Introduce about wire winding machine guide,Qulity,Cost,Supplier,Certification,Market,Tips,FAQ

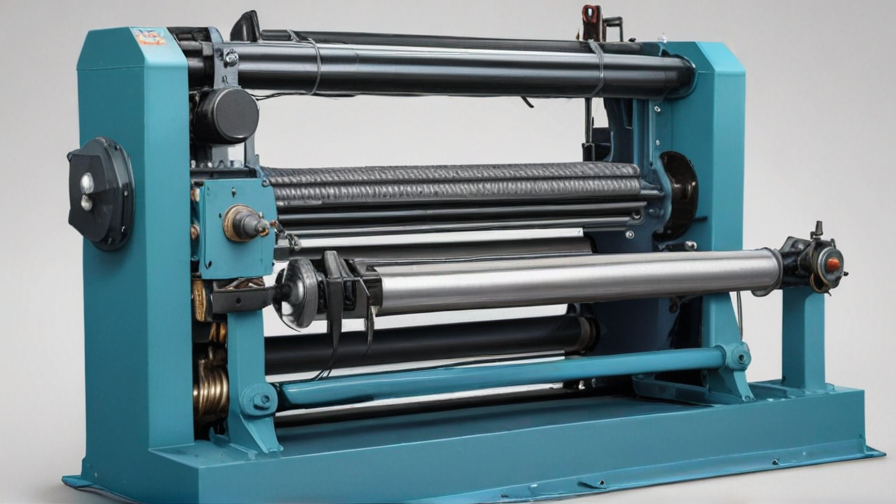

A wire winding machine guide provides valuable information about the operation, features, and benefits of wire winding machines. These machines are used to wind wires onto various types of spools or bobbins, providing convenient packaging and storage solutions for wire manufacturers.

Quality is a crucial factor when choosing a wire winding machine. High-quality machines ensure accurate and efficient wire winding, preventing tangling or damage to the wire. They also offer durability, ensuring a longer lifespan and reduced maintenance costs.

Cost is another important consideration. The price of wire winding machines varies based on factors such as capacity, automation, and additional functionalities. Buyers must carefully evaluate their requirements and budget to select the most suitable machine.

Finding a reliable supplier is paramount to acquiring a high-quality wire winding machine. It is essential to choose a supplier with vast experience in the industry, a strong reputation for delivering reliable products, and excellent customer service.

Certification is an important aspect when selecting a wire winding machine. Look for machines that comply with relevant industry standards. Certification ensures that the machine meets necessary safety and quality requirements, providing peace of mind to users.

The wire winding machine market is growing rapidly due to the increasing demand for wires in various industries like automotive, electronics, and telecommunications. As a result, manufacturers are introducing innovative and technologically advanced wire winding machines to meet market needs.

Tips for using wire winding machines include providing proper training to the operators, following the manufacturer’s guidelines for maintenance, and regularly inspecting the machines for any signs of wear or malfunction.

FAQs or frequently asked questions address common queries such as the operating procedure, maintenance, troubleshooting, and warranty-related concerns. These FAQs help users understand the machine better and resolve any issues they may encounter.

In conclusion, a wire winding machine guide covers various aspects such as quality, cost, suppliers, certification, market trends, usage tips, and FAQs. This information assists buyers in making informed decisions when purchasing a wire winding machine, ultimately enhancing productivity and efficiency in wire manufacturing processes.

Types of wire winding machine

Wire winding machines are essential tools used in various industries to wind wire onto spools or bobbins. These machines are designed to automate the wire winding process, increasing efficiency and accuracy. There are several types of wire winding machines available, each catering to specific needs and applications. Some of the commonly used types are:

1. Linear Winding Machines: Linear winding machines are the most basic type of wire winding machines. These machines consist of a rotating spindle onto which the wire is wound. Linear winding machines are ideal for winding thin and delicate wires used in industries like electronics and telecommunications.

2. Toroidal Winding Machines: Toroidal winding machines are used for winding wires onto toroidal cores. Toroidal cores are donut-shaped magnetic cores used in transformers and inductors. These machines have specialized chucks and winding heads specifically designed to wind wires onto toroidal cores.

3. Coil Winding Machines: Coil winding machines are used for winding wire onto cylindrical or bobbin-shaped cores. These machines are widely used in the electrical and electronics industry for manufacturing coils used in motors, transformers, and various other applications. Coil winding machines can be either manual or automatic, depending on the complexity of the winding process.

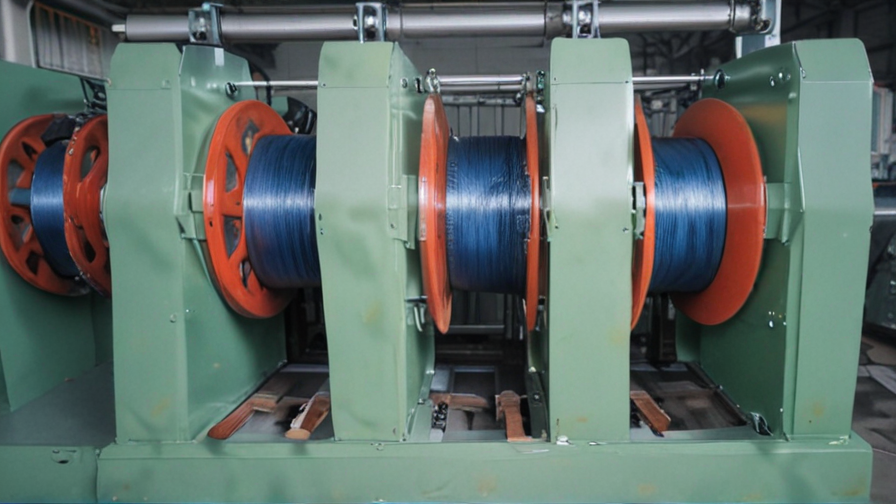

4. Drum Winding Machines: Drum winding machines are used for winding wire onto cylindrical drums or spools. These machines are commonly used in the wire and cable industry for manufacturing spools of electrical wire, cables, and cords. Drum winding machines can handle a wide range of wire diameters and can be customized to meet specific requirements.

5. Automatic Winding Machines: Automatic winding machines are advanced wire winding machines that offer higher productivity and precision. These machines are equipped with programmable logic controllers (PLCs) and various sensors for automated wire feeding, tension control, and speed regulation. Automatic winding machines are often used in high-volume production environments.

In conclusion, wire winding machines come in different types and configurations to accommodate various wire winding needs. Whether it is linear winding, toroidal winding, coil winding, drum winding, or automatic winding, each machine offers specific functionalities and advantages for different industries and applications. Selecting the right type of wire winding machine is crucial to ensure optimal performance and productivity in wire winding operations.

