Benefits of Yogurt Fermentation Tank

Yogurt fermentation tank is an essential tool in any yogurt production process. Fermentation tanks are useful in the production of various dairy products such as cheese, sour cream, buttermilk, and yogurt.

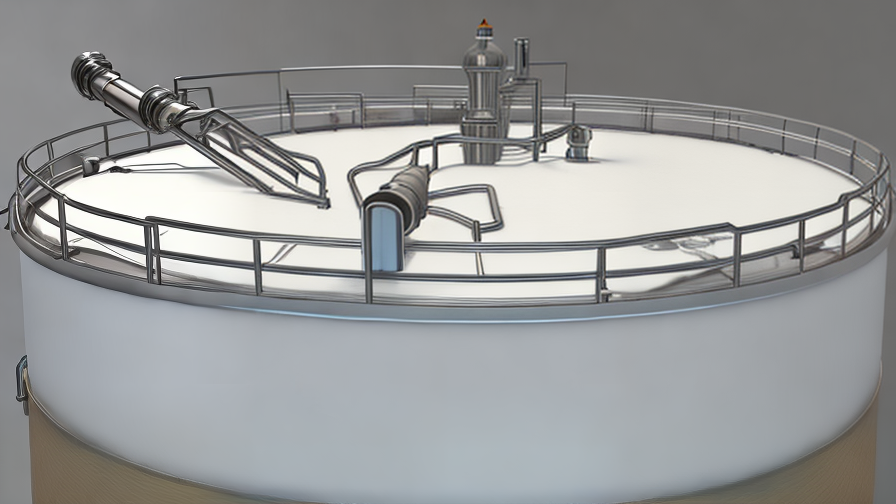

The yogurt fermentation tank is a large stainless steel container that is designed to maintain and regulate the temperature and time required for the fermentation process. The fermentation process involves the conversion of lactose into lactic acid by the lactobacillus bacteria found in milk. The fermentation process is what gives yogurt its unique taste, texture, and nutritional value.

The benefits of using yogurt fermentation tanks are numerous. Firstly, it allows for the production of large quantities of yogurt consistently. Fermentation tanks are designed to hold a considerable amount of milk, which allows for the production of large batches of yogurt. Secondly, it promotes the growth of beneficial bacteria that are essential for human health.

The fermentation process encourages the growth of lactobacillus bacteria, which is known for its health benefits. This bacterium is known to aid digestion, strengthen the immune system, and promote overall gut health. Regular consumption of yogurt has also been associated with reducing the risk of chronic diseases such as type 2 diabetes, heart disease, and obesity.

Lastly, the use of a fermentation tank allows for precise control of the fermentation process. Fermentation tanks are designed with automated systems that regulate temperature, pressure, and timing. This control ensures that the yogurt is fermented correctly, resulting in a consistent and high-quality product. The automated system also reduces the need for manual intervention, which allows for a safer and more efficient production process.

In conclusion, the yogurt fermentation tank is a vital tool in the production of high-quality yogurt. Its benefits are numerous, ranging from large-scale production capability to the promotion of beneficial bacteria that contribute to human health. The use of fermentation tanks not only ensures consistent quality and taste but also helps to reduce the risk of food contamination. The integration of the fermentation tank in yogurt production is an investment in high-quality products and overall health.

Features of Yogurt Fermentation Tank

Yogurt fermentation tanks are essential in the production of yogurt to ensure high-quality products. These tanks come in various sizes and designs depending on the production scale and processing requirements.

One key feature of the yogurt fermentation tank is its insulation. The tank must be well-insulated to maintain a consistent temperature. This temperature is critical to the yogurt-making process as it affects the bacteria responsible for fermentation.

Another important feature is the agitation system, which ensures the adequate mixing of the milk and culture in the tank. This component ensures consistency in the product’s texture and taste, and it prevents the formation of lumps.

The yogurt fermentation tank also has a monitoring system that precisely controls the temperature and pH levels during fermentation. This feature is crucial in maintaining the perfect conditions for bacterial growth and ensuring the quality of the yogurt.

The tank also has a venting system to regulate the gas and pressure buildup during fermentation. Failure to regulate the gas and pressure can lead to tank explosions and contamination of the product.

The material used to construct the tank is also essential. The material must be food-grade, easy to clean and corrosion-resistant. Tanks made from stainless steel are the most common because they meet all these requirements.

