and potential future upgrades to make an informed decision. Cummins engines are known for their durability and fuel efficiency, positively impacting TCO.

5. Evaluate environmental considerations: Depending on your specific needs, consider the environmental impact of the engines. Cummins offers engines compliant with various emission standards, such as EPA, EU Stage V, and IMO Tier III, allowing you to meet regulatory requirements.

6. Engage in vendor selection: Research authorized Cummins dealers or distributors and evaluate their reputation, experience, and customer service. Choosing a reliable vendor ensures a smooth procurement process and ongoing support.

7. Obtain multiple quotes: Request quotes from multiple vendors to compare prices, warranty terms, and additional services offered. This allows you to negotiate favorable terms and achieve the best value for your investment.

By following these tips and considerations, you can make an informed procurement decision when purchasing Cummins engines. Remember to prioritize your specific requirements, long-term costs, and vendor support to ensure a successful investment in reliable and efficient power solutions.

FAQs on Sourcing and Manufacturing who makes cummins engines in China

Who makes Cummins engines in China?

Cummins is a leading manufacturer of diesel engines worldwide, and they have a presence in China as well. However, it is important to note that Cummins engines manufactured in China are not produced by Cummins Inc. directly, but rather through their joint venture with Dongfeng Motor Corporation. This joint venture is known as Dongfeng Cummins, and it was established in 1995.

Dongfeng Cummins is a 50-50 partnership between Cummins Inc. and Dongfeng Motor Corporation, which is one of China’s largest automotive manufacturers. The joint venture is responsible for the production and distribution of Cummins engines in China, catering to various industries such as automotive, construction, mining, power generation, and marine applications.

The manufacturing facilities of Dongfeng Cummins are located in several cities across China, including Wuhan, Chongqing, and Guangxi. These facilities are equipped with advanced production lines and adhere to Cummins’ global standards for quality and efficiency.

Dongfeng Cummins produces a wide range of engines, ranging from 2.8 to 11 liters in displacement, to meet different power requirements. These engines are used in various vehicles, including trucks, buses, and construction equipment, as well as in industrial applications and power generation.

Through the joint venture with Dongfeng Motor Corporation, Cummins has been able to tap into the rapidly growing Chinese market and strengthen its position as a leading engine manufacturer. It allows Cummins to provide localized products and support to their customers in China, ensuring they meet the specific needs of the region.

In summary, Cummins engines in China are manufactured by Dongfeng Cummins, a joint venture between Cummins Inc. and Dongfeng Motor Corporation. This partnership allows Cummins to leverage the capabilities of a local Chinese automotive manufacturer and cater to the demands of the Chinese market.

Why contact sourcifychina.com get free quota from reliable who makes cummins engines suppliers?

Sourcifychina.com can potentially receive a free quota from reliable Cummins engine suppliers for several reasons.

Firstly, Cummins is a renowned and trusted engine manufacturer globally, known for producing high-quality engines for various industries. As a result, Cummins suppliers are likely to have established relationships with Sourcifychina.com, recognizing the platform as a reliable sourcing partner.

Secondly, Sourcifychina.com may have collaborated with Cummins suppliers in the past, resulting in successful transactions and a strong track record of delivery and customer satisfaction. This history of successful partnerships builds trust among suppliers, making them more willing to provide Sourcifychina.com with a free quota as a gesture of goodwill.

Furthermore, if Sourcifychina.com has a significant volume of transactions or brings substantial business to Cummins suppliers, they may offer a free quota to maintain the mutually beneficial business relationship. The suppliers may view providing a free quota as a way to incentivize continued collaboration and ensure a steady stream of business from Sourcifychina.com.

Additionally, Sourcifychina.com might possess industry expertise and a broad network of buyers looking for Cummins engines. By connecting these buyers with Cummins suppliers, Sourcifychina.com helps suppliers expand their customer base and increase their sales. This mutually beneficial partnership motivates suppliers to grant the platform a free quota, as it ultimately enhances their business prospects.

It is important to note that the specific terms and conditions under which Sourcifychina.com receives a free quota from reliable Cummins engine suppliers may vary and depend on the individual agreements reached between the platform and the suppliers.