Pros and Cons of Using wire winding machine

Wire winding machines are used in various industries for the purpose of coiling or winding wires onto spools or bobbins. These machines offer numerous advantages, but they also have certain drawbacks that need to be considered. Here are the pros and cons of using wire winding machines:

Pros:

1. Increased efficiency: Wire winding machines are capable of winding wires at a much faster rate compared to manual winding. This results in increased productivity and reduced labor costs.

2. Consistent winding: These machines are designed to provide consistent tension and winding speed, ensuring uniformity in the coiling process. This leads to improved quality and reliability of the wound wire, reducing the occurrence of defects.

3. Precise wire control: Wire winding machines have controls that allow for precise adjustments of wire tension, traverse speed, and winding patterns. This level of control ensures the desired winding characteristics and prevents damage to the wire.

4. Reduction in operator fatigue: Manual winding of wires can be physically demanding and can lead to operator fatigue. Using wire winding machines eliminates the need for repetitive manual work, reducing the risk of injuries and improving worker morale.

5. Automatic operation: Many wire winding machines are equipped with automation features such as automatic start/stop, spool changeover, and tension control. This makes the operation more convenient and reduces the need for constant supervision.

Cons:

1. Initial investment: Wire winding machines can be expensive to purchase and install, especially for small businesses or start-ups. The cost of maintenance and repair should also be considered.

2. Limited flexibility: These machines are designed for specific wire sizes and types. Switching between different wire sizes may require reconfiguration or additional equipment, limiting the versatility of the machine.

3. Skill requirement: Operating and maintaining wire winding machines may require specialized training and expertise. This can increase the upfront costs and lead to additional training needs for the workforce.

4. Size limitations: Some wire winding machines have size limitations in terms of the maximum spool diameter they can accommodate. This can restrict the application of the machine for larger wire spools.

5. Susceptible to mechanical issues: Like any machinery, wire winding machines are prone to mechanical malfunctions or breakdowns. Regular maintenance and prompt repair are essential to minimize production downtime.

In summary, wire winding machines offer increased efficiency, consistent winding, precise wire control, reduced operator fatigue, and automation benefits. However, the initial investment, limited flexibility, skill requirement, size limitations, and potential mechanical issues should be carefully considered before investing in a wire winding machine.

wire winding machine Reference Specifications (varies for different product)

The wire winding machine is a highly efficient and automated equipment used in various industries for winding wires onto spools or bobbins. It is designed to provide precise and accurate results while ensuring high productivity.

The reference specifications of the wire winding machine may vary depending on the specific product and application. However, some common specifications include a wire diameter range, spool dimensions, winding speed, and motor power.

The wire diameter range determines the range of wire thickness that the machine can efficiently wind. It typically varies from a few millimeters to several centimeters, depending on the machine’s capabilities. The spool dimensions, such as length and width, ensure compatibility with the machine and facilitate uniform winding of wires.

Winding speed is an essential specification that determines the productivity of the machine. It refers to the rate at which the wires are wound onto the spool and is typically expressed in meters per minute. Higher winding speeds result in faster production rates.

Motor power is another critical specification that defines the machine’s capability to wind wires efficiently. It is measured in watts or horsepower and determines the machine’s strength to overcome resistance while winding wires.

The wire winding machine may also incorporate additional features such as tension control systems, programmable logic controllers (PLCs), and electronic counters. Tension control systems ensure consistent and uniform tension while winding the wire, resulting in high-quality wound spools. PLCs enable easy operation and control of the machine, allowing for customization of winding parameters. Electronic counters track the number of wound turns or the length of the wound wire, ensuring accurate measurements and batch control.

It is essential for manufacturers to select a wire winding machine that meets their specific requirements, taking into consideration the reference specifications mentioned above. By choosing the right machine, they can achieve increased productivity, reduced labor costs, and improved product quality.

Applications of wire winding machine

Wire winding machines are essential tools used in various industries for the efficient and precise winding of wires onto different types of spools or cores. These machines offer numerous benefits and are widely used in applications such as:

1. Electrical and Electronics Industry: The wire winding machines are extensively used in the electrical and electronics industry for the production of transformers, inductors, motors, and coils. These machines ensure accurate winding of copper or aluminum wires onto the cores, improving the overall electrical performance and efficiency of the components.

2. Automotive Industry: Wire winding machines play a crucial role in the automotive industry for manufacturing various automotive parts such as solenoids, ignition coils, sensors, and actuators. These machines ensure consistent winding tension, precise turns counting, and uniform wire distribution, which are crucial for the optimal functioning of these components.

3. Medical Device Manufacturing: Wire winding machines are utilized in the production of medical devices such as pacemakers, defibrillators, and catheters. These machines enable the precise winding of fine and delicate wires, ensuring product reliability and accuracy in medical applications where precision is of utmost importance.

4. Communication and Telecom Industry: Wire winding machines are used in the production of communication equipment like antennas, connectors, and cables. These machines guarantee uniform winding of wire onto the spools or bobbins, enabling the seamless transmission of signals and improving the overall performance of communication devices.

5. Renewable Energy Sector: In the renewable energy sector, wire winding machines find applications in the production of wind turbines and solar panels. These machines allow for consistent winding of wire onto the cores, maximizing the energy conversion efficiency and reliability of these sustainable energy systems.

6. Textile Industry: Wire winding machines are also utilized in the textile industry for the production of textile cones, bobbins, and spools used in spinning, weaving, and knitting operations. These machines ensure efficient winding of yarn, thread, or filament onto the spools, making them ready for further processing.

In summary, wire winding machines have a wide range of applications in various industries, including electrical and electronics, automotive, medical, communication, renewable energy, and textile. These machines ensure precise winding of wire onto different types of cores or spools, improving product quality, performance, and efficiency while reducing production time and labor costs.

The Work Process and how to use wire winding machine

The work process of a wire winding machine involves several steps to convert raw wire into wound spools. Here is a step-by-step guide on how to use a wire winding machine efficiently:

1. Set up the machine: Ensure that the machine is properly installed, connected to the power supply, and all safety guards are correctly positioned. Adjust the tension, speed, and direction settings according to your requirements.

2. Prepare the wire: Straighten the wire if required and cut it to the desired length. Make sure the wire is free of knots or tangles, as it can affect the winding process.

3. Load the wire: Align the wire with the machine’s guide roller or entrance mechanism. Feeding the wire correctly into the machine is crucial to ensure smooth and even winding.

4. Start the machine: Turn on the power and activate the machine. The wire will start winding around the spool as per the predefined settings. Monitor the process carefully to ensure seamless operation.

5. Adjust settings: If necessary, modify the tension, speed, or direction settings during the winding process to achieve the desired results. However, avoid frequent adjustments that might disrupt the winding consistency.