In conclusion, the yogurt fermentation tank is a vital component in producing high-quality yogurt products. The insulation, agitation system, monitoring system, venting system and choice of material used in construction, are all critical features that ensure the production of premium yogurts.

Various Types of Yogurt Fermentation Tank

Various Types of Yogurt Fermentation Tank

Yogurt fermentation is the process of converting milk into yogurt through the action of bacteria. To successfully ferment yogurt, a vessel is required where the bacteria can thrive and convert lactose into lactic acid. That’s where the fermentation tank comes in.

There are different types of yogurt fermentation tanks available in the market, and each has its own unique features and benefits.

1. Jacketed Fermentation Tanks

Jacketed fermentation tanks are designed to keep the milk at a constant temperature during the fermentation process. They have a double-walled design, with an outer jacket that is filled with hot water or steam to regulate the temperature. The inner tank contains milk and bacteria culture, which are slowly mixed together to produce yogurt.

2. Insulated Fermentation Tanks

Insulated fermentation tanks are designed to maintain the heat generated during the fermentation process. They are built with an insulated outer layer that helps to retain the heat generated by the bacteria while fermenting the yogurt. They are ideal for small to medium-sized yogurt production and can help maintain the desired level of acidity.

3. Open Fermentation Tanks

Open fermentation tanks are designed for large-scale yogurt production. They allow for the free flow of air and are ideal for yogurt recipes that require specific bacteria culture to grow. They are also preferred for their ability to produce a tangier and more flavorful yogurt than other types of fermentation tanks.

4. Closed Fermentation Tanks

Closed fermentation tanks are designed with airtight lids that prevent external bacteria from contaminating the yogurt. They are ideal for commercial yogurt production, where hygiene and food safety are critical. They are also preferred for their ability to produce a consistent type of yogurt every time without the risk of contamination.

In conclusion, selecting the right fermentation tank for yogurt production depends on the volume of production, the desired texture and flavor, and the accessibility of the bacteria culture. It is essential to choose a tank that is durable, easy to clean, and versatile in terms of temperature regulation.

Applications of Yogurt Fermentation Tank

Yogurt fermentation tanks are essential tools in the production of high-quality yogurt. These tanks are purpose-built to facilitate the controlled fermentation of milk into lactic acid by adding various fermentation cultures to the milk. Yogurt fermentation tanks offer numerous benefits to the yogurt-making process, including the ability to regulate and customize fermentation time, temperature, and pH.

Fermenting tanks can also help to ensure consistency in the quality of the yogurt produced by blending the mixture of culture and milk in the correct proportions. The yogurt fermentation tanks are equipped with strict temperature control, which helps to maintain the optimum fermentation temperature range resulting in better yogurts.

Another use of yogurt fermentation tanks is that they control the pH levels of the yogurt. Yogurt fermentation tanks are fitted with pH sensors that help in determining the exact pH values of the yogurt as it ferments. This ensures that the pH levels of the yogurt stay consistent throughout the fermentation process. Maintaining the right pH levels ensures that the bacteria we want to grow have a suitable environment to thrive and are more likely to produce high-quality yogurt.

Yogurt fermentation tanks are also beneficial as they can minimize the risks of contamination. Fermenting tanks are sterile and airtight, which helps to prevent cross-contamination in the yogurt production process. The tanks are designed to be easy to access and clean. This ensures a hygienic environment during the yogurt production process, which results in high-quality and safe products for consumers.

Additionally, yogurt fermentation tanks are eco-friendly. They help to save energy by consuming minimal power yet still achieving optimum fermentation temperatures. They also require minimal maintenance and have a longer lifespan. Due to these reasons, yogurt fermentation tanks are an ideal choice for modern and eco-friendly yogurt production facilities.

To conclude, yogurt fermentation tanks have gained widespread use in yogurt production. They offer several benefits, including controlling fermentation time, temperature, and pH levels, preventing cross-contamination, and creating a hygienic environment. They are environmentally friendly, which saves on energy and maintenance costs. As the demand for high-quality yogurt continues to grow, so does the importance of reliable yogurt fermentation tanks.

The Process of Yogurt Fermentation Tank

Yogurt is a fermented dairy product that has become a staple in many households due to its health benefits and great taste. The process of making yogurt involves a fermentation tank that enables the milk to ferment and turn into yogurt.