6. Maintain machine and inspect winding: Regularly clean and lubricate machine parts as per the manufacturer’s instructions to maintain optimal performance. Additionally, periodically inspect the wound spools for any defects or irregularities.

7. Finishing and unloading: Once the desired length or quantity of wire has been wound onto the spool, stop the machine. Carefully remove the spool or reel from the machine, ensuring not to damage the wire or disrupt the winding.

Using a wire winding machine with efficiency requires proper training and understanding of the machine’s functionality. Always adhere to the manufacturer’s guidelines, conduct routine maintenance, and prioritize safety precautions to ensure smooth and uninterrupted operation.

Quality Testing Methods for wire winding machine and how to control the quality

When it comes to quality testing methods for wire winding machines, there are several approaches that can be taken to ensure a high level of quality control. These methods focus on testing the different aspects of the machine and its output to identify any potential defects or issues. Here are some common quality testing methods for wire winding machines:

1. Visual Inspection: A visual inspection is the simplest method of quality testing, which involves visually examining the machine to check for any physical defects, such as loose wires, damaged components, or misaligned parts. This can be done during the manufacturing process and also during routine maintenance.

2. Performance Testing: Performance testing assesses the machine’s ability to wind wires efficiently and accurately. This can be done by running the machine and measuring key performance parameters, such as winding speed, wire tension, and the uniformity of the winding pattern. Any deviations from the desired values indicate a potential quality issue.

3. Electrical Testing: Wire winding machines often involve electrical components, such as motors, sensors, and controllers. Electrical testing involves measuring the electrical parameters, such as voltage, current, and resistance, to ensure the proper functioning of these components. Additionally, insulation resistance testing can be performed to identify any potential electrical faults.

4. Dimensional Measurement: Wire winding machines are designed to wind wires of specific dimensions. Dimensional measurement involves using precision instruments, such as calipers or micrometers, to measure the diameter and length of the wound wire. Any deviations from the desired dimensions can indicate a quality problem.

To control the quality of wire winding machines, it is important to establish thorough quality control procedures. This includes implementing regular inspections and testing during different stages of the manufacturing process, periodic maintenance, and final product testing. Additionally, continuous monitoring and analysis of quality data can help identify any recurring issues or patterns that require corrective actions. It is also crucial to provide comprehensive training to machine operators and maintenance staff to ensure the proper operation and maintenance of the equipment.

In conclusion, quality testing methods for wire winding machines encompass visual inspection, performance testing, electrical testing, and dimensional measurement. By implementing these methods and establishing strict quality control procedures, manufacturers can ensure that their wire winding machines meet the desired quality standards.

wire winding machine Sample Policy and Post-Purchase Considerations for wire winding machine from China

Sample Policy:

1. Product Sample: Before placing a bulk order, it is advisable to request a product sample from the wire winding machine manufacturer in China. This allows you to assess the quality, functionality, and compatibility of the machine with your specific requirements.

2. Product Specifications: Carefully review the product specifications provided by the manufacturer to ensure that the wire winding machine meets all your desired criteria, such as wire diameter range, winding speed, tension control, and other relevant features.

3. Customization Options: Inquire about the possibility of customizing the wire winding machine according to your specific needs. You may need modifications in terms of dimensions, power supply, control system, or any other unique requirements. Discuss the possibility, additional costs, and timeframe for customization.

4. Pricing and Payment Terms: Request a detailed quotation from the manufacturer, including the price per unit, shipping costs, and any applicable taxes or duties. Clarify the payment terms, such as the accepted payment methods, down payment, installment plans, or any other conditions related to payment.

5. Quality Assurance: Ensure that the manufacturer offers a warranty or guarantee on their wire winding machines. In case of any defects or malfunctions within the specified warranty period, it is crucial to know the provisions for repair, replacement, or refund.

Post-Purchase Considerations:

1. Installation and Commissioning: Before operating the wire winding machine, make sure to read and understand the user manual provided by the manufacturer. If necessary, seek technical assistance from the manufacturer to ensure proper installation and commissioning of the machine.

2. Training and Technical Support: Inquire about the availability of training sessions or user support provided by the manufacturer. This can be in the form of online tutorials, instructional videos, or on-site training. It is important to have competent personnel who can effectively operate and maintain the wire winding machine.

3. Spare Parts and Maintenance: Discuss the availability, cost, and lead time for spare parts with the manufacturer. Regular maintenance of the wire winding machine is essential to ensure optimal performance and longevity. Inquire about the recommended maintenance schedule and procedures.

4. Customer Support: Ensure that the manufacturer provides reliable and responsive customer support. In case of any technical issues or queries, it is crucial to have a prompt response from the manufacturer to minimize downtime and disruptions in production.

5. Feedback and Recommendations: Provide feedback to the manufacturer regarding the performance, durability, and any suggestions for improvement of the wire winding machine. This can help the manufacturer enhance their product quality and better understand their customers’ needs.

By following these sample policies and post-purchase considerations, you can navigate your wire winding machine purchase from China more effectively and maximize the benefits of your investment.

Sourcing wire winding machine from China: Opportunities, Risks, and Key Players

Sourcing wire winding machines from China offers several opportunities for businesses looking to expand their operations. China has a well-established manufacturing industry, and there is a wide range of suppliers offering wire winding machines of various types and specifications. These machines are essential for industries such as electronics, automotive, telecommunications, and energy, making them a vital investment for companies operating in these sectors.

One of the most significant opportunities of sourcing wire winding machines from China is cost-effectiveness. Chinese manufacturers often offer competitive prices due to low labor costs and economies of scale. This can help businesses reduce their production costs and increase profitability. Additionally, Chinese suppliers have the capacity to mass-produce wire winding machines quickly, allowing companies to meet increasing market demand.

However, there are certain risks associated with sourcing from China. Quality control can be a concern, as not all suppliers adhere to the same standards. It is crucial to thoroughly research potential manufacturers and conduct quality checks to ensure product quality meets the required standards. Communication and language barriers can also pose challenges, so effective communication channels and clear specifications are essential.

Several key players dominate the wire winding machine industry in China. Some of the prominent manufacturers include SAMP S.p.A, Zhongda Industrial Group, Zhejiang Great Wall Electrical Co. Ltd., and Shanghai Leojiu Machinery Co. Ltd. These companies have a strong presence in the market and offer a diverse range of wire winding machines with different features and capabilities.

In conclusion, sourcing wire winding machines from China presents opportunities for cost savings and access to a wide range of suppliers. However, businesses should carefully assess the risks associated with quality control and communication barriers. By partnering with reputable manufacturers, businesses can navigate these risks and benefit from the competitive advantages offered by Chinese suppliers.

How to find and select reliable wire winding machine manufacturers in China,use google search manufacturers and suppliers

When searching for reliable wire winding machine manufacturers in China, Google search can be an effective tool to find and select the right supplier. Here are some steps you can take:

1. Start by typing relevant keywords into the Google search bar, such as “wire winding machine manufacturers in China” or “reliable wire winding machine suppliers in China.”

2. Go through the search results and explore the websites of different manufacturers. Look for well-established companies with a strong online presence, as this indicates credibility.

3. Check the company’s website for information about their manufacturing capabilities, production processes, and product quality. Look for certifications like ISO 9001, which signifies adherence to international standards.

4. Look for customer reviews and testimonials on the manufacturer’s website or third-party review platforms. Positive feedback from previous customers is a good indicator of reliability.

5. Verify the manufacturer’s experience in producing wire winding machines and their specialization in this field. Specialized manufacturers are more likely to provide better quality products and after-sales service.

6. Contact the shortlisted manufacturers and inquire about their products, pricing, customization options, and any other requirements you may have. Prompt and transparent communication is important when dealing with manufacturers.

7. Ask for samples or visit the manufacturer’s factory if possible. This will help you assess the quality of their wire winding machines firsthand.

8. Consider sourcing from manufacturers located in industrial clusters or regions known for their expertise in manufacturing wire winding machines. Examples include Guangdong, Zhejiang, and Jiangsu provinces in China.

9. Request references from the manufacturer and contact their existing customers to get their feedback on product quality, delivery times, and overall satisfaction.

10. Don’t solely focus on price; prioritize quality, reliability, and reputation when selecting a manufacturer. Cheaper options may sometimes compromise on quality and after-sales support.

By following these steps and conducting thorough research, you can find and select reliable wire winding machine manufacturers in China using Google search.

How to check wire winding machine manufacturers website reliable,use google chrome SEOquake check if ranking in top 10M

To check the reliability of a wire winding machine manufacturer’s website, you can follow these steps:

1. Use Google Chrome: Open the manufacturer’s website using Google Chrome browser. It provides various useful extensions and tools for website analysis.

2. Install SEOquake: Install the SEOquake extension from the Chrome Web Store. This tool helps you assess the search engine optimization (SEO) metrics of a website.

3. Check Ranking: Once installed, SEOquake will display a toolbar at the top of your browser. Type the manufacturer’s website URL in the address bar and press Enter. It will show you a summary of the website’s SEO metrics along with its ranking.

4. Top 10M Ranking: Look for the website’s ranking in the top 10 million (10M) as a higher ranking indicates more popularity and visibility. If the manufacturer’s website is ranked within the top 10M, it generally suggests that the website is reliable and has a significant online presence.

5. Additional Assessments: While SEOquake’s ranking provides a good initial assessment, it is also essential to consider other factors to evaluate a website’s reliability. Check for security indicators like an SSL certificate, professional design, clear contact information, customer reviews, certifications, product information, and any relevant industry affiliations.

6. Keep Word Count Limited: When sharing the process or results, try to keep the explanation concise within a word limit of 300 words to focus on the essential steps and details.

By utilizing Google Chrome and SEOquake, you can quickly check the ranking of a wire winding machine manufacturer’s website and determine its reliability.

Top 10 wire winding machine manufacturers in China with each 160 words introduce products,then use markdown create table compare

1. Sampsistemi S.r.l: Sampsistemi produces a range of wire winding machines suitable for various applications. Their machines are highly efficient, ensuring precise winding and tension control. They offer a wide range of wire winding machines, including single spindle, double spindle, and multi-spindle models.

2. Xiamen Hiprecise Technology Co., Ltd: Xiamen Hiprecise specializes in the production of precision wire winding machines. Their machines feature advanced control systems, high-speed winding capabilities, and automatic tension adjustment. They offer both manual and fully automated wire winding machines.

3. Wenzhou Yibo Automation Equipment Co., Ltd: Yibo Automation is a leading manufacturer of wire winding machines in China. Their machines are known for their high precision and reliability. They provide a range of wire winding machines suitable for different wire diameters and lengths.

4. Suzhou Crown Electronic Technology Co., Ltd: Crown Electronic Technology offers a wide range of wire winding machines designed for various industries, including electronics, automotive, and telecommunications. Their machines are highly efficient, ensuring consistent winding quality and high productivity.

5. Hangzhou Juli Insulation Co., Ltd: Juli Insulation specializes in the production of wire winding machines for the electrical industry. Their machines are designed to handle different wire types and sizes. They provide customized solutions to meet specific customer requirements.

6. Jiangsu Bozhiwang Automation Equipment Co., Ltd: Bozhiwang Automation is a renowned manufacturer of wire winding machines in China. Their machines are known for their high-speed winding capabilities and precision. They offer a range of different models suitable for various applications.

7. Dongguan Gemyoung Wire & Cable Equipment Co., Ltd: Gemyoung Wire & Cable Equipment is a leading manufacturer of wire winding machines in China. Their machines are designed for high-speed and high-volume winding. They provide solutions for both manual and automatic wire winding.

8. Shenzhen Fortune Sky Technology Co., Ltd: Fortune Sky Technology specializes in the production of wire winding machines for the electronics industry. Their machines feature advanced control systems and precise tension control. They offer a range of different models to cater to different customer needs.

9. Dongguan Xiehui Electronic Equipment Co., Ltd: Xiehui Electronic Equipment manufactures wire winding machines for the electronics and electrical industries. Their machines are known for their high precision winding and automatic wire feeding capabilities. They offer both manual and fully automated wire winding solutions.

10. Hangzhou Panun Electric Development Co., Ltd: Panun Electric Development produces a range of wire winding machines suitable for various winding applications. Their machines are known for their high productivity, reliability, and easy operation. They provide customized solutions to meet specific customer requirements.

| **Manufacture** | **Product Range** | **Key Features** |

|————————————–|—————————————–|——————————————|

| Sampsistemi S.r.l | Single spindle, double spindle, multi-spindle | Efficient, precise winding and tension control |

| Xiamen Hiprecise Technology Co., Ltd | Precision wire winding machines | Advanced control systems, high-speed winding |

| Wenzhou Yibo Automation Equipment Co., Ltd | Wire winding machines | High precision and reliability |

| Suzhou Crown Electronic Technology Co., Ltd | Wire winding machines | Consistent winding quality, high productivity |

| Hangzhou Juli Insulation Co., Ltd | Wire winding machines for electrical industry | Handling different wire types and sizes |

| Jiangsu Bozhiwang Automation Equipment Co., Ltd | Wire winding machines | High-speed winding, precision |

| Dongguan Gemyoung Wire & Cable Equipment Co., Ltd | Wire winding machines | High-speed, high-volume winding |

| Shenzhen Fortune Sky Technology Co., Ltd | Wire winding machines for electronics industry | Advanced control systems, precise tension control |

| Dongguan Xiehui Electronic Equipment Co., Ltd | Wire winding machines for electronics industry | High precision, automatic wire feeding |

| Hangzhou Panun Electric Development Co., Ltd | Wire winding machines | High productivity, reliability |

Background Research for wire winding machine manufacturers Companies in China, use qcc.com archive.org importyeti.com

When searching for wire winding machine manufacturers in China, several websites can be utilized to gather background research. Three websites that can provide valuable information are qcc.com, archive.org, and importyeti.com.