The first step in yogurt production is to heat milk to a specific temperature to deactivate any unwanted microorganisms that could spoil the yogurt. The heated milk is then cooled to a temperature of around 45°C and inoculated with yogurt starter culture, which contains lactic acid bacteria. This culture ferments the milk and converts lactose, the main sugar in milk, into lactic acid.

Once the milk has been inoculated, it is put into the fermentation tank, which maintains the ideal temperature and pH levels for the bacteria to grow and ferment the lactose. The fermentation period typically takes between four to twelve hours. During this time, the milk thickens as the lactic acid bacteria produce lactic acid.

The fermentation tank is a crucial component of the yogurt production process. It allows for the precise control of temperature and pH levels to guarantee that the lactic acid bacteria work optimally. The design of the fermentation tank is essential to avoid contamination, which could lead to unwanted bacteria growth that could spoil the yogurt.

After the fermentation process is complete, yogurt is packaged and stored for consumption. The yogurt can be flavored or consumed plain depending on personal preference. Yogurt is an excellent source of protein, calcium, and probiotics that improve gut health, among other benefits.

In conclusion, the fermentation tank plays a vital role in the yogurt production process. It enables the milk to ferment and turn into yogurt by providing the ideal conditions for lactic acid bacteria to grow and ferment lactose into lactic acid. Therefore, the right design and temperature control of the fermentation tank are essential to ensure the production of high-quality and safe yogurt.

How to use Yogurt Fermentation Tank

Yogurt fermentation tank is a device that helps in the production of yogurt. The fermentation of milk is one of the most essential processes that take place in making yogurt. The fermentation tank helps in controlling the temperature, speed, and timing of the fermentation process. In this article, we will explain the steps involved in using a yogurt fermentation tank.

The first step is to heat the milk that will be used in the fermentation process. It is essential to heat the milk to a temperature of approximately 180°F to make sure that all harmful bacteria are destroyed.

Next, the milk should be cooled down to a temperature of about 110°F, which is the ideal temperature for the fermentation process. Once the milk has been cooled, it is then transferred to the fermentation tank.

After placing the milk in the fermentation tank, the next step is to add the starter culture. A starter culture is a mixture of beneficial bacteria that helps in the fermentation process. The culture can be obtained from a previous batch of yogurt or purchased at a health food store.

Once the starter culture has been added, the fermentation tank should be sealed and left undisturbed for about 6-12 hours. The time varies, depending on the desired thickness and tanginess of the yogurt. The longer the fermentation time, the thicker and tangier the yogurt will be.

After the fermentation process, the yogurt should be removed from the fermentation tank and stored in the refrigerator to prevent further fermentation.

In conclusion, using a yogurt fermentation tank is an easy and effective way to make yogurt. With a few simple steps, anyone can produce a delicious and healthy yogurt at home. Remember, the key to making great yogurt is controlling the temperature, speed, and timing of the fermentation process.

Selecting the Ideal Manufacturer Yogurt Fermentation Tank

Selecting the Ideal Manufacturer Yogurt Fermentation Tank

When it comes to manufacturing yogurt, selecting the ideal manufacturer fermentation tank is crucial for the success of your business. Fermentation tanks facilitate the growth of bacteria responsible for the fermentation process to produce a tasty yogurt product. Here’s what you need to consider when selecting such tanks.

Quality and Durability

Choosing a high-quality and durable fermentation tank is essential. Such tanks will last longer, require fewer repairs and maintenance services, and offer a better return on investment in the long run. You need to assess the quality of the material used to build the tank to ensure it can withstand pressure, temperature changes, and other factors that might impact its durability and effectiveness.

Size and Capacity

The size and capacity of your fermentation tank should match your business needs. Consider the size of your operation and the amount of yogurt you need to produce daily so you can choose the right-sized tank. A small tank may be ideal if you don’t require a high volume of yogurt, while a larger tank is more suited to large scale production.

Ease of Cleaning

Maintaining hygiene in your yogurt production process is crucial. One way to ensure that no bacteria or harmful contaminants find their way into your product is by selecting a fermenter tank that is easy to clean. Afermentation tank that is easy to dismantle and clean will reduce downtime, helping you to be more productive.

Additional Features

Other features to consider when selecting a fermentation tank include the ability to control temperature, agitation, and efficient cooling. You should also decide whether to choose an insulated or non-insulated tank.