QCC.com is a Chinese business directory and search engine platform. It offers comprehensive information on various companies, including contact details, business scope, and history. By searching for wire winding machine manufacturers on qcc.com, one can identify potential companies in China and gather basic information about them.

Archive.org, also known as the Wayback Machine, is a digital library of internet sites and other cultural artifacts. It enables users to access archived versions of websites, allowing for historical research. By using archive.org, one can track the development and changes in a manufacturer’s website over time. This can provide insights into the company’s growth, innovation, and product offerings.

Importyeti.com is an import-export trade data website. It provides information on shipments, importers, suppliers, and manufacturers involved in international trade. By using importyeti.com, one can obtain data on the export activities of wire winding machine manufacturers in China. This data includes shipment details, such as the destination country, quantity, and value of products exported. Such information can be beneficial in assessing the manufacturer’s market presence and international business activities.

By utilizing qcc.com, archive.org, and importyeti.com, researchers can gather comprehensive background information on wire winding machine manufacturers in China. This information can include company details, historical website data, and export activities, aiding in the evaluation and selection of potential manufacturers.

Leveraging Trade Shows and Expos for wire winding machine Sourcing in China

Trade shows and expos provide valuable opportunities for sourcing wire winding machines in China. These events are specifically designed to bring together industry professionals, suppliers, and manufacturers, making them an ideal platform for anyone looking to find reliable sourcing partners in the wire winding machine industry.

Attending trade shows and expos allows buyers to interact directly with suppliers and manufacturers, providing an opportunity to physically examine the products, compare different options, and negotiate prices. It also enables buyers to gain insight into the latest trends, technologies, and innovations in the industry, ensuring that they stay up to date with the most advanced wire winding machines available in the market.

China is the manufacturing hub for wire winding machines, hosting numerous trade shows and expos related to the industry. Some notable events include the China International Industry Fair, China Import and Export Fair, and the Shanghai Intelligent Factory Exhibition. These exhibitions attract a large number of domestic and international suppliers, providing buyers with access to a wide range of products and services.

To leverage trade shows and expos effectively, buyers should prepare in advance by researching the exhibitors and identifying the ones that specialize in wire winding machines. They can then schedule meetings with these companies to discuss their specific requirements and evaluate their suitability as sourcing partners. Additionally, buyers should utilize these events to network with industry professionals and gather valuable market intelligence that can inform their sourcing decisions.

Trade shows and expos offer a unique opportunity to establish personal connections with suppliers, ensuring a higher level of trust and transparency in the sourcing process. It is essential to maintain open communication channels and develop strong relationships with potential suppliers to establish a long-term partnership for sourcing wire winding machines from China.

In conclusion, trade shows and expos in China are an effective tool for sourcing wire winding machines. By leveraging these events, buyers can access a wide range of suppliers, gather market intelligence, and establish personal connections with potential sourcing partners, ensuring successful and efficient sourcing operations.

The Role of Agents and Sourcing Companies in Facilitating wire winding machine Purchases from China

Agents and sourcing companies play a crucial role in facilitating wire winding machine purchases from China. These intermediaries act as a bridge between buyers and manufacturers, streamlining the sourcing process and ensuring a smooth transaction.

First and foremost, agents and sourcing companies have extensive knowledge of the Chinese market, including its manufacturing capabilities, product quality, and current industry trends. This expertise enables them to identify reliable and reputable manufacturers that produce wire winding machines to meet the buyer’s specific requirements. Their established networks and relationships with manufacturers also provide access to a diverse range of options, ensuring buyers can find the most suitable machine for their needs.

Furthermore, agents and sourcing companies conduct thorough due diligence on behalf of the buyer. They thoroughly vet manufacturers, assessing their production capabilities, quality control processes, certifications, and compliance with relevant regulations. This evaluation minimizes the risk of working with subpar manufacturers and ensures that the purchased wire winding machine meets industry standards and specifications.

Agents and sourcing companies also assist with the negotiation and contracting process. They have a comprehensive understanding of pricing structures, trade terms, and legal requirements, enabling them to secure favorable terms and conditions for the buyer. They also handle the logistics and shipping arrangements, making sure the machine is safely transported from China to the buyer’s location.

Throughout the purchasing process, these intermediaries act as a point of communication between the buyer and the manufacturer. They facilitate effective communication, ensuring that both parties clearly understand each other’s requirements and expectations. This avoids misunderstandings and minimizes the likelihood of delays or issues during the manufacturing and delivery stages.

Overall, agents and sourcing companies play a vital role in facilitating wire winding machine purchases from China. Their market knowledge, due diligence, negotiation skills, and logistical support streamline the sourcing process, providing buyers with a hassle-free and efficient experience. By engaging these intermediaries, buyers can confidently source high-quality wire winding machines from trusted Chinese manufacturers.

Price Cost Research for wire winding machine manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for wire winding machine manufacturers in China, two reliable sources to consider are temu.com and 1688.com. These platforms offer a vast array of manufacturers and suppliers, making it easier to compare prices and gather cost-related information. Here is a summary within 300 words:

Temu.com is an online marketplace that specializes in providing industrial machinery and equipment. It features numerous wire winding machine manufacturers in China, offering a wide range of options to choose from. By utilizing the search filters and categories provided on the website, users can narrow down their search based on specific requirements such as machine capacity, features, and price range. The platform also offers detailed product descriptions, customer reviews, and ratings, providing buyers with valuable insights into the quality and performance of different manufacturers.

1688.com, on the other hand, is a leading wholesale platform owned by Alibaba Group. It connects international buyers with Chinese suppliers and manufacturers, including those specializing in wire winding machines. The platform is user-friendly and enables users to directly communicate with manufacturers, negotiate prices, and request customized quotes. By analyzing the wide range of options available on 1688.com, buyers can gain a comprehensive understanding of the industry’s price range and factors affecting the cost, such as machine specifications, technology used, and manufacturing capabilities.

To conduct price cost research effectively, it is important to note that wire winding machines’ prices can vary significantly based on various factors. These factors include machine type (automatic or semi-automatic), capacity, speed, accuracy, durability, and additional features. Additionally, factors like order quantity, customization requirements, and shipping costs need to be considered.

By utilizing temu.com and 1688.com, buyers can compare prices, read reviews, and communicate directly with manufacturers. Further negotiation and discussions on these platforms can help buyers understand the cost breakdown, including factors like raw material cost, labor cost, and profit margins.

In conclusion, conducting price cost research for wire winding machine manufacturers in China can be done effectively by using temu.com and 1688.com. These platforms provide a wide variety of manufacturers, detailed product descriptions, customer reviews, and the ability to communicate directly with suppliers. By considering factors such as machine specifications, customization requirements, and shipping costs, buyers can gather the necessary information to make informed purchasing decisions within their budget.

Shipping Cost for wire winding machine import from China

The shipping cost for importing a wire winding machine from China can vary depending on various factors such as the size, weight, mode of transportation, and destination. Typically, there are two main methods of shipping: sea freight and air freight.

For sea freight, which is usually the most cost-effective option for larger and heavier machinery, the shipping cost can range from $800 to $5000. This cost includes various charges such as handling fees, customs clearance, and transportation from the factory to the port. However, it’s important to note that additional charges like import duties and taxes may apply upon arrival at the destination port.

Alternatively, air freight is a faster but more expensive option. The shipping cost for air freight can range from $2000 to $10,000 depending on the weight and destination. While air freight may be more costly, it saves time and reduces the risk of damage during transit.

It’s crucial to consider additional expenses such as insurance, packaging, and local transportation upon arrival. Import duties and taxes should also be taken into account, as they can significantly add to the overall cost.

To ensure accurate cost estimation, it is recommended to consult with shipping agents or freight forwarders who can provide a detailed quote based on the specific requirements of the wire winding machine and the desired delivery destination.

Overall, when importing a wire winding machine from China, it is essential to carefully assess the shipping costs and choose a method that aligns with the budget and timeline while also taking into consideration any additional charges that may arise during the customs clearance process.

Compare China and Other wire winding machine Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the largest wire winding machine markets in the world, and as such, it is important to compare it with other markets in terms of product quality and price, as well as visible and hidden costs.

In terms of product quality, China is known for manufacturing a wide range of wire winding machines, catering to diverse industrial needs. These machines are often produced with advanced technology and adhere to strict quality control measures. However, the quality of Chinese machines can vary greatly depending on the manufacturer and price. It is essential to consider the reputation and track record of the manufacturer to ensure a high-quality product.

When it comes to price, China has a competitive advantage due to its large manufacturing capabilities and lower labor costs. Chinese wire winding machines are generally more affordable compared to those produced in other markets like Europe or North America. This pricing advantage has made China a popular choice for businesses looking for cost-effective solutions.

Visible costs, such as the initial purchase price of a wire winding machine, are generally transparent and straightforward. Chinese manufacturers often offer competitive prices without compromising quality. However, it is crucial to consider hidden costs, such as shipping, import duties, and taxes, when sourcing machines from China. These additional costs can significantly impact the overall price and should be carefully considered during the decision-making process.

Furthermore, other wire winding machine markets may have their own set of visible and hidden costs. For instance, machines produced in Western countries may have higher visible costs due to higher labor and manufacturing expenses. However, these markets may have more transparent pricing, and hidden costs like shipping and import duties could be relatively lower.

In conclusion, China’s wire winding machine market offers a wide range of products with varying quality and price options. It is important to thoroughly assess the reputation and track record of manufacturers to ensure high-quality machines. While China provides competitive prices, hidden costs such as shipping and import duties need to be considered. Other markets may have higher visible costs but lower hidden costs. Choosing the right market ultimately depends on a company’s specific needs, budget constraints, and preferences for visible versus hidden costs.

Understanding Pricing and Payment Terms for wire winding machine: A Comparative Guide to Get the Best Deal

When looking to purchase a wire winding machine, understanding the pricing and payment terms is crucial to ensure you get the best deal possible. This comparative guide aims to provide insights into these aspects, helping you make an informed decision within 300 words or less.

Pricing for wire winding machines can vary significantly based on factors such as brand reputation, machine specifications, and additional features. It is advisable to research multiple suppliers and compare their prices to identify the most competitive offer. Consider the specific requirements of your business and find a machine that meets your needs without unnecessary add-ons, which can drive up the price.

Payment terms will also affect your overall investment. Some suppliers may offer flexible options such as installment payments or leasing, which can alleviate the burden of a lump-sum payment. Evaluate the long-term financial implications of each payment term and choose an arrangement that suits your budget and cash flow.

It is essential to consider the total cost of ownership (TCO) while evaluating pricing and payment terms. A machine with a higher upfront cost may have lower maintenance and operational expenses, resulting in a lower TCO over time. Ensure you assess not only the immediate expenses but also the long-term savings and maintenance requirements when making your decision.

Additionally, consider the warranty and after-sales support offered by different suppliers. A reliable supplier should provide a comprehensive warranty that covers any manufacturing defects or malfunctions. Prompt and accessible customer support is equally important to address any issues that may arise during the machine’s operation. Consider the reputation and customer reviews of suppliers in terms of service quality and responsiveness.

Furthermore, consult industry experts or seek recommendations from other businesses in your field. Their experiences and insights can help you find the best deal, enabling you to invest in a wire winding machine that offers optimal performance and value for money.

In conclusion, understanding the pricing and payment terms for wire winding machines is essential to get the best deal. Compare prices from different suppliers, consider flexible payment options, evaluate the TCO, and assess warranty and after-sales support. By employing these strategies and conducting thorough research, you can make an informed decision to ensure a successful investment in a wire winding machine.

Chinese Regulations and Industry Standards Certifications for wire winding machine,Import Regulations and Customs for wire winding machine from China

Chinese Regulations and Industry Standards Certifications for wire winding machine:

In China, wire winding machines are subject to certain regulations and industry standards certifications to ensure product quality, safety, and compliance with national and international standards. These regulations and certifications include:

1. China Compulsory Certification (CCC): This certification is mandatory for wire winding machines sold in the Chinese market. It ensures that the products meet specified safety, performance, and quality requirements.

2. GB/T (Guobiao) Standards: These are national standards established by the Standardization Administration of China (SAC) that define the technical requirements, test methods, and acceptance criteria for wire winding machines. Compliance with GB/T standards is crucial for manufacturers to meet the national product quality requirements.

3. ISO Certifications: ISO 9001 certification demonstrates that the manufacturer has implemented a quality management system that ensures consistent quality and continuous improvement. ISO 14001 certification indicates compliance with environmental management standards.

4. CE Marking: Although not mandatory in China, CE marking is essential for exporting wire winding machines to the European Union (EU) and demonstrates compliance with EU health, safety, and environmental protection standards.

Import Regulations and Customs for wire winding machine from China:

When importing wire winding machines from China, importers need to comply with certain regulations and customs procedures. Here are some key points to consider:

1. Import License/Registration: Depending on the destination country, importers may need to obtain an import license or register with the relevant authorities before importing wire winding machines from China. These licenses/registrations are aimed at monitoring imports and ensuring compliance with safety and quality standards.