Conclusion

Selecting the ideal manufacturer yogurt fermentation tank requires careful consideration. Make sure that you choose a quality tank that can withstand daily use and has the capacity to meet your production needs. Remember to focus on ease of cleaning and additional features, and you’ll be on your way to producing delicious yogurt.

list FAQ with answer about Yogurt Fermentation Tank

Yogurt fermentation tanks are an essential component of the yogurt production process. They are an integral part of the fermentation stage, which is crucial in determining the final taste, texture, and quality of the yogurt. If you are unfamiliar with yogurt fermentation tanks and their operation, here are some frequently asked questions and their answers.

1. What is a yogurt fermentation tank?

A yogurt fermentation tank is a large vessel in which milk is heated, inoculated with bacteria culture, and kept at the optimal temperature for fermentation, typically between 105-115°F.

2. What is the capacity of a yogurt fermentation tank?

The capacity of yogurt fermentation tanks can vary widely, ranging from small home-use sizes of a few liters to industrial sizes of several thousand liters.

3. How long does it take to ferment yogurt in a tank?

The exact time it takes for yogurt to ferment in a tank depends on several factors, including the type and quantity of bacteria used, the temperature of the milk, and the desired final texture and acidity of the yogurt. In general, most yogurt fermentation cycles last anywhere from 4 to 12 hours.

4. What kind of bacteria is used for yogurt fermentation?

The bacteria used for yogurt fermentation is typically a combination of Lactobacillus bulgaricus and Streptococcus thermophilus. Some yogurt makers may also add other probiotic cultures to enhance the health benefits of the yogurt.

5. How do you clean a yogurt fermentation tank?

To clean a yogurt fermentation tank, you need to first drain any remaining milk from the tank. Then, use hot water and cleaning agents, such as sodium bicarbonate or chlorine, to thoroughly clean the tank. Rinse the tank with clean water and sanitize it with a food-grade sanitizer solution.

In conclusion, yogurt fermentation tanks are specialized equipment that play a critical role in the yogurt production process. Understanding how they work and how to maintain them is essential for producing high-quality yogurt consistently.

Things to Consider When Purchasing Yogurt Fermentation Tank

Yogurt fermentation tanks are essential tools for those who want to start their own yogurt making business. These tanks are used to ferment milk and allow it to develop into delicious and healthy yogurt. When purchasing a yogurt fermentation tank, there are certain things that you should consider to make sure that you get the best one that fits your needs. In this article, we will discuss the things you need to consider when buying a yogurt fermentation tank.

1. Tank Capacity

The first thing to consider when purchasing a yogurt fermentation tank is the tank’s capacity. The size of the tank will dictate the volume of milk that can be fermented at a given time. If you plan to produce a large quantity of yogurt, it is important to choose a tank that has enough capacity to meet your needs.

2. Type of Material Used

Yogurt fermentation tanks are made from different materials such as stainless steel, plastic, and glass. Each material has its own advantages and disadvantages. Stainless steel tanks are durable, easy to clean, and can withstand high-temperatures. Glass tanks are good for home use, but they are fragile and can easily break. Plastic tanks are lightweight, easy to handle, and affordable, but they are prone to scratches and can break easily.

3. Temperature Control

Temperature control is crucial for yogurt fermentation. The ideal temperature for fermentation is between 40-45 °C. A good fermentation tank should have a temperature control system that allows you to adjust the temperature according to your needs.

4. Agitation System

The agitation system is another factor to consider when purchasing a yogurt fermentation tank. It helps to mix the yogurt thoroughly and ensures that the milk is evenly fermented. A good agitation system will help you to produce high-quality yogurt.

5. Ease of Maintenance

A yogurt fermentation tank should be easy to clean and maintain. A tank that is difficult to clean can harbor bacteria and germs, which can affect the quality of the yogurt. It is important to choose a tank that is easy to disassemble, clean, and put back together.

In conclusion, purchasing a yogurt fermentation tank requires careful consideration of several factors. The capacity of the tank, the type of material used, the temperature control system, the agitation system, and ease of maintenance are all important factors to consider when selecting a yogurt fermentation tank. By taking the time to consider these factors, you can be sure to get a tank that is best suited for your needs and budget.

Properties of Yogurt Fermentation Tank

Yogurt fermentation is a crucial process that requires a specific environment to promote the growth, survival, and activity of lactobacillus bacteria, and inhibit the growth of spoilage and harmful microorganisms. One of the key elements of this process is the yogurt fermentation tank, which is designed to control various factors that affect the quality, consistency, and safety of yogurt.