2. Customs Duties and Taxes: Importers should be aware of the customs duties, taxes, and tariffs imposed by their respective countries. These charges vary depending on the product classification, customs valuation, and origin.

3. Import Documentation: The required import documentation may include the commercial invoice, packing list, bill of lading/airway bill, and certificates of origin and conformity. These documents provide proof of purchase, product details, shipping information, and compliance with regulations.

4. Customs Clearance: Importers should work with a licensed customs broker or agent to handle the customs clearance process. This involves presenting the required documentation, paying customs duties and taxes, and inspections, if applicable.

It is important for importers to stay updated with the latest regulations and import procedures in their respective countries and consult with customs authorities or professionals for specific requirements related to the import of wire winding machines from China.

Sustainability and Environmental Considerations in wire winding machine Manufacturing

Sustainability and environmental considerations play a crucial role in the manufacturing process of wire winding machines. These machines are used to wind wire onto spools or coils, and ensuring their production is environmentally friendly is important for minimizing the impact on the planet.

Firstly, the choice of materials used in the manufacturing of wire winding machines is essential for sustainability. Opting for materials that are recyclable and have a low environmental impact is key. For instance, using components made from recycled or bio-based materials can significantly reduce the carbon footprint of the machine. Additionally, selecting materials that have long lifespans and are resistant to deterioration can help minimize waste generation and the need for frequent replacements.

Energy efficiency is another crucial aspect to consider. Wire winding machines require motors and other electrical components to operate, and reducing energy consumption is vital for sustainability. Incorporating energy-efficient technologies such as variable frequency drives and high-efficiency motors can help minimize energy usage during machine operation. Implementing efficient power management systems and optimizing the machine’s design to minimize energy loss can also contribute to reducing the environmental impact.

Furthermore, waste management is an essential consideration. Manufacturing processes often generate waste, and proper handling and disposal methods must be in place to minimize the impact on the environment. Implementing recycling programs for materials that can be reused or repurposed is an effective way to reduce waste generation. Additionally, adopting lean manufacturing principles to optimize production processes and reduce material waste can contribute to a more sustainable manufacturing approach.

Lastly, the transportation of wire winding machines should be carefully considered. Minimizing the distance traveled and using eco-friendly transportation methods, such as electric or hybrid vehicles, can help reduce carbon emissions associated with the transportation process.

In conclusion, sustainability and environmental considerations should be at the forefront of wire winding machine manufacturing. By choosing eco-friendly materials, focusing on energy efficiency, implementing proper waste management strategies, and optimizing transportation, the environmental impact of the manufacturing process can be minimized. Emphasizing sustainability in the production of wire winding machines not only benefits the environment but also aligns with the growing demand for eco-friendly products in the market.

List The Evolution history of “wire winding machine”

The evolution of wire winding machines began with their invention in the mid-19th century. Initially, these machines were manually operated and had limited capabilities. They were primarily used for simple tasks such as winding copper wire around spools or bobbins.

In the late 19th century, with the advent of the industrial revolution, wire winding machines started to be powered by steam engines and were able to handle larger quantities of wire. This allowed for increased production and efficiency in industries such as electrical engineering and telecommunications.

During the early 20th century, with the introduction of electric motors, wire winding machines became more automated and could perform a wider range of winding operations. Manufacturers began developing specialized machines for specific applications, such as the production of coils for motors or transformers.

The mid-20th century saw significant advancements in wire winding technology with the integration of electronics and computer controls. These advancements enabled precise control and programming of winding parameters, leading to improved quality and consistency of wound products. Additionally, the use of automated feeding systems and sensors increased the speed and accuracy of the winding process.

In recent decades, the evolution of wire winding machines has been influenced by the demand for smaller, more compact devices. Micro-winding machines have been developed to cater to the needs of industries like electronics, where components are shrinking in size while requiring intricate winding patterns.

The introduction of robotics and artificial intelligence has further revolutionized wire winding machines. These modern machines can provide fully automated and customizable winding solutions, eliminating the need for manual labor and increasing productivity. They can handle a variety of wire types and sizes with unparalleled precision and speed.

In conclusion, wire winding machines have undergone a remarkable evolution since their inception. From simple manually operated devices to highly sophisticated and automated systems, they have become indispensable tools in various industries requiring precise and efficient winding operations.

The Evolution and Market Trends in wire winding machine Industry

The wire winding machine industry has witnessed significant evolution and market trends in recent years. With advancements in technology and increasing demand for precision winding, manufacturers have been developing more efficient machines to cater to various industries such as electronics, automotive, aerospace, and telecommunications.

One major evolution observed in the wire winding machine industry is the shift towards automation and robotics. Automated wire winding machines offer numerous advantages such as increased productivity, reduced labor costs, improved accuracy, and enhanced safety. These machines are equipped with advanced software and motor control systems, enabling precise and consistent winding of different wire types and sizes. The integration of robotics in wire winding machines has further boosted their efficiency by allowing for automated operations, reduced human errors, and faster production cycles.

Another significant market trend is the growing adoption of digitalization and connectivity in wire winding machines. Manufacturers are incorporating IoT (Internet of Things) technologies to enable remote monitoring, data analysis, and predictive maintenance of these machines. This connectivity provides real-time insights into machine performance, improves operational efficiency, and minimizes unplanned downtime. Additionally, the integration of cloud computing capabilities enables enhanced data storage, analysis, and collaboration among stakeholders, further driving the market growth.

Furthermore, there is an increasing focus on the development of environmentally friendly and energy-efficient wire winding machines. Manufacturers are implementing sustainable practices and utilizing energy-efficient components to reduce the environmental impact of these machines. This trend aligns with the growing global concerns about climate change and the need for sustainable manufacturing processes.

In terms of market trends, the wire winding machine industry is witnessing a steady growth rate due to the rising demand for miniature and lightweight electronic devices, electric vehicles, renewable energy systems, and high-speed telecommunications infrastructure. The automotive industry, in particular, is a major consumer of wire winding machines for applications such as electric motor manufacturing.

To remain competitive, manufacturers in this industry are investing in research and development activities to introduce innovative features, improve machine efficiency, and adapt to changing customer requirements. Additionally, partnerships and collaborations between manufacturers and end-user industries are playing a vital role in driving market growth and technological advancements.

In conclusion, the wire winding machine industry has evolved significantly, incorporating automation, digitalization, sustainability, and connectivity to meet the growing demand for precise winding in various industries. The market trends indicate a positive outlook with continuous advancements and collaborations shaping the future of this industry.

Custom Private Labeling and Branding Opportunities with Chinese wire winding machine Manufacturers

China is renowned for its manufacturing capabilities and is a popular choice for businesses looking to source wire winding machines. Among the numerous advantages of working with Chinese manufacturers are the custom private labeling and branding opportunities they offer.