The main properties of a yogurt fermentation tank include its size, material, shape, insulation, agitator, and temperature and pH control systems. The size and shape of the tank depend on the production volume and the type of yogurt being made, with larger tanks generally used for commercial production and smaller tanks for home or artisanal production. The material of the tank can be stainless steel, plastic, or glass, depending on the durability, hygiene, and cost requirements. The insulation of the tank helps to maintain a constant temperature and prevent heat loss or gain, as well as reduce the energy consumption. The agitator is responsible for mixing the milk and the starter culture, as well as distributing the heat and nutrients evenly throughout the tank.

The temperature control system is critical for creating the optimal environment for lactobacillus bacteria, which thrive at around 110-115°F (43-46°C) and produce lactic acid. The pH control system is also important for monitoring the acidity level of the yogurt, which should reach a pH of around 4.5-4.7 to achieve the desired texture, flavor, and shelf life. Other features that can be included in a yogurt fermentation tank are sensors, alarms, timers, and valves, which help to automate and streamline the process, and reduce the risk of contamination or errors.

Overall, the properties of a yogurt fermentation tank play a crucial role in ensuring the success of the yogurt fermentation process, and the quality and safety of the final product. By selecting the right tank size, material, shape, insulation, agitator, and control systems, producers can create consistent and delicious yogurt, that meets the preferences and needs of their customers.

Technical Parameters Terms for Yogurt Fermentation Tank

Yogurt fermentation tanks play an essential role in the production of high-quality yogurt. As such, various technical parameters must be considered when selecting, designing or constructing a yogurt fermentation tank.

One of the critical technical parameters for yogurt fermentation tanks is temperature control. The fermentation process requires a specific temperature range for optimal growth of lactobacillus bacteria, which are responsible for the yogurt’s unique aroma and taste. Therefore, the tank should have a precise temperature control system to maintain the desired range throughout the fermentation process.

Another important technical parameter is agitation. To ensure even growth of bacteria and reduce the formation of lumps, the tank’s agitation system should be carefully designed. The motion of the agitator should be gentle to avoid damaging the bacteria while ensuring adequate mixing.

Sterilization is also a crucial technical parameter for yogurt fermentation tanks. Before fermentation, the tank’s interior must be thoroughly sterilized to prevent contamination by unwanted bacteria. The sterilization process should be efficient, ensuring that there are no persistent bacteria that may survive and compromise the quality of the yogurt.

Yogurt fermentation tanks must also have the appropriate capacity based on the production needs. The size of the tank should match the volume of milk to be fermented while leaving enough space for expansion during the fermentation process. Additionally, the tank should be easy to clean and have smooth surfaces to avoid bacterial buildup.

Finally, monitoring and control systems are essential parameters for yogurt fermentation tanks. These systems should be accurate and reliable, enabling production managers to oversee the fermentation process and make necessary adjustments to maintain the quality of the yogurt.

In conclusion, technical parameters play a critical role in ensuring the quality and safety of yogurt production. The parameters discussed above, including temperature control, agitation, sterilization, capacity, and monitoring, should be considered when selecting, designing, or constructing a yogurt fermentation tank.

Yogurt Fermentation Tank Price

Fermentation is a crucial process when it comes to making yogurt. The fermentation tank is the primary equipment used in this process. The price of the yogurt fermentation tank can vary depending on various factors, such as its capacity, design, and material used.

One of the significant factors affecting the price of fermentation tanks is the material used. Most fermentation tanks are made of stainless steel, which is reliable, durable, and hygienic. The price of the fermentation tank also depends on the thickness of the steel material used. Thick steel tanks are expensive, while thinner steel tanks are cheaper.

The capacity of the fermentation tank also plays a role in determining its price. A larger fermentation tank will cost more compared to a smaller one. The design of the tank also affects the price. Some tanks come with intricate designs, which may increase the price.

The price of a yogurt fermentation tank can range from a few hundred to thousands of dollars. The cost also varies depending on the type of fermentation tank. There are various types of fermentation tanks, such as batch tank, continuous tank, and stirred tank. Each has different features, and the cost varies accordingly.

In conclusion, the cost of a yogurt fermentation tank depends on several factors. The material used, capacity, and design are some of the most significant determinants of the price. When buying a fermentation tank, it is essential to consider its quality, durability, and efficiency. Investing in a high-quality fermentation tank may cost more upfront, but it will save you money in the long run by reducing maintenance costs and increasing productivity.