Chinese wire winding machine manufacturers understand the importance of branding for businesses. They are willing to accommodate custom private labeling requests, allowing businesses to showcase their own brand identity on the machines. This provides a unique marketing opportunity and helps create a strong brand presence in the market.

When it comes to custom private labeling, Chinese manufacturers offer flexible options. Businesses can choose to have their logo, company name, and even specific colors and designs incorporated into the machines. The manufacturers typically have skilled graphic designers who can assist in creating personalized labels and branding elements.

In addition to custom private labeling, Chinese manufacturers also provide branding opportunities through OEM (Original Equipment Manufacturer) services. OEM allows businesses to market the wire winding machines under their own brand name as if they were the original manufacturer. This enhances brand value and customer loyalty.

Furthermore, Chinese manufacturers are experienced in international trade and understand the importance of meeting specific regulatory guidelines and standards. They can provide necessary certifications and ensure compliance with safety and quality regulations imposed by different countries. This reassures businesses that their branded wire winding machines will meet international standards and regulations.

To sum up, working with Chinese wire winding machine manufacturers not only provides access to high-quality products at competitive prices but also opens up custom private labeling and branding opportunities. This enables businesses to establish a unique brand presence and enhance their marketing efforts in the industry.

Tips for Procurement and Considerations when Purchasing wire winding machine

When purchasing a wire winding machine for procurement, there are several important considerations to keep in mind. These considerations will ensure that you make the right choice and invest in a machine that meets your specific requirements. Here are some tips and considerations for purchasing a wire winding machine:

1. Capacity: Evaluate the capacity of the wire winding machine to determine if it matches your production needs. Consider factors like the diameter, length, and material of the wire you will be working with. Ensure that the machine can handle the volume and specifications of your wire winding requirements.

2. Speed and efficiency: Assess the speed and efficiency of the machine. Look for features like a high-speed winding capability and automatic controls to improve productivity and reduce labor costs. Consider the machine’s performance in terms of wire winding accuracy and consistency.

3. Machine compatibility: Ensure that the wire winding machine is compatible with other equipment and machinery in your production line. This will facilitate seamless integration and minimize disruptions in the manufacturing process.

4. Quality and durability: Determine the quality of the machine and its components. Look for a machine constructed with durable materials to withstand continuous use and minimize maintenance requirements. Consider the reputation and track record of the manufacturer in producing reliable and long-lasting wire winding machines.

5. Safety features: Check if the machine has adequate safety features to protect operators and prevent accidents. Look for features like emergency stop buttons, safety guards, and automatic shut-off mechanisms to ensure a safe working environment.

6. Maintenance and support: Evaluate the availability of maintenance and technical support for the wire winding machine. Ensure that the manufacturer provides comprehensive manuals, troubleshooting guides, and access to spare parts to minimize downtime in case of repairs.

7. Cost and ROI: Consider the cost of the machine and evaluate its return on investment (ROI). Compare prices from different suppliers while also considering the expected productivity gains and cost savings that the machine will provide over time.

8. Warranty and after-sales service: Review the warranty provided by the manufacturer and inquire about after-sales service options. A reliable warranty and accessible customer support can give you peace of mind and assurance that your investment is protected.

By carefully considering these tips and considerations, you can make an informed decision when purchasing a wire winding machine that aligns with your specific requirements and provides optimum performance and efficiency in your manufacturing processes.

FAQs on Sourcing and Manufacturing wire winding machine in China

1. Why should I consider sourcing and manufacturing wire winding machines in China?

China is known for its manufacturing capabilities and cost-effectiveness. The country has a vast network of suppliers, offering a wide range of wire winding machines at competitive prices. Moreover, China has a well-established infrastructure and industry expertise in manufacturing machinery, making it an ideal choice for sourcing and manufacturing wire winding machines.

2. How can I find reliable suppliers for wire winding machines in China?

There are several ways to find reliable suppliers in China. One option is to attend trade shows and exhibitions related to machinery and equipment, where you can meet with potential suppliers and evaluate their products. Another option is to use online sourcing platforms, such as Alibaba and Global Sources, which provide a large database of suppliers and allow you to compare their products and prices.

3. What are the key considerations when sourcing wire winding machines in China?

Some key considerations when sourcing wire winding machines in China include product quality, technical specifications, pricing terms, lead time, and after-sales service. It is essential to thoroughly evaluate the supplier’s reputation, production capabilities, and the quality control measures they have in place to ensure that the machines meet your requirements.

4. Can I customize wire winding machines manufactured in China?

Yes, many suppliers in China offer customization options for wire winding machines. You can discuss your specific requirements, such as wire diameter, speed, winding capacity, and control system, with the supplier. They can provide design modifications or develop a completely new machine to meet your customization needs.

5. Are there any risks associated with sourcing and manufacturing wire winding machines in China?

There are potential risks associated with sourcing and manufacturing in any country, including China. Some common risks include language barriers, cultural differences, intellectual property protection, and product quality control. However, by conducting proper due diligence, selecting reputable suppliers, and having clear communication channels, these risks can be minimized.

In summary, sourcing and manufacturing wire winding machines in China can be a cost-effective and efficient option. By considering key factors such as product quality, customization options, and reliable supplier selection, you can successfully navigate the process and acquire high-quality wire winding machines for your specific needs.

Why contact sourcifychina.com get free quota from reliable wire winding machine suppliers?

Sourcifychina.com, as a renowned sourcing platform, has established solid partnerships with reliable wire winding machine suppliers. These suppliers understand the value of collaborating with Sourcifychina.com to reach a wider customer base and enhance their market presence. Offering a free quota to Sourcifychina.com allows these suppliers to showcase their products and services to potential buyers, increasing the likelihood of securing orders.

By providing Sourcifychina.com with a free quota, the suppliers allow the platform to connect them with interested buyers who may require wire winding machines for different industrial applications. The free quota essentially serves as a marketing tool for the suppliers, enabling them to display their capabilities and attract potential clients.

Moreover, the suppliers recognize the benefits of Sourcifychina.com’s extensive network and expertise in sourcing from China. The platform has a deep understanding of the Chinese market, including the intricate details of product sourcing, supplier assessment, and quality control. By teaming up with Sourcifychina.com, these suppliers can streamline their sales processes, improve efficiency, and focus on their core business operations.

Additionally, the free quota provides suppliers with the opportunity to gain valuable feedback from Sourcifychina.com’s team and potential buyers. This feedback helps suppliers refine their products, processes, and services, ensuring continuous improvement and meeting market demands effectively.

In conclusion, offering a free quota to Sourcifychina.com allows reliable wire winding machine suppliers to benefit from the platform’s extensive buyer network, market expertise, and feedback. This collaboration ultimately leads to increased visibility, enhanced market presence, and better sales prospects for the suppliers.